Wow this is my first time documenting a project in a very long time....

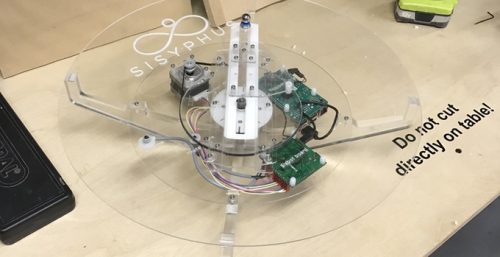

So basically this project takes inspiration from ZenXY, Sandscript and the Sisyphus table. I've done a lot of the groundwork and this post will be a summary of the background.

Step 1: Core Components

After doing a lot of research into existing sand plotter I've come to the following list of components as "crucial"

- Gantry motion system

- Examples include cartesian (CoreXY, Hbot), polar (lazy susan+slip ring or scare robot) & many others

- Magnetically coupled ball bearing

- The gantry will carry a magnet under the sand bed that's coupled to the ball bearing

- Cool LED strip

- To cast shadows & better see the patterns created!

- Stepper motors

- Easiest motor to work with for this application

- Motor control system

- This can be a CNC SBC (single board computer) for easy GCODE motion or an Arduino+stepper controllers such as a motor shield if you want to make simple geometric patterns

- Sand bed

- Type of sand & bedding material vary

Step 2: Motor form-factor limitations

So I want this thing to be TINY but just how tiny is tiny? Briefly looking at available components on the internet I quickly realized that the limiting factor will be the size of the motor. I essentially see 3 classes of motors suitable for the task of a sand plotter (open loop position control, easy location based movements)

1. DVD drive micro steppers

These guys are difficult to control, expensive to source & hard to mount (very low torque as well). For these reasons I've largely ignored them

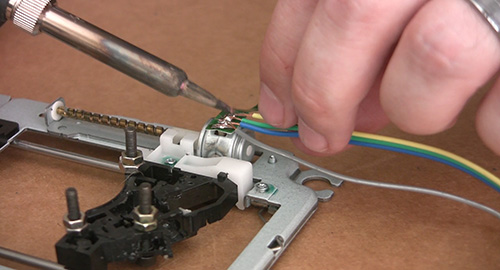

2. Hobby/toy stepper motors (geared, eccentric shaft)

So I tried these guys out for my first prototype, unfortunately the vendor I used has very poor quality control which resulted in multiple motor failures. They also don't have the best mounting features & the shaft can quickly overheat causing spur gears to slowly melt and deform (if printed from PLA)

3. NEMA standard size stepper motors (no gearing, pretty beefy)

NEMA motors come in a variety of sizes, all the way down to Nema 8. Unfortunately Nema 8 is pretty expensive and I wasn't able to locate any pancake (low profile) variants for that specific size.

Fortunately Nema 17 pancake stepper motors are commonly used in 3D printing and I was able to snag a few for $10 a piece from Amazon.

Step 3: Enclosure form-factor limitations

With the motor issue being dealt with, the remaining form factor limitations are electronics & other general enclosure related factors. I plan on using an Arduino Uno to keep this project fairly simple. As for the enclosure, I plan on using an Ender 5 to print the round enclosure (yes I want round) which gives me a maximum bounding box for the sand plotter.

Other enclosure related limitations include

- Size of viewing window/lid (I was able to find round discs of acrylic on amazon in a few different sizes)

- Size of your office desk?

- Honestly at this point there are no other limitations...

Step 4: Motion system form-factor limitations

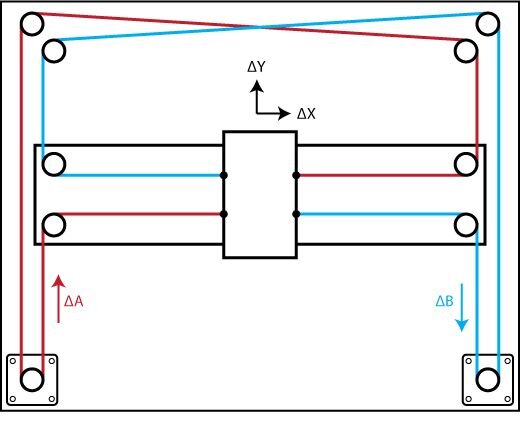

OK so I lied, the type of motion system you use will heavily effect your form-factor and final footprint. While CoreXY is very efficiency for 3D printing & other typical cartesian applications, it leaves a lot of deadspace for a sand plotter which would require a larger bezel (not a big fan). Because my project is intended to be very tiny this issue is amplified so CoreXY/Hbot/Cartesian systems are out of the running.

Next there is the variety of polar solutions, many of which require typically requires a slip-ring or less than 360 degrees of rotation (another non-negotiable for me), other polar solutions I've researched result in quite a high z stackup (total height) which also put me off.

The final option (and the one I settled on) was a modified Scara robot. This modification is very similar Mark Roland's design which in turn in similar to Rob Dobson's design (funny how that happens)

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.