More often than not my life feels like a "15 puzzle". For those of you who know know what they are, I just learned the proper name myself. They are those puzzles are sliding puzzles that consists of a frame of numbered square tiles in random order with one tile missing. The object of the puzzle is to place the tiles in order by making sliding moves that use the empty space.

This is a good analogy of life oftentimes. You want to do one thing but that one thing is dependent on the 14 things beneath it, and, and of course each of those has their own dependencies. On a really good day the dependencies don't overlap. You just need to get a lot of ducks lined up.

So, I have another project. I will no doubt write it up as it is interesting and I have a lt of faith that I can make it work. That project depends on making two wifi antenni. Wifi antenni are generally fun to make but not cost effective to make because you wind up getting taken for a ride on the pigtail you need to connect them to anything. That is unless you have a good junkbox.

Anyway, the antenni that I have in mind are a pair of Yagi's. These are a type of directional antenna invented in japan by a professor Shintaro Uda. One of his students filed the patent without professor Yahi's name on it, and now they are generally known as Yagi antennas.

I tend to be anal when I build things and I like making jigs, Truthfully it would probably be faster in this case to just crank out the two antennas in question by hand but that takes the fun out of it. Each one will be about 2 feet long and have 13 elements. The longest elements will be 56mm, so the entire antenna will be pretty small. I want to build the beam out of 3/4" PVC tubing and the elements out of 1mm stainless tig filler rod. The PVC will let me cap the end off weather tight with PVC caps and use PVC plumbing pieces to mount it.

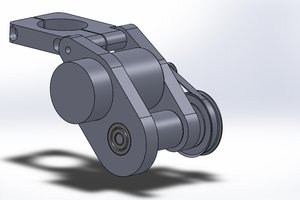

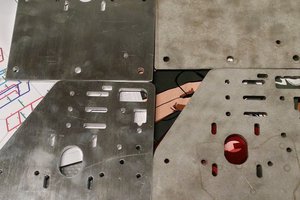

I am envisioning three jigs. One is a hardwood V block that has a top cap that will hold a piece of 3/4" PVC tight in the groove with a bolt and wingnut at each end. The holes that the tig rod will go through will be drilled in the V block very accurately. Years ago I got an XY slide table for a drill press and I just remembered that I had it. It is just a bit too short to do all the holes in one pass but I suspect even with one re-zero part way through it will be much better than what I could do with a digital caliper or tape measure. The second jig will be a frame the PVC fits in with blocks on both sides to center all the elements. This one I will do with my digital caliper. And last, a block that you can bend the piece around to create the folded dipole driven element.

The idea being if I ever want to make another one of these, I can crank it out very quickly and with almost no measuring, except the elements themselves. I will cut them with a stop on my metal chop saw. As an aside, that was a recent purchase and I am wondering how I lived this many years without one.

So, the other night it is above freezing out. The shop is not heated. I figure I will go out and get the XY table set up on the drill press and get an idea of how all the pieces are going to fit together. I went to turn my drillress on and the lights dimmed and it barely turned. After a lot of looking at it, sand wasps had infested the motor. The entire motor was full of sand and the remains of their nests. The centripetal switch that controls the start capacitor (in a motor with one you can hear it click as the motor comes up to speed and no longer needs the start cap) and the bearings were the casualties. I was not happy.

It has also been decades since I bought a motor. I was unpleasantly surprised by what they cost, even at discount places like HF. Replacing the drill press was starting to sound like a more...

Read more » matthewkleinmann

matthewkleinmann

Chaz

Chaz

charliex

charliex

Daren Schwenke

Daren Schwenke

polyfractal

polyfractal

I love freecycle. I do everything on the cheap and I am an awful garbage scow. I rarely post give ways, as most of my junk I have a semi use for, but if someone actually needs something I am usually willing to part with it unless it is a hard to come by piece. I would rather see something being used than have it sit in my pile.. If I have time tomorrow I am going to pop the old motor off and see if I can get the pulley tree off of it. What are the odds of the new motor (1) having the same shaft diameter and (2) going in the same direction. The direction is reversible but it would be sweet to not have to screw around with that. There is a temptation to put a switch on it, though I have never seen a drill press like that. Might be handy once in a while if you get a bit stuck in a hole or for using left hand bits for drilling threaded fasteners out..