Hello this is 3DMeister Julius and i hope you like this project and my english.

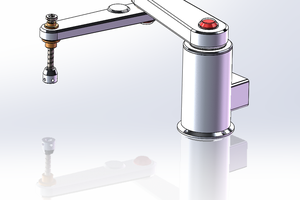

This is an experimental prototype for a manual controlled mechanic 6 axis robot arm.

All 6 axis are connected across a cable with the slider controllers. 3 rotation axis and 3 pivot hinges can turn and lift at the same time with closed loop cables.

The controls are on the base of the arm. This is where all cable loop. Each loop is connected to a sliding knob.

By operating the slider, the cable gets pulled on one side and therefor it lifts or rotates the axis on the arm.

All cables must go through the center of the arm and they must bend in the center with each axis. The rotation axis twists the cables so they must be well sorted for minimal friction in any position.

The hinges work in an 180 degree angle and the rotation axis can turn more than once.

I got a very good result in this first arm without noticable interference between the cables during all positions of the 6 axis arm.

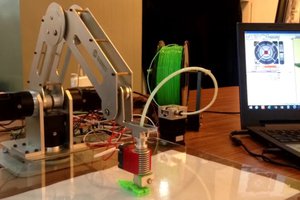

The structure is made of a quality plastic with very good sliding abilities because i made everything without ball bearings in this simplified prototype.

The cable are also plastic plump cords with few thick fibers and wich can hold about 15kg .

The sliding controllers hold there position when there is a tension on any cable after trough lifting and moving the axis. This happens with an anchor in the slider.

At the end of the arm, there is another hole for the tools to activate by another cable.

It is all very tricky and i hope i can make a second version with optimal proportions, ball bearings and even add stepper motors to the cables.

This is the first video review with some test movements. More will come.

3D Meister

3D Meister

HITBOT

HITBOT

BB

BB

Thomas

Thomas

Interesting concept. It would certainly cut down on the weight in the arm. You might find you lose a lot of the power of the end effector through the cable transmission though. I like how effective the 'yaw' joints work. I am currently considering a similar system for the upper portion of the arm of my humanoid, although the motor will be in the arm, but the gearing will be via cable transmission similar to this.