For documentation I would like to refer to the github page.

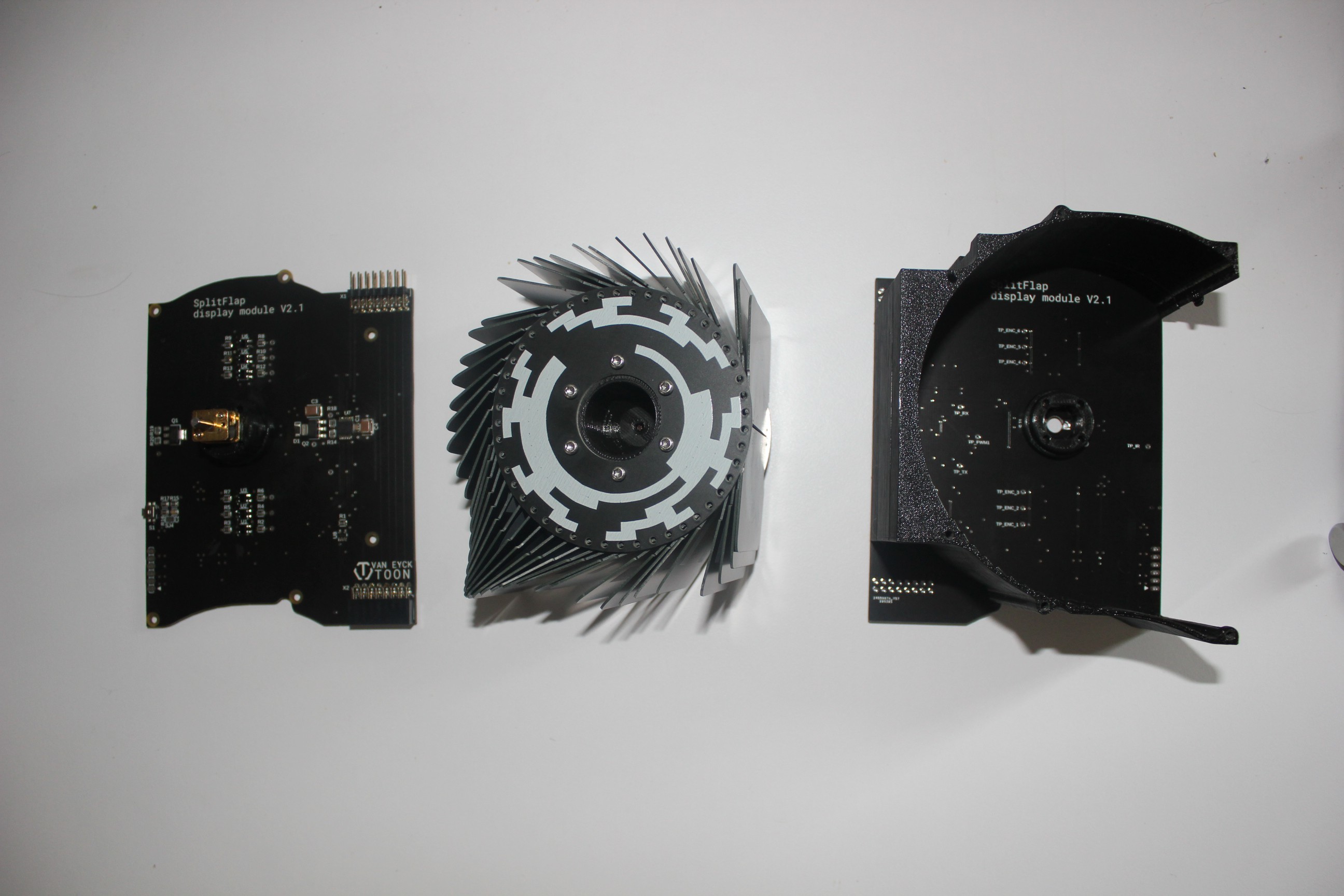

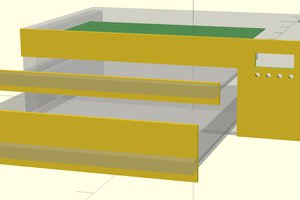

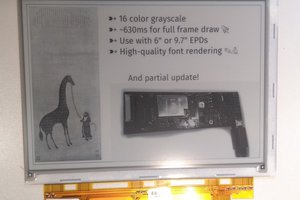

The display uses PCB's and 3D printed parts as structural materials. The side panels, the flaps and the encoder wheels are all PCB's

Only one of the PCB's contains any electronics.

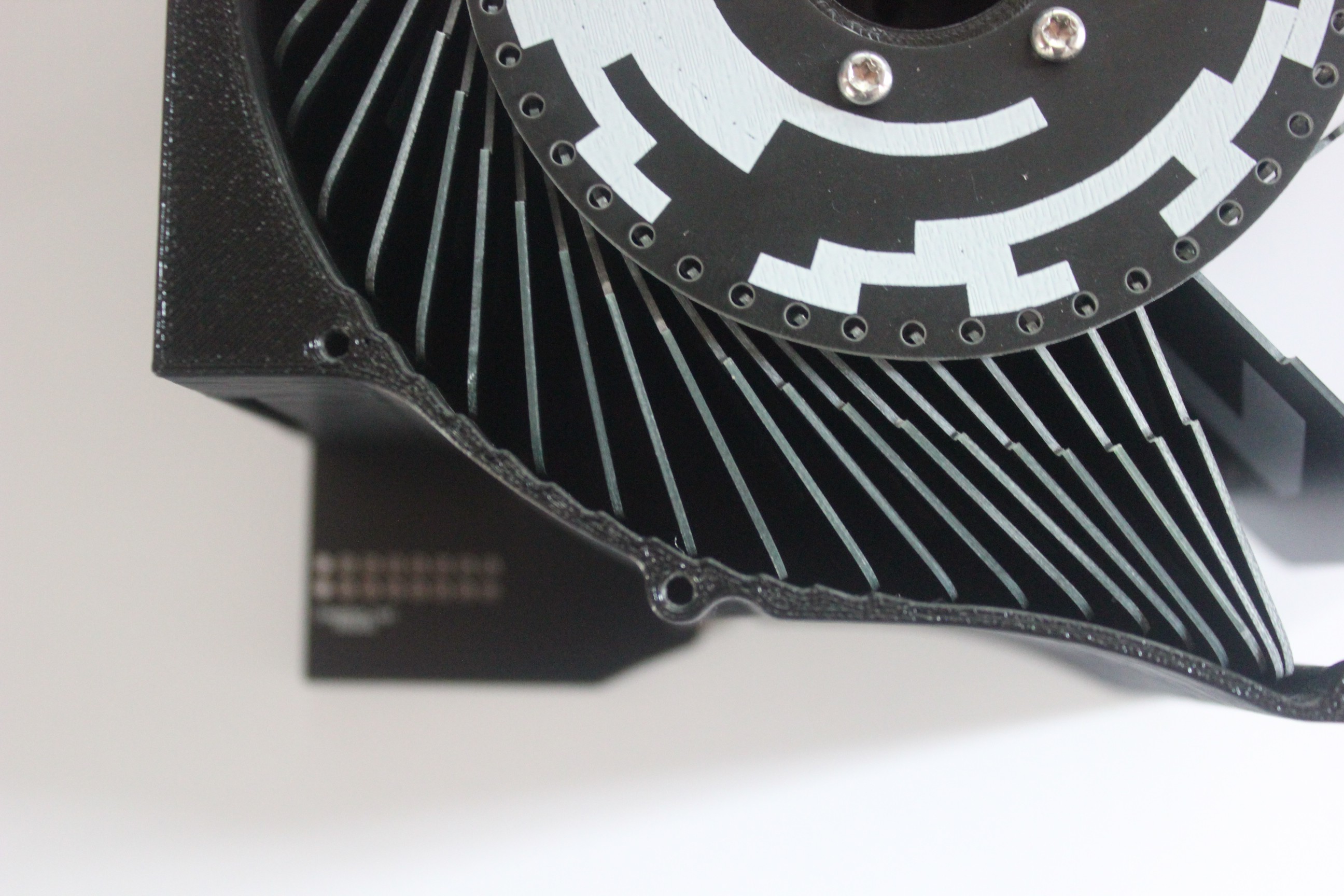

The 3D printed enclosure features small tooth like indentations that prevent the flap wheel from rotating back.

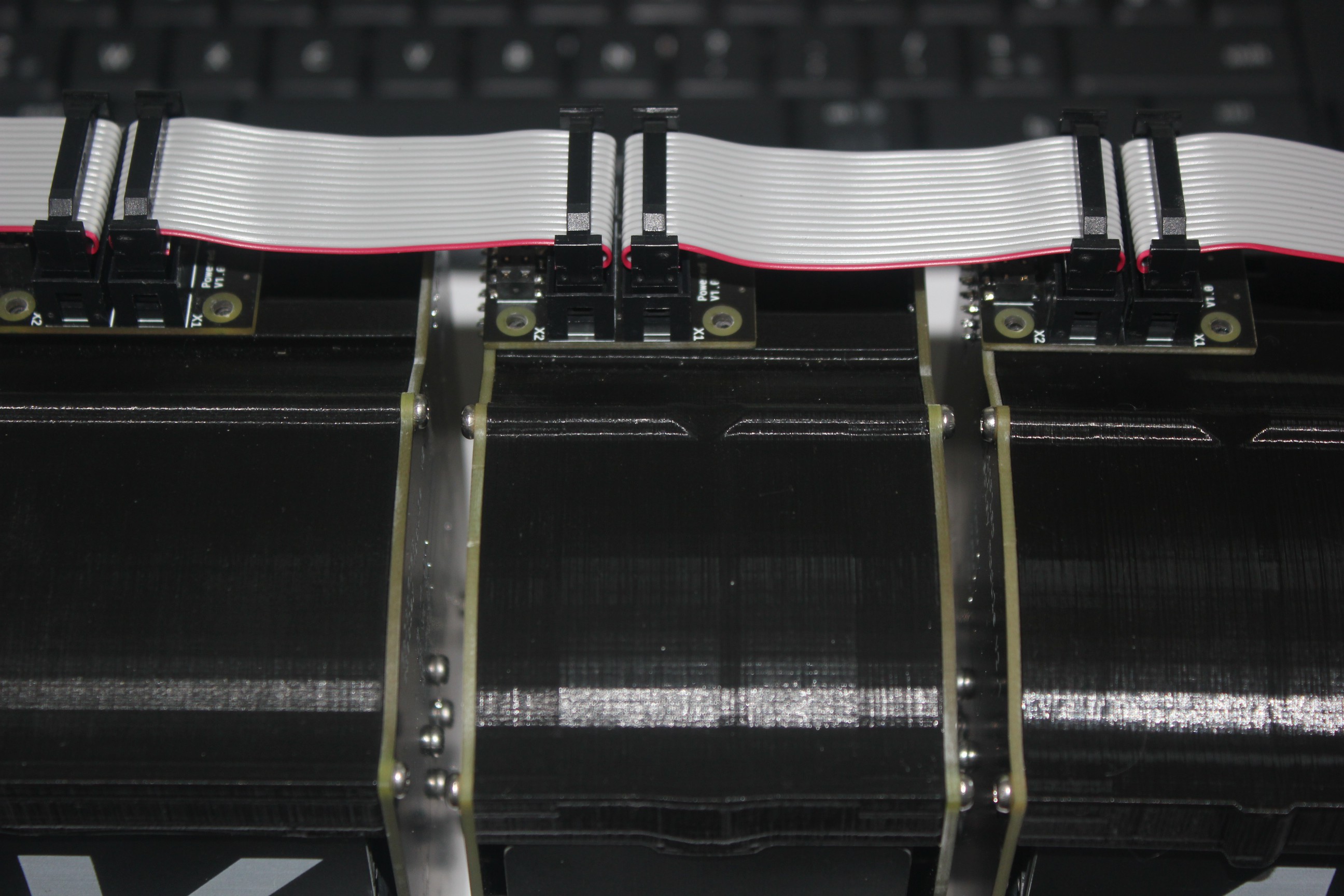

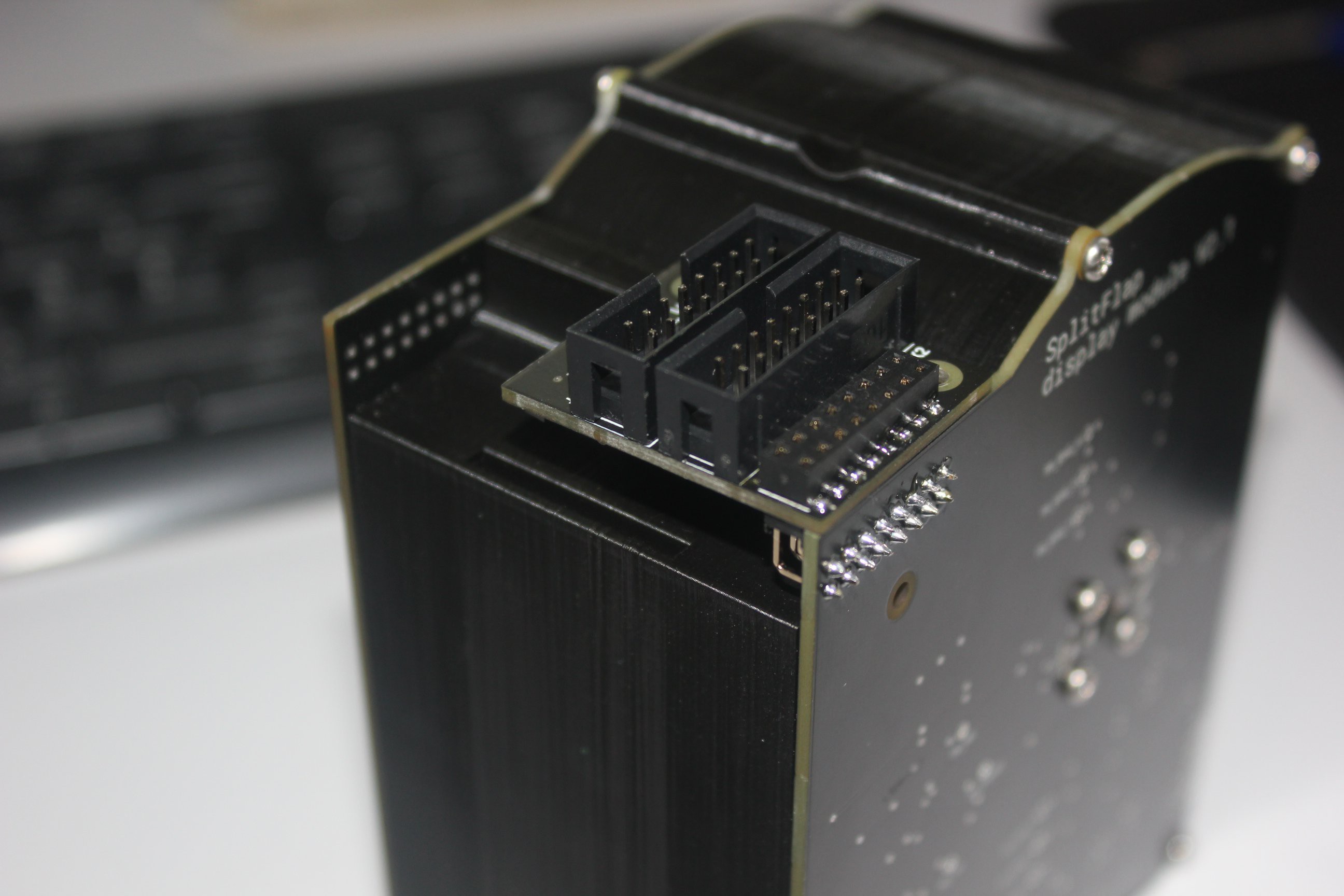

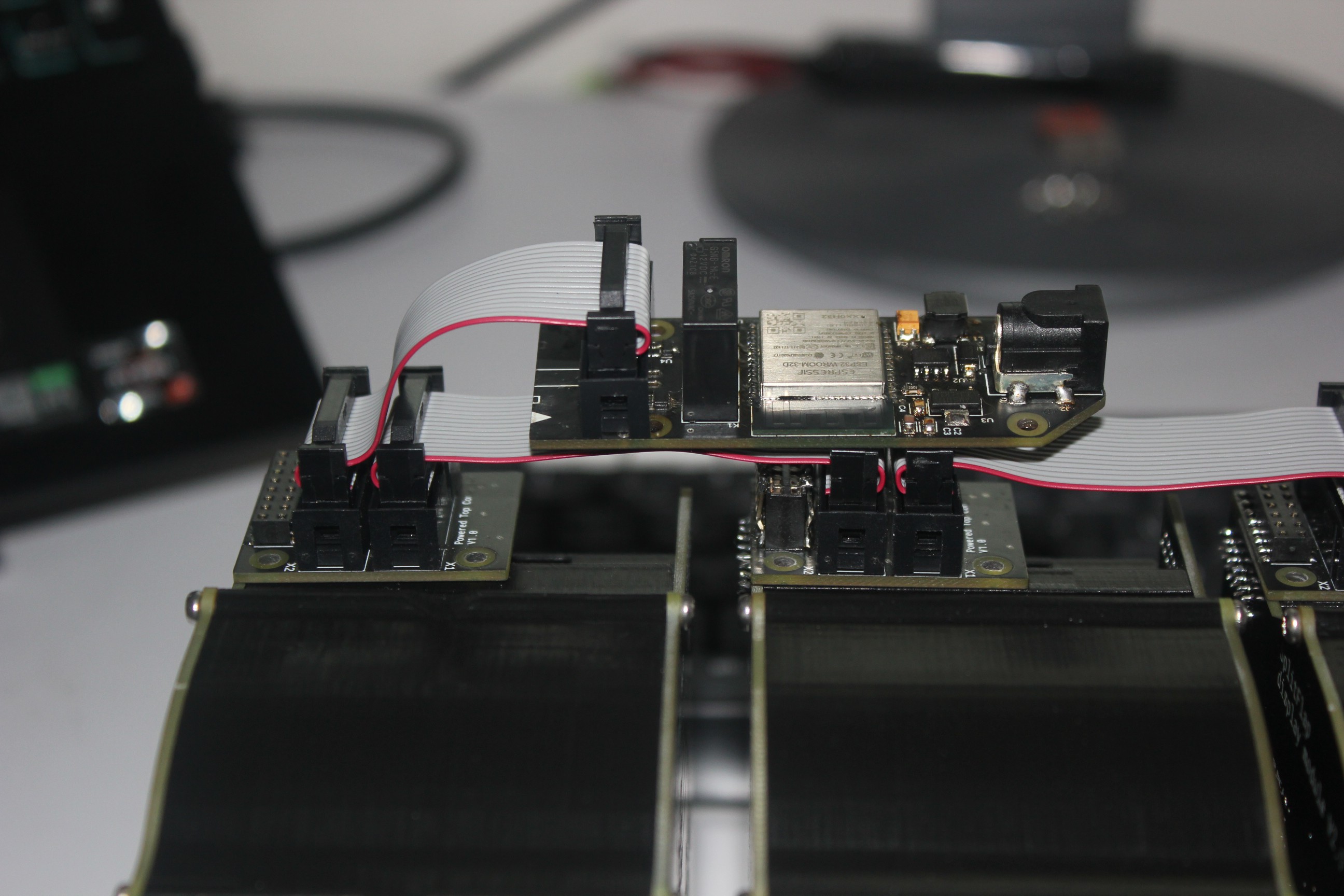

The modules, can be stacked on-top of each other. Through the connector on the top and bottom of each module.

The top-most module of each stack should be equipped with a special top-con PCB. This board provides power and data to the module and allows multiple modules to be linked together using a ribbon cables.

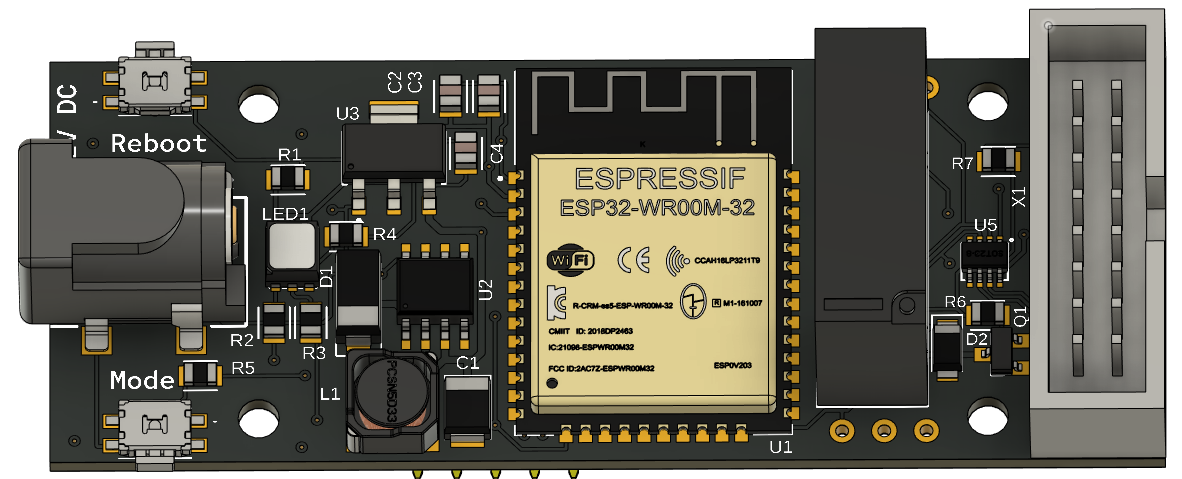

The controller can be attached to the input of the first top-con PCB. The controller hosts a webpage and REST api to allow users to interface with the display.

The controller can be attached to the input of the first top-con PCB. The controller hosts a webpage and REST api to allow users to interface with the display.

The OpenFlap display modules and top-con boards contain a sensor allowing them to detect if another board is connected below or next to them. This allows the display to configure itself automatically. This is shown in action in the video below.

Toon Van Eyck

Toon Van Eyck

SUF

SUF

Valentin

Valentin

Platinenmacher

Platinenmacher

Count me in when you go to KickStarter.