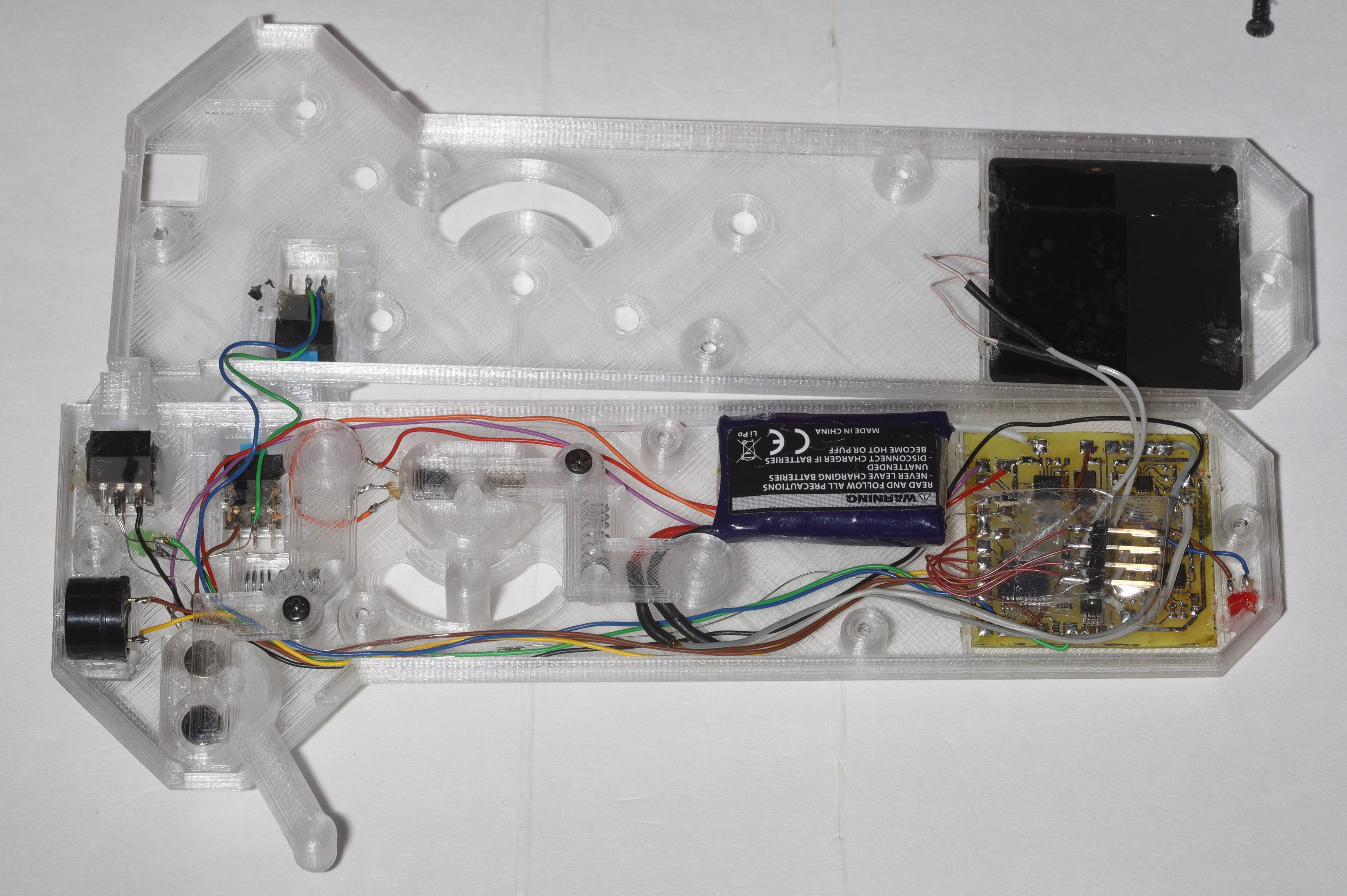

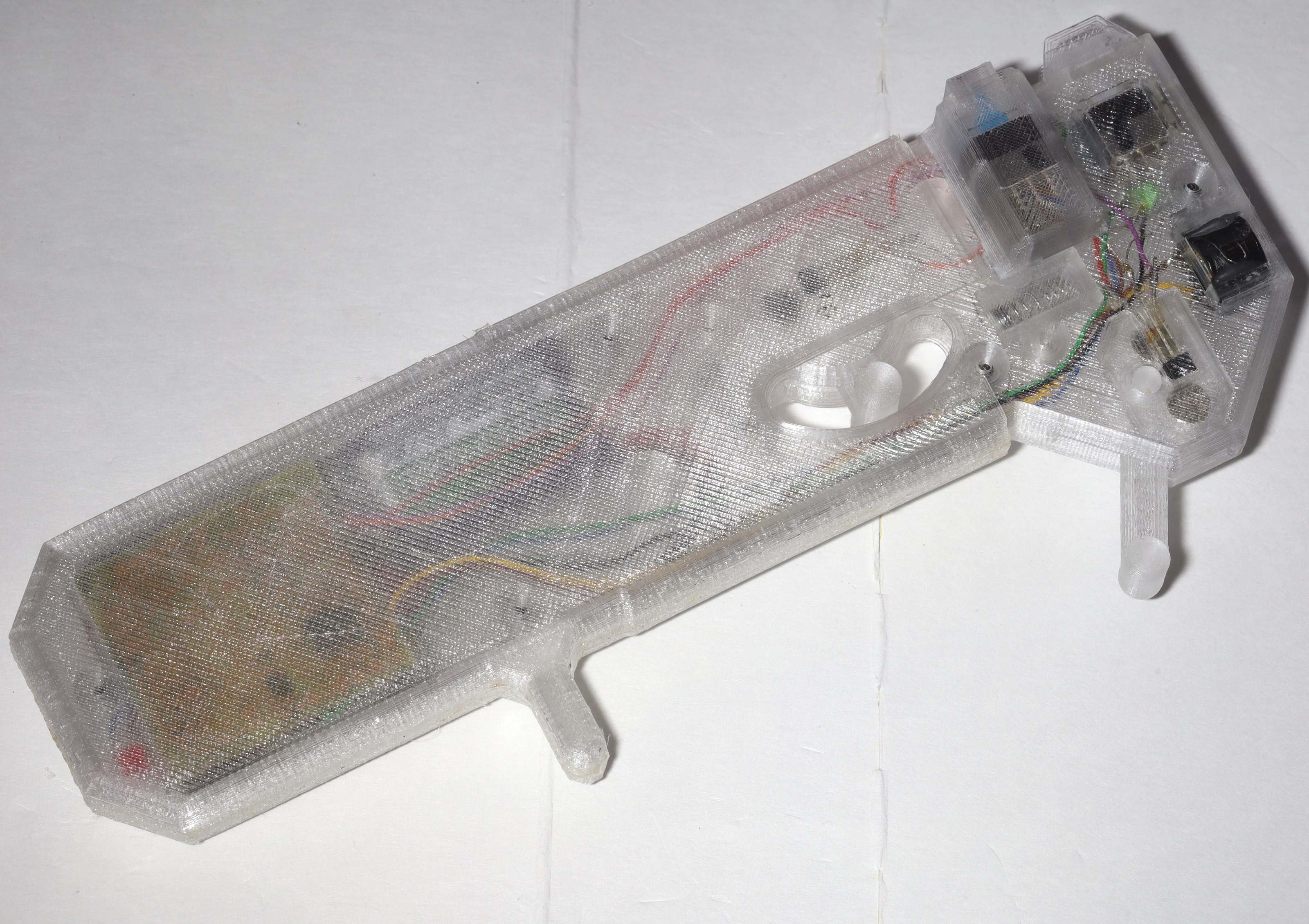

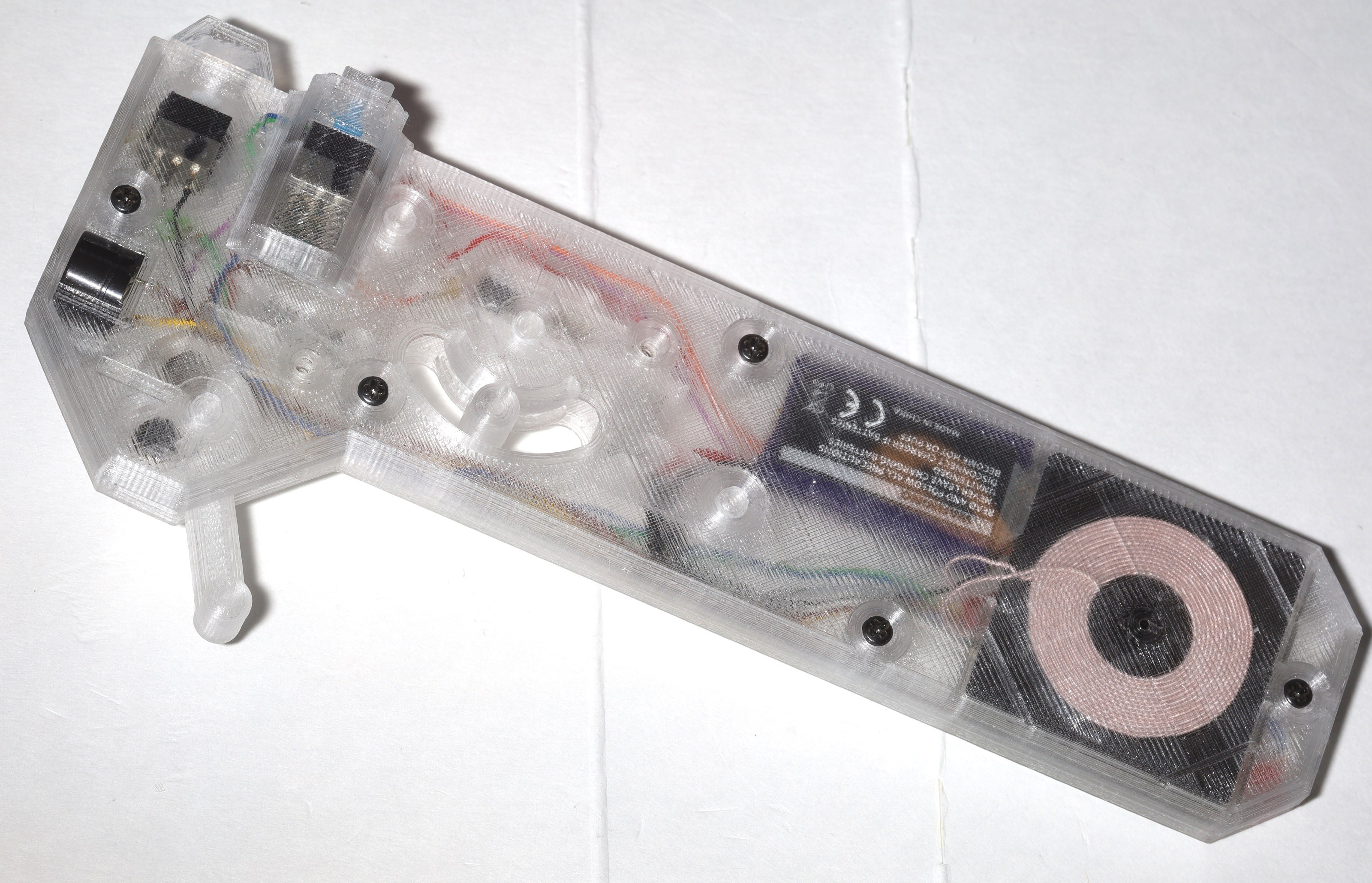

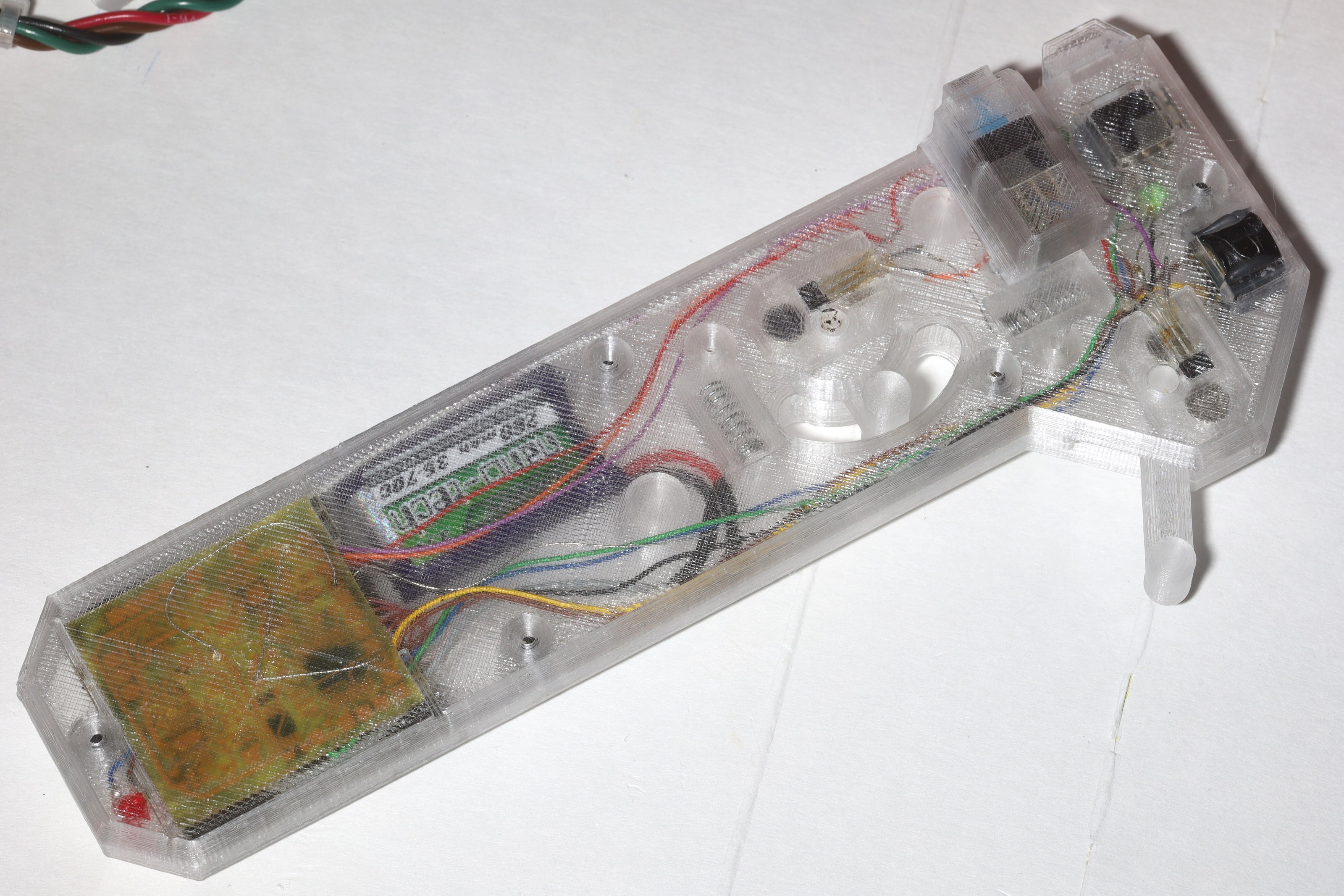

The current waterproofing & having all the LEDs on the inside worked, but growing pains with the orange beast finally reached a point where it was time. The mane problem was the power button constantly getting accidentally bumped when it was in leash mode. There were cosmetic desires for a glossy enclosure, better LED visibility.

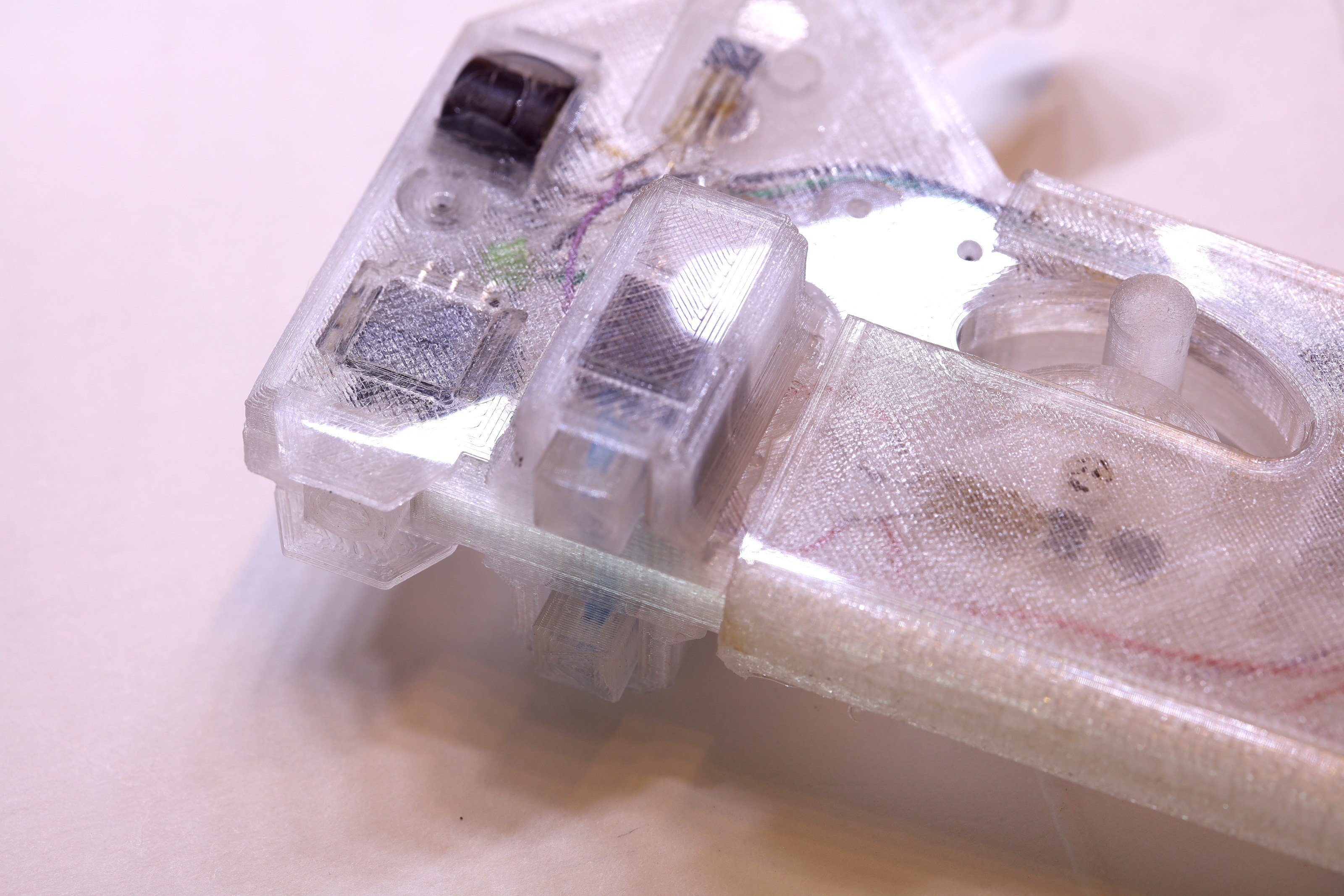

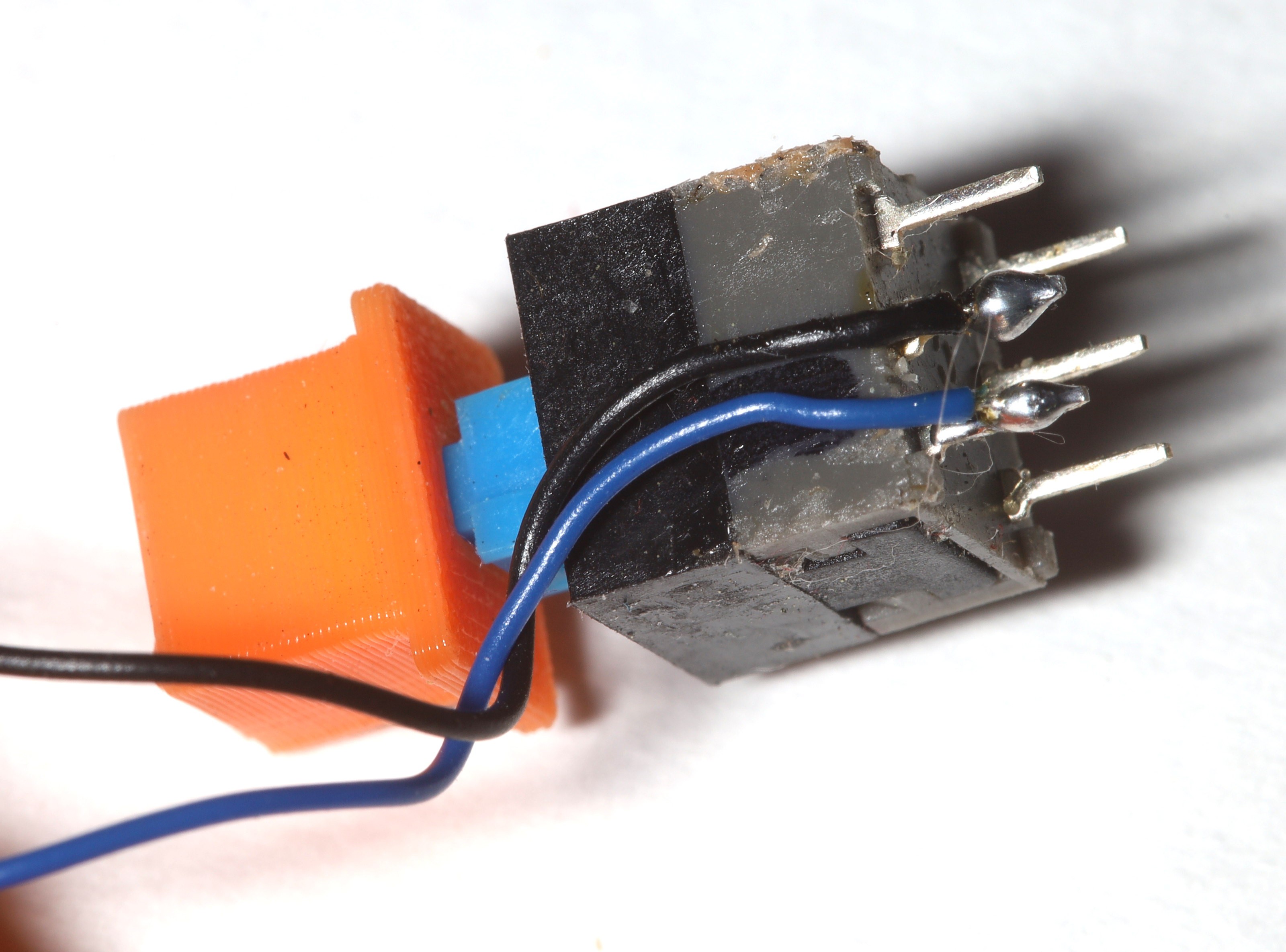

There was once a theory that an easily accessed power button would allow emergency killing of the motors. In reality, there was never a case where accessing the power button would have killed a runaway vehicle. The throttle stick always worked. If it got stuck, it was faster to unstick it than reach for the power button. The power button would not interrupt the leash & the leash now does half the driving. It was finally time to add some minimal guarding to the power button.

Assembly still takes 2 days, manely involving fiddly bits, removing the old circuit intact, reaming holes. PLA rivets are much harder to undo than hot snot. Undoing them melts plastic parts & removes a layer from the inductor. It pays to make the PLA rivets smaller.

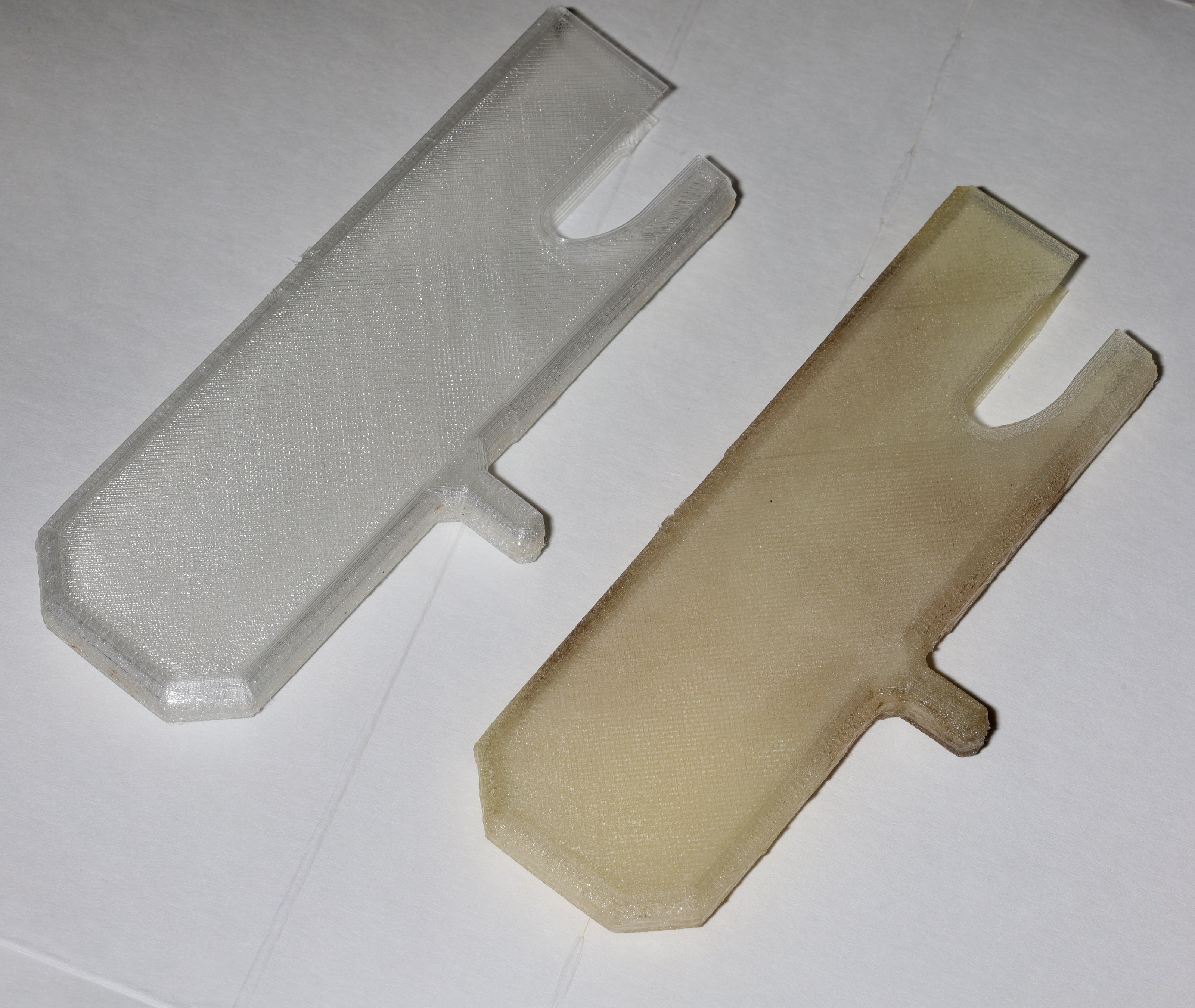

The 1st sock rapidly turned yellow either from biological matter or sunlight. It definitely smelled like biological matter. There's a warping from the clamshell not fitting perfectly. Stick controllers still need lubrication. The hall effect sensors got moved to where the datasheet showed their hotspots + a .2mm margin & they reported nearly the exact center.

Time will tell if a glossy exterior was a good idea. The sock might grip better with a buildtak finish.

The next big feature is going to be OTA firmware updates. It's not possible to get the oral cues perfect as is. There should be a way to put the radio in a serial port passthrough by holding power & a direction button. Then it can run a bootloader. It's a big job.

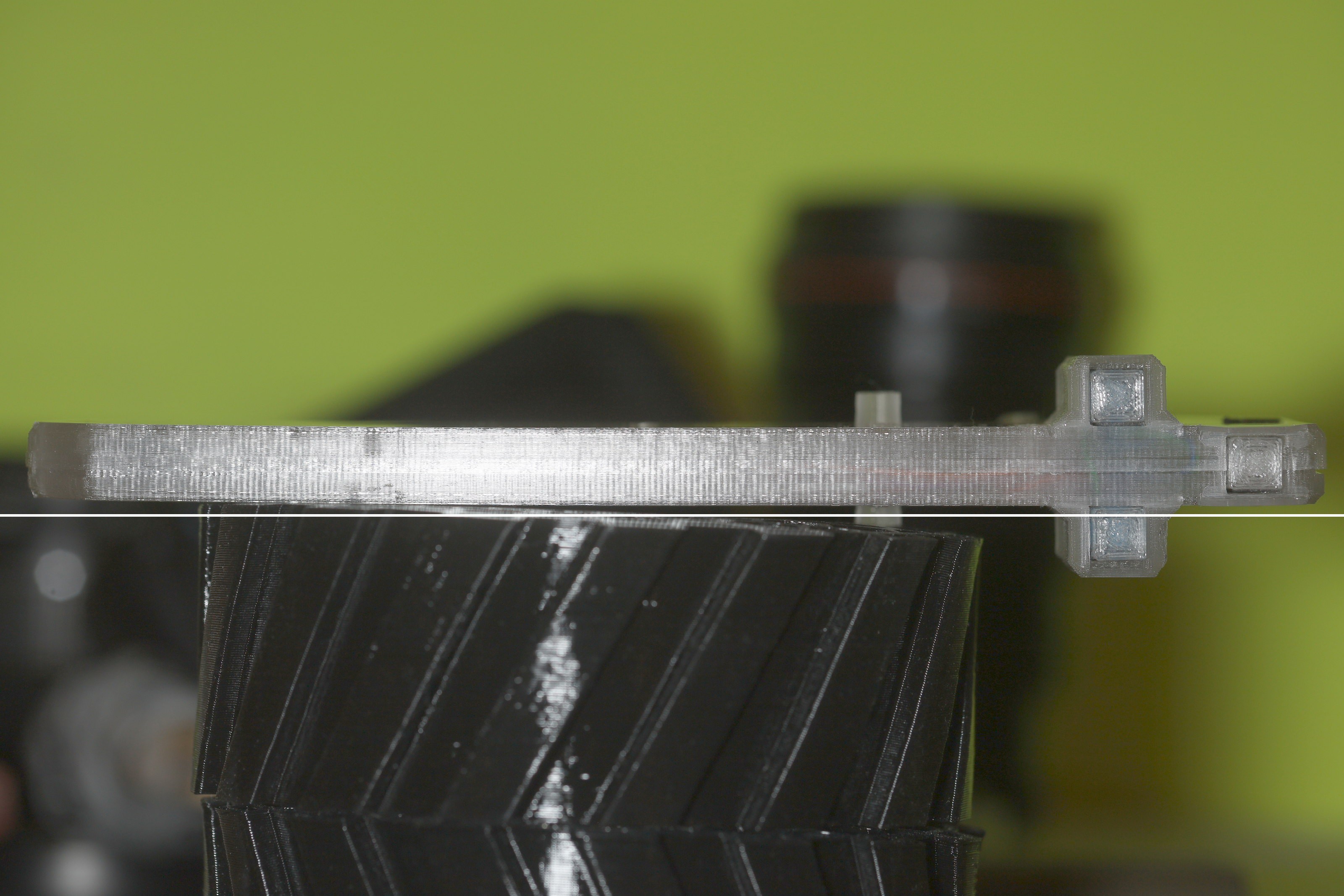

There's a growing desire to make the panels 1mm thick. They were made .8mm thick before lions were fully educated on PLA tolerances. There's a growing desire to make the power button exposed on 1 side & riveted in. The current hot snot system is a mess. Maybe it could be scotched over for waterproofing. Maybe it could be passively clamshelled in. The 3 button caps could actually be smaller. Still no better system than hot snotting the hall effect sensors.

The mane problem with the translucent controller is it gets hot in sunlight & alignments change.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.