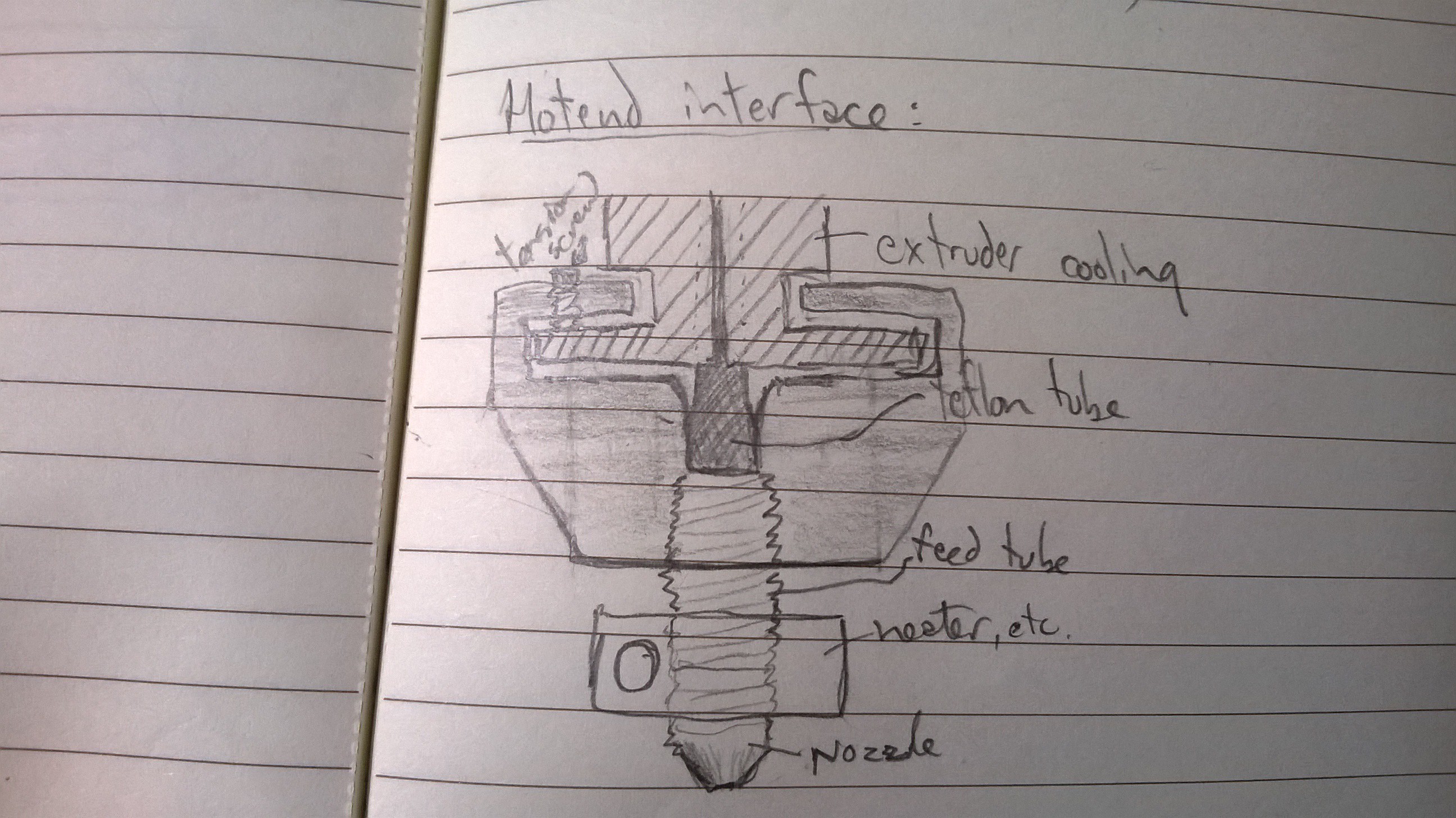

A big challenge that I have mentioned before is that we will be dealing with a flat feed material. The problem comes when this flat material with a rectangular cross section enters the hot end of the extruder. Most extruders have round holes, we have a rectangular peg. I have come up with something I think will work. Flattening a PTFE tube will create an elliptical guide that will be a better match for the material, but what happens when it reaches the heated zone that is cylindrical? How do we make that transition without leakage, airlocks, or other unforeseen consequences?

A warm zone between the cool end and the hot end may do the trick. If we can create a slightly heated chamber, warm enough for the material to become malleable but still hold its form somewhat, in which the guide tube can revert to its natural cylindrical shape, then the material can be both reshaped and compressed to provide the force necessary for extrusion. This is represented by the green section in the picture above.

ken.do

ken.do

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.