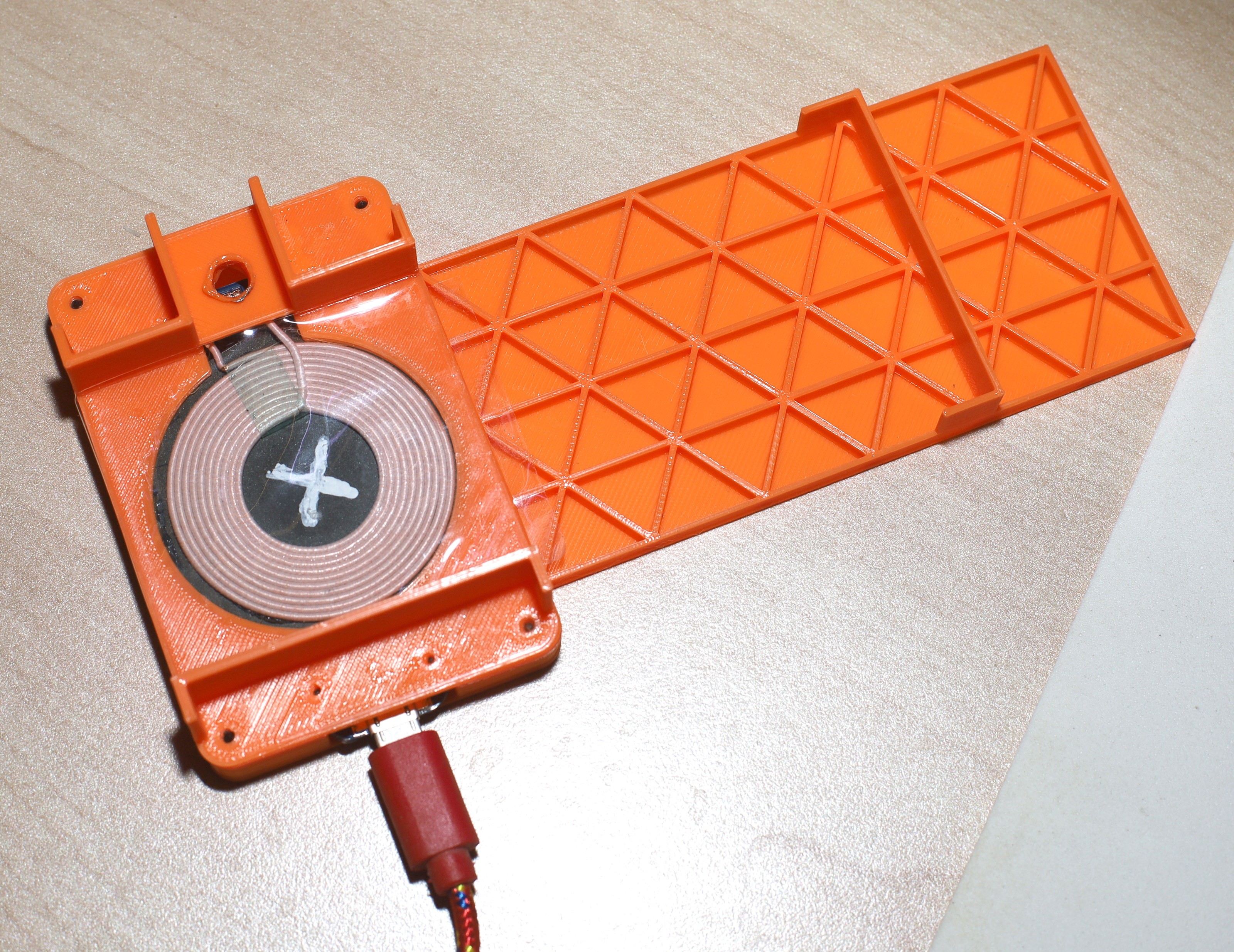

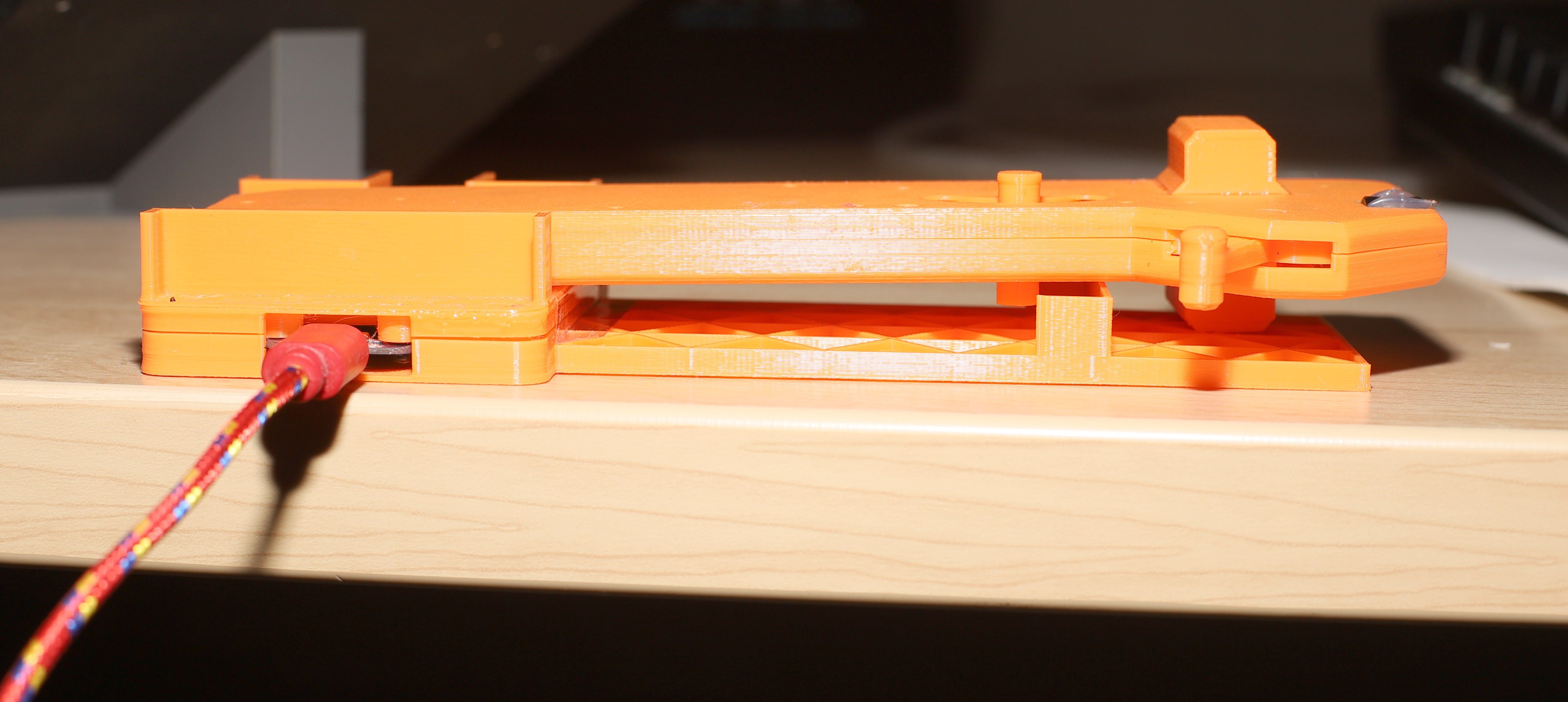

To make the controller waterproof, the TPU sock eventually had to be permanent which meant updating the charging stand.

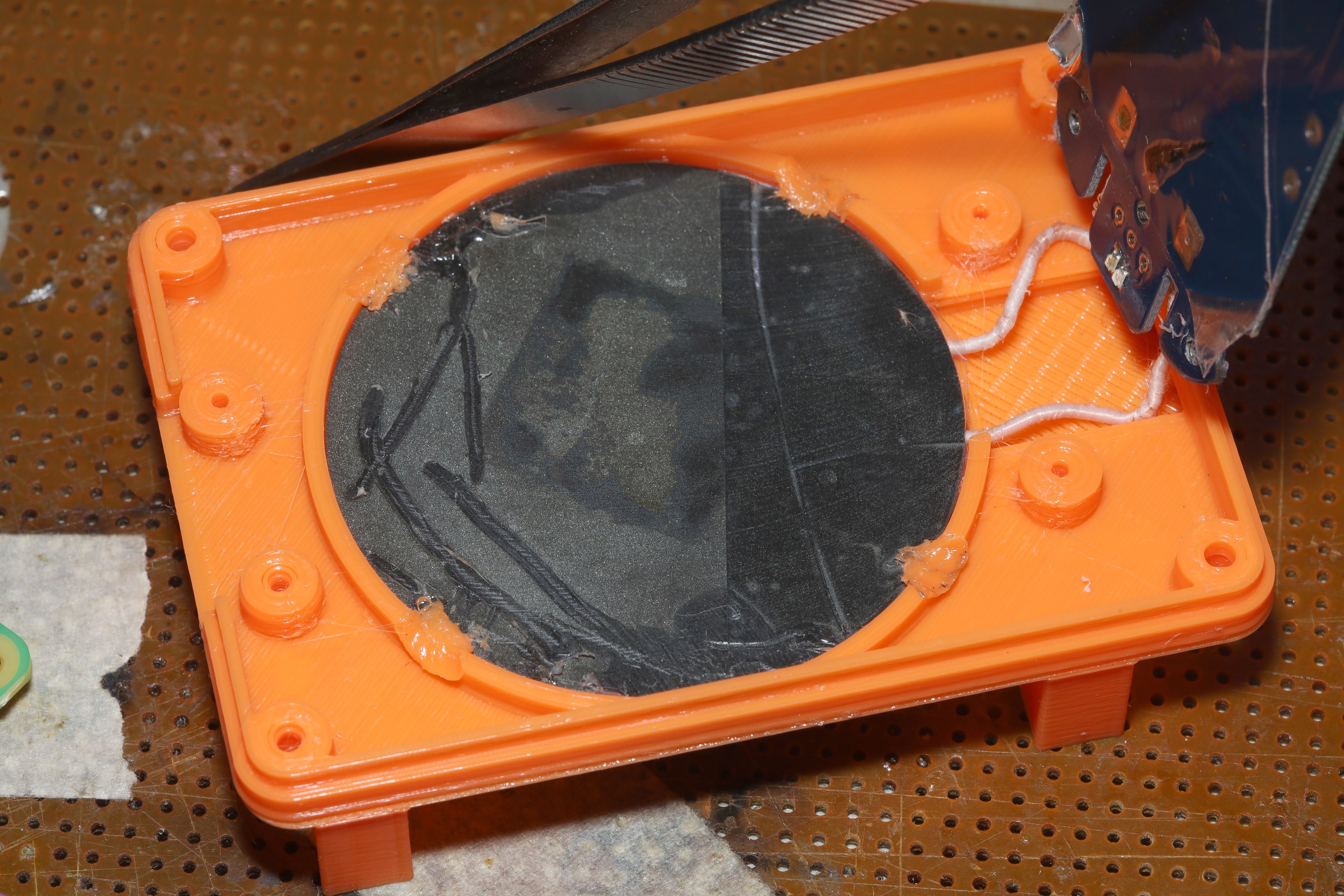

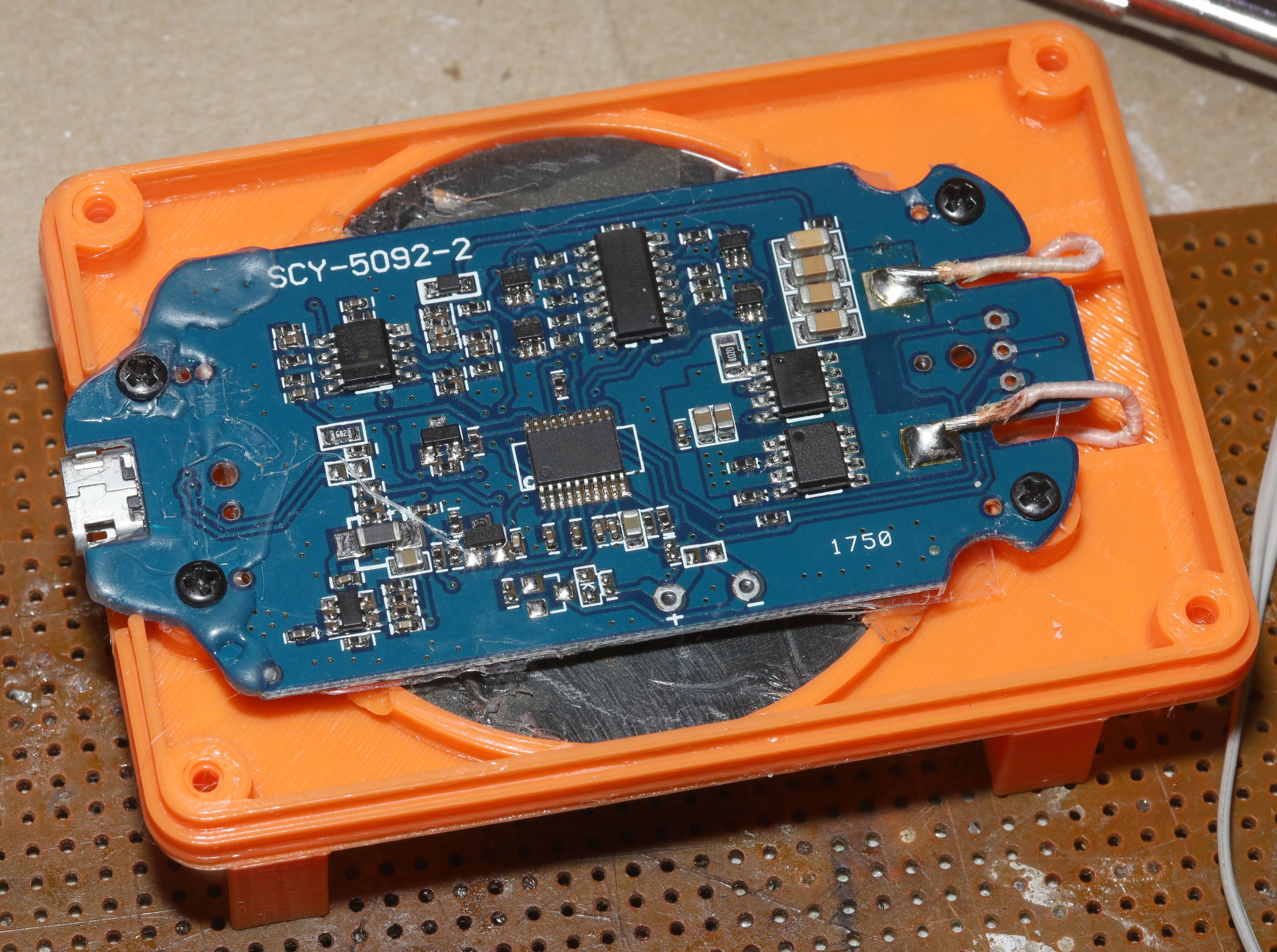

In this process, the charging inductor cracked. Those are really fragile. If the enclosure is too small or you try pulling it out when any PLA rivets are holding it in, it's going to crack.

The temptation is to press it when grabbing the charger. The problem is the new design fully exposes the inductor & nothing supports it in the middle. Below it is an air gap followed by the circuit board. At least Walmart has qi chargers locally at a reasonable price. The easiest solution is to not PLA rivet it & have some kind of foam press it out from the circuit board. It has a packing tape cover which could also prevent it from rotating.

The lion kingdom's PLA riveting skills have improved to melting it with a brushing motion of the soldering iron rather than keeping the soldering iron stationary. This keeps it from sticking to the soldering iron. Then use the mark 1 lion paw to press it in position before it cools.

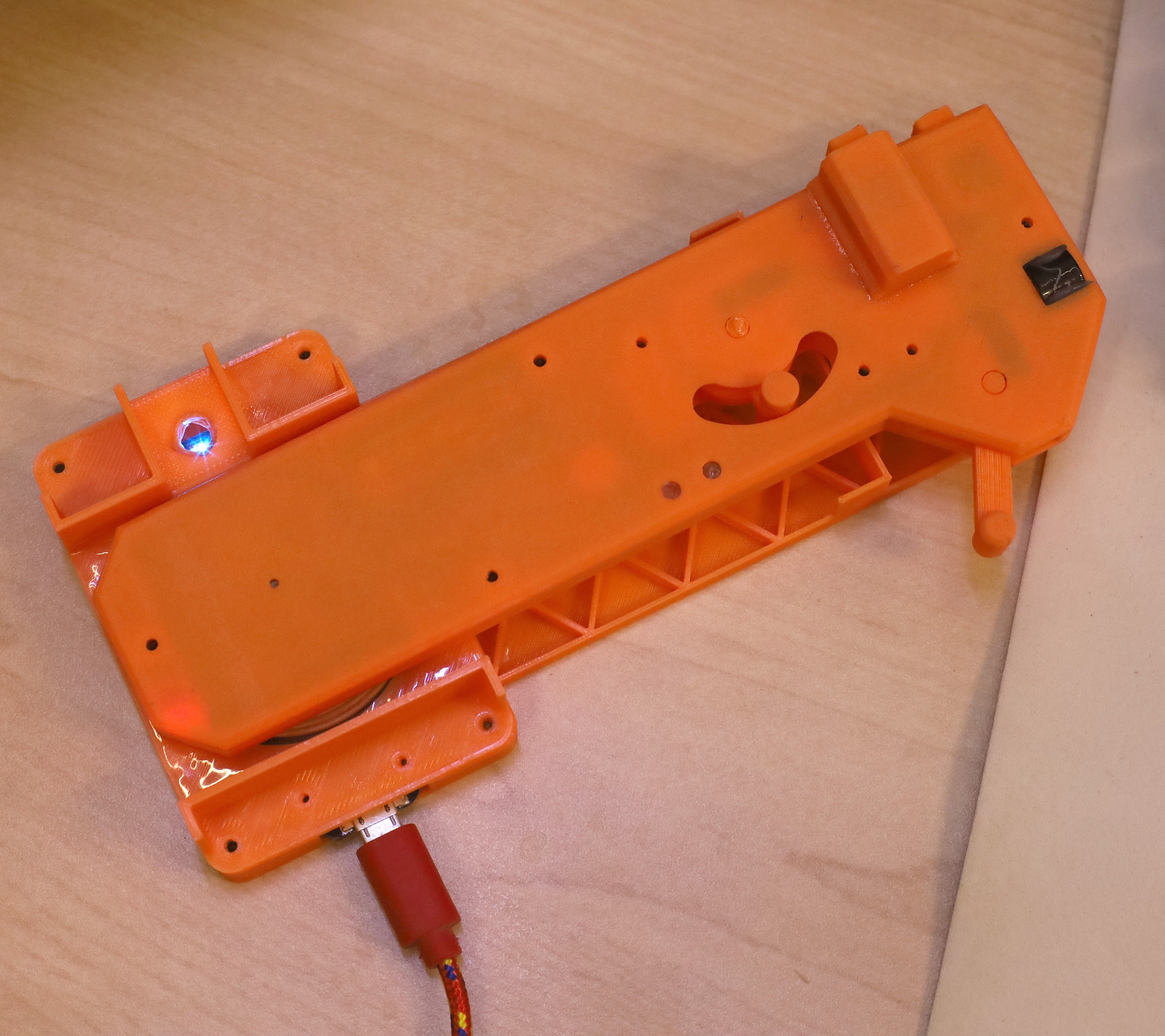

With the sock now permanent, it would have to be translucent to see the charging LED.

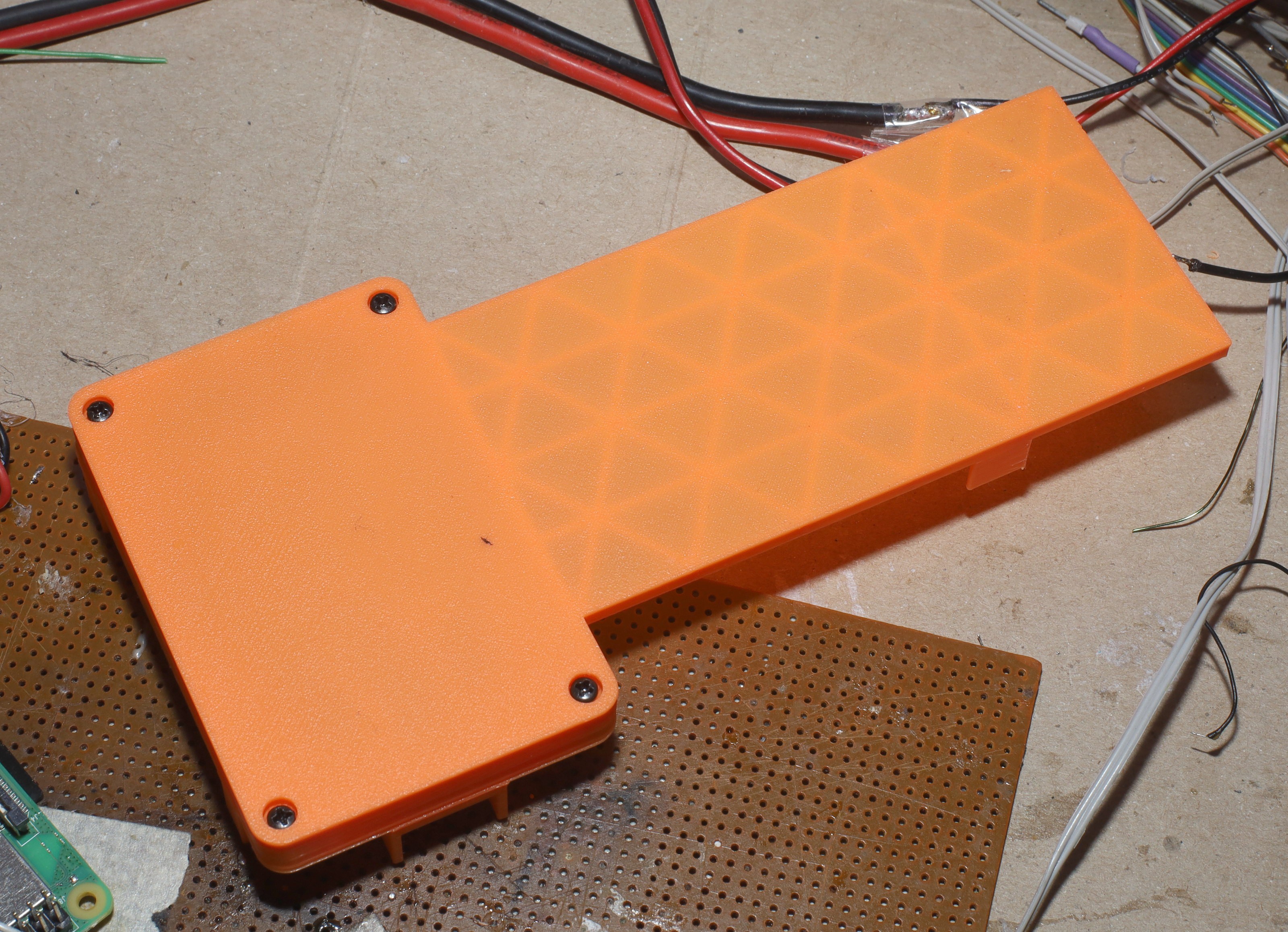

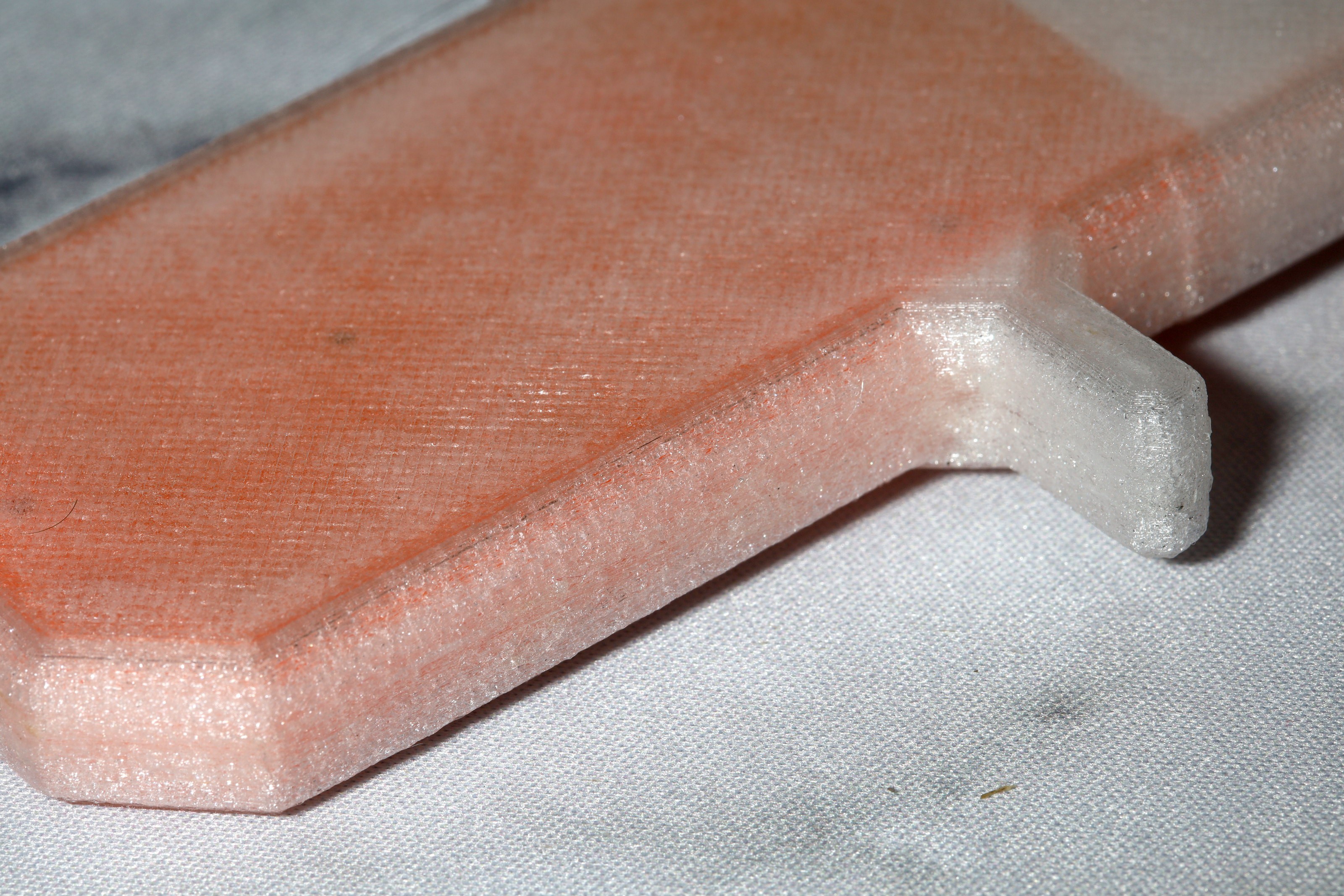

Translucent TPU & PLA entered the printer. The decision was made to retire orange PLA & hard black TPU. TPU is manely used for tires. The hard variant had very little use.

Panels which dominate lion prints come out a lot clearer than walls. It not obvious whether the filament came wet from China.

The charging LED is now visible.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.