After attending the demo of a FDM (Fused Deposition Modeling) 3D plastic printer during a training session in 2014, I was immediately impressed by this additive manufacturing principle. Then, with the acquisition of a model 'commercial' for professional reasons I was faced with (almost) all the common problems on this type of machine: reliability, overheating, stuffing, etc ... Some concerns can be understand given the low price of the model 'base' but what is most frustrating is especially the character 'closed' and not evolving both software and hardware (although I tinkered some improvements 'home') .

This principle of construction could be applied to many other materials and potential applications make you dizzy ... Well used, they could easily be part of an eco-design approach (provided they are the least dependent possible some firms that want to impose their 'laws').

For this, we need to create from A to Z an additive building system that is as 'efficient' as possible; in this quest I have come to question the 'classical' system called Cartesian; I studied the possible architectures a bit and for several reasons (see blog) I therefore chose a architecture of the type articulated arm simple (Single Arm Articulated in English) categorized in the SCARA family.

In my opinion, this architecture has almost only advantages:

- small footprint

- no guide rails (savings / reliability)

- speed (according to load)

- extended working area

- simple addition of cleaning / color changing zone for nozzle (without reducing printable area)

- good self-replicable ratio (plastic)

- number of limited parts (low part count)

For my first project in this way I chose to integrate it into the RepRap movement (http://forums.reprap.org/read.php?110,521712) to produce a functional plastic prototype (ABS or PLA) capable of self-replication; When I started there was no equivalent and therefore, having no reference, I started from scratch ...

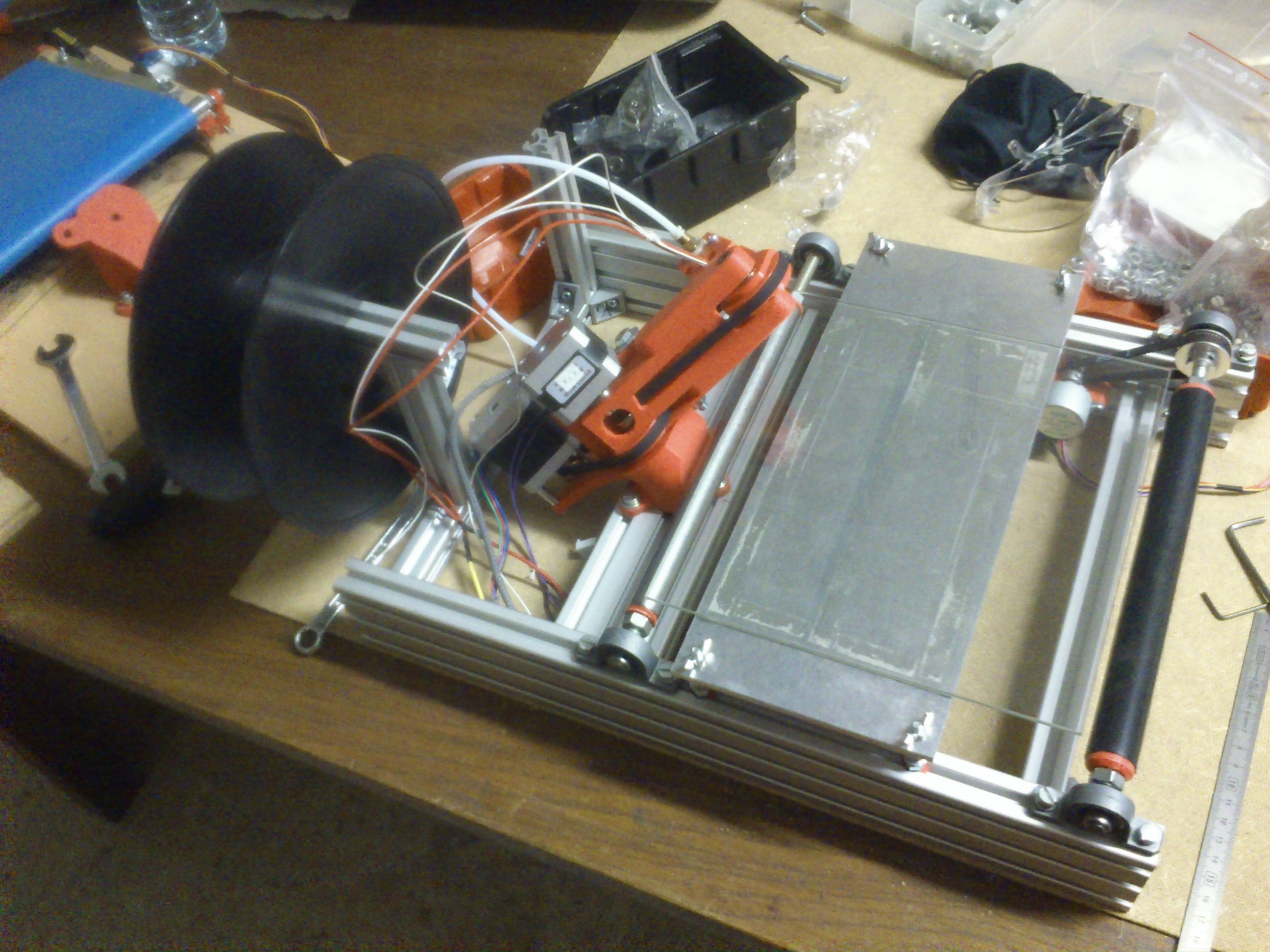

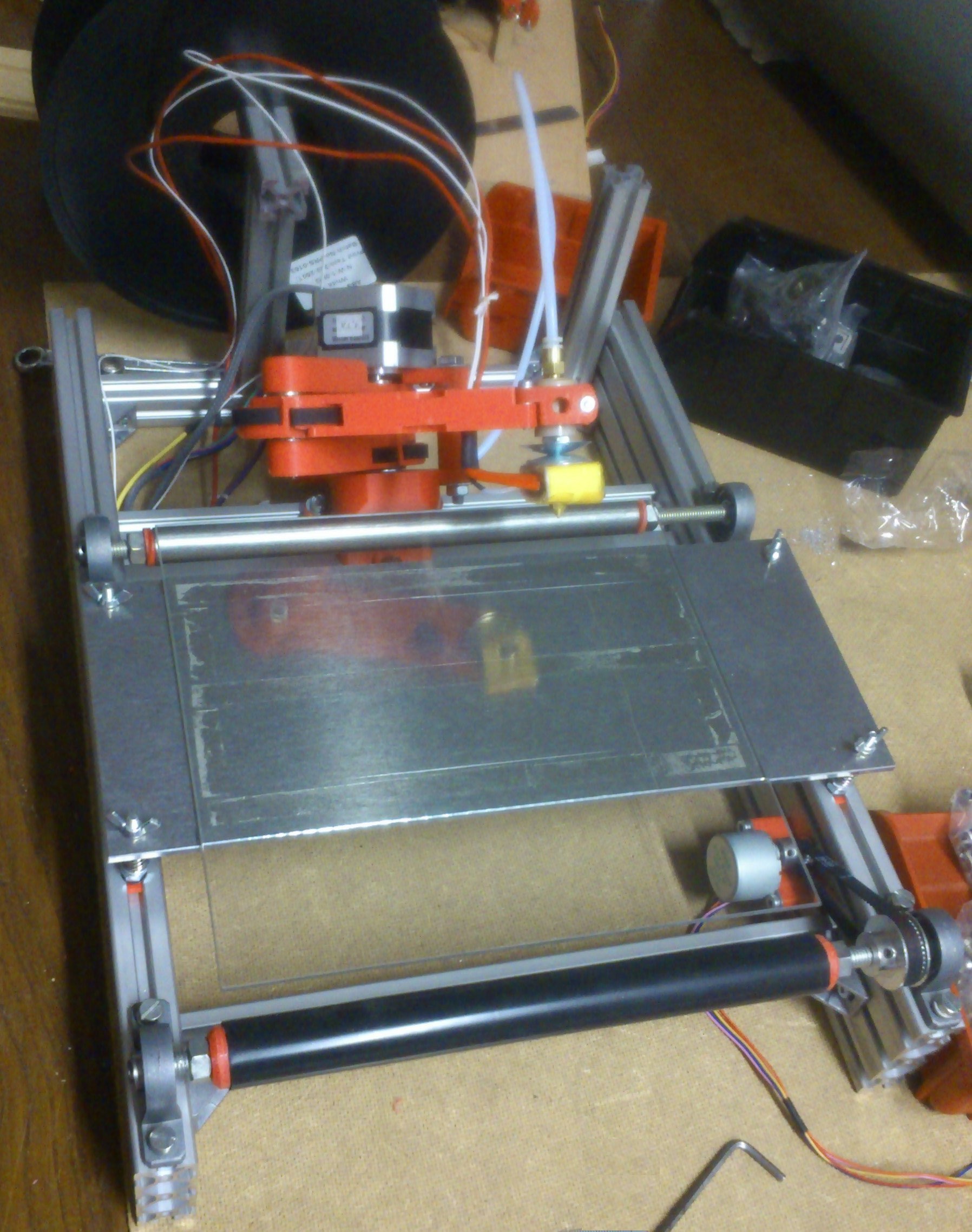

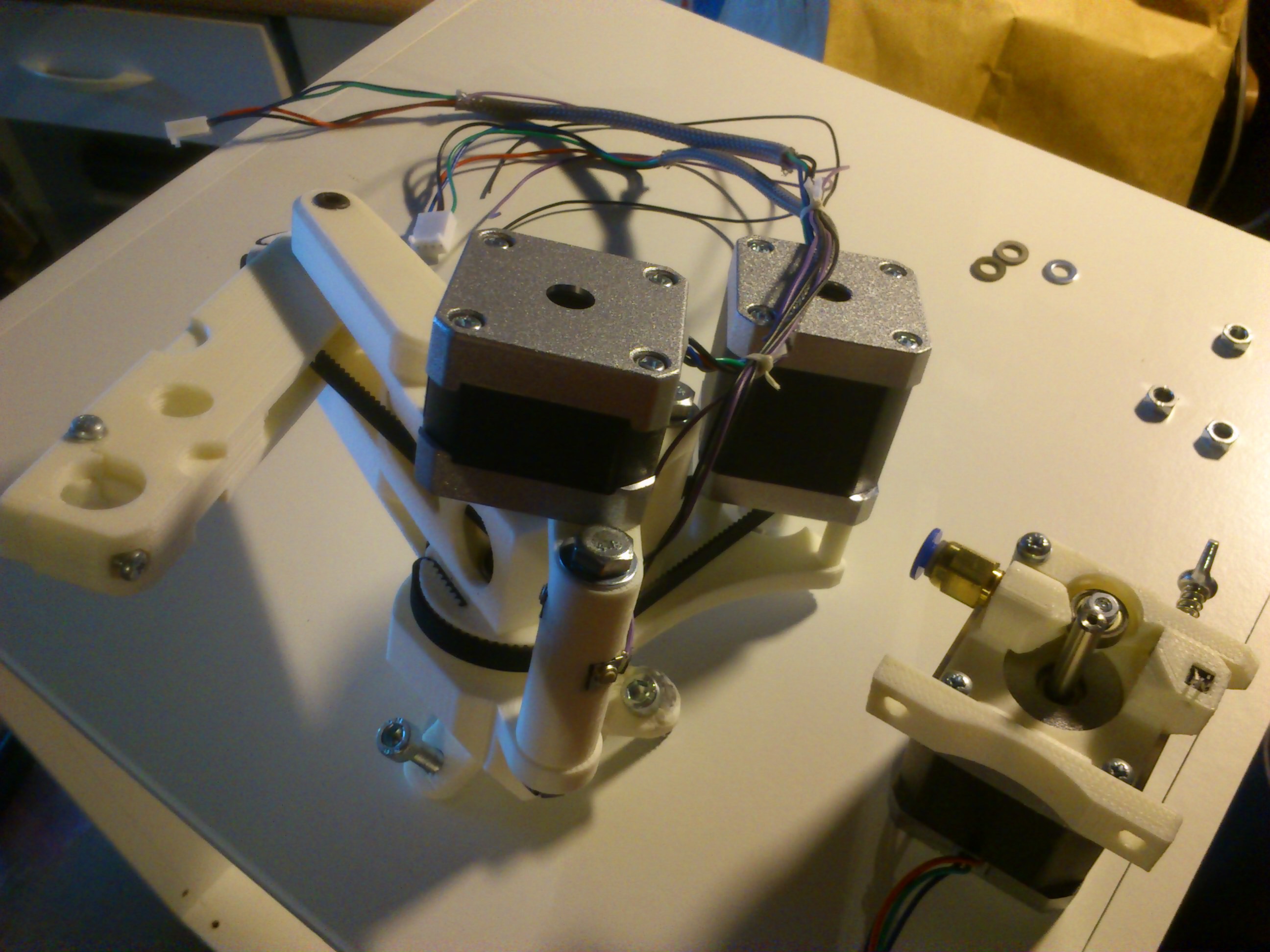

After several trials / improvements the project begins to take shape and is called ArmOni-Solo.

The first functional prototype begins to look like a '3D printer'

The files / sources are there:

github (https://github.com/invent2main/s2a)

Videos are here:

https://vimeo.com/user41156378

I tested a lot of solutions to do without linear guides for the Z axis but nothing very conclusive (a good compromise is with only 1 guide associated with a mechanism sarrus but it remains complex)

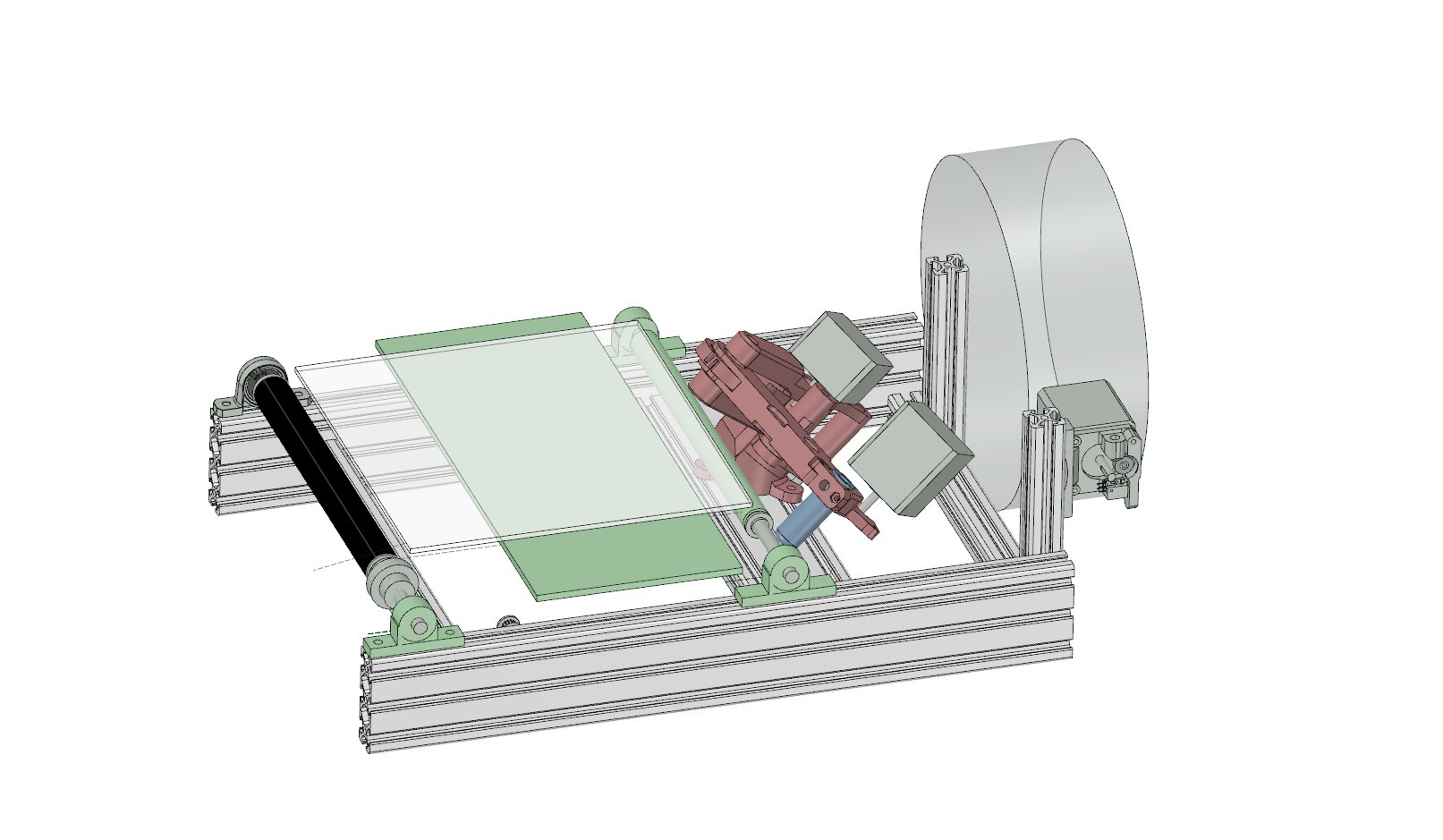

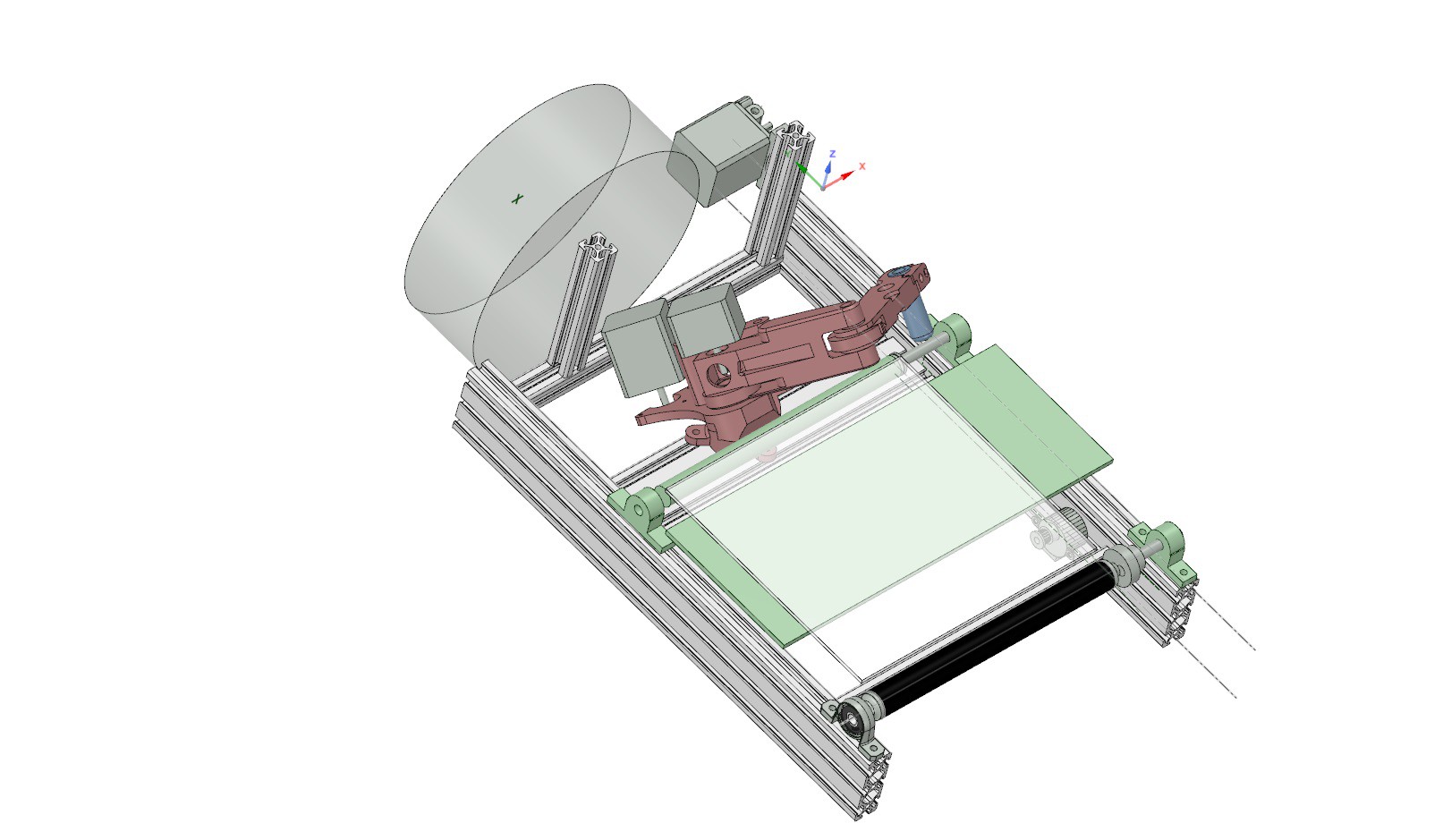

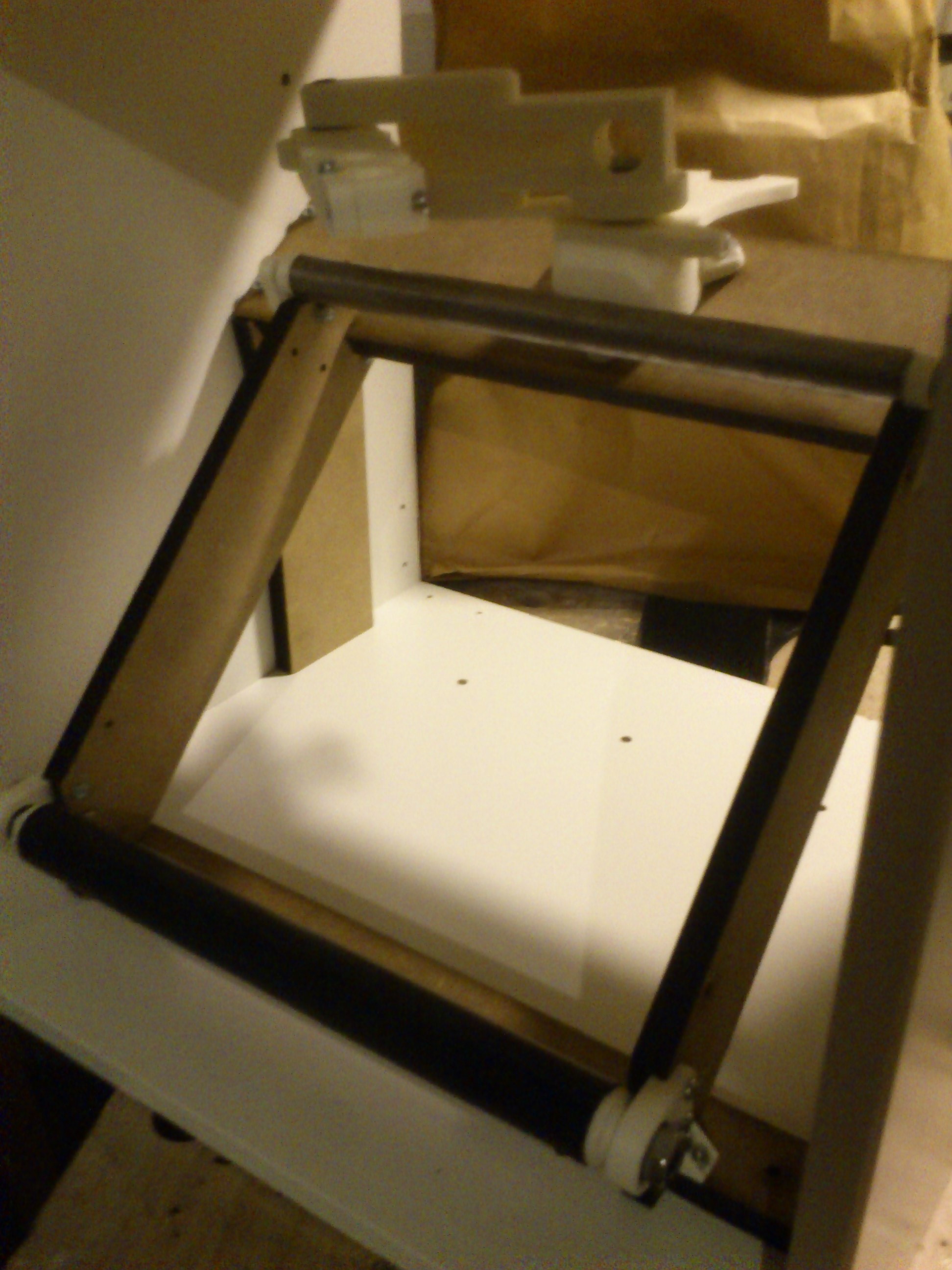

Finally I found that the solution to completely do without linear guides may well be to have a pseudo Z with a 'conveyor belt' that allows dimensions virtually unlimited in one direction; this brings significant benefits: continuous printing (production), longer printable parts than the plate, fewer supports...

This is how the RollRap version of Single Arm project comes into play with a first prototype as proof of concept:

there is still a lot of work (customised Marlin software) to finalize and make reliable this concept: homing, calibration, software optimization...

but if it works well we will have a compact printer with an excellent rate of self-replication and 'scalable';

now I'm working on a second prototype in a box, with a heating plate, a better belt...

invent2main

invent2main

printed parts do not need to be extremely precise; armlenght can be measured and pulleyratio is modified with the calibration, it is one of the key points at the software level on which there is some work...