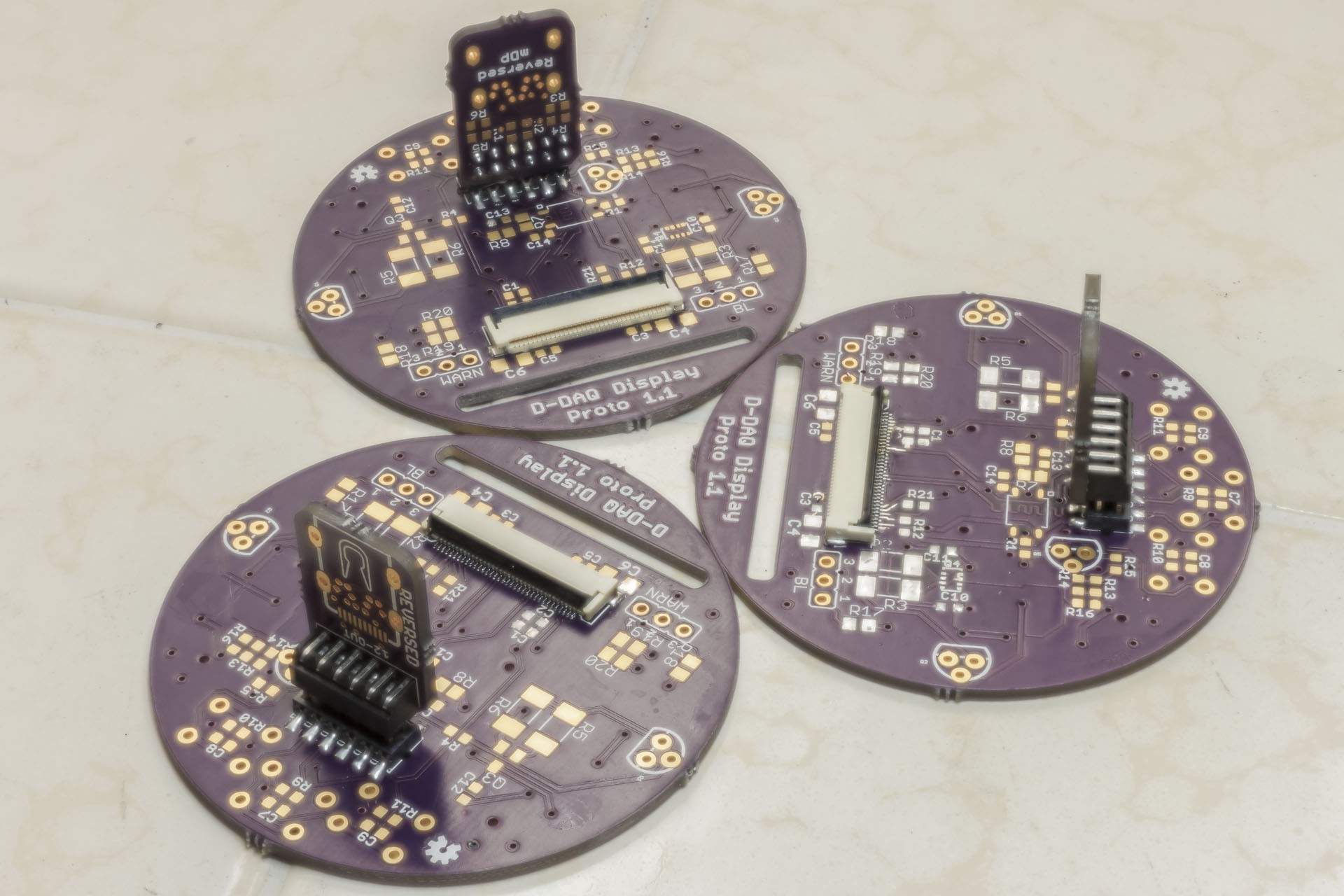

Honestly, it's been a few years since I've done some significant solder work. I do have an unfinished, but recent brush up on SMT soldering but yeah. I decided to break out some more heat tolerant parts to get a feel for the hot air rework station and it's iron compared to my old one. Tonight's victims were some interconnect work on the display boards and adapter boards.

I need to adjust the mDP footprints a little bit to accommodate for the slots, also make the tabs on the 35-pin FPC connector stick out a bit more, and tweak the placement of the slot every so slightly, but I like the layout of the Display Board. After experiencing quite a bit of bridging on the 0.5mm pitch FPC I think I'm comfortable with the iron's and hot air gun's temperature controls, the SAC305 stick solder, and the 63/37 solder paste. I have most active components, a few passives, etc. I *still* need to finish my BOM and order up the remaining parts. I'll still be able to map out an initial order of assembly for soldering the mainboard and display boards. Things are still looking good for starting to code a week from 7 minutes from now!

Side note: Soft focus effect on the photo is unintentional, but resultant of the focus stacking algorithms.

Michael O'Brien

Michael O'Brien

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.