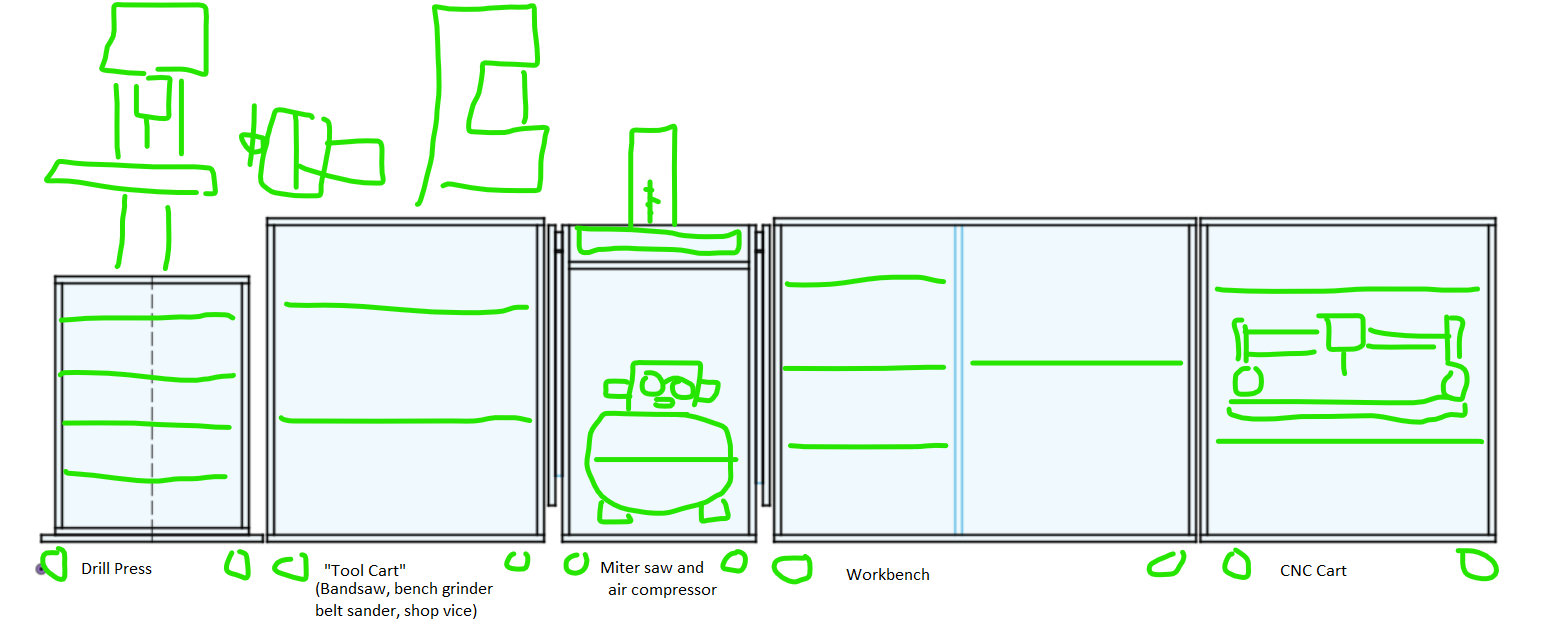

So now that I have my first piece built it is time for me to get serious about designing the rest of the carts. I have the dimensions basically worked out, here is a front view of the carts together. This fully fills in the available space, so there really is no way to increase things beyond this.

The drill press is relatively simple, there is a very limited amount of space to work with so it is best served with a small tool storage box. Something that could hold files, drill bits, router bits and other smaller items. There is some space beside and behind the main column that I could possibly use for storing clamps or something, but for now I will leave that alone. I think I will make the tool box removable from the base. I will put two pins in the base that interface with the tool box so you can lift it off if you need the full range of the drill press. I need to decide if I want to use fancy drawer slides or use wood strips for drawer runners here.

I think I have the top of the tool cart worked out, but the inside is up in the air. I could fit my air compressor into this cart and store larger tools along side it, or I could make this medium sized drawers that are roughly 3-4" tall and that can be used for everything from screws to hammers. For now I think I would rather have more drawers.

The miter saw stand is fairly fleshed out already. My only worry is that it will be unstable when the wings are fully extended. I think I could fit stabilizing feet that swing out from the base if I need it. I don't expect to need to extend the wings all that often. And one of my design hopes is that I can make it so I can cut 45 degree miters without opening the wings. I need to come up with some sort of dust collection port on the top end, but that can be worked out after the fact.

I think I will fit the air compressor into this cart. I really hate using the air compressor because it is so loud, and I think fitting it into a drawer that can be closed while it is running will help a lot. I'm contemplating picking up a hose reel as well and fitting it into the cart permanently so I can more easily access air without dealing with pesky hoses. I need to pick out a reel and test it out, it may not fit into this smaller cart so I may need to move it back over to the tool cart. But I feel this smaller cart would be easier to wheel around if I need to use it somewhere else.

For the CNC cart I have settled on two drawers for CNC related storage, and a third drawer to hold the CNC itself. I'm hoping to fit in an air filter and fan into this contraption that can be routed out of the house when cutting. I think I will leave the top bare and use this as a small outfeed/assembly table.

The big one is the main worktable. I have been going back and forth on what to do with this for a very long time. My workbenches in the past were just a place to store things. I had a shop vice on the corner for holding the occasional item and otherwise there was no sort of hold down system at all, and I did not worry much about it being flat either. I think I want to integrate some sort of system into the bench to help with shaping, cutting, and building items that are square, but there are so many ideas out there.

- I really want some way to clamp material to the table from the edge. I do this all the time on my current workbench and don't really see wanting to give up on this. This could be a relatively shallow lip all the way around the bench. Or a series of holes or notches that clamps could be slotted into.

- I could build a torsion box top to ensure a perfectly square and ridged top. This is very attractive to me, but it takes up a lot of vertical space and is complicated to assemble and I don't know how important a perfectly flat top is, especially on such a small bench.

- I'm very intrigued by the MFT style tops with t-tracks on the edges for clamping boards vertically and evenly spaced (and square) bench dog holes on the top. This has a lot of potential for making things very square and being much more flexible for glue ups or other such work. However all those holes are difficult to drill accurately (but I do have a CNC) and they require space under the top to allow for the clamps to be inserted as well as for dust to fall through the holes, and it will require either a lot of work to produce my own bench dogs or a lot of money invested in commercial clamps and dogs.

- I'm very intrigued by the idea of having a MFT style cross cut sled built into the table top. Having a way to place a rack square to a fence repeatably and reliably with a built in clamp on the fence would solve a lot of my cutting problems as well as making it much faster to perform a cut. I think I will find a way to do this no matter what top I come up with. I can make a fence out of an aluminum extrusion and have it slotted into the bench in such a way that I can remove it if I need the full top to be flat. And coming up with a way to hold a track at right angles to the fence should not be that difficult.

- I looked into t-slots on the top of the bench. I'm not really a fan of t-slots in general. They are cumbersome to use and I always find it frustrating slotting clamps into them. However they are fairly low profile and don't need a lot of space below the top of the bench and can easily be retro fitted to any bench. They only help with holding down material, there is no sense of square with them.

- I could go with a more traditional table with a vice and bench dogs for clamping. However I own exactly one plane and it is only 3" long and complete junk, so I don't see myself using any traditional wood working skills any time soon.

- I'm intrigued by the benches that have a cavity under the top where you can store items. That would help unclutter the top and it compliments the bench dog system as well as providing a face to clamp onto. I'm extremely nervous that this would soon become a pit of despair, but my bench top already trends that way and this may actually help things out in the end.

- In the back of my mind I would like to have room to put a router into the table top. I know router tables are not that safe, but they do seem quite useful. However I don't know if it is worth designing around this any more than designing around some future table saw I will probably never buy.

I'm thinking of combining a few of these ideas together and making a (sparse) torsion box style top with holes in the side so you can easily store tools inside as well as providing a lip to clamp onto if needed. I could put some MFT style holes into parts of the top and leave the rest alone. Those could allow for a cross cut setup without having to have swiss cheese for a table top. And if I size it right I could add in a bench vice or a router lift at some point in the future.

I'm also contemplating making some sort of registration pins so that I can lock the CNC table and my workbench together firmly to form an uber table for the few times where having one continuous flat top is important. However I'm unsure if I could make this strong enough to eliminate any sag caused by an uneven shop floor. If I can't then it is probably enough just to push the tables together and lock the casters.

In summary I really need to pick a location for the air compressor, and work out the style of top for my workbench. Everything else can be planned more or less as we go along. Once I have the carcass up and running the shelves and drawers could be retrofitted if needed (although having a proper plan in place is always best).

I'm quite happy with my 2" caster wheels. They work even better once you have some weight on them, so I'm going to stick with those. I do need to pick drawer slides out. Part of the hang-up there is that my CNC and workbenches are actually quite deep at 32" and I can't decide if I should try to push it and make 30" deep drawers or try to come up with a way to have limited storage on the back side of the carts that is not accessible very easily. I could make these workbenches less deep but I have the space for them and I don't think I will ever regret the depth.

So many thoughts running through my head, I need to make some hard decisions so I can move forward here. Anything is probably better than nothing and my guess is whatever I come up with is more than enough, since I only have simple benches right now and really am happy enough with them, other than the total lack of storage.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.