Over the last month or so i've been mulling over the options for the hardware / mechanics. I've decided to design around off-the-shelf components that I can get off ebay, laser cut flat materials and 3D printed components. As I only have 2ft x 2ft work area (not including the kitchen table) and basic hand tools at my disposal, something that has taken some adjustment.

The two primary rails for the print head are fixed, with four bearings with press fit 'tyres' that ensure that the base-board is the correct distance from the print head. Ive decided to use graphite brass bushings rather than linear bearings as the Chinese ones sound dreadful and i've only been able to source one SKF at a reasonable price so far.

Below them is another pair of rails held by bearings with a degree of adjustment capability to allow take up to the upper wheels. This pair are driven by a pair of 32T GT2 pulleys. The drive rollers will be 3D-printed bobbins with groves for o-rings that will provide grip to drive the base board through the printer.

The paper drive tension is adjusted by the slotted stepper mount and the head translate is tensioned by slotted mounts for the reduction pulley holder.

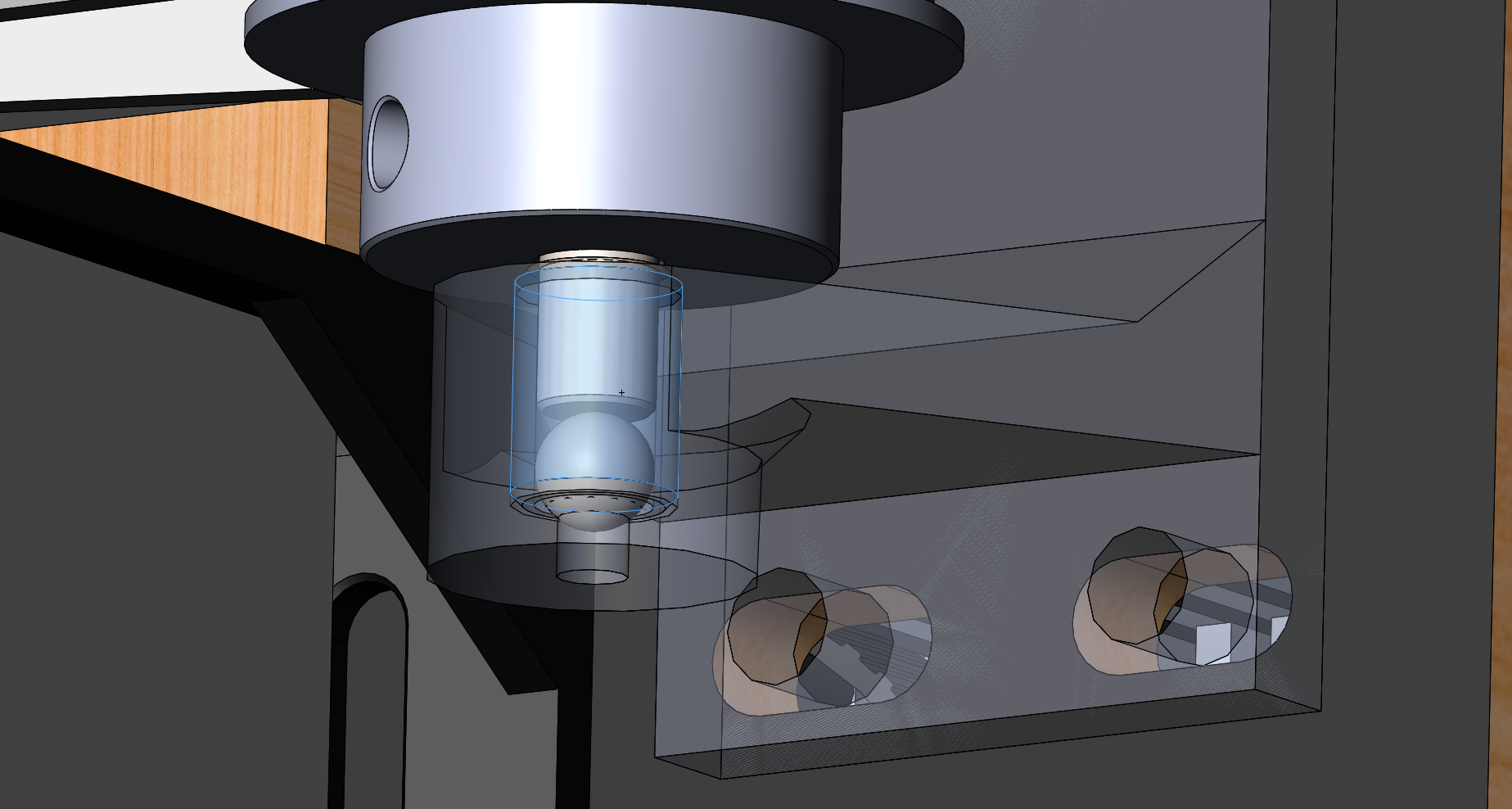

The pulleys are mounted via Teflon coated brass bushings using 3D printed holders with the lower end of the shaft resting on a ball bearing placed within the bore of the bushing; see below.

Bushing mount, bush and ball bearing supporting the shaft end.

The geometry for some of the mounts is not exact and will need updating from the actual components, once in hand.

David Brown

David Brown

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.