Other than being a cool way to get people into hardware that is more "heavy duty" than the normal garage project, the can crusher also serves a purpose. For example, when people are over and soda gets drunk, I always take them to the can crusher. By the end of the night everybody wants to use it, and instead of a lot of half empty cans that make their way to the trash (vs. the recycle bin), I have a 5 gallon bucket of perfectly crushed cans that are ready to be dumped into the recycle bin. This greatly reduces the amount of reuable metals going into a landfill.

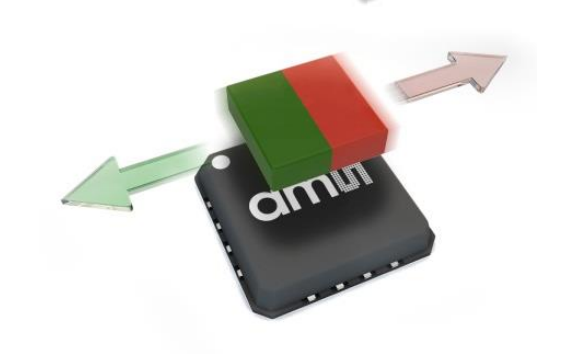

I already have all of the mechanics, and much of the electronics already working. Embedded into the slide of the pneumatic piston that is used as the ram is a magnetic quadrature encoder as seen below:

This, coupled with a strain gauge, can provide total work needed to crush a can. I have a detailed explanation of this at the end of the video Linked at the left.

Since I began working on this project, I have wanted to make it Internet connected. I am heading off the engineering school the next few weeks, and hope to bring my can crusher with me at some point shortly after that. By adding a "social" aspect to the can crusher, I hope to be able to inspire more friends and peers to recycle and consciously think about where their waste is going, one can at a time.

I plan to use a Raspberry Pi to Tweet the total volume saved in landfills (hypothetically) by using the linear sensor to measure how much each can was crushed, and calculate volume from that. I will also be able to add other useful information such as work needed to crush a can, total cans crushed in a time frame, etc.

I plan to make my design open source in hopes that other people will follow me and create connected recycling initiatives.

Adam Wiesler

Adam Wiesler

RodolpheH

RodolpheH

Mike

Mike