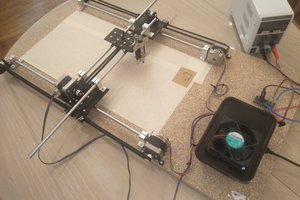

We all have seen the 3D printers around the world.

Well.........I'm feeding this one with steroids!

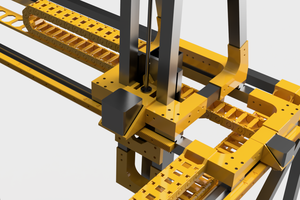

Some technical info:

-4 NEMA23 1,7A per coil stepper motors, two on the Z axis

-20x20 extrusion Structure, very sturdy

-X axis powered on two sides, belt driven on two sides

-Z axis powered on four sides, belt driven on all four corners

-Every stepper motor has his own TB6600 stepper driver

-Smoothieboard controller

-Raspberry Pi with Octopi distro, wireless network

When the machine is done it will be able to:

-3D print (stage 1)

-Mill (stage 2)

-Turn (stage 3)

-3D scan (stage 4)

-Laser cut (stage 5)

Stage 1 is well on it's way

mbasecnc

mbasecnc

Greg Duckworth

Greg Duckworth

Brian Brocken

Brian Brocken

Daniel

Daniel

Recommend a perfect axis drive stepper motor and driver.

Frame Size: 57 x 57mm (Nema 23)

Body Length: 76mm

Motor Type: Bipolar Stepper

Step Angle: 1.8 deg

Holding Torque: 1.9Nm(269oz.in)

Rated Current: 2.8A/Phase

Holding torque: 1.9Nm

Stepper motor:

https://www.motiongoo.com/index.php?route=product/product&product_id=106&search=23HT30S4280

Driver:

https://www.motiongoo.com/index.php?route=product/product&path=59_95&product_id=228