Motivation

I have four little kids and a full time job, so I don't get out to the apiary as often as I'd like. I keep the hives healthy, but they do occasionally fill up most of their available space with nectar and slow down collection before I can get out there to add more boxes. This problem isn't unique to me -- any beekeeper with remote apiaries has to weigh the possibility that a sudden, strong nectar flow has filled up their hives against the time it takes to drive out and make an inspection. Measuring weight alone will eliminate this problem as I'll know exactly how much nectar is coming in and I can make a quick trip to add supers (honey collection boxes) when the nectar is flowing fast while spreading out my trips when the nectar is coming in slowly.

Additionally, NASA has a HoneyBeeNet program that relies on volunteers to manually record the hive weight every day so the local nectar flows can be correlated with satellite measurements of climate change and land use changes. Unfortunately, my hives are all installed at remote apiaries, and I can't visit them every day.

I want to contribute to NASA's HoneyBeeNet program, save myself unnecessary trips out to the apiary, and frankly, I want to collect gobs of data from the hives to see what I might learn about easily detectable signs that something might be wrong.

First Prototype

I tried to document a lot of my work over the last couple years on my blog, hackerbee.com, although I'll repeat a more concise (and uninterrupted) version here with the massive benefit of hindsight.

First, I purchased a range of scales and started ripping them apart to see how I could get them to meet my needs. I was very new to hacking electronics at this point, so I thought it would be easier to connect to a cheap scale than to try to build a scale from scratch. Unfortunately, I kept running into black potted chips on anything cheaper than the ADAMS CPWplus 200, which costs $163 at Amazon.

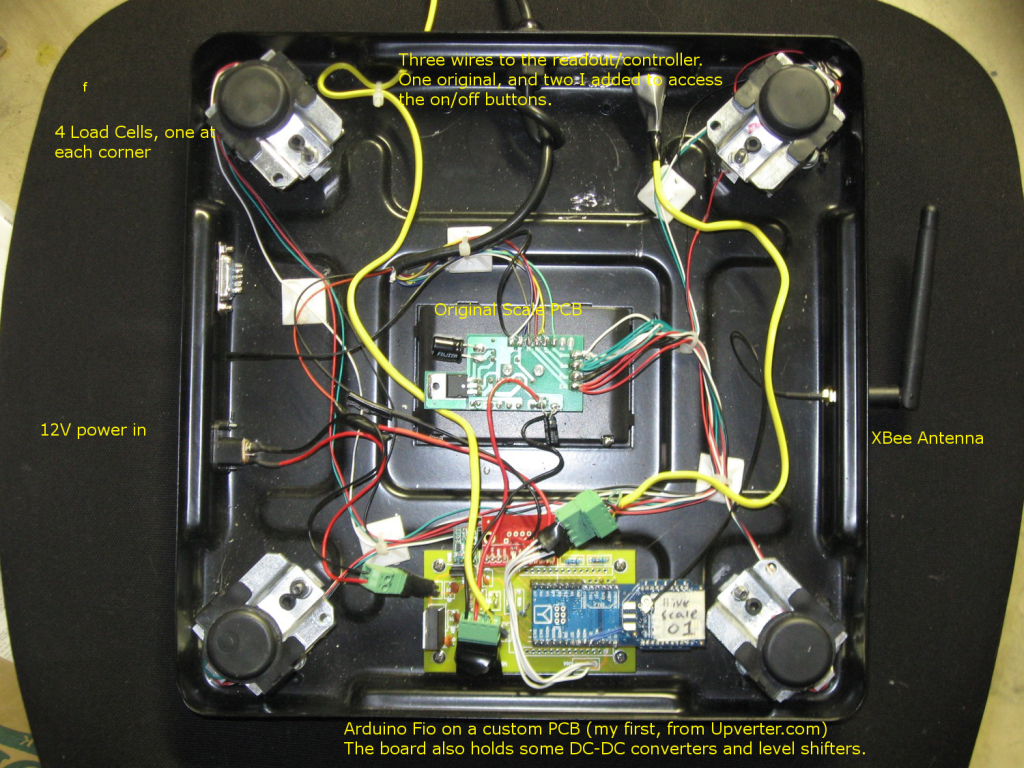

If I knew everything I've learned in the past 3 years, I would have gone a much different route from the start, but I finally settled on an CPWplus 200 scale. While it has a easily hackable serial interface, I found that the scale is designed to tare (zero) on powerup, and since I need to run the system at a remote apiary on a battery with solar, I badly wanted to turn off the scale between measurements!

Eventually, I gave up on turning off the scale and simply oversized the solar panel and battery to make up the difference. I added an Arduino Fio with XBee to stream the data back to Thingspeak.com over a nearby internet connection.

I successfully streamed data from a beehive to Thingspeak.com for about a week last spring before my buggy coding of the wireless connection started getting interrupted. Unfortunately, I didn't have the foresight to add an SD card to backup the data, and between life and work, I didn't have time to get it working again last year.

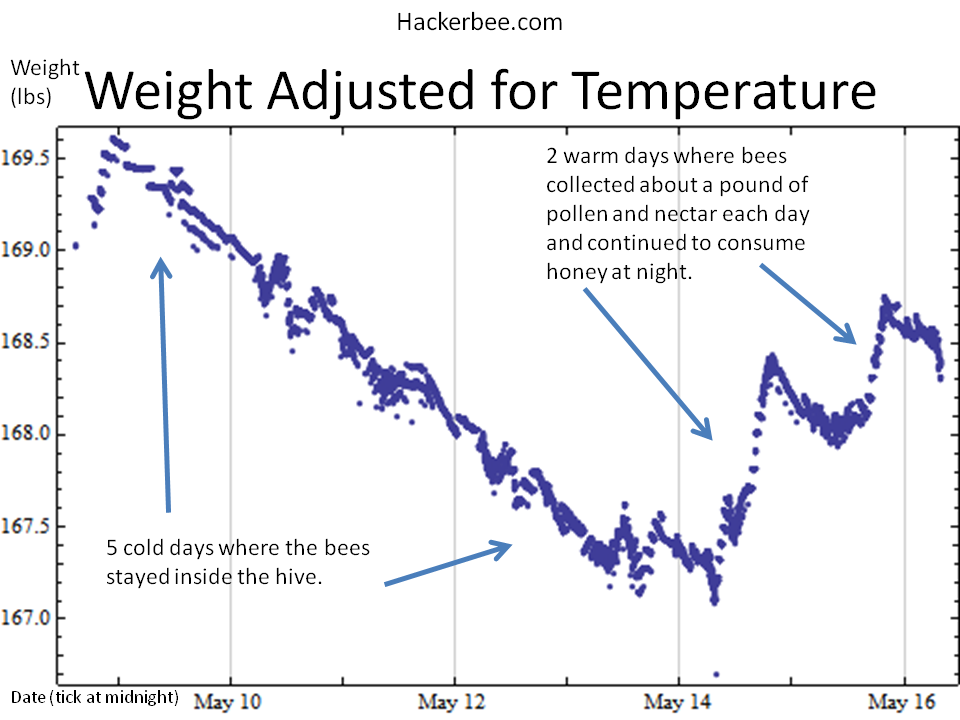

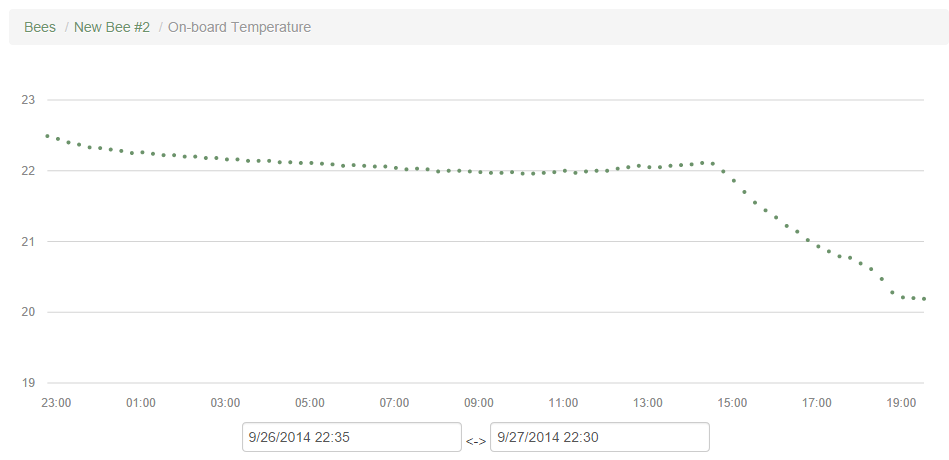

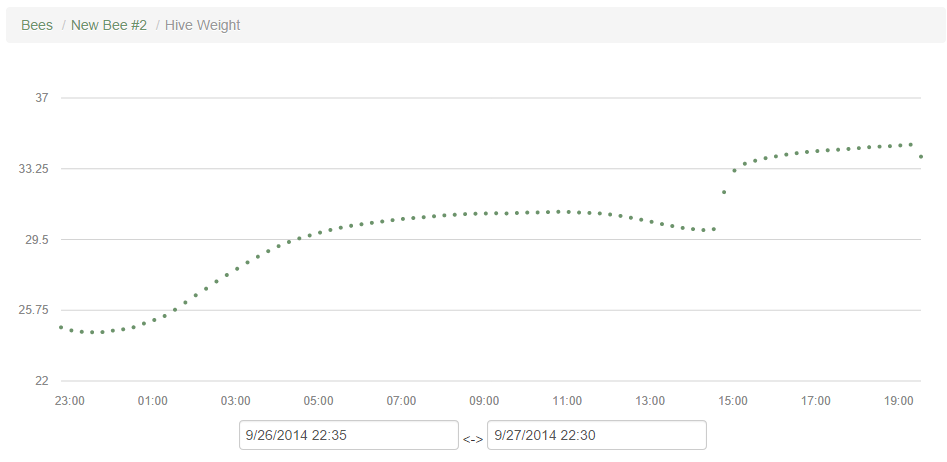

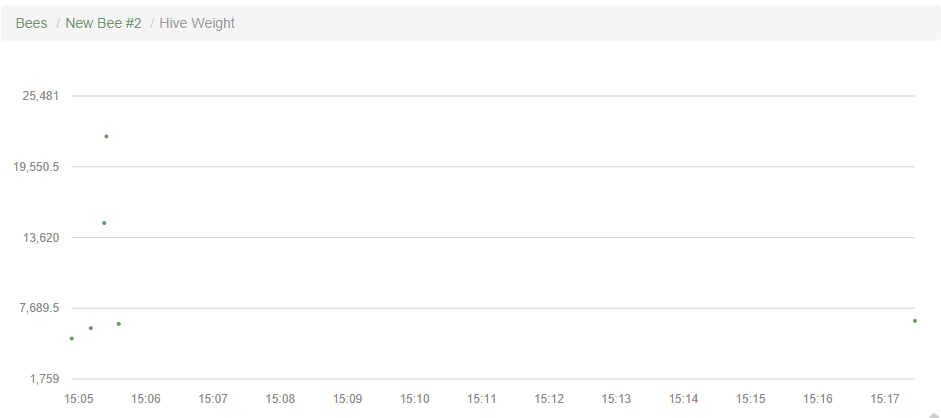

I knew that the load cells would be significantly sensitive to temperature, and this original data was quite noisy as I hadn't yet been able to calibrate the scale for temperature. Here's a sample of some data I collected while the system was working. I removed the temperature sensitivity with a regression analysis after the fact, so this data is somewhat questionable, but it shows what I expect to see once I've got a properly calibrated scale working.

Beehive Monitoring System Design

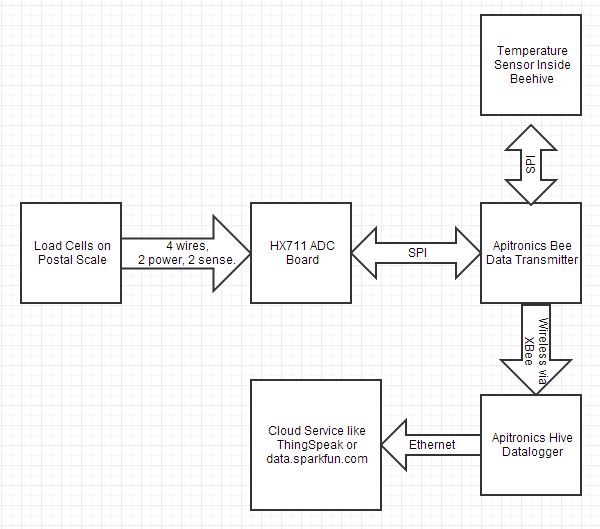

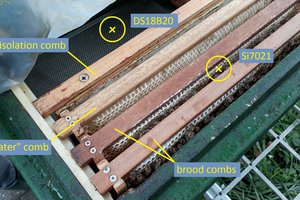

Here's my plans for the current beehive monitoring system. Instead of trying to rely on firmware that was designed for a postal scale and doesn't allow easy power management, I'll measure the load cells directly with a 24-bit ADC. The output of the HX711 ADC board will be read by the Apitronics Bee unit and, along with a temperature sensor inside the bee hive, sent to the Apitronics Hive that saves the data. I'll also be streaming the logged data to a cloud service so I can monitor my hives in real time!

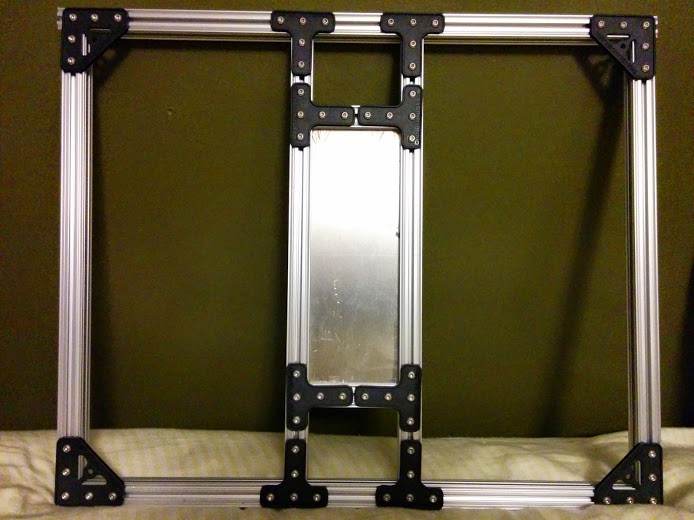

I've chosen 200 kg (440 lbs) as a load limit for the scale...

Read more » Ken Meyer

Ken Meyer

Kevin Arne

Kevin Arne

Ashwin K Whitchurch

Ashwin K Whitchurch

Jan

Jan

sparks.ron

sparks.ron

Hello Ken, you have nice project, really liked) Trying to build smth similar. Interesting about accuracy of micro load cells (cheap chinese, you tried it in beginning) what is there accuracy? and precision due to temperature intervals?