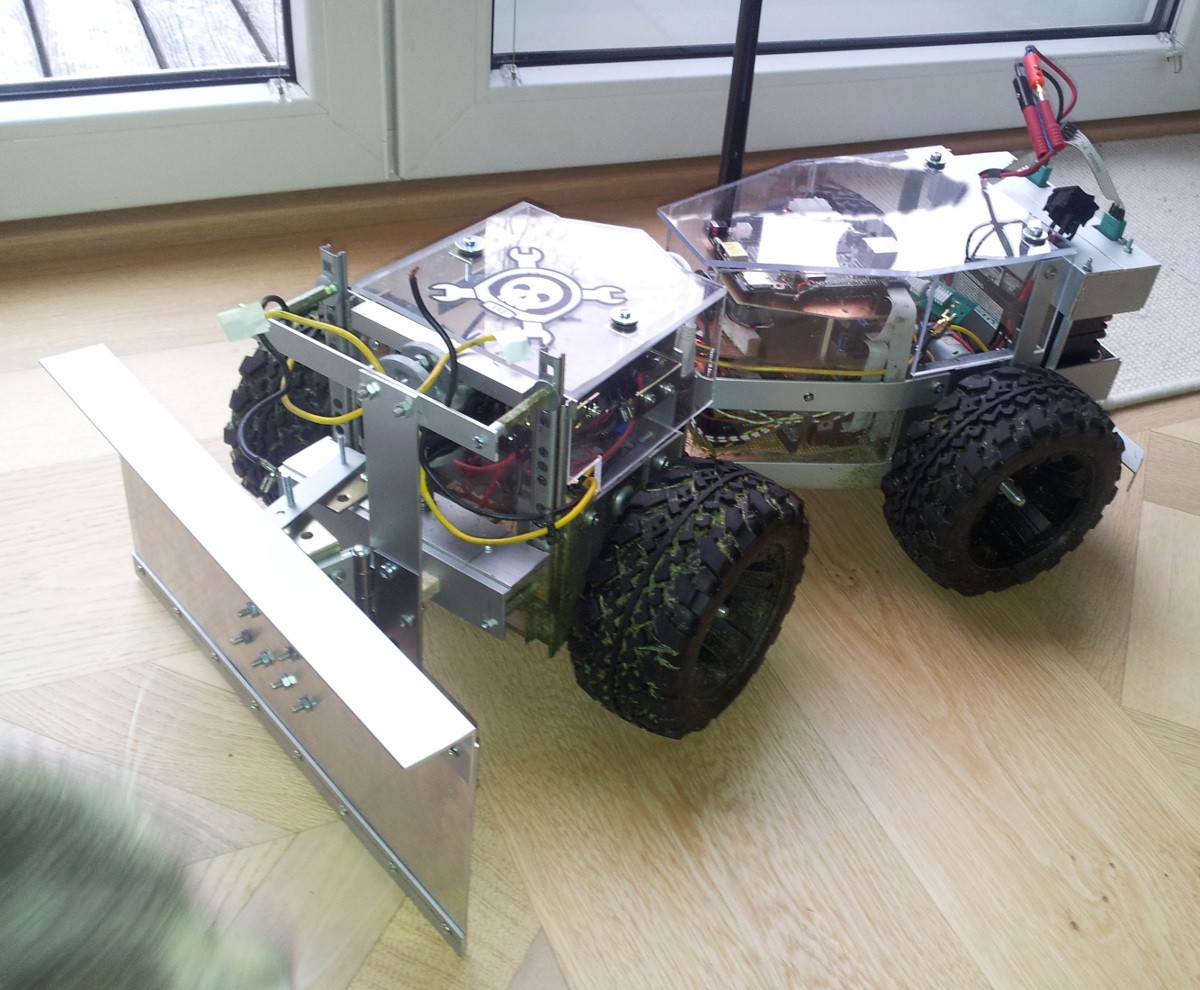

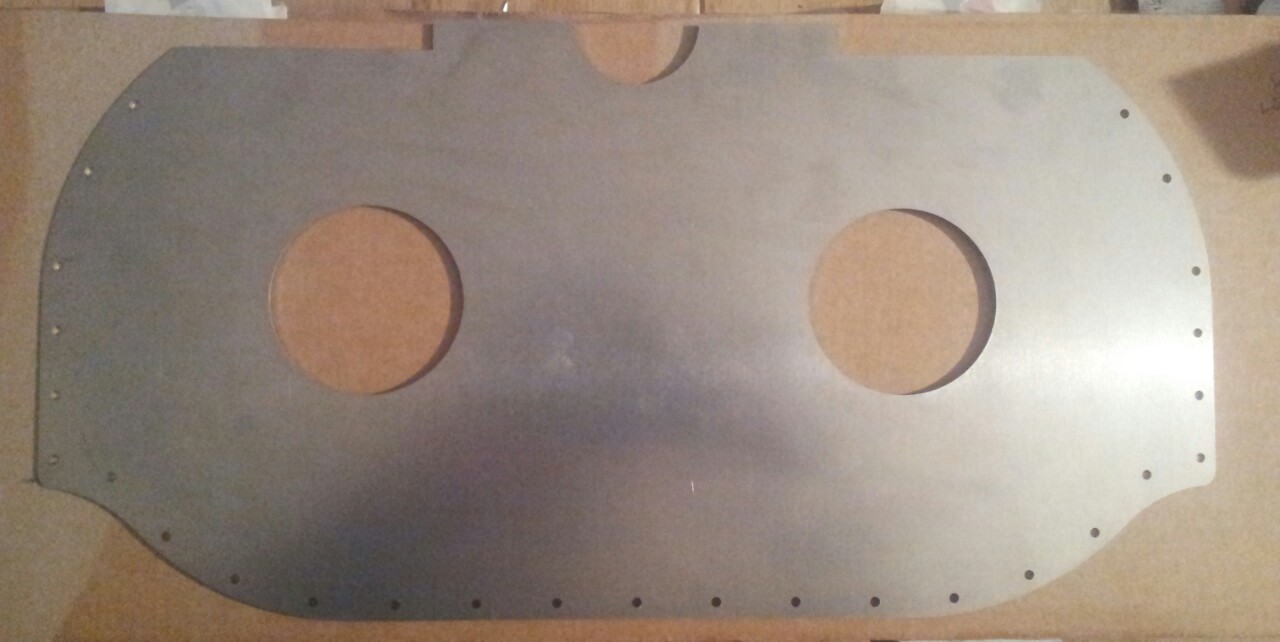

- Four weel drive with kink steering

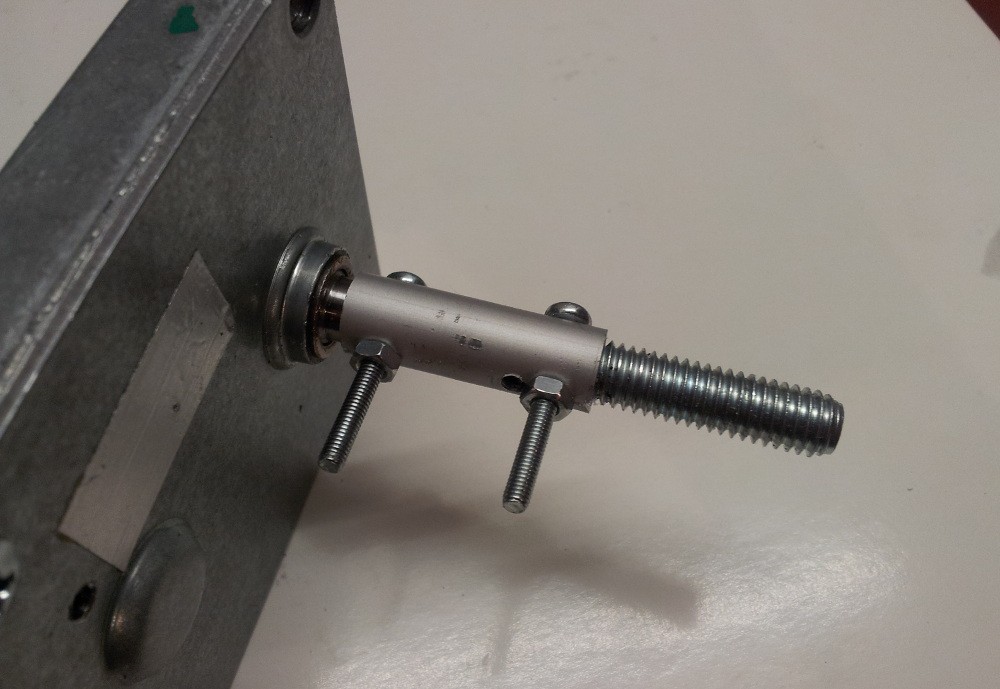

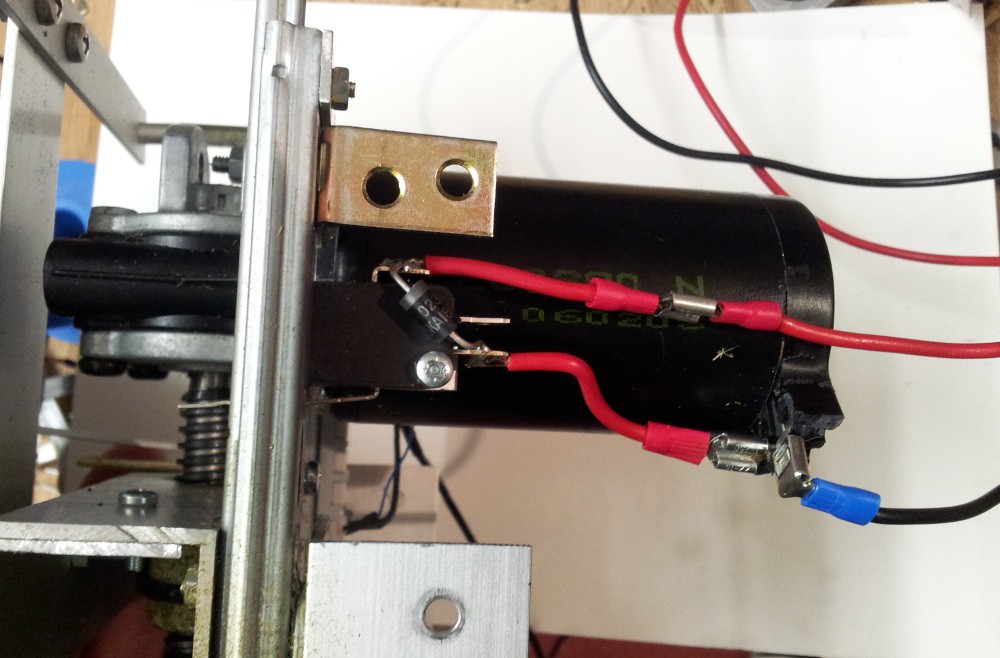

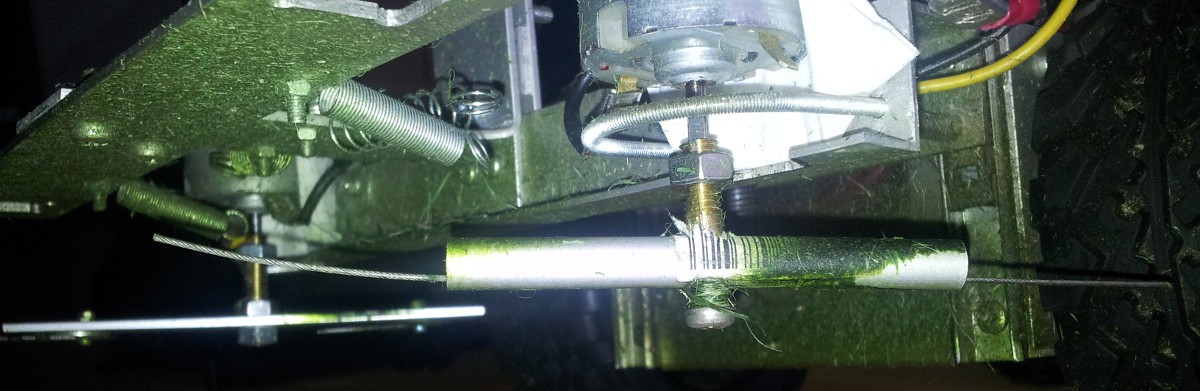

- Electric mowing height leveling

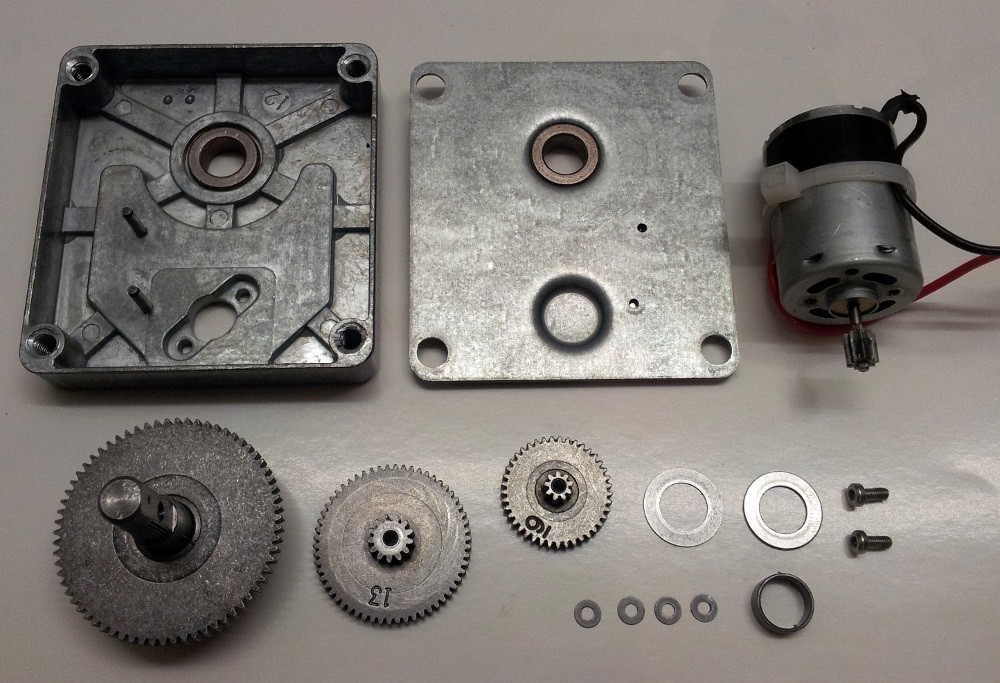

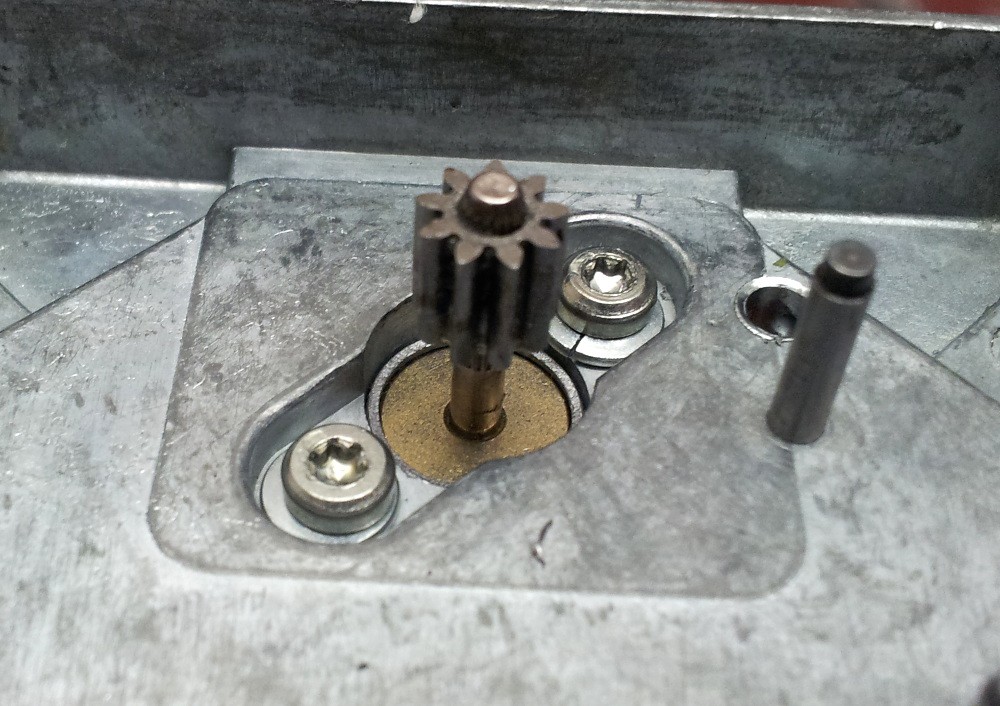

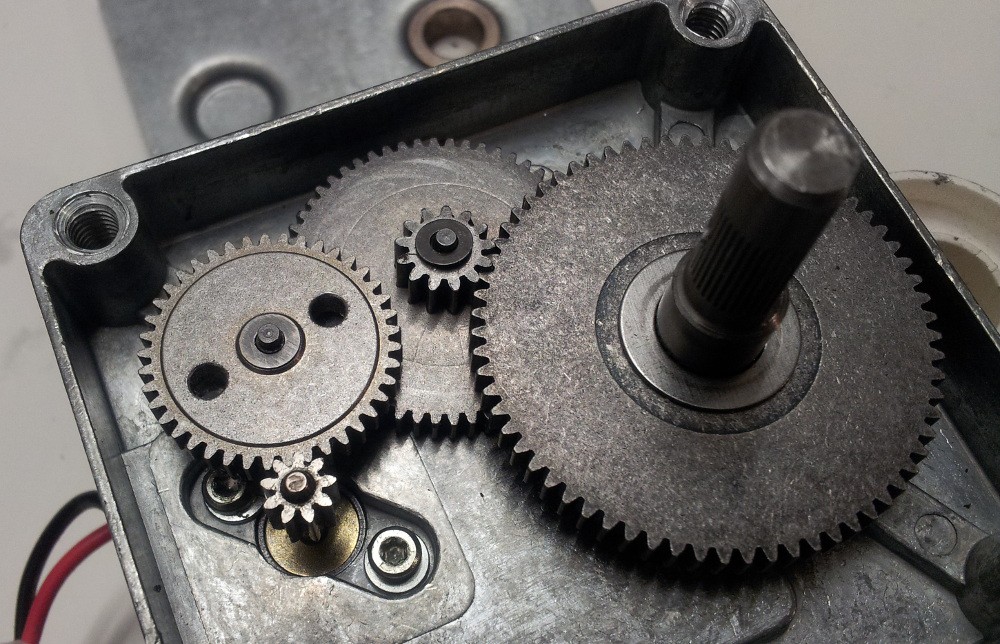

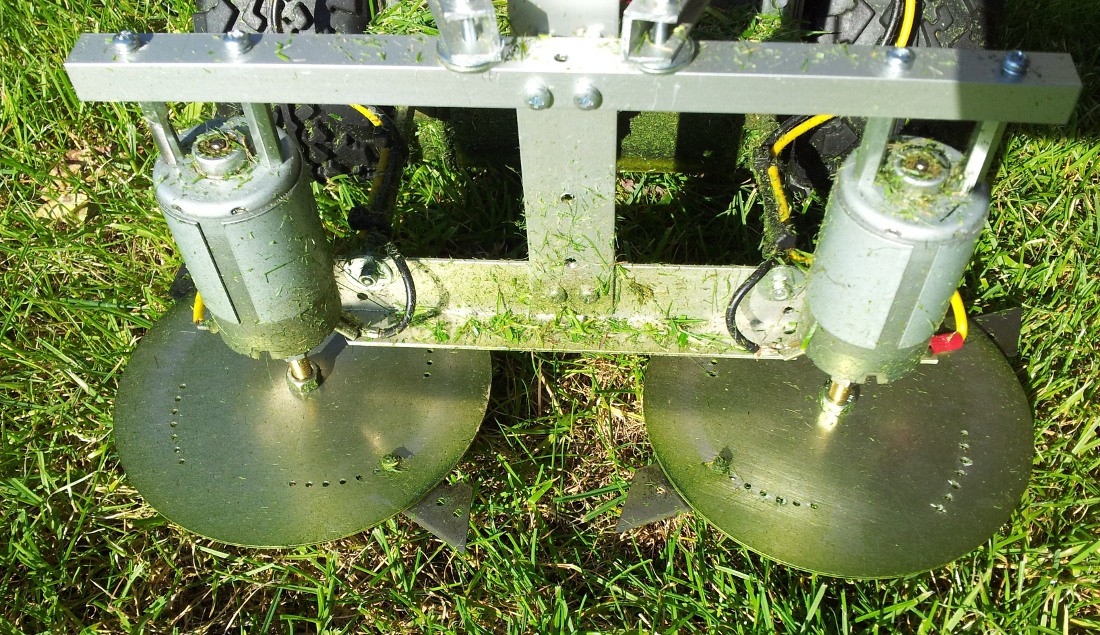

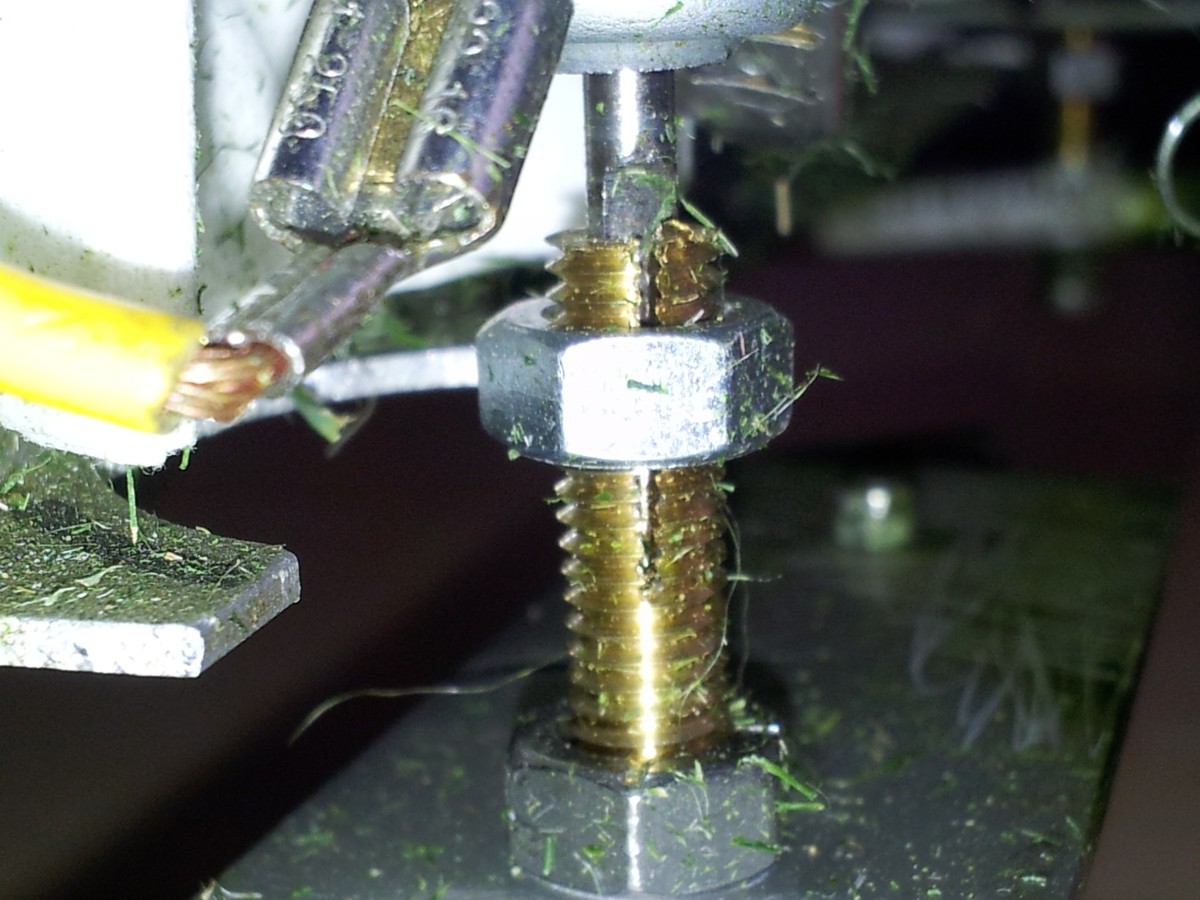

- Two 85 watt mowing motors, each equipped with two very sharp blades, able to snap back on hard obstacles

- On the fly interchangeable LiPo-battery with voltage monitoring, about 1 hour of battery live on active mowing

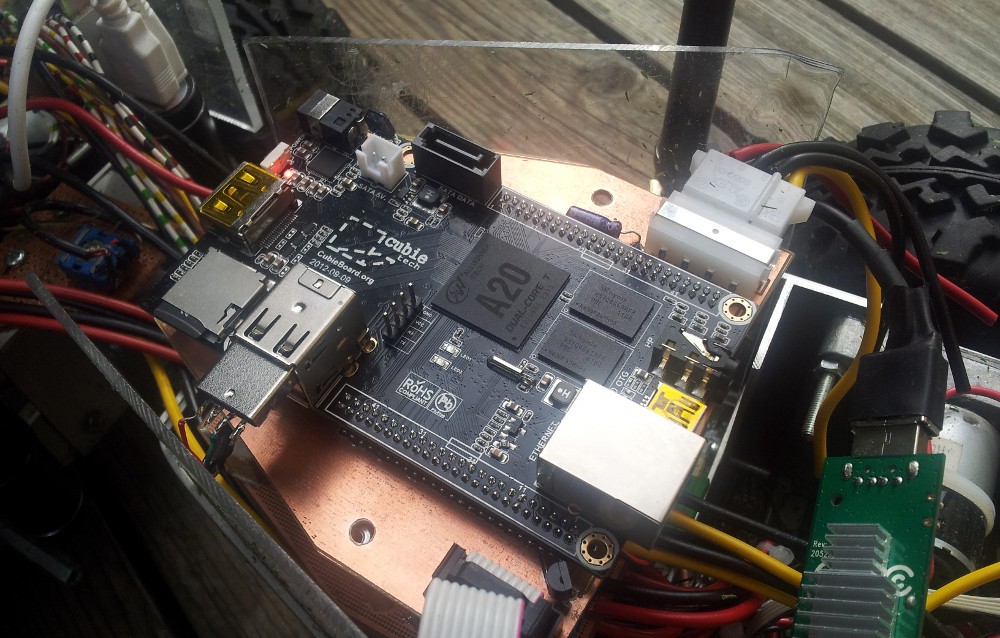

- Wifi network connection for web interface which includes gamepad/joystick remote control

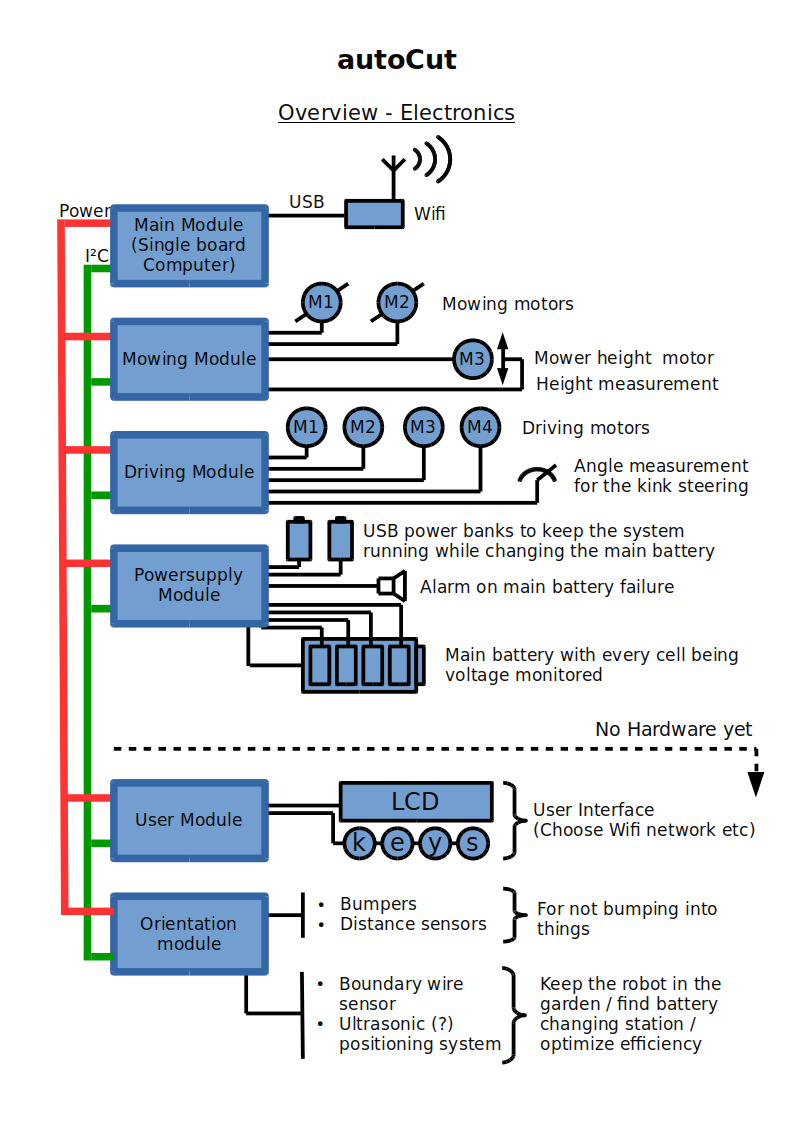

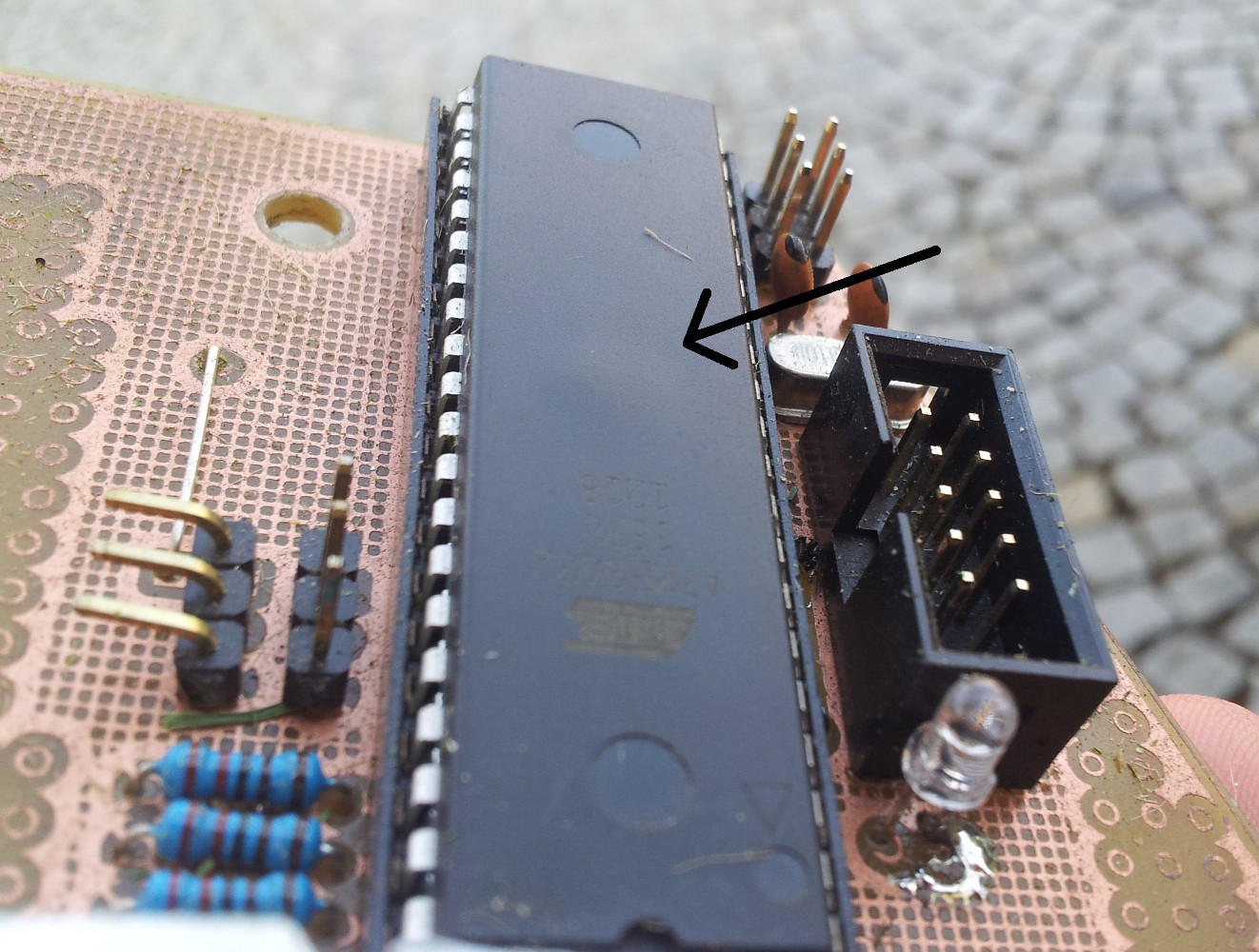

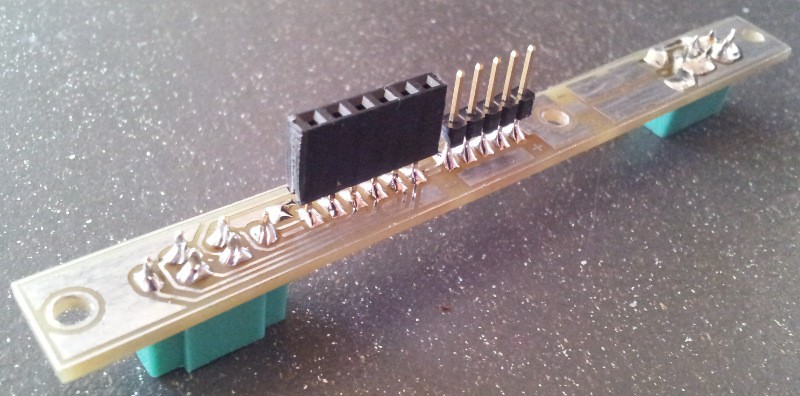

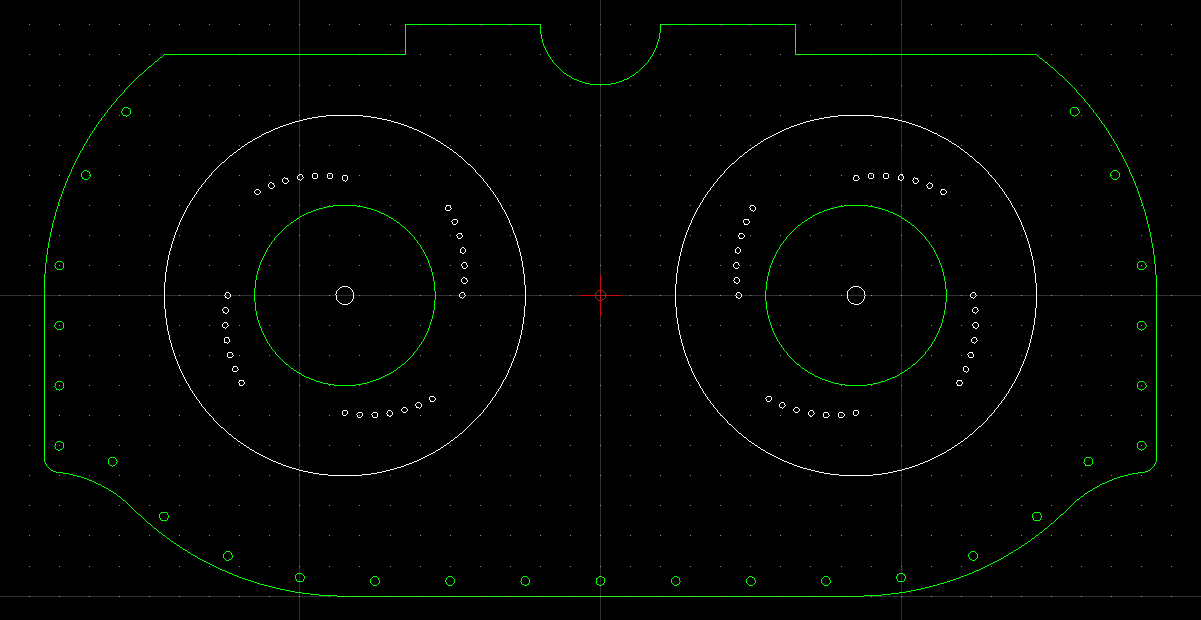

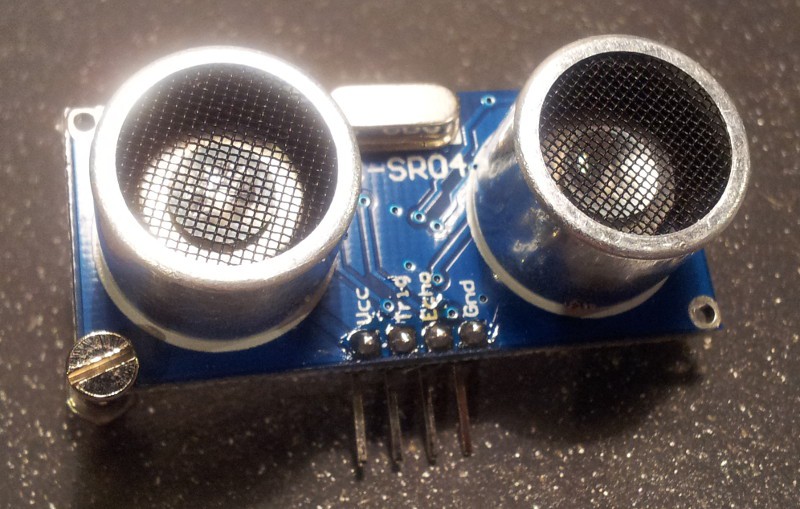

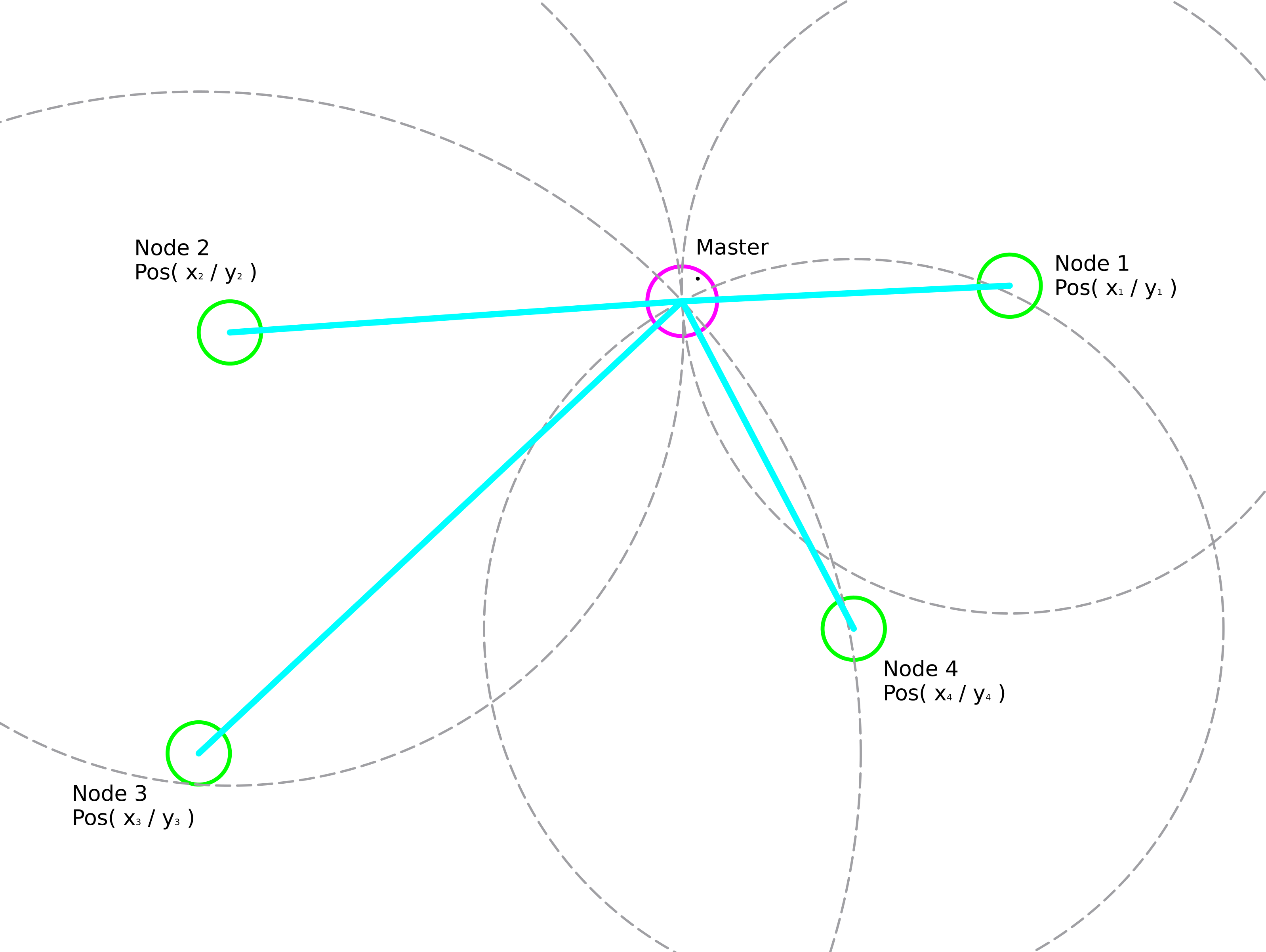

- Modular electronics: a cuple of modules, connected with a power- and I²C-bus with a Raspberry Pi as master

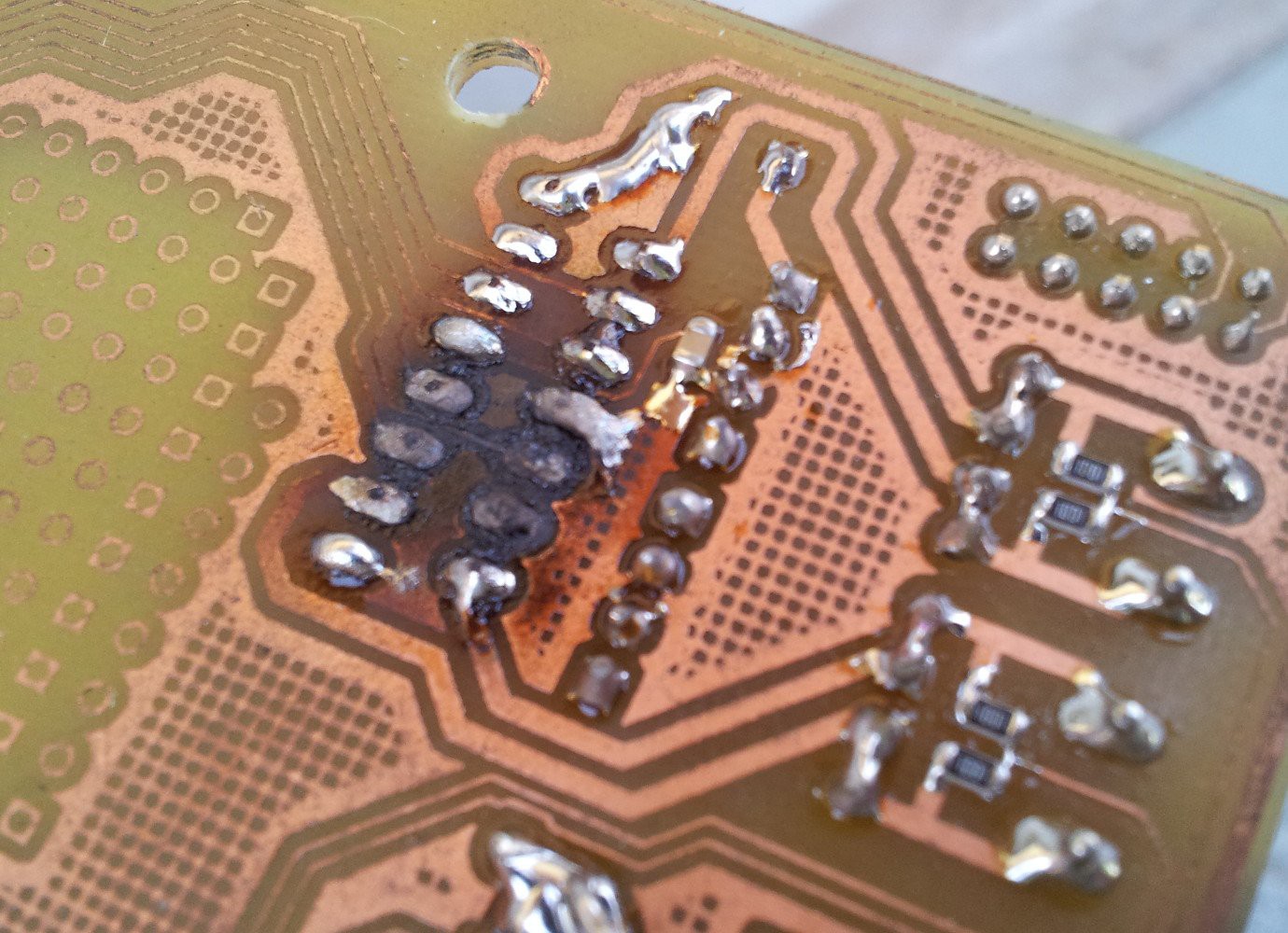

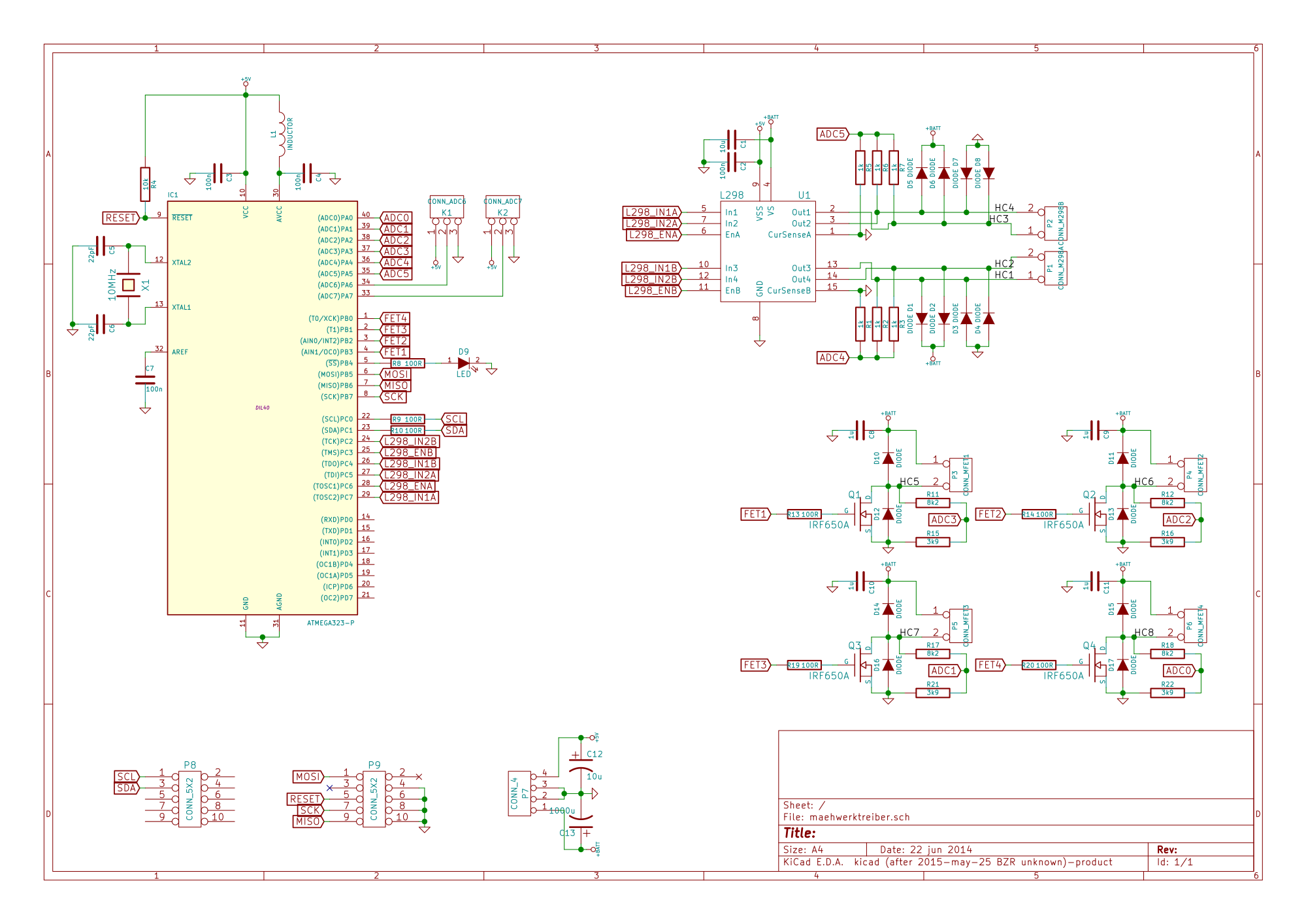

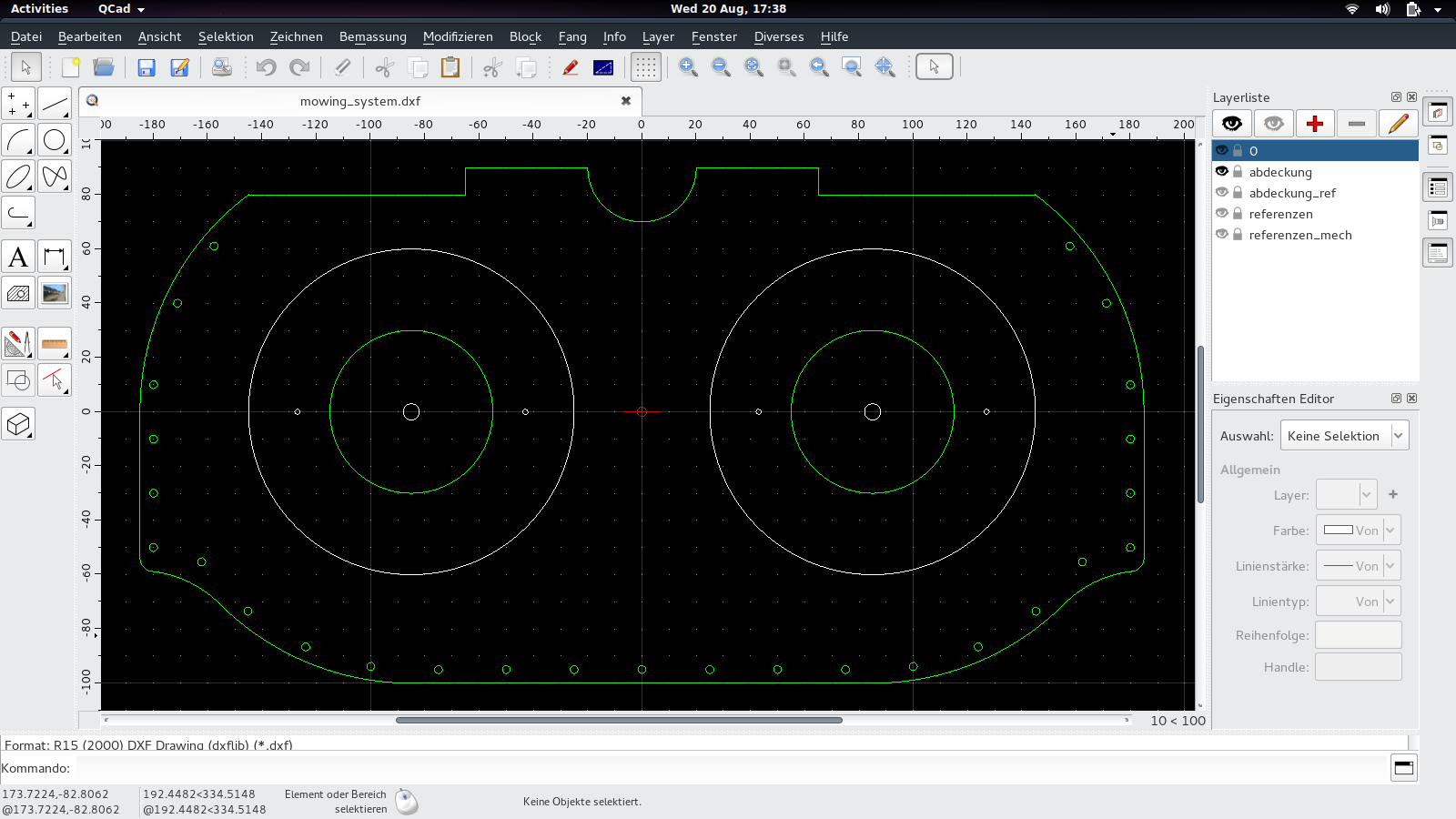

System design of the robot itself:

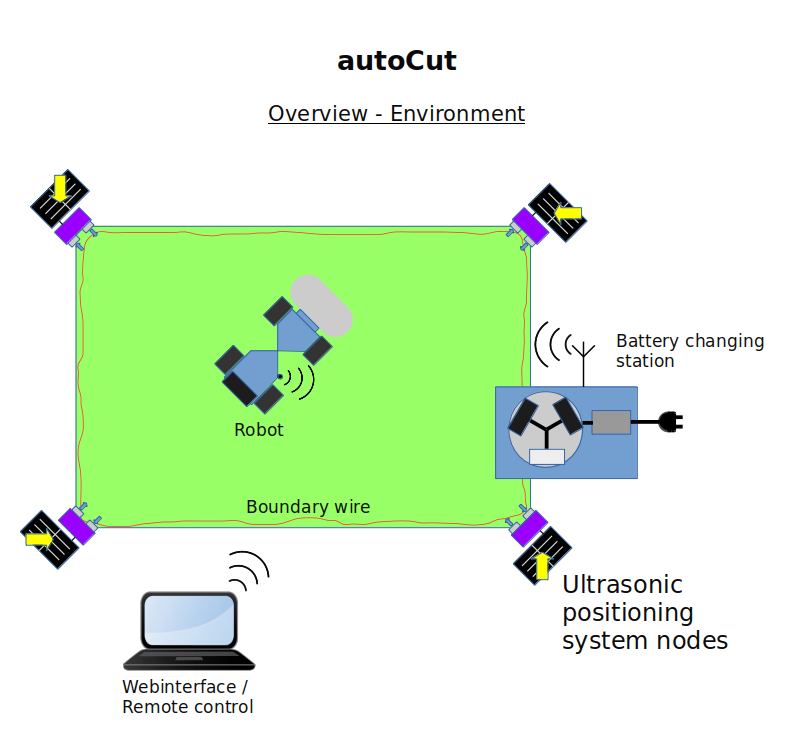

Overview of the whole system:

schuhumi

schuhumi

Roger

Roger

Josh Starnes

Josh Starnes

Apollo Timbers

Apollo Timbers

Emmanuel

Emmanuel

Interesting meaning and I agree, that the best high lift lawn mower blades are so useful! And what's more, such things are really important, because without good lawn mower blades, getting a quality lawn tidy becomes a chore, whereas with quality ones it's more of a pleasure and an easy walk.