Slant 3D 3:05 PM

What's up yall. sorry about that. Gabe Bentz here

|

|

addodesign 3:05 PM

Hello everyone

|

Slant 3D 3:05 PM

Hows it going Dan?

|

Kaushlesh C. ( KD9VFU ) 3:05 PM

Hi Gabe & Chris.

|

eeprom 3:05 PM

Good afternoon!

|

|

mbrown 3:06 PM

Is there a presentation that will accompany the chat?

|

Dan Maloney 3:06 PM

Great, and welcome to the chat! Can you kick us off with a little background info on yourself?

|

Slant 3D 3:06 PM

Well I was born on a dark stormy night...

|

Dan Maloney 3:06 PM

@mbrown - it's usually more of an AMA session, so if you've got questions, fire away

|

eeprom 3:06 PM

Thank you for your time today! Can you tell us from the experience you gained form Slant what features/specifications do you look for/must have in a printer to print in production mode reliably with a wide array of material support?

|

Slant 3D 3:07 PM

lol. Robotics engineer originally. Worked in product design for many years. Now Slant 3D focuses on makeing a warehouse when the shelves make the product

|

Slant 3D - Gabe Bentz 3:08 PM

We really don't consider any off-the-shelf machine to be viable for large scale print farms. Products targeted at consumers generally are not ideal for production

|

Mark J Hughes 3:08 PM

How are print prices calculated/estimated?

|

Kaushlesh C. ( KD9VFU ) 3:09 PM

@Mark J Hughes You stole my question. I dont have anything to ask now :)

|

Slant 3D - Gabe Bentz 3:09 PM

Pricing takes into account ~20 different variables. They include the obvious print time and material. But then take into account complexity and specific QC standards from the client that might increase rejection/recycling rate

|

John Vaccaro 3:09 PM

Is Slant 3D making its own printers, then?

|

Slant 3D - Gabe Bentz 3:10 PM

Yes. We only use our internally developed machines

|

eeprom 3:10 PM

Then what are your focus when designing a printer? Or is it too much information on the ''secret sauce''?

|

John Vaccaro 3:10 PM

and custom firmware as well, then

|

Mark J Hughes 3:10 PM

Do you have a DFM guide? So laypeople can make better design choices?

|

Slant 3D - Gabe Bentz 3:10 PM

Reliability and scalability are the driving goals. The details of the machine fall out from those north stars. A products should never be an amalgum of "features"

|

Nicolas Guilbert 3:11 PM

What makes off-the-shelf machines unviable for large scale production? Print quality?

|

Slant 3D - Gabe Bentz 3:11 PM

Our entire channel is really committed toward showing how to design real products for real mass production with 3d printing. https://www.youtube.com/channel/UC6QNjBn6KMq5-pe3OE11zZg

|

Kaushlesh C. ( KD9VFU ) 3:12 PM

Cost wise... how would 3d printing compare to injection molding, for small batches?

|

Slant 3D - Gabe Bentz 3:13 PM

Off-the-shelf machines are designed to become increasingly "user-friendly" which is not a design feature in mass production. The user in a production context has very different needs from a user in a garage. What is designed for a person can very rarely be used in a factory.

|

eeprom 3:14 PM

Is there a specific thing that you think is not though of enough when designing 3d printed products?

|

|

Thomas Shaddack 3:14 PM

Any specific show-stoppers for the off-the-shelf? What are some of the example differences?

|

Slant 3D - Gabe Bentz 3:14 PM

Our metric is that 3D Printing is generally a more cost effective alternative up to 100,000 units. But if a client commits to the process there is really no ceiling because the savings in shipping and wasted inventory make up for a potential higher unit cost with printing.

|

Slant 3D - Gabe Bentz 3:14 PM

Chamfers are not used enough in DFAM FDM

|

John Vaccaro 3:15 PM

Do you use the concept of "cells"? Grouping a few machines to share some common infrastructure?

|

Slant 3D - Gabe Bentz 3:15 PM

Bedslingers are a show-stopper for mass production

|

Carlo Clores 3:15 PM

What do you believe that bedslingers are a show-stopper for mass production?

|

Slant 3D - Gabe Bentz 3:15 PM

No cells. Fully distributed facilities. Our largest factory is speced for 3000 machines.

|

|

Thomas Shaddack 3:15 PM

Bedslingers suck even for home use.

|

Slant 3D - Gabe Bentz 3:16 PM

Older video on bed slingers: https://www.youtube.com/watch?v=iWHBH_T-xqI&t=1s&ab_channel=Slant3D

|

Slant 3D - Gabe Bentz 3:16 PM

Bedlsingers you are moving the foundation that you are printing on. It is like building a building during an earthquake

|

John Vaccaro 3:16 PM

How do you handle removing finished parts from a printer?

|

Slant 3D - Gabe Bentz 3:16 PM

Number of automation methods are used to remove parts wherever possible.

|

John Vaccaro 3:17 PM

Is post printing processing aslo automated?

|

Carlo Clores 3:18 PM

How do you do that? a robotic arm to remove the prints off the bed? Im assuming your machines are CoreXY

|

Slant 3D - Gabe Bentz 3:18 PM

Post processing is not always automated. For large quantities for small parts we might use tumbling. But for print on demand it is almost always people. But the good news is that as Dfam gets better Post processing also reduces.

|

|

Thomas Shaddack 3:18 PM

What materials are most common? Most troublesome? Also, any high-grade exotics like PEEK or PEI...?

|

Slant 3D - Gabe Bentz 3:18 PM

Our machines are not coreXY

|

Slant 3D - Gabe Bentz 3:19 PM

Exotics are not really viable for mass production because of the cost of the material and the demand are relatively low. We generally focus on more traditional materials that you would see in the molding.

|

Slant 3D - Gabe Bentz 3:19 PM

#molding industry

|

John Vaccaro 3:20 PM

Do your printers communicate over tcp/ip or a custom protocol? What is the connection medium? Ethernet?

|

Carlo Clores 3:20 PM

^building up on John's question, how do you manage large numbers of printers? You guys have an in-house farm management software?

|

Slant 3D - Gabe Bentz 3:20 PM

We have created a new methodology for communicating with all of them. Can't go too deep into it.

|

eeprom 3:21 PM

Is there anything that you've been wishing for for a long time, but can't find a good implementation yet? (could be software or hardware feature on the printer)

|

Vitor Boschi 3:21 PM

Do you think coreXY is bad for mass production, or you don't use just because what you have works fine?

|

Slant 3D - Gabe Bentz 3:21 PM

Yes we develop all of our own software. Most print farm management software unforutnately were not able to deal with the scale that we have to hit. Amazon ships 1.5 million products a day. To displace them as a form of distribution we need a minimum of 1.5 million 3D Printers

|

Mark J Hughes 3:21 PM

What do you wish your clients knew?

|

Nicolas Guilbert 3:22 PM

Can 3d print achieve the precision of injection molding (supposedly 10 microns)?

|

Slant 3D - Gabe Bentz 3:23 PM

CoreXY has some benefits. But it creates design restrictions that are not always helpful. The biggest of these is an elegant failure mode. You don't really notice as a belt goes loose so you can't realy maintain it. With other systems something like a loose belt really calls attention to itself.

|

|

Thomas Shaddack 3:24 PM

Could the failures be caught early by acoustic emissions of the machines? Microphones/vibration sensors in strategic positions, some neural network to classify pass and needs-attention?

|

Slant 3D - Gabe Bentz 3:24 PM

I think many clients don't realize the actual scale possible. As far as we are concerned molding is already dead. There are really no benefits it has that printing hasn't already matched

|

John Vaccaro 3:24 PM

So besides custom control, do you do maintenance tracking failure warnings, predictive failures, etc?

|

Kaushlesh C. ( KD9VFU ) 3:24 PM

Does your printing process have variable infill option? e.g. 15% on body, but 100% on standoffs for screws?

|

Slant 3D - Gabe Bentz 3:25 PM

Yes the precision is either already there or very achievable. In our operation we don't really target super high precision. There are billions of dollars of plastic components that can be printed with standard FDM.

|

Mark J Hughes 3:25 PM

Also -- maybe I missed it. You've said which types of printers you don't like (CoreXY, etc.) What type do you like?

|

Slant 3D - Gabe Bentz 3:25 PM

Acoustic failure tracking is a cool idea. We will have to look into that. But the system does track/control maintenance and has some predictive elements

|

eeprom 3:26 PM

At which part dimensions is 3d printing falling short compared to injection molding in term of large scale production?

|

Slant 3D - Gabe Bentz 3:26 PM

Yes. Every part of the process is tweaked to the needs of the clients. Though our API and shopify/etsy integrations are more restrictive to particular settings and colors.

|

|

Thomas Shaddack 3:27 PM

Microphones should be easy to add, many now have usb interface. The signatures can be collected froom running machines in advance and THEN write the software on them.

|

Dan Maloney 3:28 PM

@Thomas Shaddack Almost sounds like a job for machine learning. Train on the sounds of good printers, listen for variances from baseline

|

Slant 3D - Gabe Bentz 3:28 PM

Part dimensions is tough. I don't think there is a category that is uniquely protected in molding. Scale is still the deciding factory. Beyond 1 million units (if your tunrouver is fast enough) the challenges of molding become trivial. But we expect that few products in the future will pass 1 million units. Few products today pass 1 million. Toyota considered 25k mass production

|

|

martinandrewesser 3:30 PM

Any Tipps for what an Hobbyist can manufacture to sell on Etsy or a webstore ?

|

Slant 3D - Gabe Bentz 3:30 PM

Microphone are a bit like low grade vibration tracking. A more direct method would be utilizing accelerometers. If the architecture fo the machines transfers that vibration enough

|

|

Thomas Shaddack 3:30 PM

It *is* job for machine learning. Common in preventive maintenance of rotating machinery. Should work here too, judging from how an anomalous sound from the machine can tell me something is wrong.

|

|

Colin 3:30 PM

How smooth of a surface finish is reasonable with current 3d printing? Are there easy (low cost) post processes to improve surface finish?

|

Slant 3D - Gabe Bentz 3:31 PM

No good reccomendations from Etsy. Product creation is super risky. But Printing lets you play a numbers game. Today a designer can try 100 inventions to find the winner. Even 10 years ago a single try would cost thousands of dollars

|

Nicolas Guilbert 3:31 PM

On average, how often can you avoid support material?

|

Slant 3D - Gabe Bentz 3:31 PM

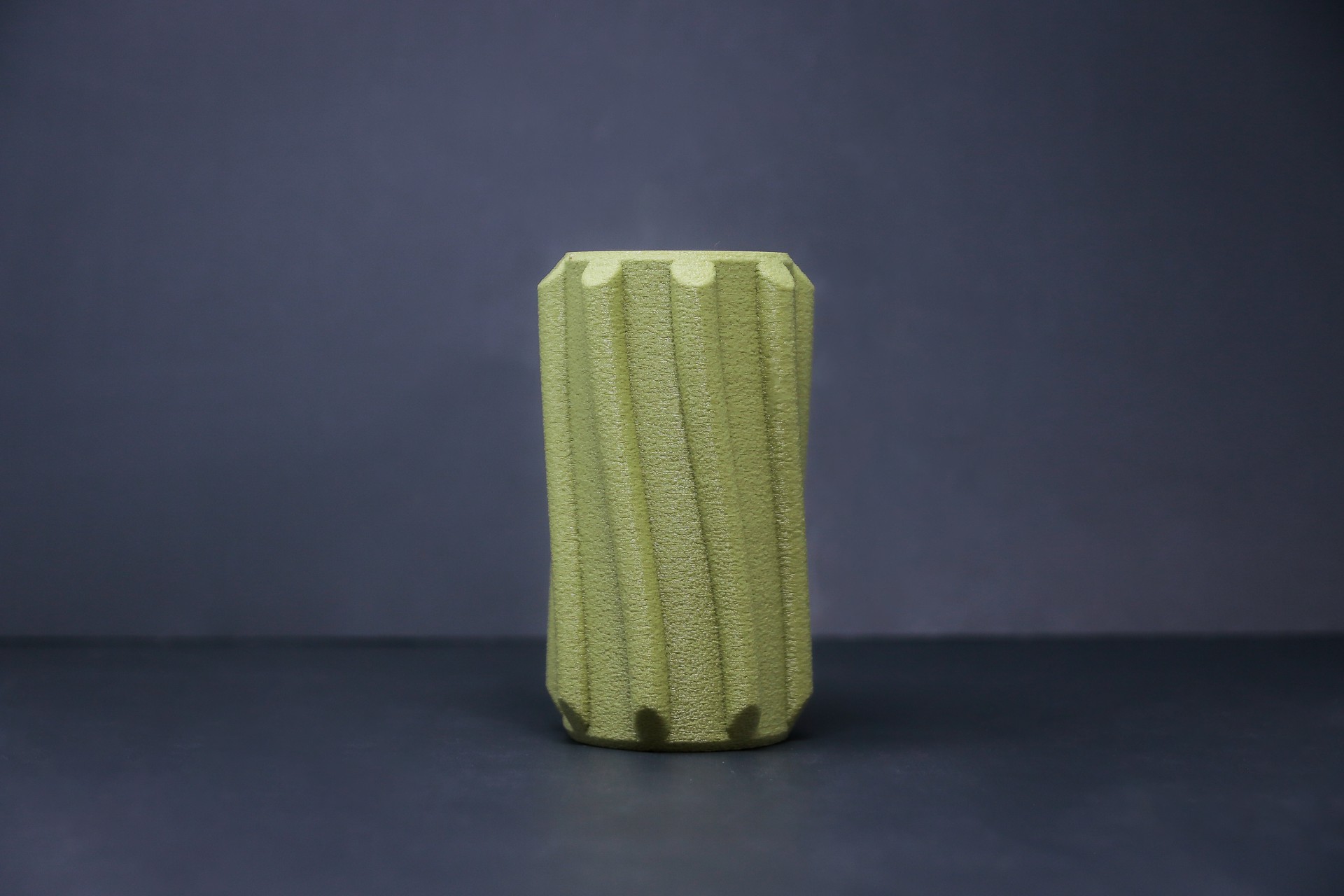

People don't use textures enough in 3D Printing. It is a super power and makes the virgin finish irrelevant

|

John Vaccaro 3:32 PM

Can you do paining and/or decorative work on finished pieces?

|

Mark J Hughes 3:32 PM

Textures?

|

Slant 3D - Gabe Bentz 3:32 PM

Support material can always be avoided completely. The question is how much design freedom do you have of the product. But somtimes all it takes is a 45 degree rotation

|

Kaushlesh C. ( KD9VFU ) 3:32 PM

And how does wasted plastic compare to molding. Do you have any way/process to recover the wasted plastic on supports or failed prints?

|

Slant 3D - Gabe Bentz 3:32 PM

We try to avoid post processing like painting as much as possible. It adds another layer of complexity to the production process.

|

anfractuosity 3:33 PM

Are your printers all FDM based?

|

Dan Maloney 3:33 PM

Re: textures -- the recent massage roller video mentions them, they look great. I think you once said it's done in the slicer by adding noise. Does that mean each piece is actually unique at the layer level?

|

eeprom 3:33 PM

What are you the most exited about looking at the future of 3d printing?

|

Slant 3D - Gabe Bentz 3:33 PM

15-25% of plastic products produced currently are never sold. That is the baseline waste. Printing should be able to reduce at least that much waste by removing the need for overproduction

|

Slant 3D - Gabe Bentz 3:35 PM

I am excited for the mainstream products that will be made with printing. The industry has been focusing on the machinery for too long. But no one has made the killer product that really utilizes the advantages of printing

|

|

Slant Media 3:35 PM

|

|

Slant Media 3:35 PM

|

|

Slant Media 3:35 PM

Some examples of the massage roller textures

|

Kaushlesh C. ( KD9VFU ) 3:38 PM

@Slant 3D Those look nice. Do you have a link with some type of galley of samples?

|

|

Thomas Shaddack 3:38 PM

What about multimaterial printing?

|

John Vaccaro 3:39 PM

Have you considered doing 3D printing including conductive materials to produce simple electronic devices?

|

|

Thomas Shaddack 3:40 PM

Even just capacitive sensors, or ECG/EMG contact arrays, won't need so much conductivity.

|

Slant 3D - Gabe Bentz 3:40 PM

Multimaterial is still a bit gimmicky. And if the goal is to match existing production processes multimaterial is not a standard anywhere else.

|

Slant 3D - Gabe Bentz 3:41 PM

Embedded devices are a great opportunity. But the product has to be created first. Otherwise making machines that can do it is simply a solution in search of a problem. Printing has that issue enough already.

|

Slant 3D - Gabe Bentz 3:42 PM

We don't use multimaterial internally either because most of the solutions increase opportunity of failure. Reliability trumps the feature.

|

Dan Maloney 3:42 PM

Question on distributing the work - if you have, say, 1,000 printers, you could either print 1,000 of one thing all in one shot, or use the printers to print 1,000 different parts. And obviously everything in between. How do you figure out what the right balance of resources is?

|

John Vaccaro 3:43 PM

Do you have an MRP system tied into your workflow?

|

Slant 3D - Gabe Bentz 3:43 PM

Distribution is always in development as we stress test it. This type of manufacturing is an entirely new paradigm so there are whole to methodologies to invent around production optimization

|

Slant 3D - Gabe Bentz 3:44 PM

We do have an MRP system

|

eeprom 3:44 PM

What is an acceptable rate of failure for a print farm to be profitable?

|

Slant 3D - Gabe Bentz 3:45 PM

Dan, The distribution is often highly biased toward just the timeline. But at peak demand that starts to break down.

|

Carlo Clores 3:45 PM

I know we've mentioned consumer grade printers earlier but what do you think of Bambulab printers? I know they've had issues with cloud services recently but what do you think of the overall machine design?

|

Slant 3D - Gabe Bentz 3:45 PM

Failure rate is not the main determing variable in profitability. But a reasonable factory should have a failure rate below 1%

|

Kaushlesh C. ( KD9VFU ) 3:45 PM

Do you have some supplycrowd type model? i.e. I have a product whiich uses an enclosure. On my site, I can give a link to slant3D, a customer orders the enclosure on Slant & pays you, and you print and ship it to the customer?

|

Nicolas Guilbert 3:46 PM

What material do you use mostly? ABS?

|

Slant 3D - Gabe Bentz 3:46 PM

Bambulab is a really cool company. Their backgrounds are perfect to make the machine that they did. But we don't consider them a viable machine in print farms since they are so consumer focused. But undoubtably larger farms will continue to be built around them.

|

|

salec 3:47 PM

Since you are using your own 3D printer designs, are you actively innovating FDM and do you have any patents of your own?

|

Slant 3D - Gabe Bentz 3:49 PM

Patents are not a very effective tool, unless you want to use them offensively. Since we don't sell our machines most of our innovations are able to remain as trade secrets.

|

Slant 3D - Gabe Bentz 3:49 PM

We are releasing a shopify app very soon that will allow you to sell prints on your site that we will then print and ship to your customer. Hopefully it will allow designers to focus on customers and making awesome products rather than having to change nozzles in a print farm

|

Slant 3D - Gabe Bentz 3:50 PM

Question for the group. What are topics in 3D Printing do you think are under explored.

|

Dan Maloney 3:50 PM

I recall a quote: "A patent is just a license to get sued."

|

Slant 3D - Gabe Bentz 3:50 PM

A patent is more of a liscense to sue. lol

|

Nicolas Guilbert 3:52 PM

Concerning under-explored topics: textures (that was new to me).

|

|

salec 3:52 PM

I share your disillusionment with patents, I was just interested to find out if you are innovators. I have some ideas (... are cheap ...) regarding FDM which I haven't had chance to bounce around.

|

Nicolas Guilbert 3:52 PM

Dont't textures make the STL files explode?

|

Dan Maloney 3:53 PM

@Slant 3D - One thing you haven't mentioned (I think) is design factors that make something unsuitable for injection molding

|

Slant 3D - Gabe Bentz 3:54 PM

TExtures can make a very large file. But the benefits they provide are enourmous. But they can also be added in the slicer settings. Ideamaker has a solution that used grayscale height maps. And there are options like fuzzy skin that are low bandwidth solutions also.

|

eeprom 3:55 PM

Personally a series explaining design choices on a printer from top to bottom would be great to a. understand how it works, b. make better choices when buying/building a printer.

|

Carlo Clores 3:55 PM

For me, under-explored is really the lack of standardization operations of print farms. You look at CNC machines, they have highly trained personnel from end-to-end, scheduled maintenance from professional millwrights. I hope to see 3D printers get the same attention.

|

|

salec 3:56 PM

The under explored topics in 3D Printing perhaps:

- how to achieve better volume rate (faster printing/printing larger objects in reasonable time)?

- how to achieve better adhesion between layers of print?

|

Slant 3D - Gabe Bentz 3:56 PM

Great question Dan. Molding has a ton of restrictions (just like any process). No thick features like over 1/4 inch, draft angles for ejection so you can't make a perfect cube, undercuts, no enslosed pockets. And of course the cost of the mold up front has to be factored into the design. That is a few of the big ones.

|

Slant 3D - Gabe Bentz 3:57 PM

Standardization is a big problem in the industry right now. But mainly because there are have been no big winners to set the standard. We are still really early on.

|

Slant 3D - Gabe Bentz 3:58 PM

The easiest way to get more volume is to add more machines.

|

|

salec 3:58 PM

Another unexplored: How to extend FDM to include removal (basically, move, reuse) of small portions of material, to combine material deposition with material removal?

|

John Vaccaro 3:58 PM

Perhaps DARPA and/or NIST have a role to play in driving standards for improved ease of procurement

|

|

Thomas Shaddack 3:59 PM

Would pellets have advantage over filaments in such volumes?

|

Steven McCulloch 3:59 PM

Another underexplored area - pellet printers. Probably great for mass-production since you'll never have to change filament. Just top up the hopper

|

Tom Nardi

Tom Nardi

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.