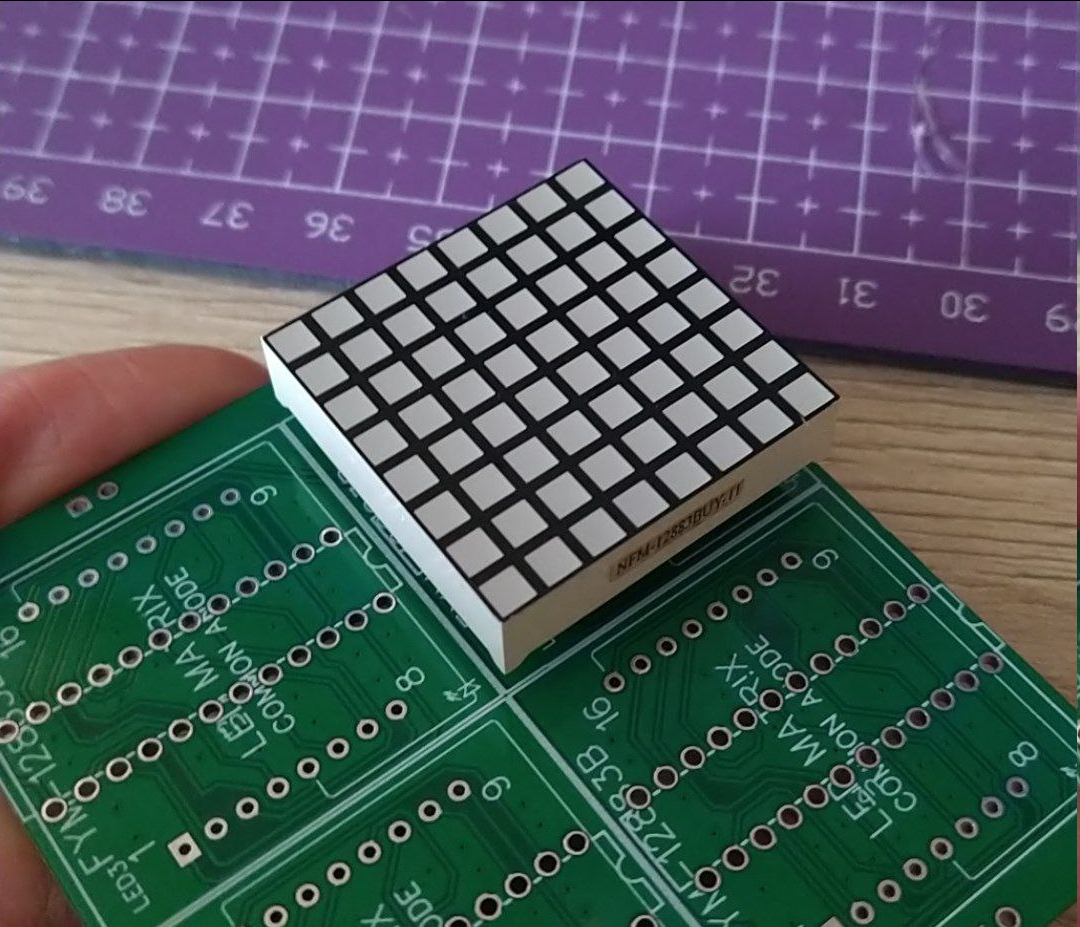

- There was a simpler time when I was having this sudden urge to pay a visit to our local flea market for different stuff, which usually ended with me going home with such stuff - namely some electronic parts, enclosures, etc. That is how i ended up with a few dozens of LED matrices - some were torn out of marquee signs (not by me), some were just surplus the seller got somewhere else. And they need some use now.

- After my previous public projects I decided to take on something really simple functionally, and, if possible, mechanically. So I can better orient myself in regard to scope, time, materials etc.

That is how REST project series shows on my DIY scene - "RElatively Simple Things".

And this project is also an answer to a question of "what to do with all these LED matrices, layout of which does not fit de-facto standard MAX7219 arduino modules that people toss around?"

They glow juicy yellow, btw.

So, first i went to JLCPCB to design and fabricate several carrier modules - different versions, actually. I made 1x, 2x, 3x, 2x2, 3x2, 5 of each, just so I could reuse them later after this project also.

So, first i went to JLCPCB to design and fabricate several carrier modules - different versions, actually. I made 1x, 2x, 3x, 2x2, 3x2, 5 of each, just so I could reuse them later after this project also.There is also this hilariously tragic story of how I ordered 25 pcs of DIP MAX7219 a long while ago (prior to designing the modules) from aliexpress and all 25 of them turned out to be dead.

But module PCBs are already made, what do I do now? That's right - order some more LED drivers, because matrices won't drive themselves!

But module PCBs are already made, what do I do now? That's right - order some more LED drivers, because matrices won't drive themselves!New materials arrived, i verified that new chips do work and matrices work as expected (although current schematic version has decimal point pin driven last instead of first - so in this regard my module is not compatible with arduino-like MAX7219 libraries), and it is time to pull a concept together.

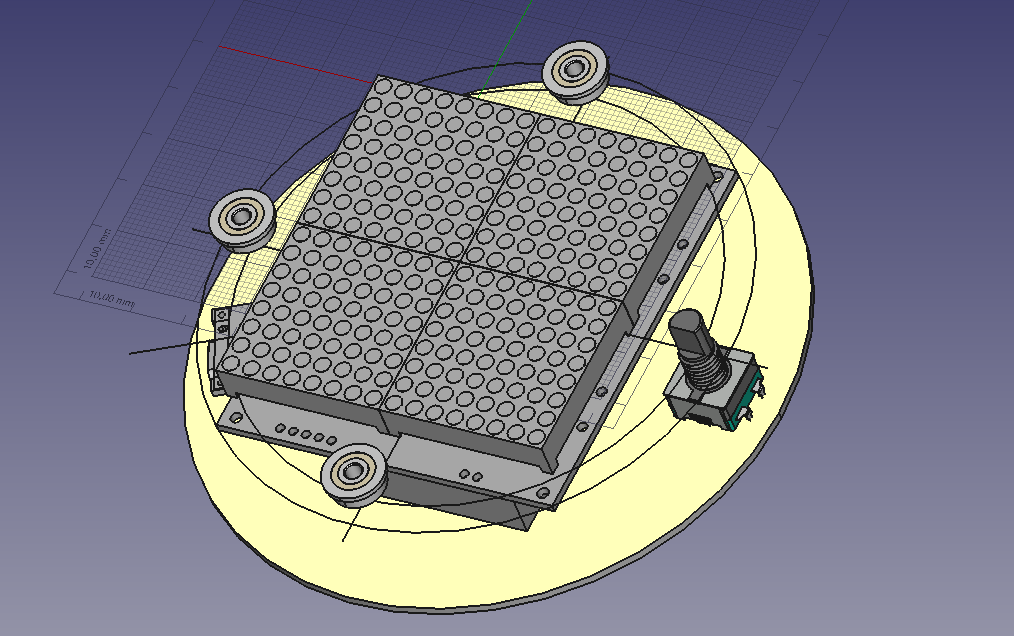

I wanted to design a simple kitchen timer with a rotatable bezel and which also can be magnetically attached to, say, a fridge. Not really an original idea - i saw even a DIY version that uses segment digital display, but nonetheless, this one is better at being my own take at it.

Now what's left is to arrange things in a way that they are nice and snug and won't bite each other when bezel is rotated. Instead it has to drive encoder shaft with either gear teeth, or some kind of friction (will a hockey tape work?).

mkdxdx

mkdxdx

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.