Video of the finished suit functions-

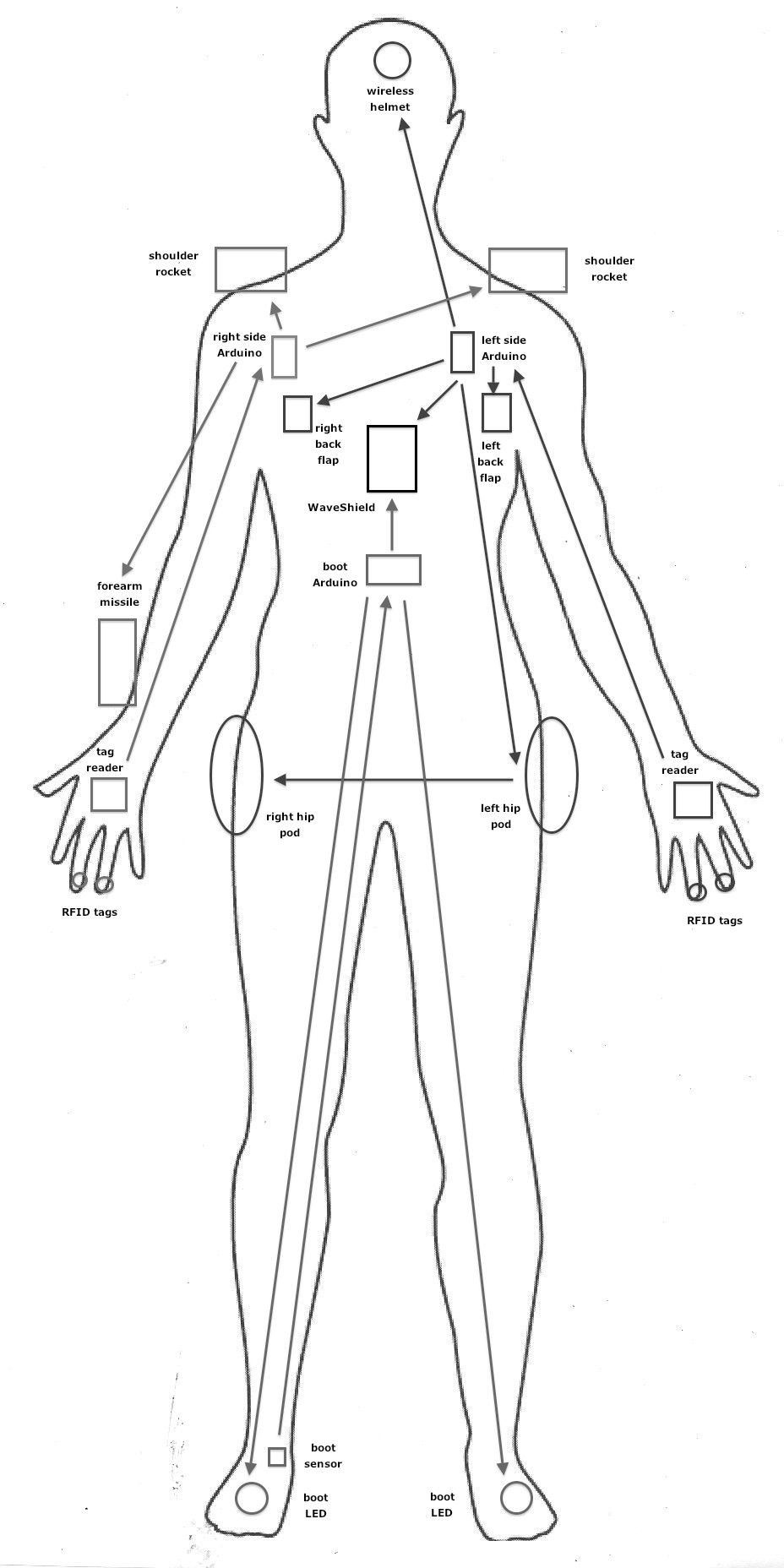

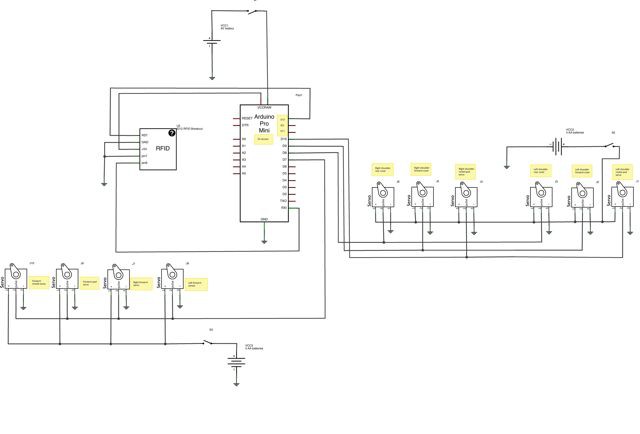

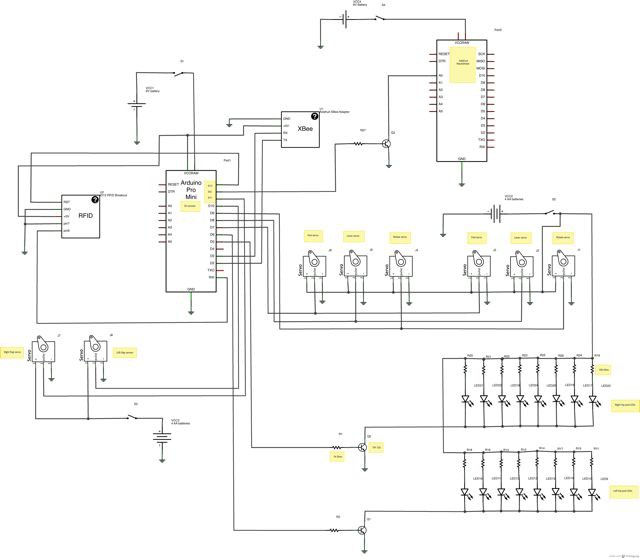

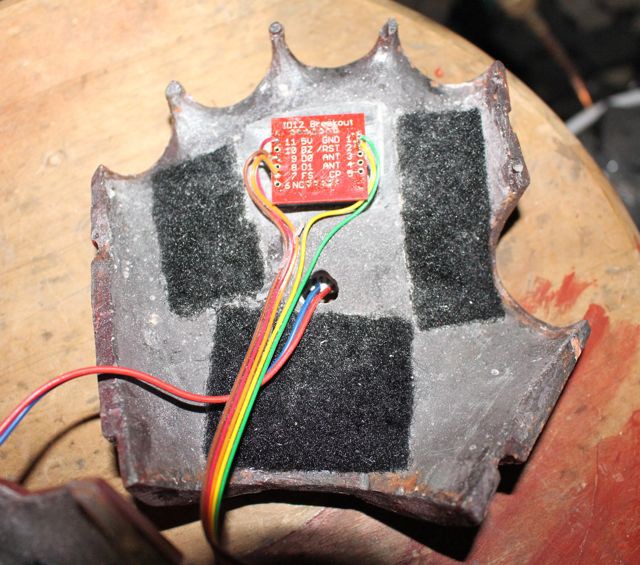

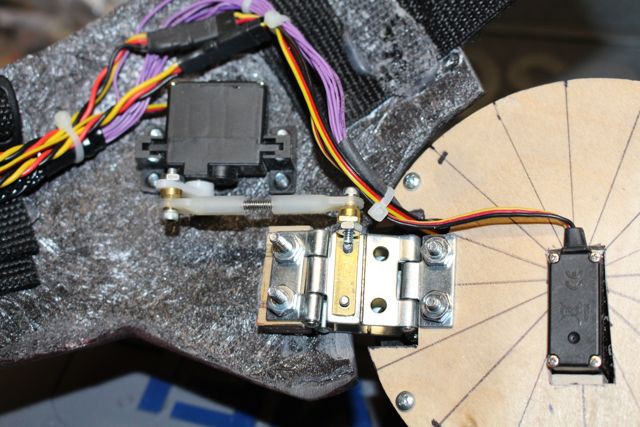

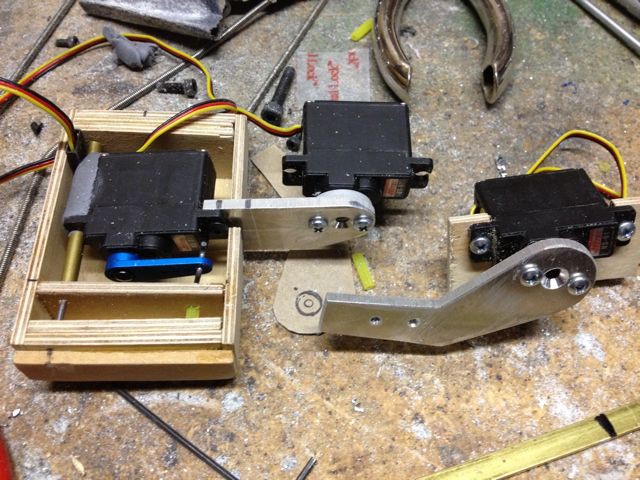

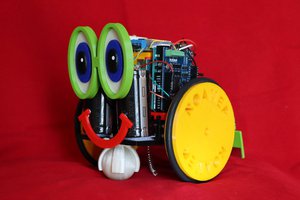

The suit is basically broken down into three systems: left side, right side and boots. The left hand has two RFID tags that trigger programmed sequences for the helmet, hip pods and back flaps. The right hand RFID tags trigger programmed sequences for the forearm missile and shoulder rockets. The boots have an infrared sensor that triggers the boot lights and sound effect as soon as the boot is lifted from the ground.

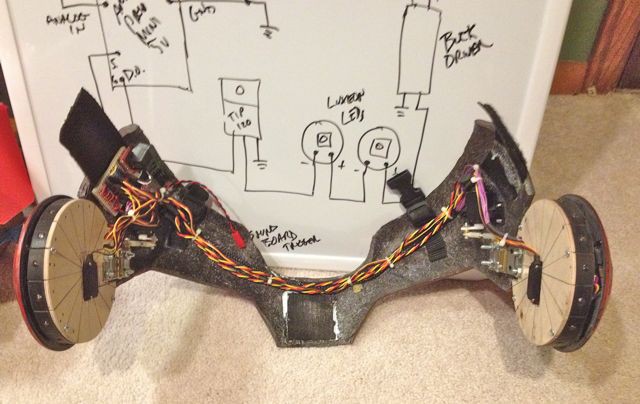

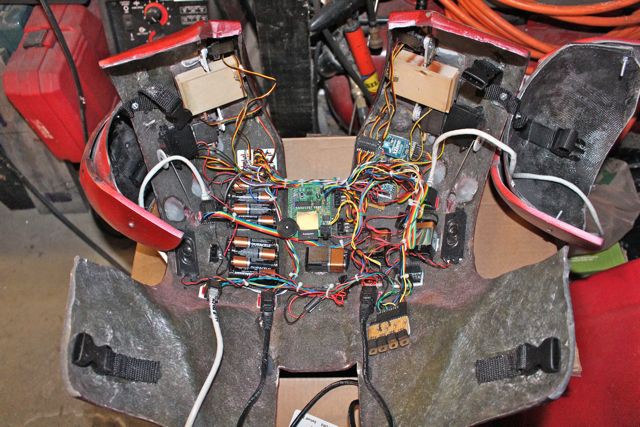

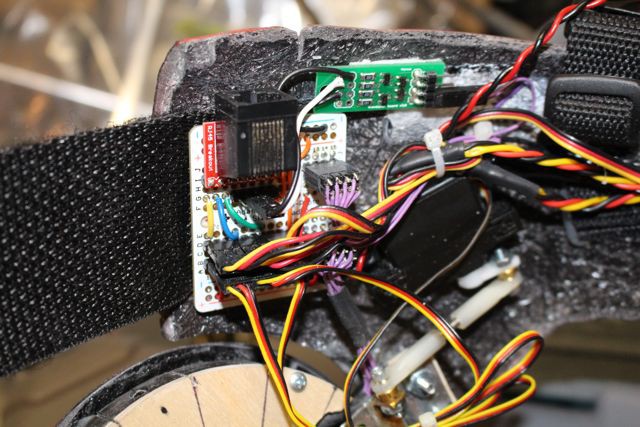

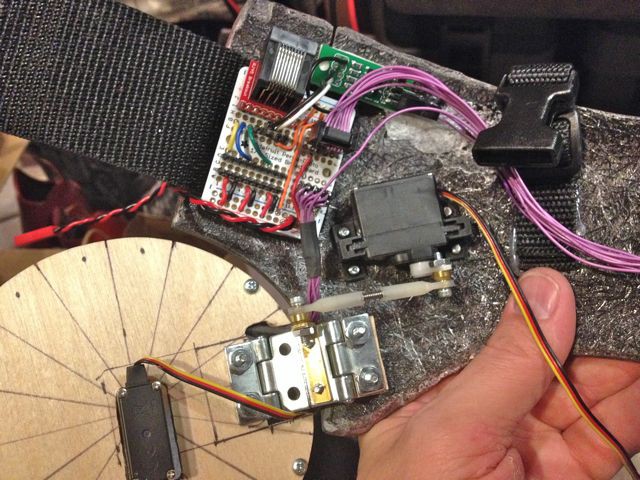

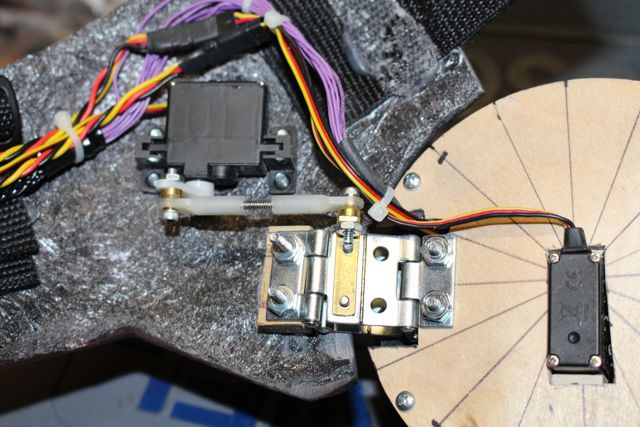

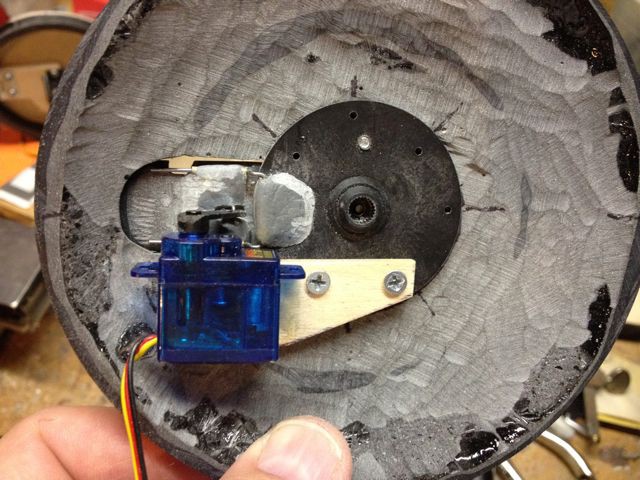

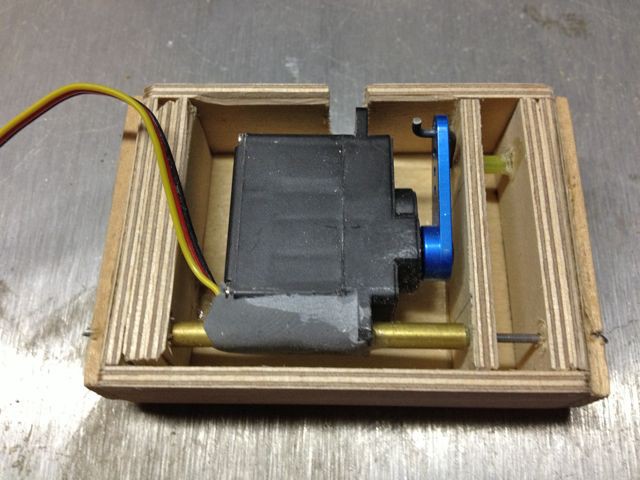

The single most difficult thing about this build is that the suit fits like a glove- there's no room in it! The helmet has less than 1/2" of space around the head, there's about 1" depth for the shoulder rocket pods and the hip pod area has less than 1" depth available so the packaging of the mechanics and electronics is really tight. Another issue is that there's almost no flat surfaces so mounting servos and hardware gets really interesting.

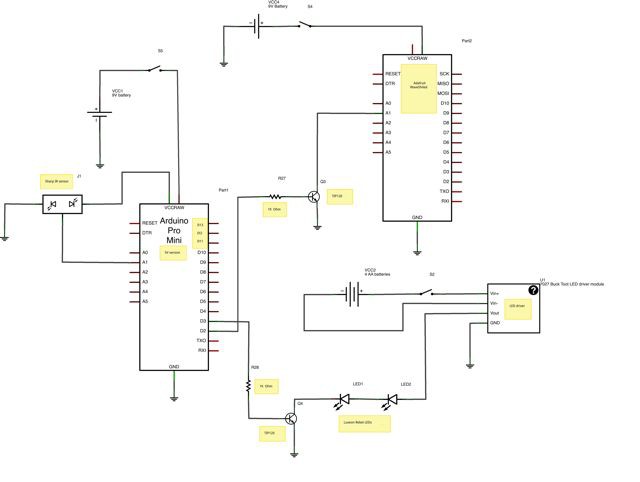

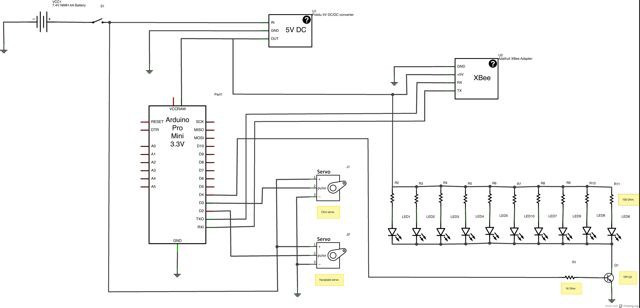

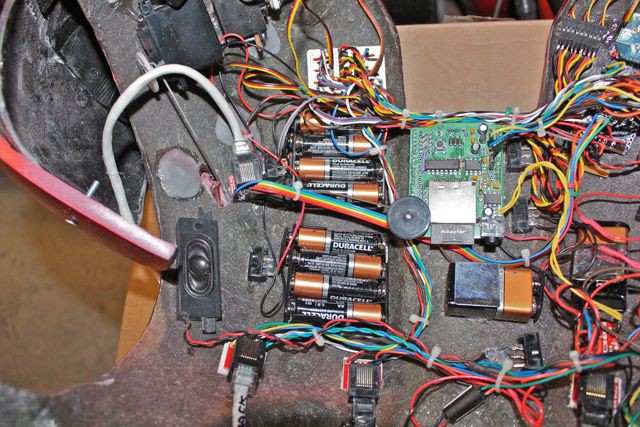

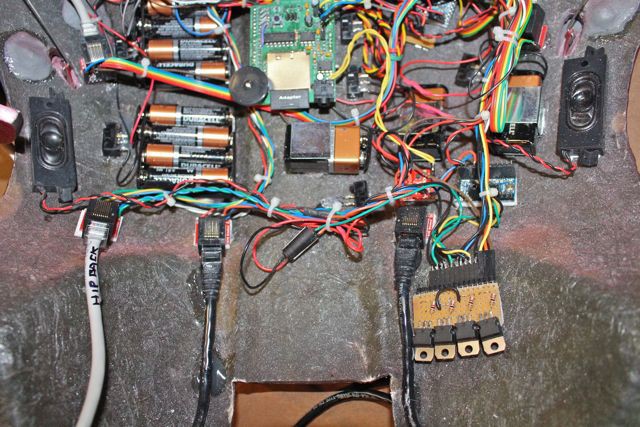

The system is Arduino based and uses four ProMinis- one for each side, one for the boots and one in the helmet. Since we wanted the helmet to be easy to take on and off we decided to make it wireless using XBee radios to send the control signals. For the point to point wiring running from the electronics mounted in the back to the arms and feet we used Ethernet cables and jacks so they could be easily disconnected. The sound effects for the boots are handled by a WaveShield that sits on a Arduino Pro.

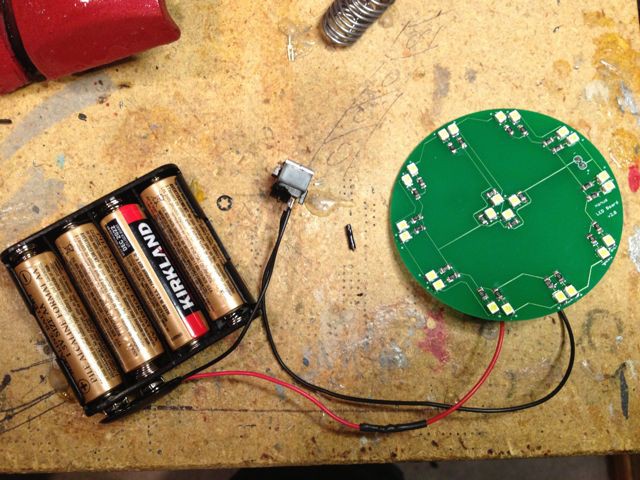

Another issue with systems like this is the voltage and current requirements so we thought it best to power the servos separately using AA batteries, primarily for ease of availability if the suit is to be worn at conventions.

In the end this build was an enormous learning experience- it was a difficult build, somewhat frustrating at times and a real challenge to figure out ways to get the desired effects while making it as practical as possible and as convincing as possible. My house and garage looked like a hurricane had gone through it and deposited Iron Man parts everywhere. Many things didn't work as originally planned ( I think I revamped the helmet twice ) and I managed to fry a servo but in the end we stuck to it and it all worked out. :)

Please note that I do not manufacture Iron Man armor suits or helmet castings nor do I sell them. This particular set of fiberglass Iron Man armor belongs to my friend Greg who asked for my help in animating it. My friend Greg acquired the molded fiberglass suit and helmet castings from Clinton Hoines of Tundra Designs and they were modified to accept the animatronics. The boots and gloves came from Replica Prop Forum member Zabana.

jeromekelty

jeromekelty

Mike Rigsby

Mike Rigsby

mihai.cuciuc

mihai.cuciuc

holy crap, are you crazy man?!?! why isin't this in the scifi contest