Probably one of the most (if not THE most) important component of a DLP 3D printer when it comes to results quality is the material you use for the bottom of your vat. People out there is still looking up for a solution that complies all the specifications. (Transparent, anti-adhesive, non-reactive)

The Sunrise it's been using this food-grade silicone sheet, that was not-quite as transparent but translucent enough; and not quite as anti-adhesive, but flexible enough to peel off from the part. It's good, gets the job done, but one's always looking for something better.

The community it's been experimenting with this material called FEP, that has similar properties to PTFE, but somehow it differs in the way it's produced. This material comes in transparent sheets, but it's price makes people choose sheets 0.1mm thick, and that looked way thin compared to the 0.5mm I'm used to. I was hesitant to use it for fear it would rip, but that was until we saw a FEP membrane with a 11kg weight on top, and not ripping at all.

So we tried FEP.

It's a 0.25mm film, but 0.1 would have performed good as well. Image is completely clear on the other side of the image, and resin doesn't stick at all. It's not as elastic as silicone, but it just adapts to the shape of the vat wonderfully, and stays there. It gives a nice clear surface, that resists the attack of the resin quite good.

Because it doesn't blur the image, print quality is increased. Take a look at the hair of this sappho, you can actually see the perimeter of the last layers:

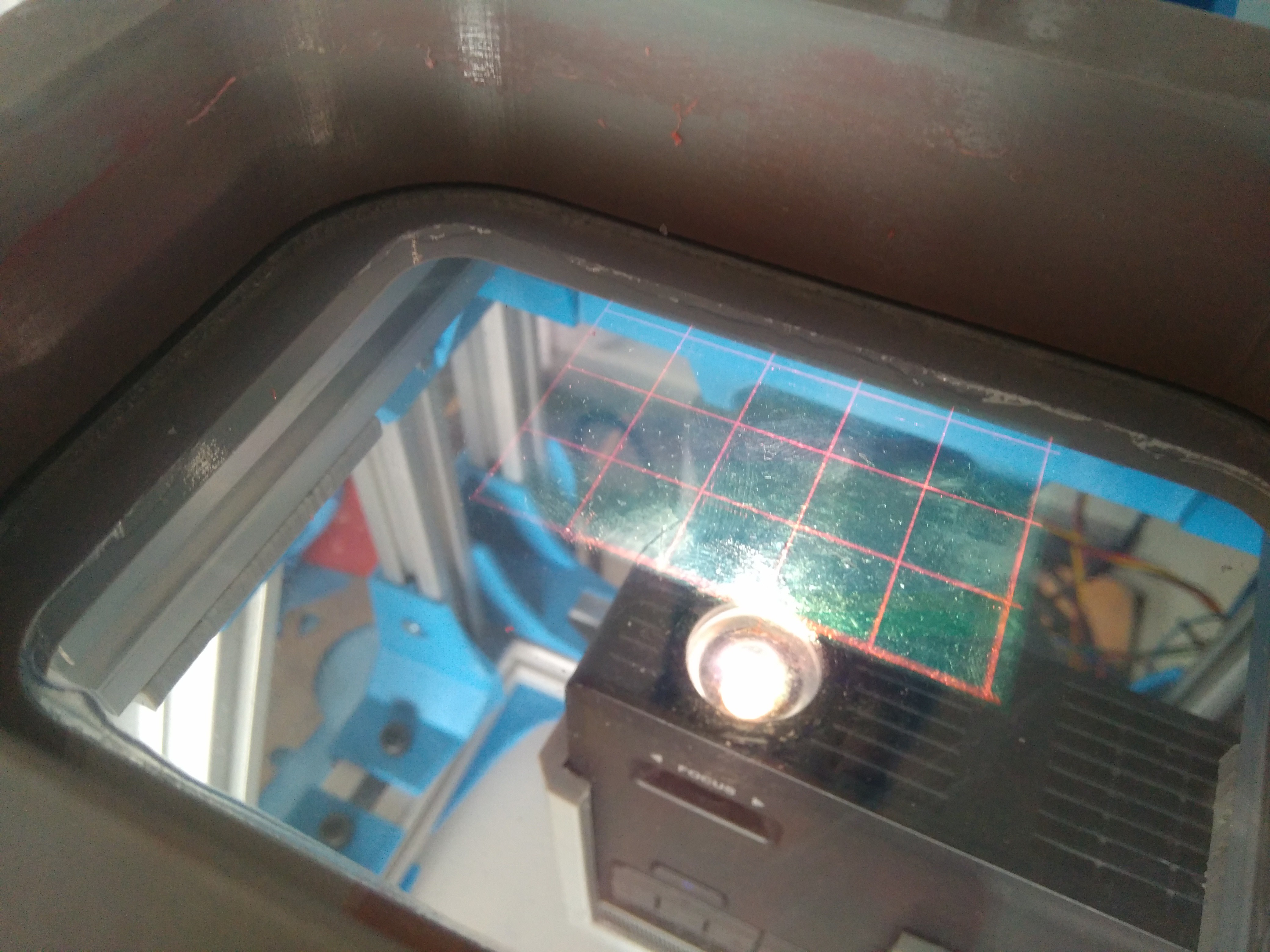

It so happens that I moved the Sunrise to a room with a window, and it's been sunny lately. With the new optical upgrade, natural light level on the lower side of the vat was quite high, and because the Sunrise a naked kind of machine (for now), the resin cured a bit on the bottom:

You can see, a resin patch with the same shape of the vat window. There. Sitting on my dear FEP. I thought this would be the end of that sheet, as it happens when resin cures on top of methacrylate, but for FEP, this is actually no big deal.

@paclema showed me that FEP can do better than that: took a cutter, and peeled of the resin, leaving the FEP intact. That actually happened while I was writing this post:

So we are back in business! FEP shows no damage, so we will print with it until it does. In the meantime maybe I should design a specific vat for this kind of membrane.

Jaime García

Jaime García

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.