-

How to Install a Fusible Link?

04/21/2022 at 10:06 • 0 commentsUnlike a circuit breaker, all fusible links can't be reset and need to be replaced once it is blown. Take the following guidelines to replace it by yourself.

Materials to prepare:

- New and Proper Size Fusible Links

- Wire Cutter

- Wire Stripper

- Heat-shrink tubes

- Solder

- Soldering Gun

- Heat Gun

- Wire Crimps

![]()

- Dismount the negative pole of the battery

- Cut off both ends of the blown fusible links from the main wire harness

- Strips the ends of the new fusible link for 1-2 inches

- Blend the stands of copper of one end of fusible links with the main wire

- Puts crimps onto the connecting point and solder it to build a stronger connection

- Slide the heat shrink tube to cover the joint area

- Use the heat gun to fasten the heat shrink tube

- Repeat 4-7 for the other end of the fusible links

(Originally posted on Easybom)

-

How to Test a Relay

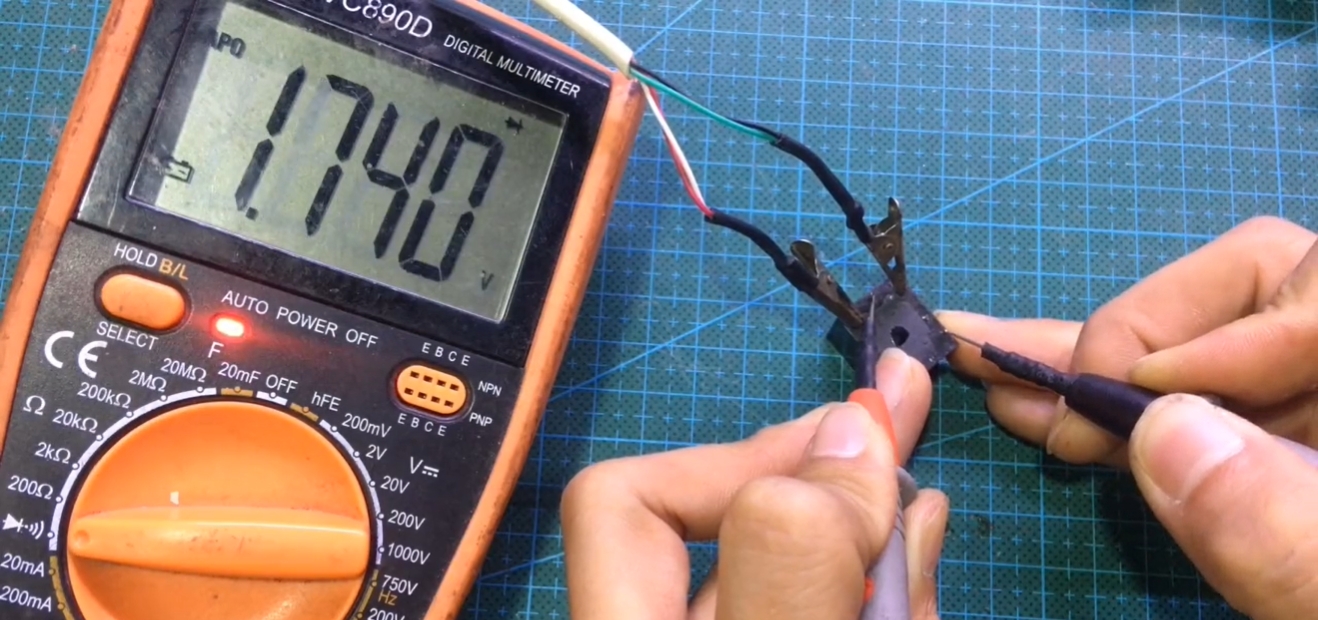

04/21/2022 at 10:02 • 0 commentsTake this 4 pin NC relay as an example; you can test a relay with a multimeter in the following steps:

![test rely coil circuits]()

1. Turn off any power load to the relay

2. Set the multimeter to 2KΩ resistance mode

3. Attach the probes with two coil contacts of the relay

A standard 12V relay has a coil resistance of around 50~200 ohms.

![test conducting contacts]()

4. Switch the multimeter to continuity mode (some DMM integrates it with the diode mode)

5. Connect the probes with both the COM contact (30) and the NO contact (87)

![supply coil contacts with load]()

6. Supply an independent power source to the coil terminations according to the relay ratings

![test second coil continuity]()

7. Keep the relay mounted with power and connect the meter probes with two switch contacts again.

(Originally posted on Easybom, Click to Read more)

-

What's the Difference between Managed and Unmanaged Switch

03/23/2022 at 03:25 • 0 commentsManaged vs Unmanaged Switch: Which to Choose?

When packets reach network switches, they're compared against an inventory of addresses and network segments. If the segments are not compatible then packets are transferred and if not, they are blocked. Nodes with high traffic or mission-critical systems are often connected to an individual switch port.

When devices are linked to the switch the switch will record its media access control (MAC) address. It is a number encoded within the network interface card (NIC) that connects to an Ethernet cable that connects to the switch. The switch makes use of its MAC address in order to know which connected device is sending outgoing messages and the location to which packets from incoming ones should be sent.

Certain Ethernet solutions providers classify network switches as unmanaged and managed varieties. They differ from one to the other in a variety of ways.

What is the Managed Switch?

Managed switches can be called configurable switches because they are extremely configurable both for remote and local usage (which implies it's a good idea to outsource your network management). The primary benefit of managed switches managed switch is that its configurations can be modified to meet your particular requirements for managing your network. In addition, it comes with important features such as RSTP (Rapid Spanning Tree Protocol) as well as CLI (Command Line Interface), and many more.

They offer a level of security that unmanaged switches cannot for you are able to select the best operation for each port. They can instantly shut down identified threats, prevent access from unwanted sources and even encrypt communications as they monitor and manage the network's events.

Redundancy Protocols

Redundancy helps protect a network in the event of cables or links fail by providing a backup route for data. To ensure that integrated systems are running, standard protocols eliminate loops and permit redundant links to act as a backup. This will save you time and money and any user will be grateful for.

VLANs (Virtual Local Area Network)

One of the biggest advantages of a managed networking switch is the ability to divide local networks using VLAN. This means that it doesn't just fill MAC tables with data, but also provides information regarding the frame's connection to an individual network segment. This means that we can reduce excessive broadcast traffic, adjust access to devices for a particular subnetwork, and increase security.

QoS (Quality of Services)

It is a function that prioritizes bandwidth to data subsets, which allows for greater bandwidth to be shared over the network to ensure IP data flows seamlessly and sensor data can be accessed without interruption, using only a small amount of bandwidth.

SNMP (Simple Network Management Protocol)

SNMP is a protocol that permits network devices to collect information, arrange, and modify management data. Thus, without needing to physically inspect the switches or devices, IT administrators can examine the SNMP information and track the performance of the network from a distant location and even identify and correct network issues from a central point.

SFP (Small Form-factor Pluggable)

The advantage of SFP slots with multiple rates is the flexibility of the network that allows users to utilize 100Mbps and 1Gbps SFP Modules to use single-mode or multimode fiber-optic (or copper) depending on the requirements. If your requirements shift or your requirements change, the SFP module could be easily changed, allowing you to safeguard the investment you made in your switch.

---------- Read More: Managed vs Unmanaged Switch: Which to Choose?----------

My Pages

Projects I Like & Follow

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Mateo Miličević

Mateo Miličević Eugene

Eugene kodera2t

kodera2t J.C. Nelson

J.C. Nelson Sam Smith

Sam Smith bobricius

bobricius FabLab München

FabLab München Jeremy

Jeremy Manos

Manos David Michaeli

David Michaeli tyrigi

tyrigi 8teims

8teims nootropic design

nootropic design Giulio Pons

Giulio Pons G. Rosa

G. Rosa Stefan Wagner

Stefan Wagner