![]() Idea. A plastic bag, acting as an enclosure. Big enough and mobile enough to allow the tool moving around. Mild overpressure inside to keep it inflated to stay out of the way. Should contain the splatter.

Idea. A plastic bag, acting as an enclosure. Big enough and mobile enough to allow the tool moving around. Mild overpressure inside to keep it inflated to stay out of the way. Should contain the splatter.

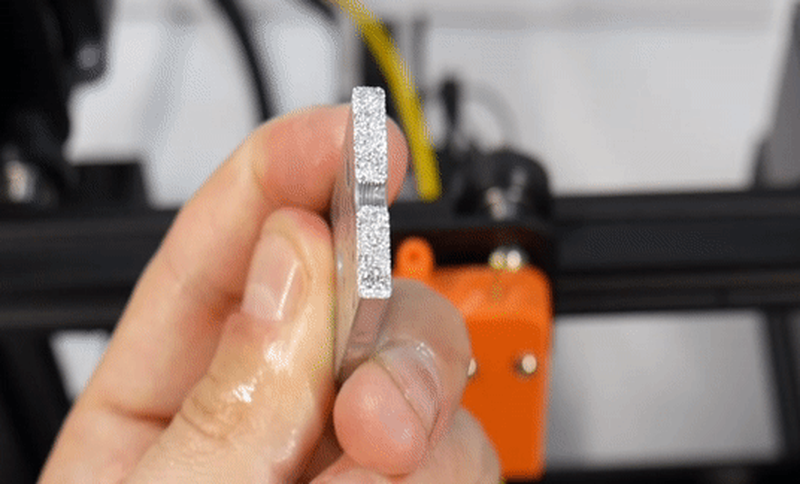

Thomas - not resin, but 3D printed plastic tooling I made:

Thomas - not resin, but 3D printed plastic tooling I made:

Yes. I've damaged expensive linear rails beyond repair with ECM

Yes. I've damaged expensive linear rails beyond repair with ECM

What do you use for the electrolyte? I think I saw sodium chloride is used sometimes?

What do you use for the electrolyte? I think I saw sodium chloride is used sometimes?

![]() Oh, that's sweet! I thought about printing a negative shape, you just deposit metal on top of a printout.

Oh, that's sweet! I thought about printing a negative shape, you just deposit metal on top of a printout.

![]() @Thomas Shaddack I have played around with using rubber sheeting, way covers, plastic bags, and tubing to try and protect RepRap ECM machines from electrolyte corrosion. It is very difficult because the hydrogen/oxygen forms water droplets as it escapes, carrying the corrosive and poisonous vapor around the room/machine.

@Thomas Shaddack I have played around with using rubber sheeting, way covers, plastic bags, and tubing to try and protect RepRap ECM machines from electrolyte corrosion. It is very difficult because the hydrogen/oxygen forms water droplets as it escapes, carrying the corrosive and poisonous vapor around the room/machine.

Yep! That was a few years ago though. I've since switched to EDM because I'm not shooting for nanometer precision

Yep! That was a few years ago though. I've since switched to EDM because I'm not shooting for nanometer precision

![]() Hence the plastic bag. A sealing membrane over the water-air interface. What could also work is some sort of covers over the rails/screws and keeping that at mild overpressure so the air current blows away the corrosive aerosols.

Hence the plastic bag. A sealing membrane over the water-air interface. What could also work is some sort of covers over the rails/screws and keeping that at mild overpressure so the air current blows away the corrosive aerosols.

![]() Would a layer of oil on the surface prevent the aerosolization?

Would a layer of oil on the surface prevent the aerosolization?

![]() For DIY J-ECM I used table salt and detergent too good effect. Perfect for micromachining aluminum.

For DIY J-ECM I used table salt and detergent too good effect. Perfect for micromachining aluminum.

I also used table salt when I experimented with JECM

I also used table salt when I experimented with JECM

![]() Does it leak under pressure or just trickles out? The latter can be approached in the similar way the dykes and dams are around big oil tanks in refineries, to contain the spills and redirect them where they can be handled easier.

Does it leak under pressure or just trickles out? The latter can be approached in the similar way the dykes and dams are around big oil tanks in refineries, to contain the spills and redirect them where they can be handled easier.

Plasma electrochemistry is no different than wet electrochemistry, just dealing with water for cooling and ions. Gas mixtures just change the chemistry at the electrode. Electron and ion implantation and machining can be done in vacuum air or water. All these technologies are part of using electrons and ions and neutral particles for practical things.

Plasma electrochemistry is no different than wet electrochemistry, just dealing with water for cooling and ions. Gas mixtures just change the chemistry at the electrode. Electron and ion implantation and machining can be done in vacuum air or water. All these technologies are part of using electrons and ions and neutral particles for practical things.

![]() ion implantation IN WATER?!?

ion implantation IN WATER?!?

Thomas - bc of the high currents involved it is necessary to have very high flow to prevent boiling. Most leaks would result in a large spray or misting of electrolyte

Thomas - bc of the high currents involved it is necessary to have very high flow to prevent boiling. Most leaks would result in a large spray or misting of electrolyte

![]() The nonscalable approaches can still have merits for one-off DIY-class component.

The nonscalable approaches can still have merits for one-off DIY-class component.

![]() ARGH. The high flow is the fly in the ointment.

ARGH. The high flow is the fly in the ointment.

What kind of control systems are needed for the ECM process? I know EDM needs pretty tight control to keep the arc consistent, but it seems like ECM might be a "kinder, gentler" process

What kind of control systems are needed for the ECM process? I know EDM needs pretty tight control to keep the arc consistent, but it seems like ECM might be a "kinder, gentler" process

If you can think of it, and search, you will find many people who have been at it for decades. I started with electrochemistry 55 years ago. The learned electrodynamics and try to keep up with all 3D scanning and replication technologies.

If you can think of it, and search, you will find many people who have been at it for decades. I started with electrochemistry 55 years ago. The learned electrodynamics and try to keep up with all 3D scanning and replication technologies.

![]() Sadly, the organic additives are very hard to get for DIY folks, so it is not too useful for small scale ECM attempts

Sadly, the organic additives are very hard to get for DIY folks, so it is not too useful for small scale ECM attempts

John - this is true. I've had great success with EDM using plain old tap water

John - this is true. I've had great success with EDM using plain old tap water

![]() What are the additives? There are DIY chemists of NileRed class out there, and you can get to anyone through six degrees of separation through friend-of-a-friend networking.

What are the additives? There are DIY chemists of NileRed class out there, and you can get to anyone through six degrees of separation through friend-of-a-friend networking.

![]() How about stability of electrolyte over time? It last long, need to be replace over some time or something else?

How about stability of electrolyte over time? It last long, need to be replace over some time or something else?

For example, here's another pic of an EDM cut with tap water

For example, here's another pic of an EDM cut with tap water

![]() Can the electrolyte be regenerated? Get the dissolved metals out by plating them onto an electrode?

Can the electrolyte be regenerated? Get the dissolved metals out by plating them onto an electrode?

@Cooper If you are using tap water that is low conductivity. So it is closer to doing EDM which is just electrical machining in air or gas. If you use distilled water and circulate, it might be close to EDM but cooler.

@Cooper If you are using tap water that is low conductivity. So it is closer to doing EDM which is just electrical machining in air or gas. If you use distilled water and circulate, it might be close to EDM but cooler.

![]() Can the bugbear Cr(VI) be reduced electrochemically, possibly to chromium itself? Possibly using a membrane electrolyzer?

Can the bugbear Cr(VI) be reduced electrochemically, possibly to chromium itself? Possibly using a membrane electrolyzer?

@RichardCollins The above pic is EDM, not ECM

@RichardCollins The above pic is EDM, not ECM

![]() so in principle similar to the systems used to keep pool water chemistry in balance, or handle the hydroponics solutions?

so in principle similar to the systems used to keep pool water chemistry in balance, or handle the hydroponics solutions?

@Cooper I was trying to explain that you can keep track of the conductivity and properties of the environment - water, air, gas, cryogenic gas, plasma, vacuum -- and treat all these with one set of equations. The cutting properties can be calculated from first principles for all of these methods - in any combination. Not just seat of the pants ball park guessing. And all the conditions for the cutting can be measured and monitored, and use for planning and optimization.

@Cooper I was trying to explain that you can keep track of the conductivity and properties of the environment - water, air, gas, cryogenic gas, plasma, vacuum -- and treat all these with one set of equations. The cutting properties can be calculated from first principles for all of these methods - in any combination. Not just seat of the pants ball park guessing. And all the conditions for the cutting can be measured and monitored, and use for planning and optimization.

![]() We don't have to be perfect. Let's aim for harm reduction instead of perfection. Perfect is a bad enemy of done.

We don't have to be perfect. Let's aim for harm reduction instead of perfection. Perfect is a bad enemy of done.

![]() @Daniel Herrington two things: Beckhoff PLC from as far as i know are very fast, so there is high chance that other controller not work as good.

@Daniel Herrington two things: Beckhoff PLC from as far as i know are very fast, so there is high chance that other controller not work as good.

For gap measuring: do you try measure gap capacitance?

I am not feeling well, I have to go. Thank you for the presentation.

I am not feeling well, I have to go. Thank you for the presentation.

Electrowinning is a big part of mining and refining processes, as I recall

Electrowinning is a big part of mining and refining processes, as I recall

Thomas - when it comes to harm reduction, why even take the chance with maker-tier ECM? I love using ECM, but it just hasn't been DIY friend IME

Thomas - when it comes to harm reduction, why even take the chance with maker-tier ECM? I love using ECM, but it just hasn't been DIY friend IME

![]() "Part is not made" is part of the harm equation on the "do nothing" side.

"Part is not made" is part of the harm equation on the "do nothing" side.

I love what it can do for aerospace and large scale manufacturing. Recently my experiences with EDM have been far more fruitful than years playing with low level ECM

I love what it can do for aerospace and large scale manufacturing. Recently my experiences with EDM have been far more fruitful than years playing with low level ECM

OK, wow -- that was a whirlwind chat! I've been wanting to do an ExM chat for a while, and this did not disappoint! I learned a ton, thanks so much Daniel for your insights here today. And thanks to everyone for the great questions and for sharing your experiences. I'm looking forward to a ton of new DIY projects in the ExM space!

OK, wow -- that was a whirlwind chat! I've been wanting to do an ExM chat for a while, and this did not disappoint! I learned a ton, thanks so much Daniel for your insights here today. And thanks to everyone for the great questions and for sharing your experiences. I'm looking forward to a ton of new DIY projects in the ExM space!

![]() @Cooper That is why I have been collaborating with you to make open source EDM a reality. I really enjoyed ECM, but it is not as fun or friendly as EDM

@Cooper That is why I have been collaborating with you to make open source EDM a reality. I really enjoyed ECM, but it is not as fun or friendly as EDM

![]() after I write I thought that maybe electrolyte because of being conductive is not perfect for capacitance. Try this: https://en.wikipedia.org/wiki/Spread-spectrum_time-domain_reflectometry :D

after I write I thought that maybe electrolyte because of being conductive is not perfect for capacitance. Try this: https://en.wikipedia.org/wiki/Spread-spectrum_time-domain_reflectometry :D

![]()

![]() Here is some early attempt I did with EDM for circuitboards. Handheld electrode under a drop of vegetable oil. Capacitor discharge at low voltage.

Here is some early attempt I did with EDM for circuitboards. Handheld electrode under a drop of vegetable oil. Capacitor discharge at low voltage.

![]()

https://www.improwis.com/projects/method_EDMdischargeCircuitboardEtching/

Method under development - EDM machining of circuitboards

A printed circuit board is a heart of modern electronics. There are many ways to make one at home - photoresist, laser engraved resist, manual scribing, CNC milling, and others... and all of them suck in one or another way, mostly by requiring costly precursors, machines, or being finicky and prone to process variables.

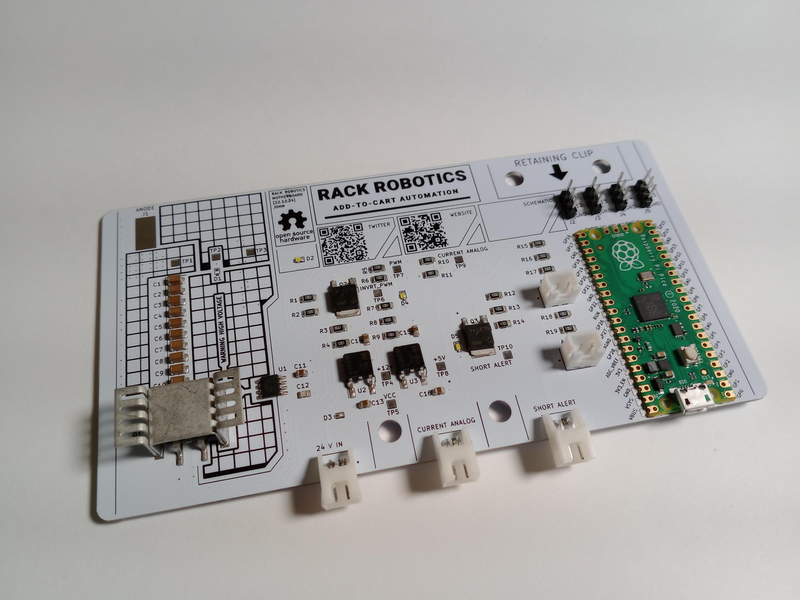

![]() Cooper and I will be releasing our open source EDM motherboard soon. We want everyone to have the power to machine metal at home, on their own 3D printer

Cooper and I will be releasing our open source EDM motherboard soon. We want everyone to have the power to machine metal at home, on their own 3D printer

Thanks for stopping by, Daniel

Thanks for stopping by, Daniel

You bet, thanks so much for your time today. I really appreciate it!

You bet, thanks so much for your time today. I really appreciate it!

Thanks!

Thanks!

Great chat everyone! Transcript coming up...

Great chat everyone! Transcript coming up...

![]() Thank You for Your time :)

Thank You for Your time :)

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.