Although this mill has produced some good results, it has also made some garbage. It would be naive of me to expect this mix of dumpster parts to perform as well or reliably as a proper mill. I don't want to make this sound too discouraging, but I'll try to describe some of the weak points of this project.

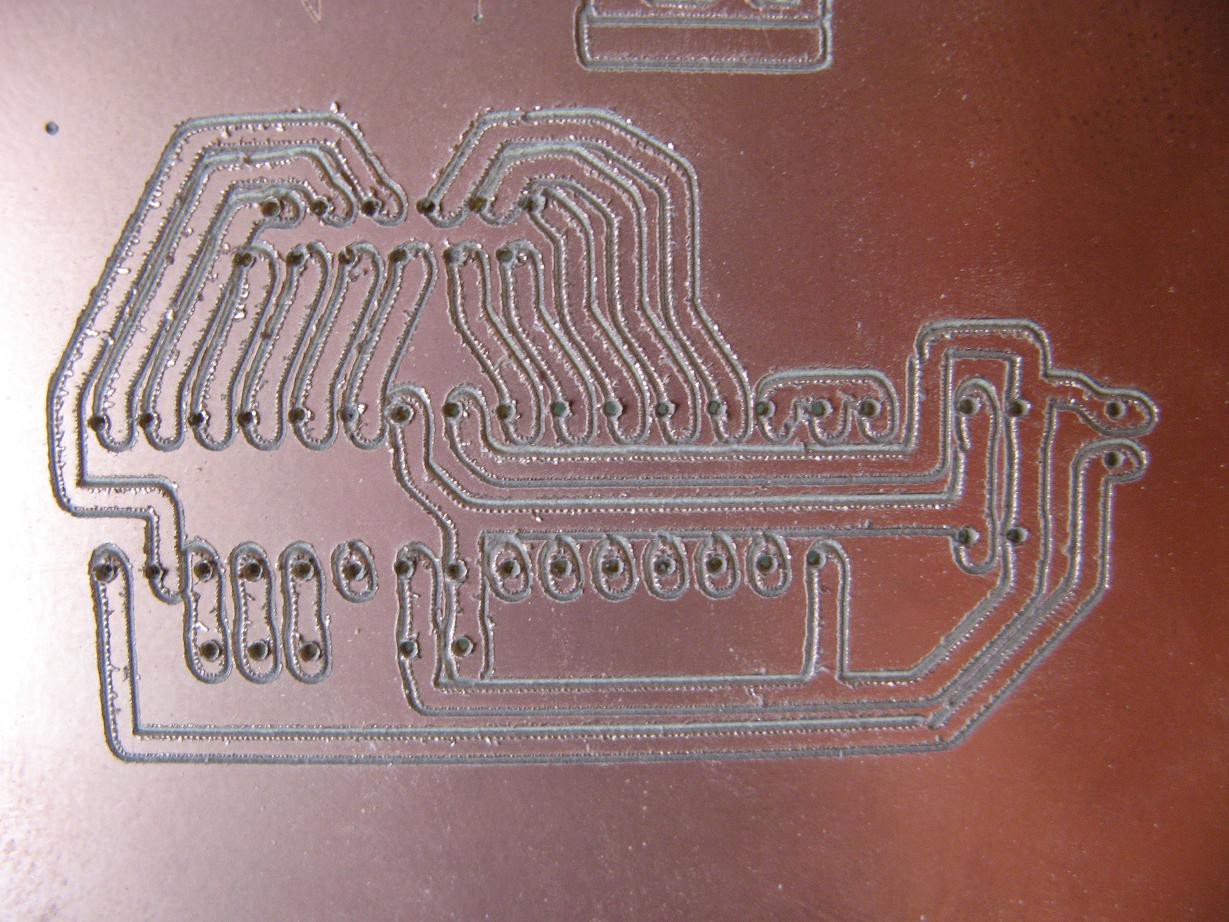

The X and Y axes behave exactly as they did in the printer. One motor moves the print head along a shaft using a toothed belt, while the other turns a roller that moves the object via friction. I have not had any real problems with the print head axis, but the paper axis is not as reliable. There were no problems when I was simply drawing on nice, flat paper. When milling, however, I produce lots of chips, dust and bumps in the surface. Usually these are able to go through the rollers just fine, but sometimes something gets caught and the board slips slightly. Unfortunately, even a slight shift can completely mess up the result. Here is a picture of a pcb for which there was a little slip that caused the drilled holes to be off. As a result, this pcb is no longer functional.

I also had a problem with friction wearing out the plastic "bearing" that guides the bit. It is not actually a bearing, but simply a tight hole in the plastic base of the Z-axis. While milling parts for the stargate project, the mill had to work for rather long periods of time. After a while I noticed that the bit had enlarged the hole in the plastic. It probably melted slightly from friction. I started applying a little oil each time I use it, but the enlarged hole has thrown the precision way off. Of course this could be fixed by replacing the plastic part and remembering to oil it.

A third problem is with cut depth. At this point I have to calibrate the cut depth each time by eye. I've looked at zeroing methods used on other designs, but they would not work here due to slop in the Z-axis. I'm usually able to eyeball a reasonable depth, but sometimes it is just a little too shallow, causing poor electrical isolation, or too deep, causing too much loading on the bit that results in poor precision.

This project has been very educational and a ton of fun. I'm pleased with the way it has turned out, considering the cost and parts used. But with these problems, pcb production has been a long and wasteful process. I'm looking for an alternative and these are some of the options I'm looking at:

- A properly designed and funded mill.

- Chemical etching, which I am trying to avoid.

- Buying them from a fab house. This gives the best result, but lacks fun, education and the feeling of hacking.

- An entirely new experimental method. This is by far the most difficult and educational way. If I can do it, maybe I'll enter it in the hackaday contest.

Do you have any other ideas?

shlonkin

shlonkin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Perhaps instead of moving the entire Y/Z-axiz mill assembly with an X-axis drive, just mount the PCB on an X-axis platform and move it under a stationary Y/Z-axis assembly.

Are you sure? yes | no

I think this may be a similar idea... though I'm having difficulty figuring out which axes are which in your description...

But, basically it seems to boil-down-to that the paper-feed axis is unreliable, due to slippage, etc... certainly that could be improved.

A) if it's a stepper-motor losing steps, that can be handled similarly to the ink-carriage system by using a DC-motor/encoder (which, just happen to exist in old inkjets :) Though, removing that belt-pulley from the stepper looks to be difficult in my case...

B) I'm reminded of the stepper-to-linear translation-systems used in old (5.25inch) floppy-drives... wherein a strip of flexible metal is wrapped around the motor shaft and attached to each end of a linear slider... as the motor rotates, it pulls/pushes a linear slider quite reliably... either bolt the ends of the metal-strips to the PCB, or create a carriage of some sort... (this could be handled with belts and a pulley, as well). And TWO google-image searches result in Nada. Woot!

Are you sure? yes | no

Are you sure? yes | no

Another thought: I have something simmilar to this in the works, but using the drive systems from two printers. Couldn't you ditch the paper roller and add another 'axis' to push the pcb back and fourth?

Are you sure? yes | no

Are you sure? yes | no

with one made from oil-impregnated brass.... a small piece shouldn't be expensive,

and would probably last much longer.

Cut depth - Another off-the-cuff thought... I think tungsten carbide is somewhat

conductive. You might rest an electrode against the mill bit, and cautiously lower

it towards the blank (uncut) PCB. The PCB has another electrod

contacting it, so

when the carbide bit first touches the PCB, a circuit is completed. This would tell you

the 'zero-height' Z position for the current setup. You could then advance the Z

axis downward 'a few steps more' to get the desired cut depth (start your motor

1st.... :-) )

If ideas worthless, cut and discard above dotted line.....

...................................................................................................................................................

best of luck!

Stan smale

stanleysmd@gmail.com

Are you sure? yes | no

Are you sure? yes | no