Exciting times in Minneapolis--a few boxes showed up this week. Pictures and descriptions below:

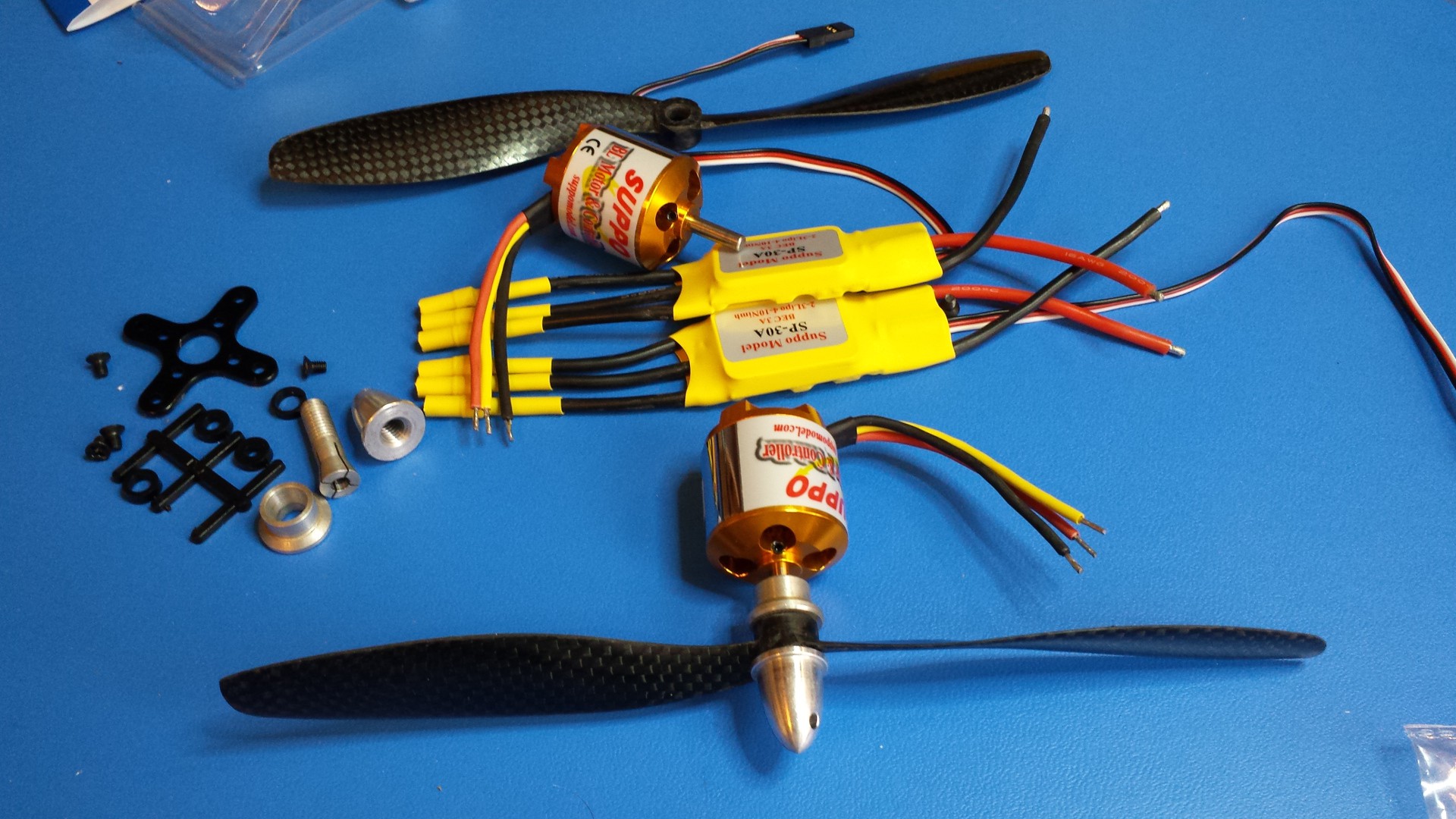

Brushless motors, ESCs, props, and various bits of mounting hardware

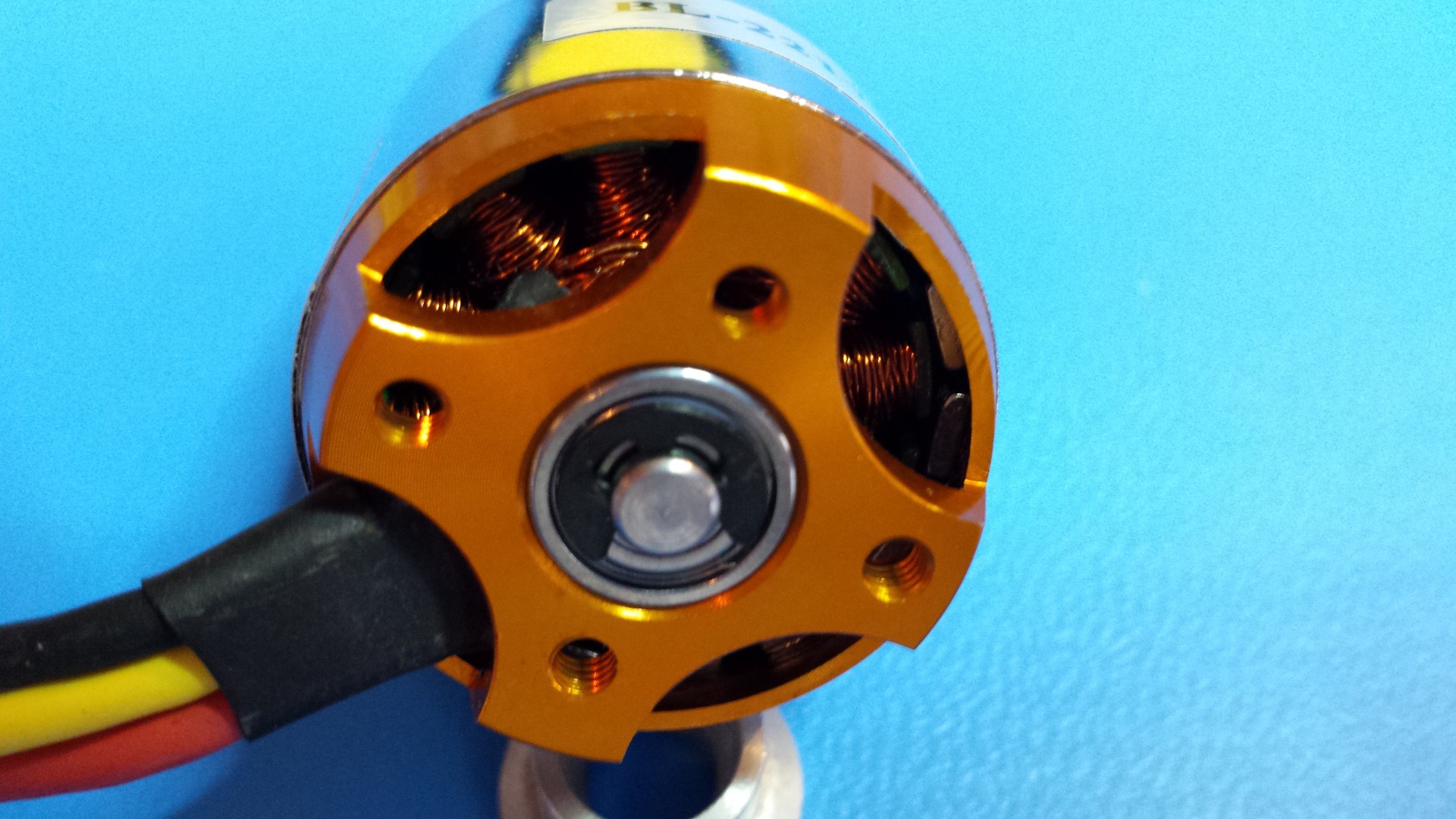

I'm new to the brushless/RC scene, so I'm not sure if these are great motors; they seem decent enough, but I haven't fired 'em up yet. One thing I didn't realize: the output shaft is attached to the case, so the white label actually rotates (it's what holds the permanent magnets). As such, the motors come with little X-shaped mounting brackets that screw in to (what I believe are) M3 threaded holes at the motor's base:

I'll probably design brackets that directly mate up with these holes rather than use the X-shaped dealies that came with the motors.

Otherwise, the props seem pretty well balanced (at least when I hang them off a screwdriver shaft) and the collet, washer, and prop nut all seem to be nicely machined. The ESCs are pretty dang small for handling 300 watts!

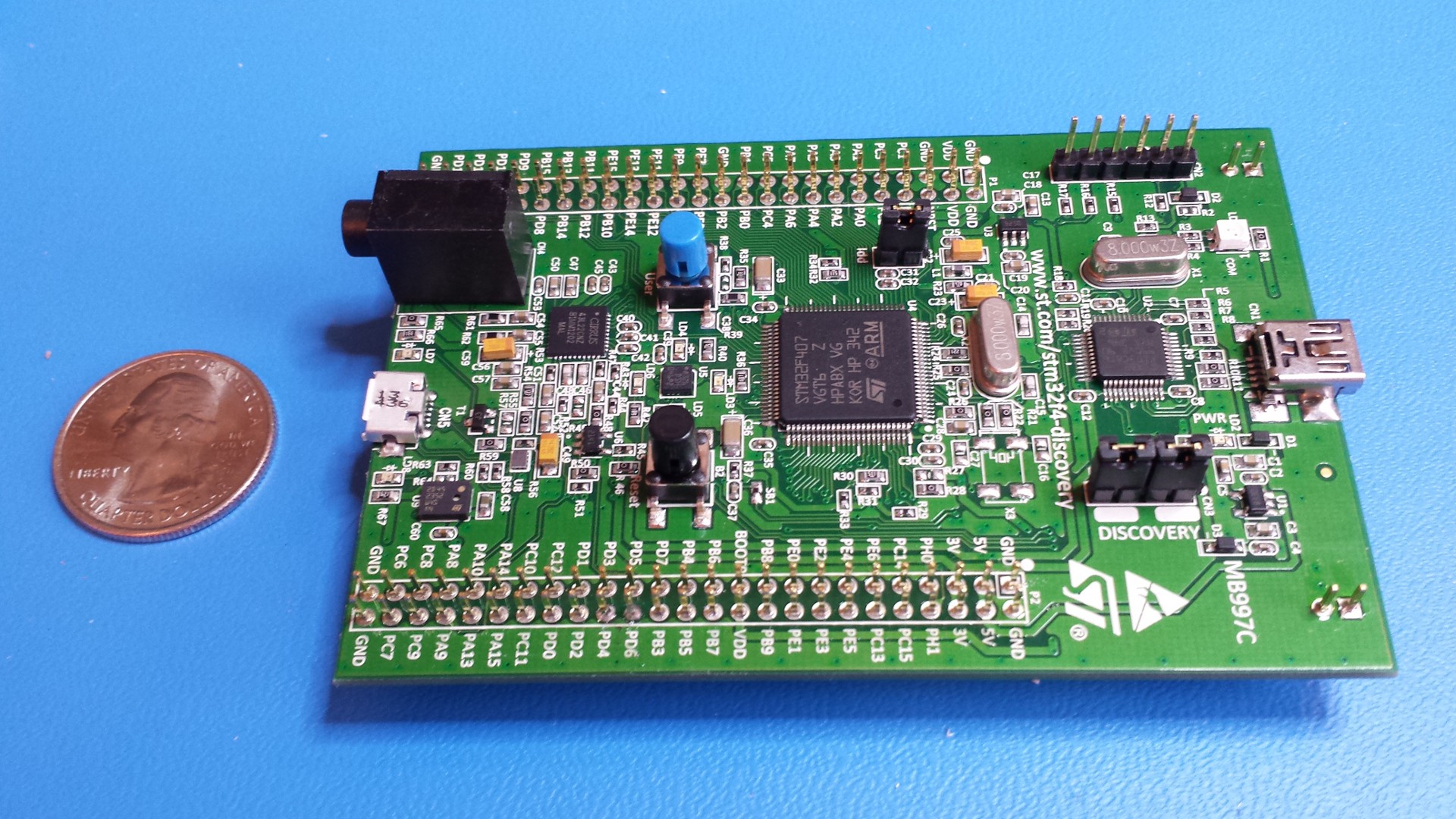

ARM Cortex M4 discovery boards

Suggested by the always-helpful Curtis, these were cheap and seem to be more than powerful enough for my needs.

They're also fairly light (my cheap-o scale says 36g), so they may end up in the final design. However, making boards is fun; I'd be able to shave a lot of size off if I designed my own, since these include stuff like an accelerometer (but no gyro, so it's not a ton of use for me).

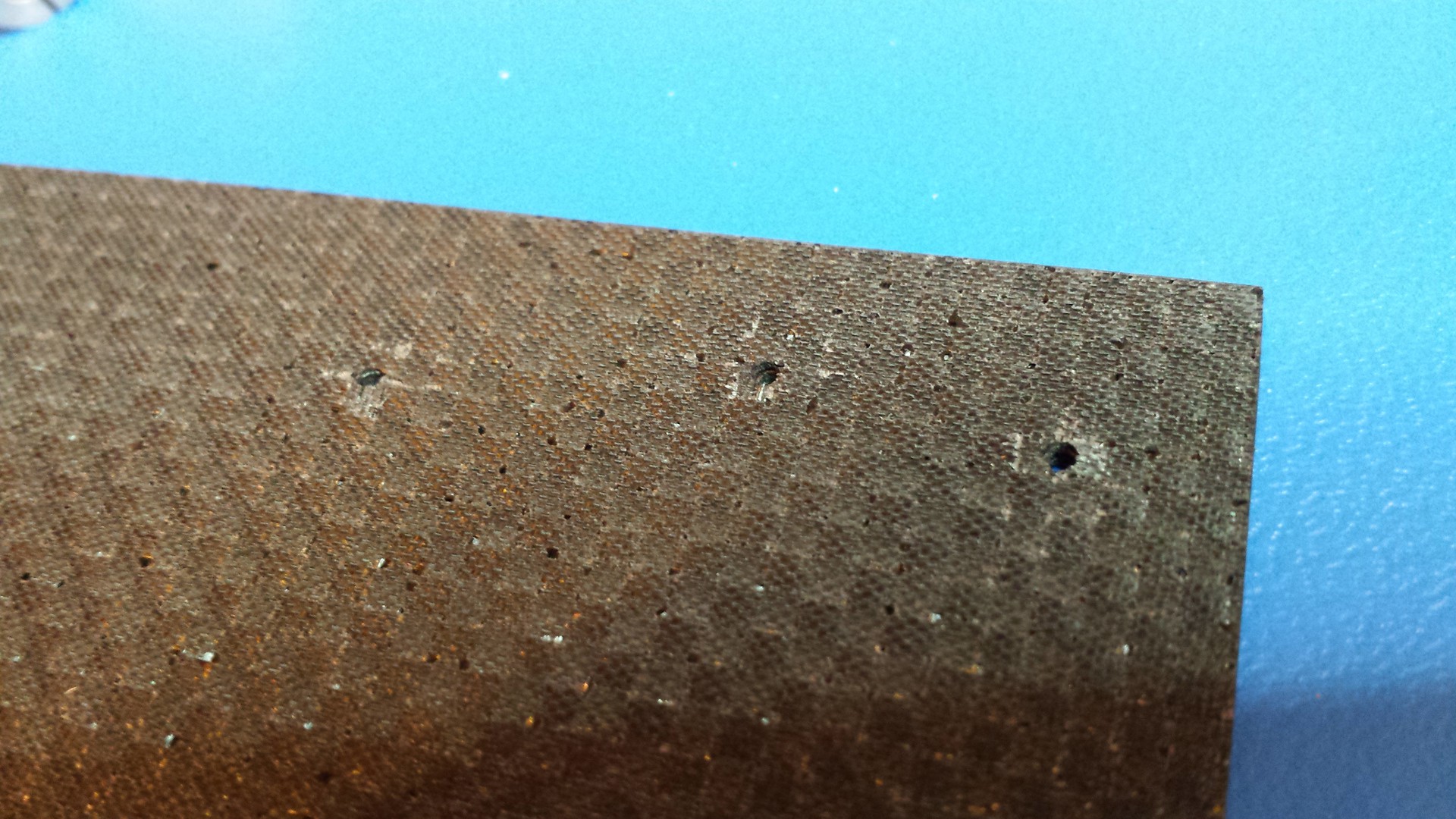

CFRP plate

Two different samples of 1.6mm CFRP plate arrived; I think I'll use the slightly cheaper and less dense 0/90 double weave stuff. As previously discussed, I'll probably make most of the frame out of 0.8mm stock to save weight. I dropped by a local waterjet outfit Friday and had them try a few cuts:

Needless to say, the guys at the waterjet shop were damn impressed with the plate; sounds like lower quality stuff can have delamination issues. They're cutting with pure water, so I'll be designing around a 0.006" kerf. Incidentally, the test cuts were done on a machine set up for abrasive cutting, hence the slight draft angle.

Normally one doesn't pierce CFRP with a waterjet setup due to the aforementioned delamination problem; however, they gave it a shot just for kicks:

Clearly there's a bit of localized delamination occurring, but it's minimal enough that I can probably design it into a waste section. Alternatively, they can start cuts from a hand-drilled starter hole.

Either way, the next test will likely involve a bit of Space Glue. I deliberately ordered CFRP plates with a textured surface, as I've read that this is best for epoxy work; I'll probably hit 'em with some 120 grit before trying a few different types of glued joints. Ideally, I need to be able to do lap joints and tee joints.

Oh yeah, and some aluminum rectangular tubing arrived too. No pictures of that because it's pretty basic.

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.