With our new top ten goal in mind, the electrical systems members are building upon our previous designs to improve our performance. We have made changes to our ACU (accumulator control unit) which is comprised of a microcontroller board, a latching board, and the larger low-voltage board. The changes include changing to new surface mount mosfets that are a stronger package and rating to accommodate the thermal strain under which they must perform. A new connector was also included so that our low-voltage battery can be charged while inside the enclosure and mounted to the car.

Our VCU (Vehicle Control Unit) has also seen revisions. A new surface-mount Bluetooth module has been added so that data can be relayed to the driver in real-time to replace the previous outdated module. Newer wheel-speed sensor circuitry has also been added to the circuit board so that the team can implement traction control, accompanied by two LED push-buttons to activate traction control or launch control.

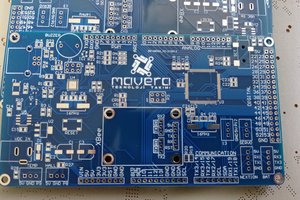

Over the past 4 years, the team has sourced our PCBs from JLC PCB. JLC PCB has always provided UMSAE Formula Electric with the highest quality PCBs that are reliable and deliver conditions to easily solder our surface-mount components to our boards without issue. JLC PCB always supplies high-quality PCBs with perfect surface-mount component pad placement to easily and efficiently assemble our boards to build our racecar. We thank JLC for their invaluable support in the creation of our cars.

NealonMaxwell

NealonMaxwell

Vitaly

Vitaly

Kelvin Brammer

Kelvin Brammer

maveratt

maveratt

bobricius

bobricius