Overview

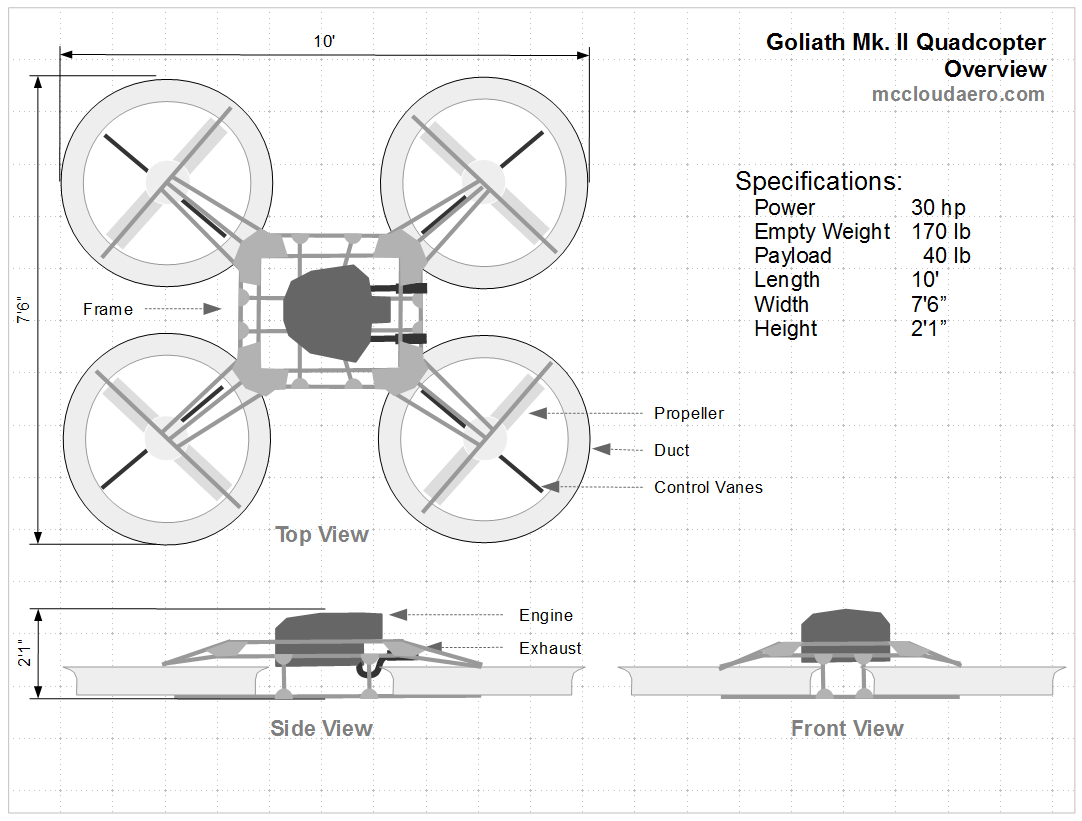

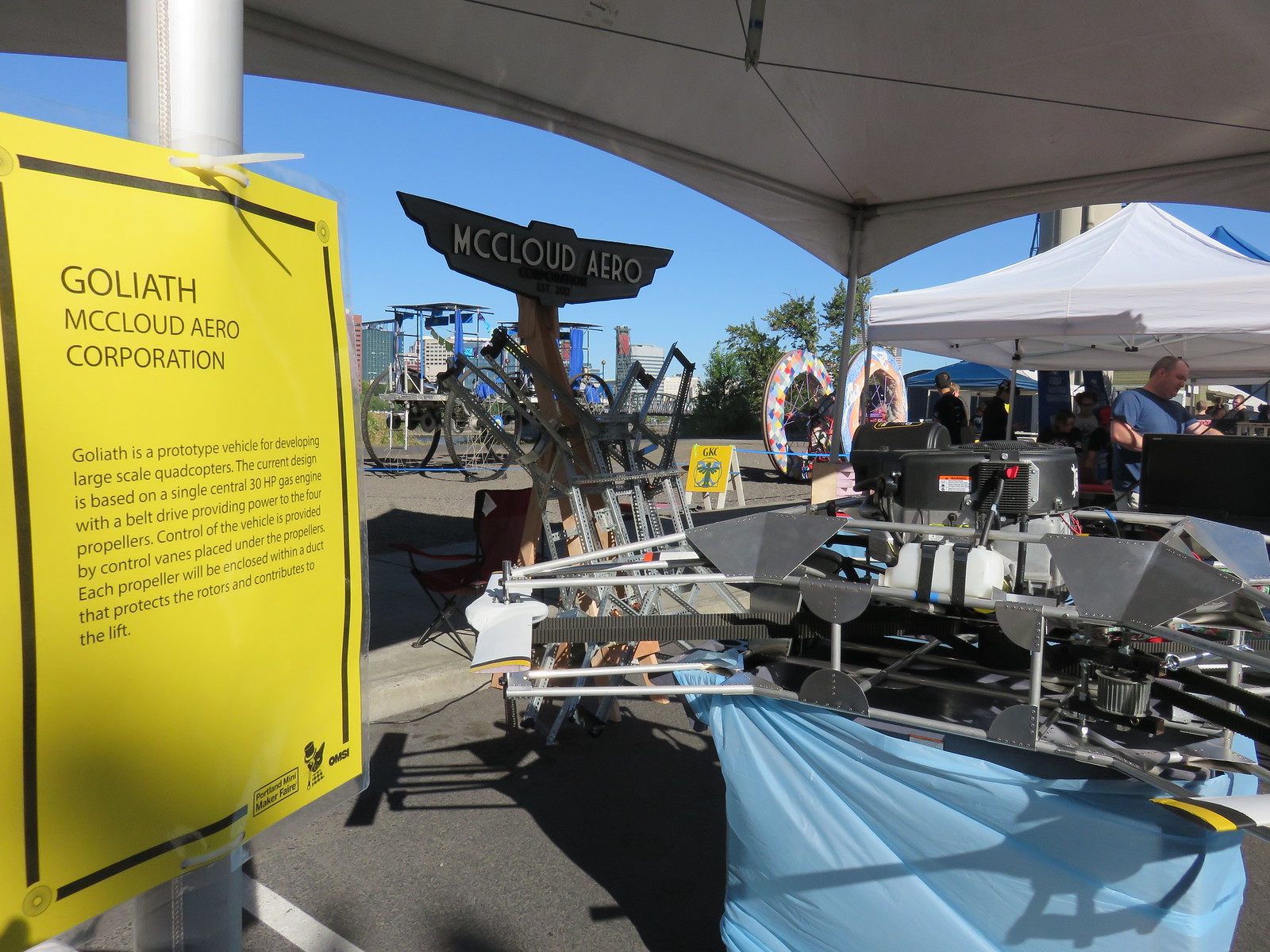

Goliath is a prototype vehicle for developing large scale quadcopters. The current design is based on a single central gas engine with a belt drive providing power to the four propellers. Control of the vehicle is provided by control vanes placed under the propellers. Each propeller will be enclosed within a duct that protects the rotors and contributes to the lift. Goliath itself will be open source with the creative commons license, and whenever possible open source components are used.

The Mk I vehicle was focused on developing the drive train. The Mk II vehicle was built with lighter weight aluminum frame. Even when completed Goliath is intended as a starting point for future vehicles.

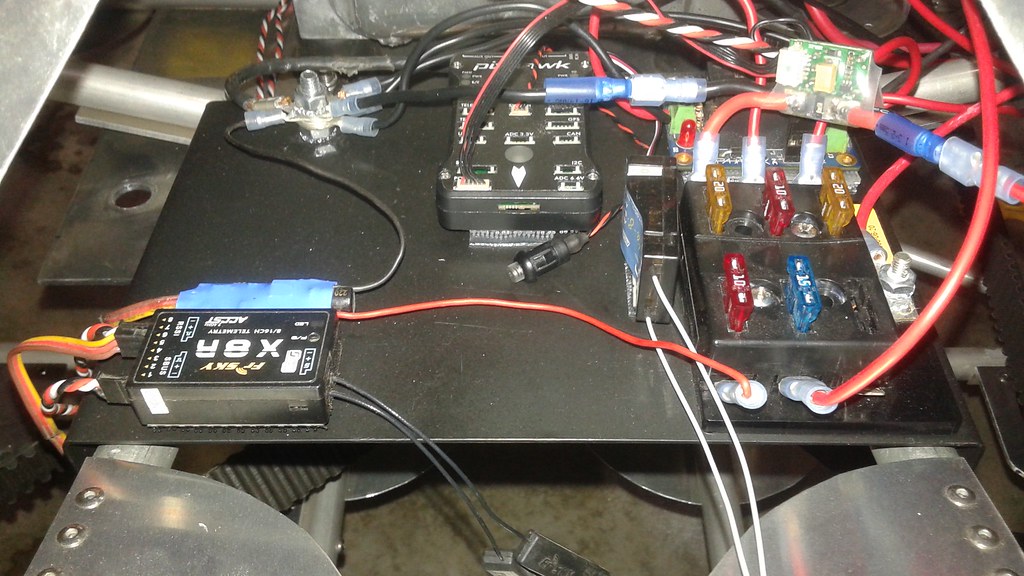

Flight control will be performed using the Pixhawk controller running the PX4 flight stack.

Related Projects

#Inexpensive Composite Propellers/Rotors

#Measuring Engine RPM with the Pixhawk

#EVPR: Electric Variable Pitch Rotor

Current Status: HOVERING!

The Mk II vehicle has been assembled and hovered for the first time in September 2016.

Details

Structure

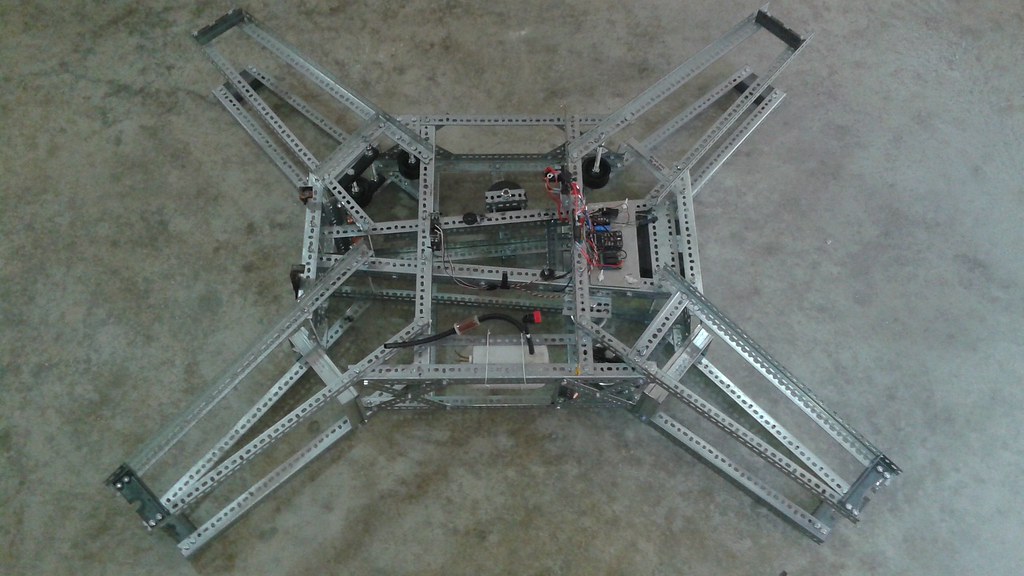

The initial Mk I frame was constructed using slotted galvanized angle, also known as Dexion, bolted together. While this is heavier than a steel tube or composite frame, the dexion is quickly assembled and can easily be reconfigured. This allowed for multiple iterations of the drive system to be tested with a minimum of time and cost.

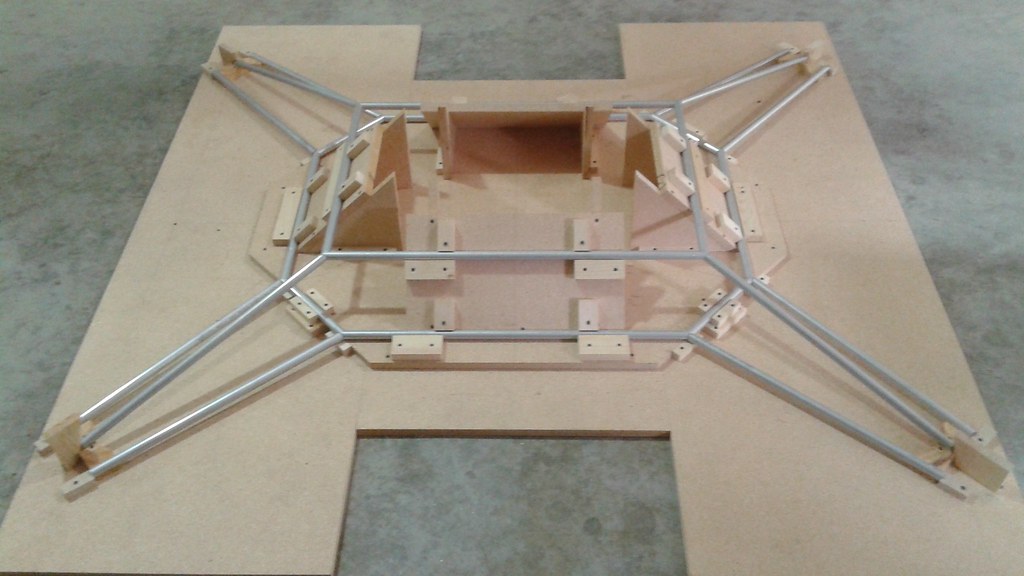

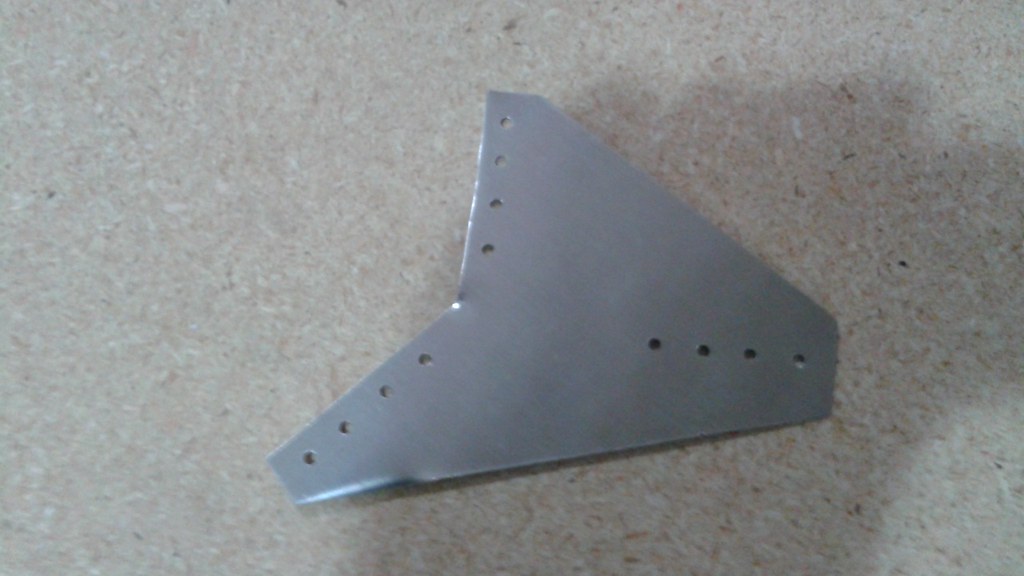

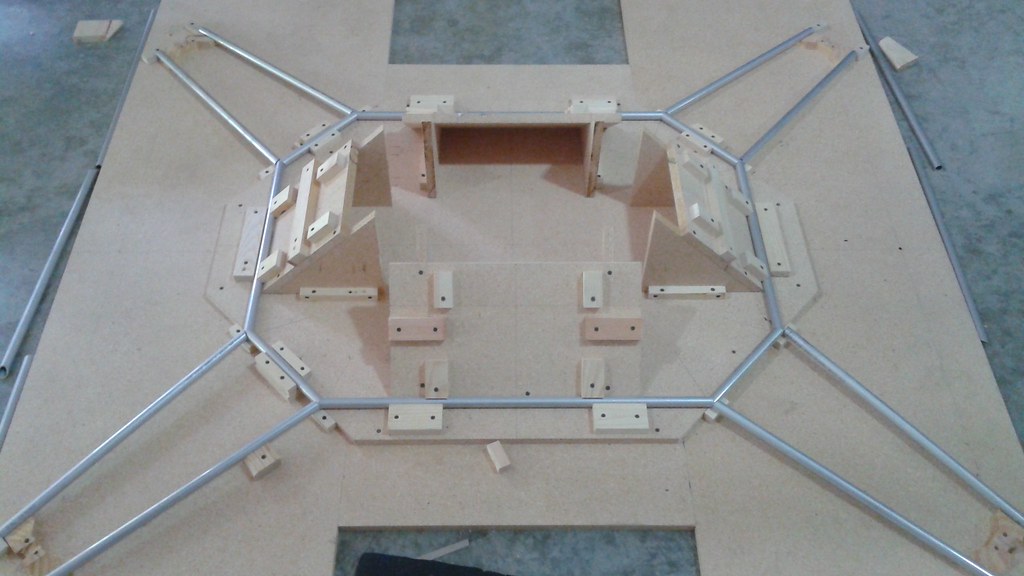

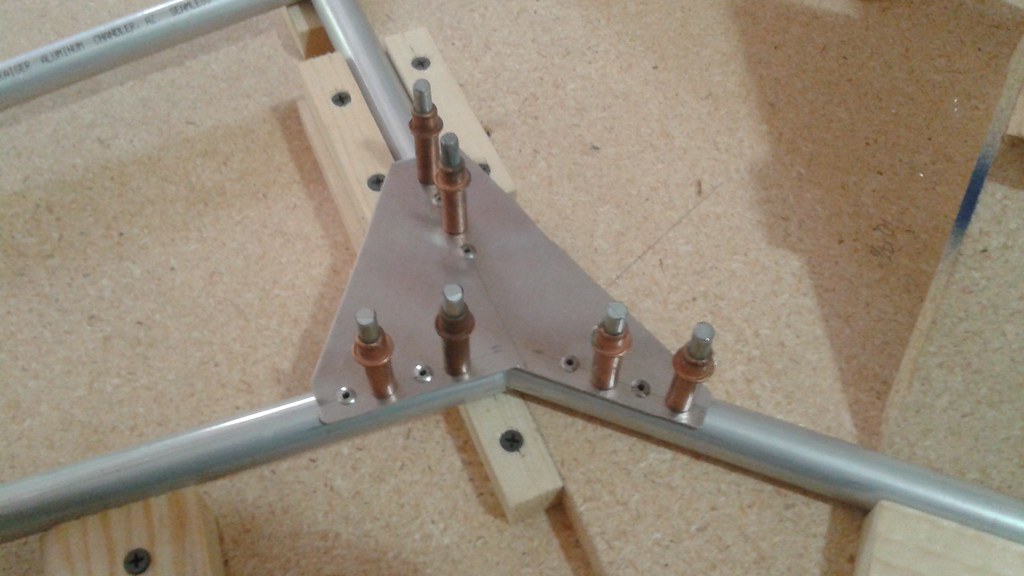

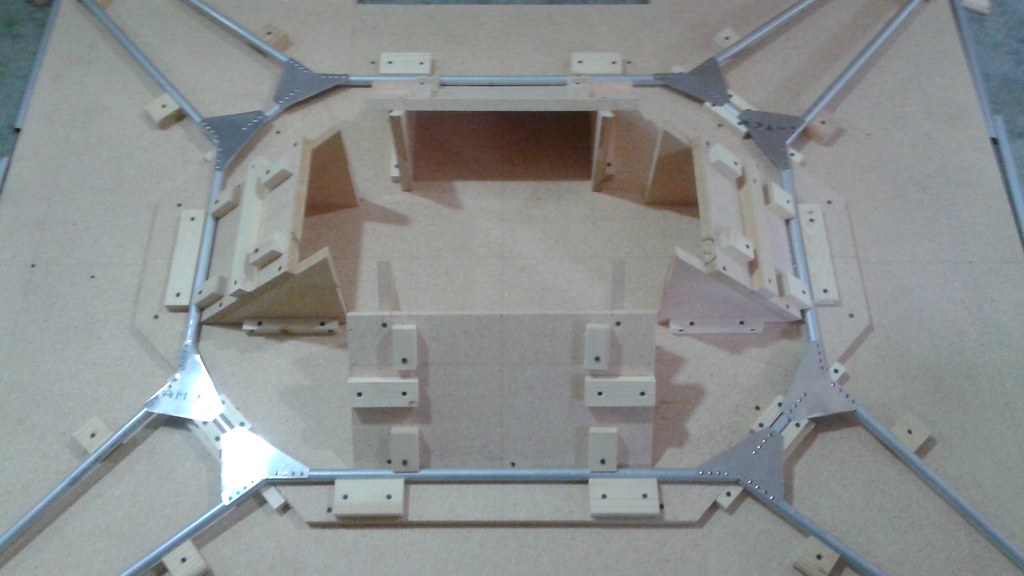

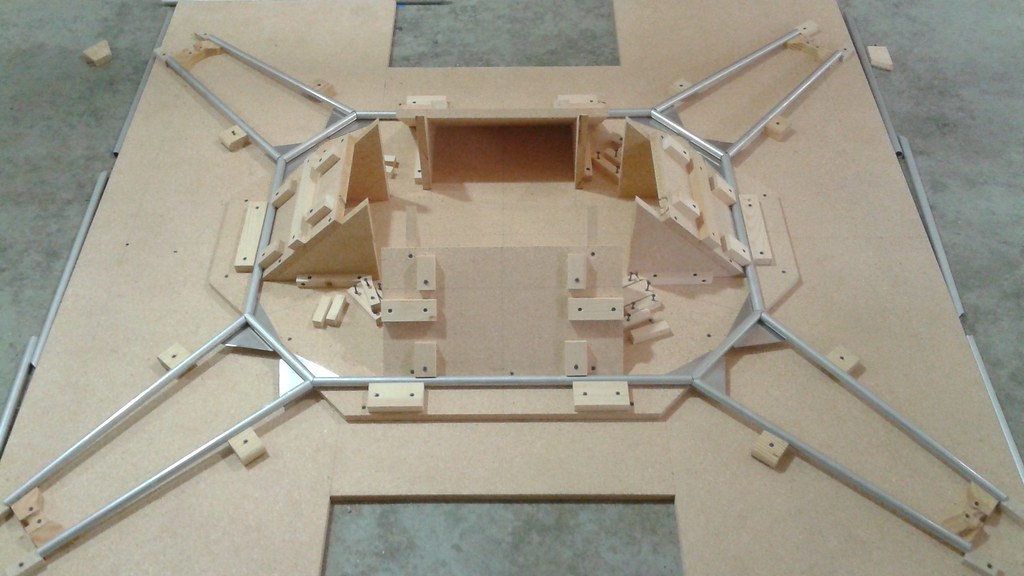

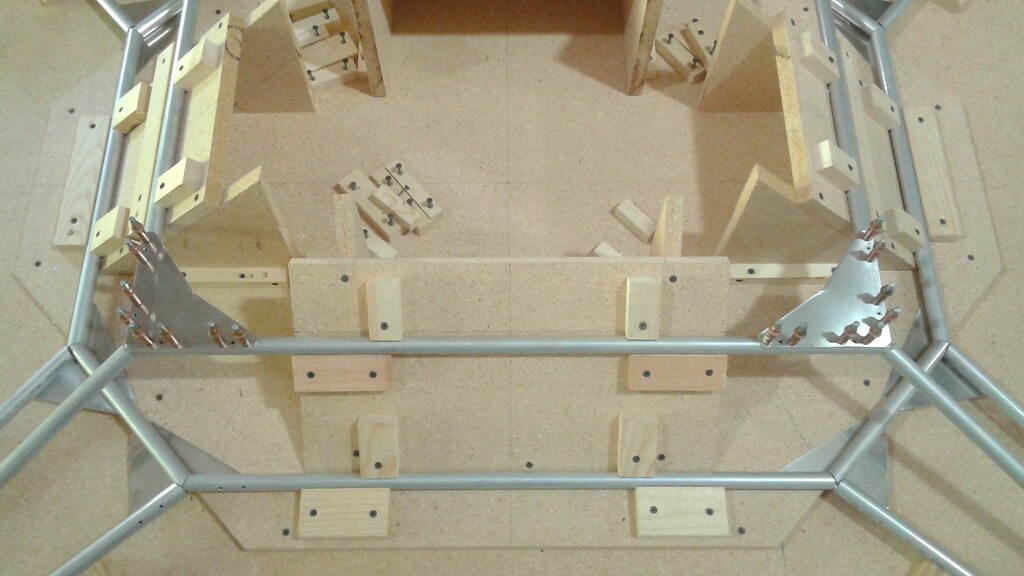

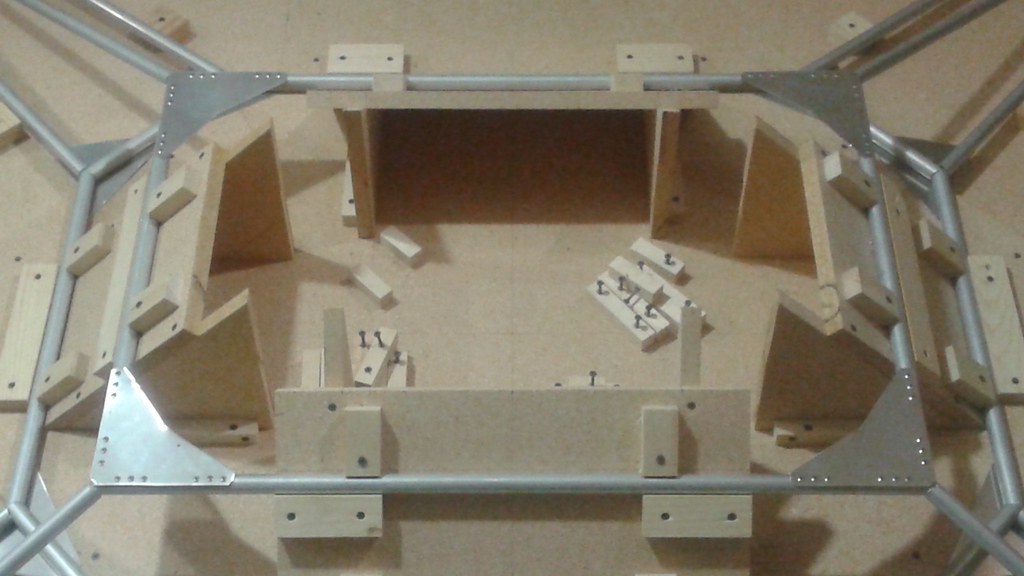

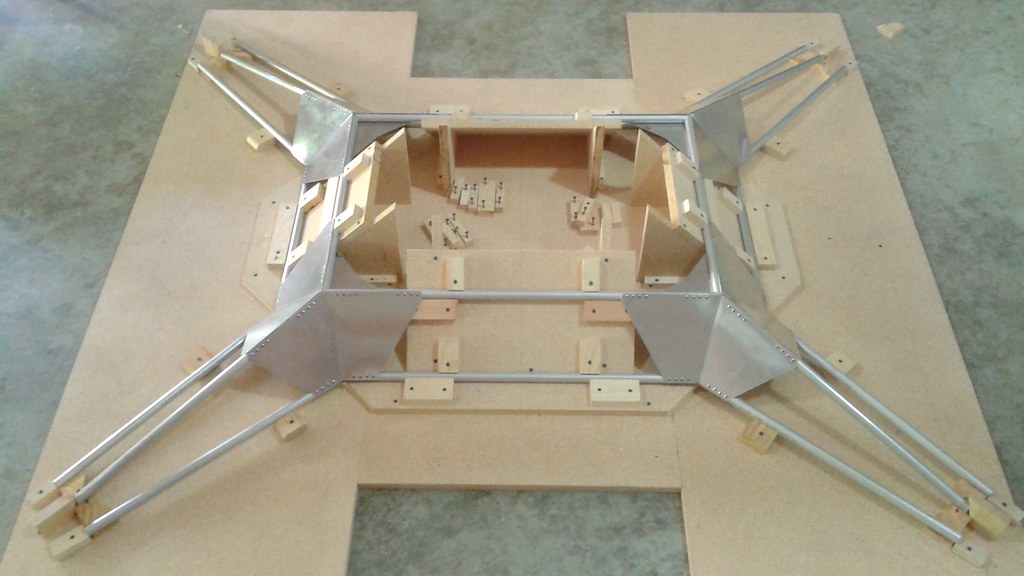

The Mk II frame is built using aluminum tube and assembled using aluminum gussets and and stainless steel rivets. This leads to a lightweight, vibration resistent design that can be assembled easily.

Engine

An electric powered design would have been the most straightforward approach. Electric motors are more efficient than gas motors, but the energy density of gasoline is much greater than today's batteries. So until battery technology improves, for large scale vehicles, gas power seemed the way to go.

Goliath currently uses a single 30 Hp vertical shaft engine and a belt system to transfer power to the four propellers. The setup was chosen because at this scale, four smaller gas engines have a smaller power to weight ratio than a single larger engine. The specific engine, an 810cc Briggs and Stratton Commercial engine was chosen primarily because of its relative low cost per power ratio.

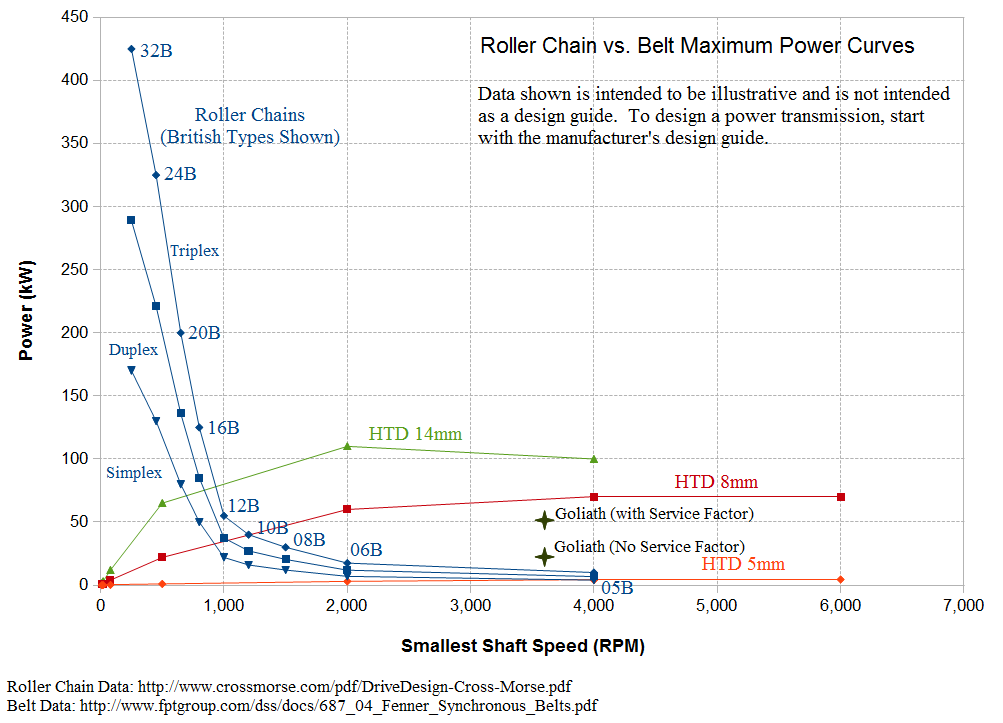

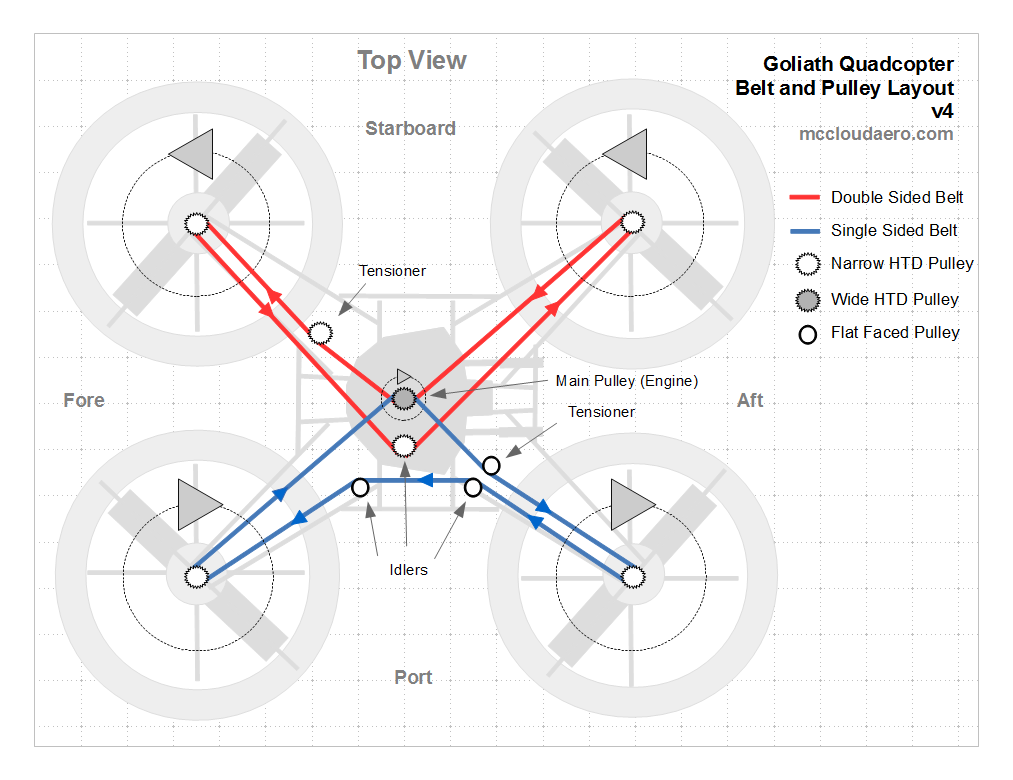

Drive System

The drive system uses High Torque Drive (HTD) belts. These belts are made of neoprene rubber with continuous fiberglass cords. HTD belts are able to transfer more power per weight than roller chain and can also run at higher RPMs that Goliath requires.

To eliminate aerodynamic torque, the drive system rotates two propellers clockwise (CW) and two counter-clockwise (CCW). This is done by using two belts, one sided sided and the second double sided. The direction of rotation is changed by placing the outside of the double sided belt against the driving pulley.

Propellers

The propellers are fixed pitch propellers 36 inches in diameter. They are custom made, starting from a foam blank with birch stiffeners. The blanks are machined using a CNC router and then fiberglass and epoxy are laid up over the machined core. This process produces a propeller that can carry over 60 lbs while only weighing one and a quarter pounds.

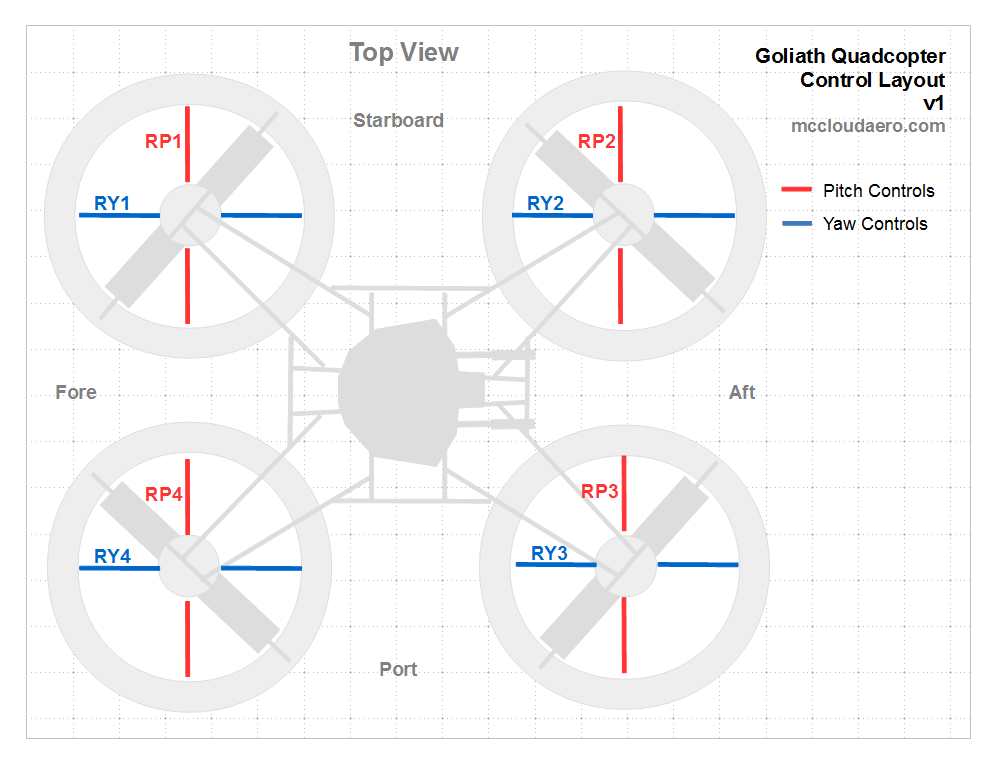

Control

An electric quadcopter would traditionally maneuver by varying the speed of each propeller to control thrust. Since Goliath uses fixed pitch propellers and all the propellers turn at the same speed due to the belt drive, maneuvering will be done by control vanes similar to those used to steer hovercraft.

Exhaust

Each of the two exhaust pipes are built from Go-Kart hardware, which are easy to procure and inexpensive. The U-Build It Kits are easily assembled using a minimum of welding and highly customizable.

Electrical System

The electrical system is powered primarily from the alternator with the battery as a backup. The battery is 12V and designed for off-road vehicles, so it'll handle high vibration loads. The micro-controllers and servos...

Read more » Peter McCloud

Peter McCloud

The next step will be cutting out a test disc and placing it under a rotor to determine the control forces generated.

The next step will be cutting out a test disc and placing it under a rotor to determine the control forces generated. Meanwhile I wanted to document the progress made on mitigating the vibrations that the avionics experience. This was accomplished by better isolating the engine from the frame and the avionics tray from the frame. The new engine mounts are made primarily of rubber, but are built such that if the rubber fails, the bolts are still captive. Stainless steel bolts are used to attach the mounts.

Meanwhile I wanted to document the progress made on mitigating the vibrations that the avionics experience. This was accomplished by better isolating the engine from the frame and the avionics tray from the frame. The new engine mounts are made primarily of rubber, but are built such that if the rubber fails, the bolts are still captive. Stainless steel bolts are used to attach the mounts. The avionics tray was switched from aluminum to steel. This was to add mass to help reduce the displacement of the avionics tray. Below is the new tray with some of the avionics populated.

The avionics tray was switched from aluminum to steel. This was to add mass to help reduce the displacement of the avionics tray. Below is the new tray with some of the avionics populated. The tray is mounted to the frame using four Expansion Nuts. I forgot to take a picture of them before I installed them, so here is a

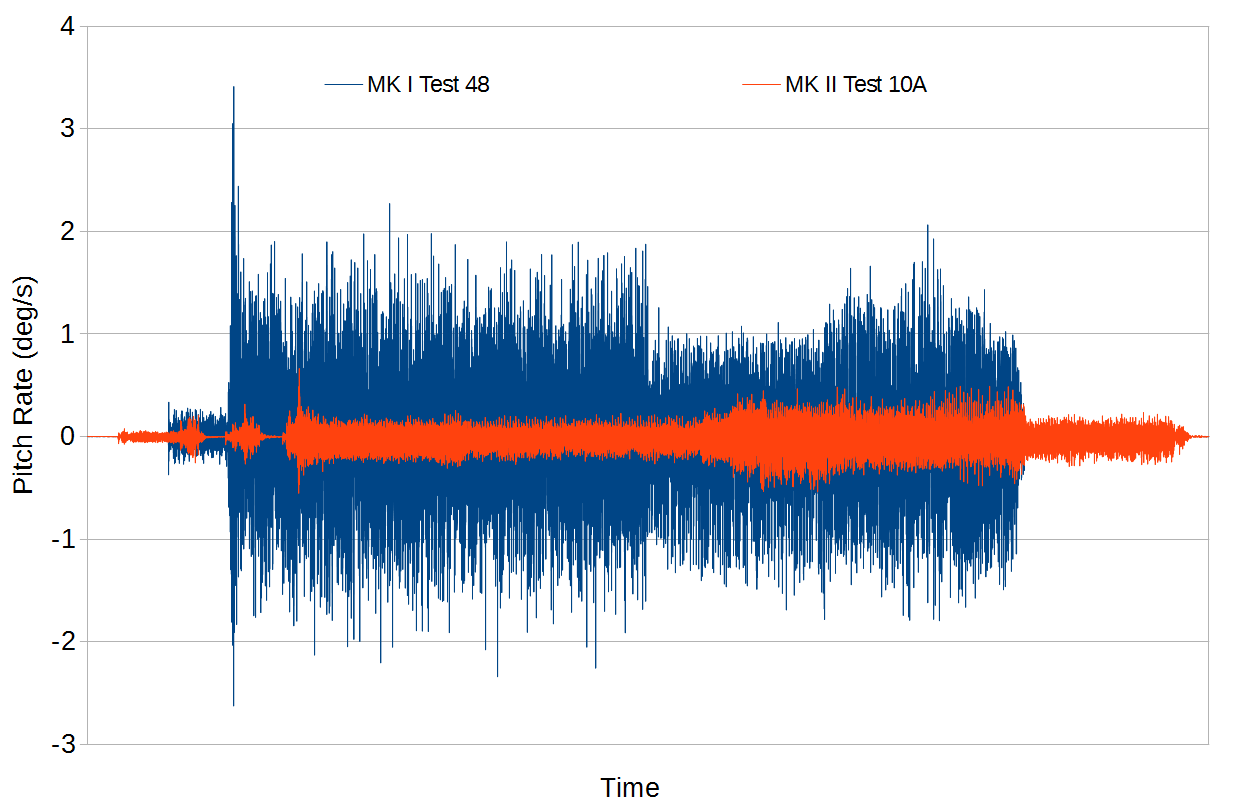

The tray is mounted to the frame using four Expansion Nuts. I forgot to take a picture of them before I installed them, so here is a  So how much did all the changes help? Data from the Pixhawk shows a huge reduction in the pitch rates down by a factor of 5 to 10. This means that the Pixhawk should be able to control Goliath once the rest of the hardware is complete.

So how much did all the changes help? Data from the Pixhawk shows a huge reduction in the pitch rates down by a factor of 5 to 10. This means that the Pixhawk should be able to control Goliath once the rest of the hardware is complete.  Hopefully the next log update in the not too distant future will be about fixing the bearing issues.

Hopefully the next log update in the not too distant future will be about fixing the bearing issues.

3) With half of the holes filled with Clecos, drill the remaining holes and fill them with rivets.

3) With half of the holes filled with Clecos, drill the remaining holes and fill them with rivets.

sebwiers

sebwiers

ibuildit123

ibuildit123

Julian Costas

Julian Costas

Hello,

could you use variable pitch like it's done on helicopter ?

It could bring some nervosity to the drive a hovercraft lacks ?