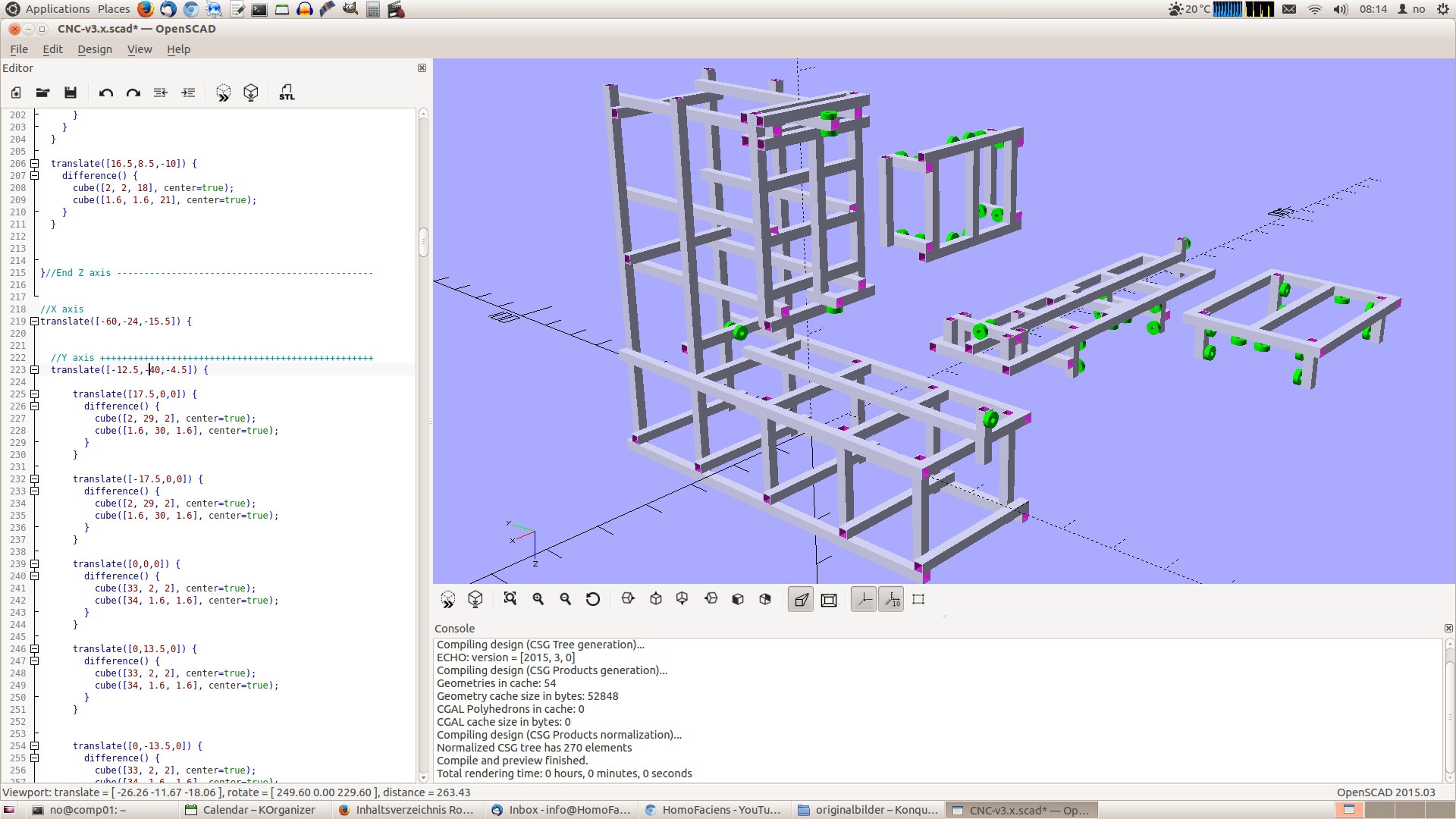

Time to build the mechanics of my CNC v3.x router. It's the first time ever I was using CAD software. The program of my choice is OpenSCAD, because I like typing source code rather than clicking with my mouse. The frame is made basically using 20x20mm steel square tubes:

With OpenSCAD I could quickly set the dimensions of the square tubes and prove if the carriages won't stuck on machine parts. It doesn't show how stiff the construction is. I will add struts and panellings where needed. The linkages are also not part of the OpenSCAD file. I will use screws and nuts of the dimensions 6mm and 4mm to join all parts.

45 ball bearings make it all run smoothly.

A CNC router is the mother of automation, but the first machine must be build without a CNC. Since the main idea of the CNC v3.x series is to keep it simple, nothing but a drill press, a vice, a hacksaw, taps, screwdriver and wrenches are needed to create the framework - no 3D printer, no CNC milled parts and no lathe.

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.