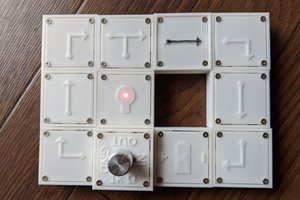

I liked the idea of the Stickvise very much, as I soldered that way for years: Pushing PCB´s around my workbench. Nowadays I often use a regular vise, but that's not too ergonomic for your wrists and arms...

Buying a Stickvise was out of question, even if 30$ is a really competitive price (though shipping to Germany would double that I guess). Plus I really don't like these 3D-printed plastic "jaws" all that much. I wanted:

- metal jaws

- a "quick change system" for the jaws

- a way to open the jaws by a pinching motion between index finger and thumb

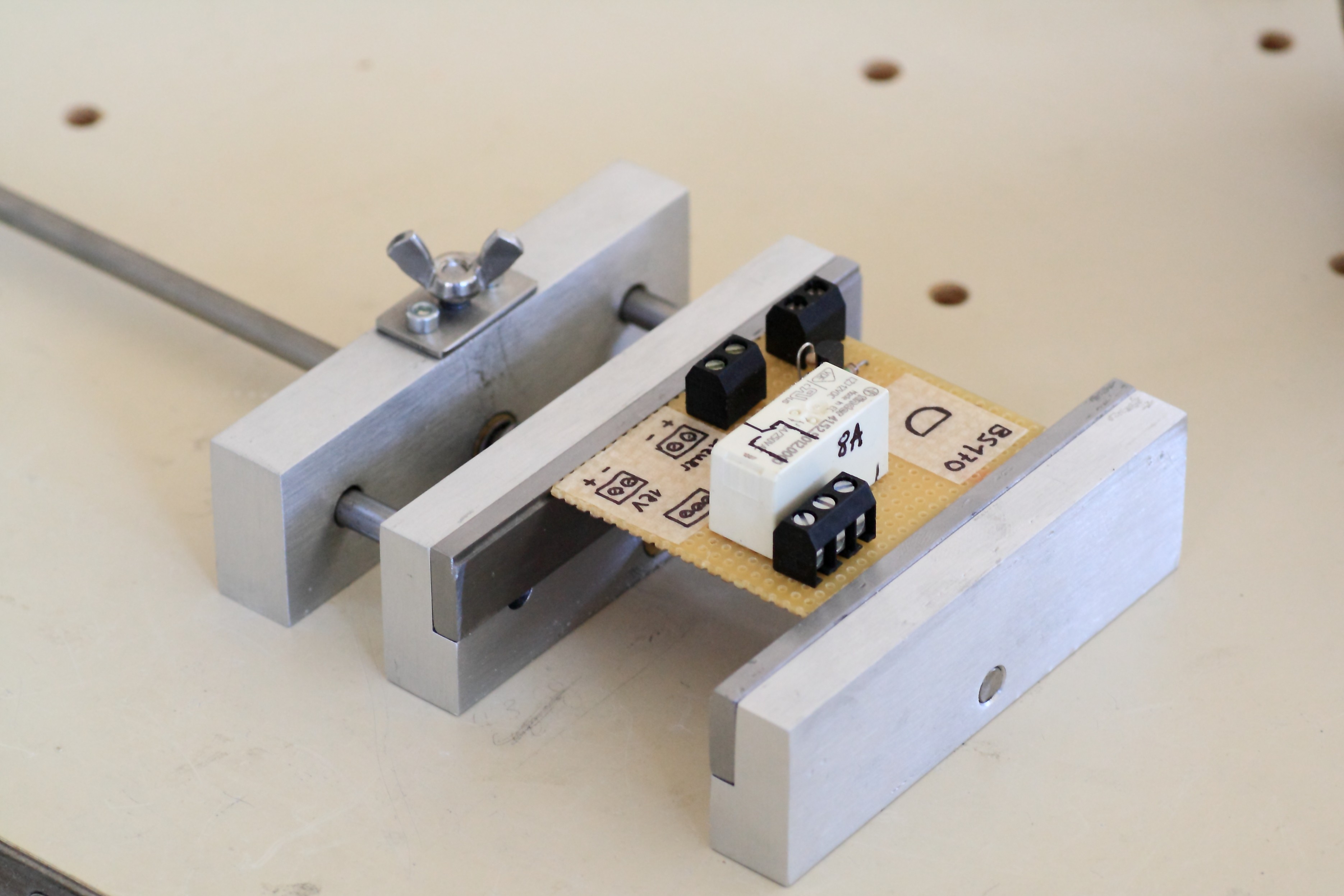

So I built my own solder vise which in fact looks a lot like the original. All three "main parts2 are made of aluminum and are 30x 15x 100mm in size. The rod is 6mm stainless steel and 250mm long. As aluminum/steel is not the best-sliding combination I made two brass sleeve bearings Ø6[H7]x Ø10x 15mm which are glued in place.

The two guiding rods are fixed by M3x 5mm setscrews in the movable jaw. On the other side, I tapped a M3 thread. Screws with washers stop the movable jaw from sliding out too far.

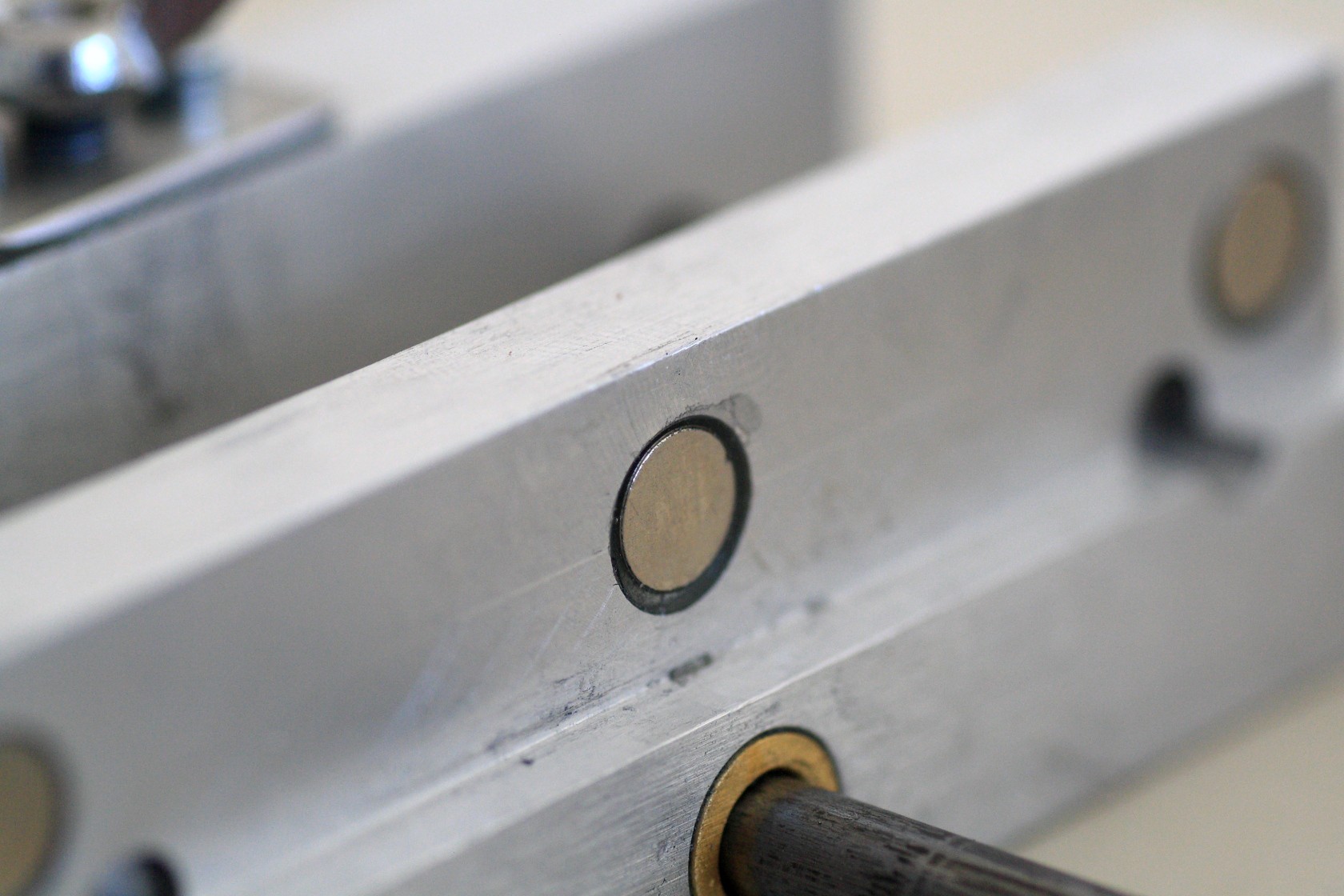

Now to the jaws. They had to be changeable. Quickly and without tools. We had 16x 5mm cold-rolled steel lying around at the machine shop, so I constructed with that. As I do not like to unscrew jaws just to be able to hold this or that, magnets came to my mind. Ø8x 2mm N50 neodymium are cheap and can hold 1,8kg each. Three of them are countersunk in each jaw. They are glued in place and are exacly flush with the metal surface:

You now just slide the jaws out a little to one side so you can grab them, turn them around to the needed groove and just stick them back in. Easy as that! Drawback: You can't print your changeable jaws at home, you have to have access to a mill. Anyway: these will last a long time.

The steel-multi-jaws will have four different grooves (but only have one at the moment):

The clamping is done with a brass rod with a radius of 7mm to prevent indents on the stainless steel rod.

This is the semi-finished SolderVise:

Jan

Jan

Timo Birnschein

Timo Birnschein

secretbatcave

secretbatcave

Giovanni Leal

Giovanni Leal

Nice, those magnets are good idea.