Hi everyone!

Hi everyone!

Welcome Mark and Elijah! Can you start us off with a little about yourselves?

Welcome Mark and Elijah! Can you start us off with a little about yourselves?

Hey everyone, my name is Elijah. I’ve worked at Royal Circuit Solutions in Hollister, California for the last 6 years. I specialize in DFM/DRC here at Royal as well as “blue-printing” the manufacturing procedures for the orders that come through the shop.

Hey everyone, my name is Elijah. I’ve worked at Royal Circuit Solutions in Hollister, California for the last 6 years. I specialize in DFM/DRC here at Royal as well as “blue-printing” the manufacturing procedures for the orders that come through the shop.

My name is Mark and I'm also part of the team. When they don't have me digging semi-precious recyclable plastics out of the dumpster, they let me research, write, speak and create content for electrical engineers.

My name is Mark and I'm also part of the team. When they don't have me digging semi-precious recyclable plastics out of the dumpster, they let me research, write, speak and create content for electrical engineers.

I also pay for my own business cards -- so you'll see my job description range from "3rd-shift Hypnotist" to "Research Director".

I also pay for my own business cards -- so you'll see my job description range from "3rd-shift Hypnotist" to "Research Director".

What questions can we provide answers for today?

What questions can we provide answers for today?

Business cards... made from PCBs I assume? ;)

Business cards... made from PCBs I assume? ;)

And just a quick disclaimer, I make no guarantees that any particular answer is appropriate for any particular question.

And just a quick disclaimer, I make no guarantees that any particular answer is appropriate for any particular question.

@Andy Geppert Oddly enough no. They end up being too thick to carry around in large volumes.

@Andy Geppert Oddly enough no. They end up being too thick to carry around in large volumes.

YES! We are here to help you guys out with choosing a finish, or just help add to your knowledge of PCB finishes

YES! We are here to help you guys out with choosing a finish, or just help add to your knowledge of PCB finishes

Even if made 0.6 mm thick or so?

Even if made 0.6 mm thick or so?

I like travelling with enough that if I ever see a "business card sweepstakes" to win something that not only is my chance of winning statistically likely, but it becomes a mathematical certainty.

I like travelling with enough that if I ever see a "business card sweepstakes" to win something that not only is my chance of winning statistically likely, but it becomes a mathematical certainty.

Although we do see PCB business cards being ordered a few times in our shop!

Although we do see PCB business cards being ordered a few times in our shop!

Choosing finishes is top of my list of "things I'd like to learn about." Understanding cost/time trade-offs.

Choosing finishes is top of my list of "things I'd like to learn about." Understanding cost/time trade-offs.

![]() What is the basic finish and pro/cons?

What is the basic finish and pro/cons?

There are more things to consider, if one goes beyond 1 GHz with their PCBs. Anyone interested in that?

There are more things to consider, if one goes beyond 1 GHz with their PCBs. Anyone interested in that?

@MS-BOSS Yeah -- if you make them too thin it gets hard to drill and route. -- 0.6mm is still too thick for a business card.

@MS-BOSS Yeah -- if you make them too thin it gets hard to drill and route. -- 0.6mm is still too thick for a business card.

I'm interested in 1 GHz+ !

I'm interested in 1 GHz+ !

My boards are all well within 1GHz, but I'm interested in hearing about it just to learn more.

My boards are all well within 1GHz, but I'm interested in hearing about it just to learn more.

hey @Andy Geppert then thats what we will do! Seeing if we have any questions off that bat, then we will get into spilling out the knowledge

hey @Andy Geppert then thats what we will do! Seeing if we have any questions off that bat, then we will get into spilling out the knowledge

Super easy question. What does "finishes" mean? Are we talking about solder mask here?

Super easy question. What does "finishes" mean? Are we talking about solder mask here?

@Elijah is going to copy/paste some stuff in as an overview and then we'll hit the questions.

@Elijah is going to copy/paste some stuff in as an overview and then we'll hit the questions.

Alrighty guys, im going to start dropping info here while mark answers your questions

Alrighty guys, im going to start dropping info here while mark answers your questions

So to start off.....When selecting your PCB finish, the main concern should be connectivity between the PCB and your components. Are you trying to temporarily protect the copper from oxidation (lower end finishes), or are we establishing the foundation of the connection with higher end finishes?

So to start off.....When selecting your PCB finish, the main concern should be connectivity between the PCB and your components. Are you trying to temporarily protect the copper from oxidation (lower end finishes), or are we establishing the foundation of the connection with higher end finishes?

As you select higher end finishes, the assembly process should become easier. The solder yield and the shelf life will also increase.

I should have asked first, is there a spreadsheet somewhere for entering questions?

I should have asked first, is there a spreadsheet somewhere for entering questions?

@MS-BOSS @guido.giunchi Let's revisit high speed after Elijah's quick once-over.

@MS-BOSS @guido.giunchi Let's revisit high speed after Elijah's quick once-over.

@Audi McAvoy - Nope, just shoot out the questions right here

@Audi McAvoy - Nope, just shoot out the questions right here

We will be covering these main finishes, but we are open to helping you however we can:

We will be covering these main finishes, but we are open to helping you however we can:

OSP, HASL/HASL-LeadFree, Immersion Tin (White Tin), Immersion Silver, ENIG, ENEPIG

OSP, HASL/HASL-LeadFree, Immersion Tin (White Tin), Immersion Silver, ENIG, ENEPIG

So the "finishes" are the last steps in PCB fabrication -- the outer layers. Most of the time that is referring to how the PCB is prepared for assembly.

So the "finishes" are the last steps in PCB fabrication -- the outer layers. Most of the time that is referring to how the PCB is prepared for assembly.

So lets start with HASL and HASL-LeadFree finishes:

So lets start with HASL and HASL-LeadFree finishes:

![]() So it is before the solder mask?

So it is before the solder mask?

HASL stands for HOT AIR SOLDER LEVEL. This is the cheapest option due to it being the most common finish used in the PCB industry. A coating of molten solder is applied to the exposed copper, then the excess solder is removed with a hot air “knife”.

HASL stands for HOT AIR SOLDER LEVEL. This is the cheapest option due to it being the most common finish used in the PCB industry. A coating of molten solder is applied to the exposed copper, then the excess solder is removed with a hot air “knife”.

Copper is a great material to work with -- but, like a lot of materials, it oxidizes quickly. So you have to do something to prevent the oxidation.

Copper is a great material to work with -- but, like a lot of materials, it oxidizes quickly. So you have to do something to prevent the oxidation.

Some are before, some are after depending on the procedure

Some are before, some are after depending on the procedure

@Mark J Hughes do you have a picture of a PCB before and after finish is applied to make it clearer for @Audi McAvoy (and myself?)

@Mark J Hughes do you have a picture of a PCB before and after finish is applied to make it clearer for @Audi McAvoy (and myself?)

Assembly is the process of "soldering" parts on the board.

Assembly is the process of "soldering" parts on the board.

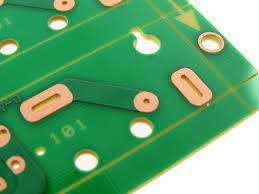

here is bare copper (no finish has been applied yet

here is bare copper (no finish has been applied yet

And the solder-resist layer forces the solder to stay put

And the solder-resist layer forces the solder to stay put

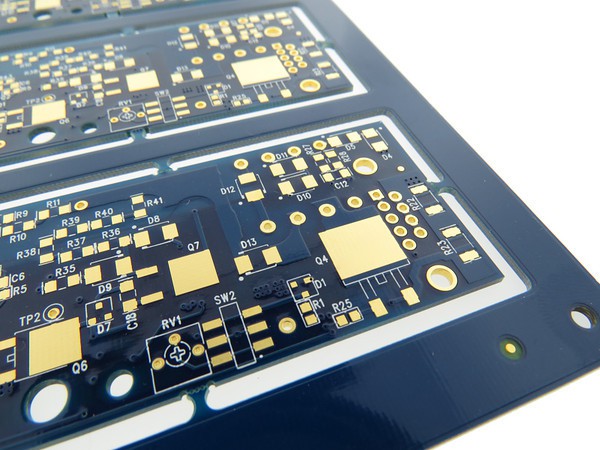

and here is a board with ENIG finish applied

and here is a board with ENIG finish applied

I can see this chat is going to get away from us quickly.

I can see this chat is going to get away from us quickly.

lol

lol

Thanks! It's okay Mark you got and Elijah got it, it usually gets like this :)

Thanks! It's okay Mark you got and Elijah got it, it usually gets like this :)

Ah. I never knew the finish was applied after the mask. I guess that kind of makes sense.

Ah. I never knew the finish was applied after the mask. I guess that kind of makes sense.

Here are the pros and cons of HASL finish:

Here are the pros and cons of HASL finish:

Pros: Cheapest Price option, 12+ month shelf life (considered great), handles contact fairly well, good solderability, great protection over copper, available in Lead-Free for the environmentally cautious.

Pros: Cheapest Price option, 12+ month shelf life (considered great), handles contact fairly well, good solderability, great protection over copper, available in Lead-Free for the environmentally cautious.

The whole point of a surface finish is to prevent oxidation before assembly.

The whole point of a surface finish is to prevent oxidation before assembly.

Cons: The surface is very uneven which can prevent solder paste printers from being used, high process temperatures, RoHS restrictions and environmental issues with Leaded-HASL, not wire-bondable.

Cons: The surface is very uneven which can prevent solder paste printers from being used, high process temperatures, RoHS restrictions and environmental issues with Leaded-HASL, not wire-bondable.

![]() ENIG def please (and the other while you're at it)

ENIG def please (and the other while you're at it)

Even an oxide layer two or three atoms thick can prevent proper solder wetting and intermetallic formation.

Even an oxide layer two or three atoms thick can prevent proper solder wetting and intermetallic formation.

@Nicolas Tremblay Elijah is going to list several definitions off for us, including ENIG

@Nicolas Tremblay Elijah is going to list several definitions off for us, including ENIG

HASL is the cheapest option due to the fact that it is the most common finish used in the industry. We run it all day every day, so its the base price when considering your finish

HASL is the cheapest option due to the fact that it is the most common finish used in the industry. We run it all day every day, so its the base price when considering your finish

What is meant by "not wire-bondable?"

What is meant by "not wire-bondable?"

@Andy Gepp

@Andy Gepp

Next is OSP finish:

Next is OSP finish:

OSP Finish: (Organic Solderability Preservative)

OSP Finish: (Organic Solderability Preservative)

OSP is another cheap option where a clear, thin, organic layer is applied. Its main function is really only to preserve the copper up until the assembly process. This is probably the easiest finish as far as PCB production is concerned.

Pros: Easy manufacturing keeps costs low

Pros: Easy manufacturing keeps costs low

Cons: The clear appearance is difficult to inspect, the thin coat is sensitive to handling (should be avoided), < 6 month shelf life, not wire-bondable. The bare copper is exposed once the OSP is removed, which is subject to oxidation.

Cons: The clear appearance is difficult to inspect, the thin coat is sensitive to handling (should be avoided), < 6 month shelf life, not wire-bondable. The bare copper is exposed once the OSP is removed, which is subject to oxidation.

So OSP is really only used for cheap, quick turn / early proto type boards.

So OSP is really only used for cheap, quick turn / early proto type boards.

Next finish is Immersion Tin:

Next finish is Immersion Tin:

Immersion Tin:

Immersion Tin:

Tin is applied through a chemical reaction, over the copper surface layer. Its works well in protecting copper from oxidation but its reaction to copper also causes it to tarnish, lowering the shelf life and performance.

Pros: Lead-Free, flat surface is ideal for assembly, high reliability, cost effective.

Pros: Lead-Free, flat surface is ideal for assembly, high reliability, cost effective.

Cons: 3-6 month shelf life (considered low), limited rework, handling should be avoided, reaction to copper lowers its performance over time.

Cons: 3-6 month shelf life (considered low), limited rework, handling should be avoided, reaction to copper lowers its performance over time.

@Andy Geppert Sometimes IC Dies are put right on the board (no epoxy packaging) and gold wires are taken off the IC and put on the PCB. I believe they are ultrasonically bonded or laser welded to the surface. The gold wires, or gold-coated wires need to "bond" or mechanically/chemically connect to the pads. Then the whole thing is covered in an epoxy blob for a "blob on board" process.

@Andy Geppert Sometimes IC Dies are put right on the board (no epoxy packaging) and gold wires are taken off the IC and put on the PCB. I believe they are ultrasonically bonded or laser welded to the surface. The gold wires, or gold-coated wires need to "bond" or mechanically/chemically connect to the pads. Then the whole thing is covered in an epoxy blob for a "blob on board" process.

If it isn't wire-bondable, the wires from the die won't stick to the PCB.

If it isn't wire-bondable, the wires from the die won't stick to the PCB.

Immersion tin comes with roughly 10% cost increase

Immersion tin comes with roughly 10% cost increase

Next is Immersion Silver: Immersion Silver is applied through a chemical reaction over the copper surface. It is a middle ground for pricing, which is helping gain popularity in the industry. It does not react to copper like Immersion Tin, although the silver does tarnish when exposed to air. Anti-tarnish packaging must be used when handling immersion silver finish.

Next is Immersion Silver: Immersion Silver is applied through a chemical reaction over the copper surface. It is a middle ground for pricing, which is helping gain popularity in the industry. It does not react to copper like Immersion Tin, although the silver does tarnish when exposed to air. Anti-tarnish packaging must be used when handling immersion silver finish.

Okay -- now for the "high-speed" guys.

Okay -- now for the "high-speed" guys.

Pros: Excellent solderability, provides a flat surface which is ideal for assembly, aluminum wire-bondable, 6-12 month shelf life with proper storage conditions

Pros: Excellent solderability, provides a flat surface which is ideal for assembly, aluminum wire-bondable, 6-12 month shelf life with proper storage conditions

Cons: Sensitive to handling (MUST be avoided), solder within 24 hours once removing from the packaging.

This gets complicated.

This gets complicated.

Yes tipically it's ultrasonic wire bonding. Once I soldered a pad meant to be wire bonded and I had to attach a golden lead for the bonder to work

Yes tipically it's ultrasonic wire bonding. Once I soldered a pad meant to be wire bonded and I had to attach a golden lead for the bonder to work

Here is ENIG:Electroless Nickel Immersion Gold

Here is ENIG:Electroless Nickel Immersion Gold

The initial copper layer is coated with nickel, the nickel is then coated with a thin layer of Gold. The acts as a diffusion barrier during soldering, while the gold provides excellent protection from the nickel oxidizing.

Pros: Very common = price is manageable, 12+ month shelf life (excellent), excellent solderability, aluminum wire-bondable.

Pros: Very common = price is manageable, 12+ month shelf life (excellent), excellent solderability, aluminum wire-bondable.

Cons: The electroless nickel can have unwanted magnetic properties, not gold wire-bondable.

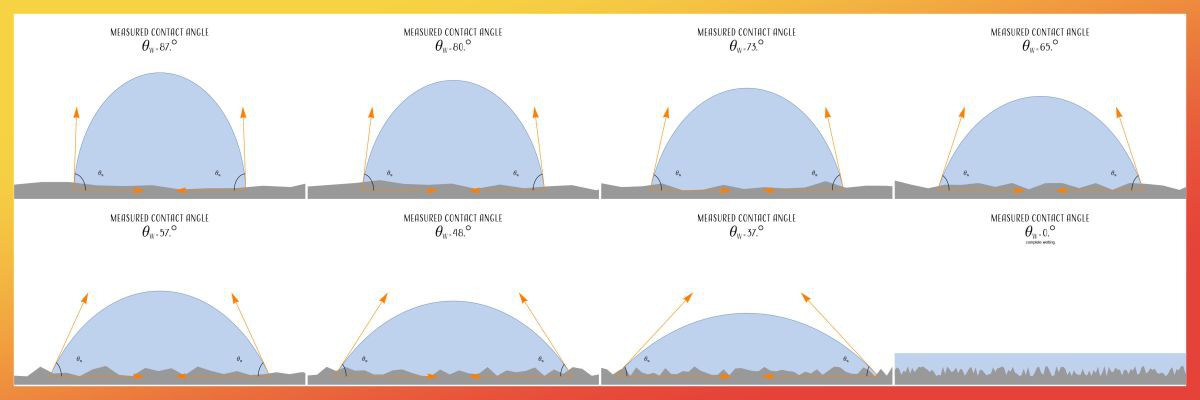

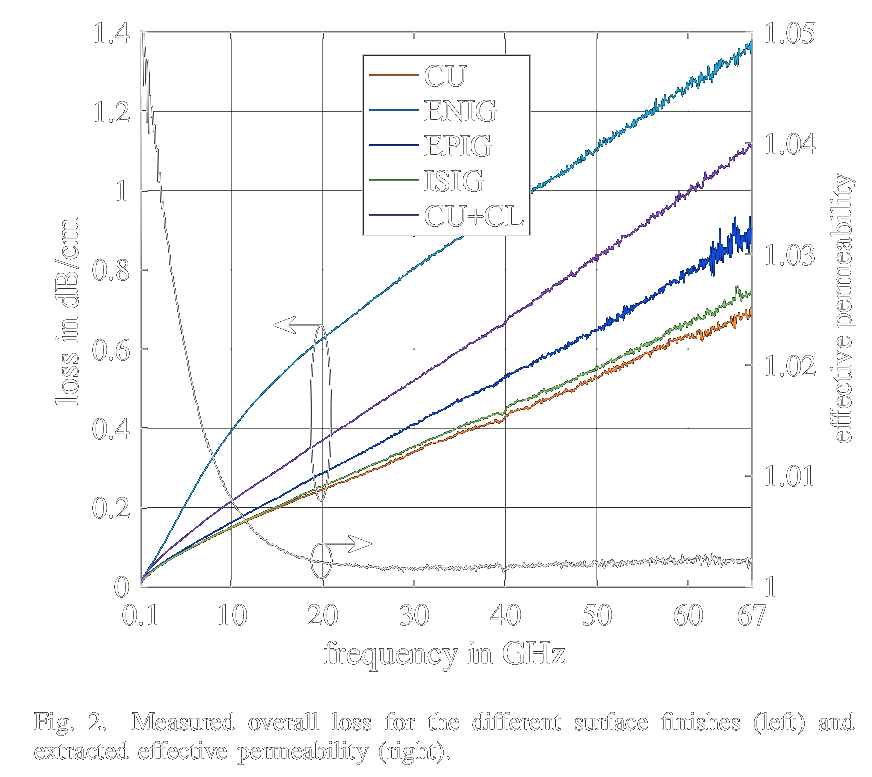

The surface roughness affects wettability. It also affects the dissipation of high speed signal energy into the surrounding environment.

The surface roughness affects wettability. It also affects the dissipation of high speed signal energy into the surrounding environment.

Last we have ENEPIG:Electroless Nickel Electroless Palladium Immersion Gold

Last we have ENEPIG:Electroless Nickel Electroless Palladium Immersion Gold

Similar to the ENIG procedure but after Nickel, a layer of electroless palladium is added. Then gold is applied on top. The palladium acts as additional protection to prevent copper diffusion to the surface.

Pros: Superior solderability, palladium provides additional protection, gold wire-bondable, flat surface, 12+ month shelf life.

Cons: Palladium causes a weaker bond with tin/lead solders.

So there is the basic info, how can we help?

So there is the basic info, how can we help?

So you've got to find the right balance of "roughness" to allow the solder to wet, but not too rough so that you're not dissipating your energy into the environment.

So you've got to find the right balance of "roughness" to allow the solder to wet, but not too rough so that you're not dissipating your energy into the environment.

And any questions asked while we were typing all that were probably lost. So ask again.

And any questions asked while we were typing all that were probably lost. So ask again.

Or followups.

Or followups.

How does the coplanarity of OSP and Immersion Tin compare to ENIG?

How does the coplanarity of OSP and Immersion Tin compare to ENIG?

What is your "to go" choice for general purpose? Prototype or finished products

What is your "to go" choice for general purpose? Prototype or finished products

@Elijah how much more expensive is ENIG than HASL?

@Elijah how much more expensive is ENIG than HASL?

There is one problem with finishes containing nickel like ENIG and ENEPIG, since nickel is ferromagnetic. Its material resonance happens between 2 and 3 Ghz, no matter how you design the PCB. Therefore it has high losses at microwave frequencies above 2 GHz.

There is one problem with finishes containing nickel like ENIG and ENEPIG, since nickel is ferromagnetic. Its material resonance happens between 2 and 3 Ghz, no matter how you design the PCB. Therefore it has high losses at microwave frequencies above 2 GHz.

@Audi McAvoy Immersion Tin is the worst for coplanarity -- so you should really use a solder-paste printer during assembly, as opposed to a solder stencil. ENIG and OSP are flat -- OSP is prone to handling damage and a shorter shelf life.

@Audi McAvoy Immersion Tin is the worst for coplanarity -- so you should really use a solder-paste printer during assembly, as opposed to a solder stencil. ENIG and OSP are flat -- OSP is prone to handling damage and a shorter shelf life.

I'm curious about maximizing shelf life for "maker" (or rapid prototyping) circuit boards, where the PCB has already gone through 1 or 2 reflow steps to solder SMT part. Then it sits on a shelf for months, or even years, before a user hand solders wires or through hole parts. What can be done to maximize the solderability if a maker buys the PCB, leaves it in a box of parts for 4 years, then tries to use for it for project?

I'm curious about maximizing shelf life for "maker" (or rapid prototyping) circuit boards, where the PCB has already gone through 1 or 2 reflow steps to solder SMT part. Then it sits on a shelf for months, or even years, before a user hand solders wires or through hole parts. What can be done to maximize the solderability if a maker buys the PCB, leaves it in a box of parts for 4 years, then tries to use for it for project?

HASL or HASL Lead Free are solid options for "general purpose" PCBs. They are highly reliable. For your final product, you might want to consider ENIG for long term reliability

HASL or HASL Lead Free are solid options for "general purpose" PCBs. They are highly reliable. For your final product, you might want to consider ENIG for long term reliability

@guido.giunchi That depends on your assembly process. If you are hand soldering, go HASL. If you are using stencils, do not use HASL.

@guido.giunchi That depends on your assembly process. If you are hand soldering, go HASL. If you are using stencils, do not use HASL.

@guido

@guido

@guido.giunchi solder-stencil applications really require a high-coplanarity finish -- so use ENIG or ENEPIG. if your assembly house has a solder-paste printer (think ink-jet printer) you can use HASL and save some coin.

@guido.giunchi solder-stencil applications really require a high-coplanarity finish -- so use ENIG or ENEPIG. if your assembly house has a solder-paste printer (think ink-jet printer) you can use HASL and save some coin.

So to answer your question -- it depends on the capabilities of your assembly house and the assembly process.

So to answer your question -- it depends on the capabilities of your assembly house and the assembly process.

Thank you!

Thank you!

![]() If the assembly house is my basement, using a solder stencil, ENIG would probably be best?

If the assembly house is my basement, using a solder stencil, ENIG would probably be best?

@MS-BOSS Thanks for that!

@MS-BOSS Thanks for that!

@Evan Juras HASL is considered the "base price" in the industry. Your starting quote will almost always include HASL finish. ENIG comes with roughly a 10% price adder

@Evan Juras HASL is considered the "base price" in the industry. Your starting quote will almost always include HASL finish. ENIG comes with roughly a 10% price adder

This diagram could help show the high losses of ENIG.

This diagram could help show the high losses of ENIG.

Why does ENIG guarantee long term reliability? Once it's soldered it doesn't matter much.. Right?

Why does ENIG guarantee long term reliability? Once it's soldered it doesn't matter much.. Right?

@Paul Stoffregen There's no great answer to your question. That's going to end badly either way. The best hope is to place it in a low-oxygen low-humidity environment and uses a fiberglass brush to rescrub the pads as well as copius amounts of flux.

@Paul Stoffregen There's no great answer to your question. That's going to end badly either way. The best hope is to place it in a low-oxygen low-humidity environment and uses a fiberglass brush to rescrub the pads as well as copius amounts of flux.

graph changes from unreadable to pretty good when I hover my mouse over it (in case any else is squinting trying to read it)

graph changes from unreadable to pretty good when I hover my mouse over it (in case any else is squinting trying to read it)

@Paul Stoffregen Sorry, I didn't know that transparency in images is broken in chat.

@Paul Stoffregen Sorry, I didn't know that transparency in images is broken in chat.

just click to open it and it's shown with a dark background - worked well for me

just click to open it and it's shown with a dark background - worked well for me

@guido.giunchi What are you referring to? One part is it helps prevent oxidation and corrosion during storage.

@guido.giunchi What are you referring to? One part is it helps prevent oxidation and corrosion during storage.

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.