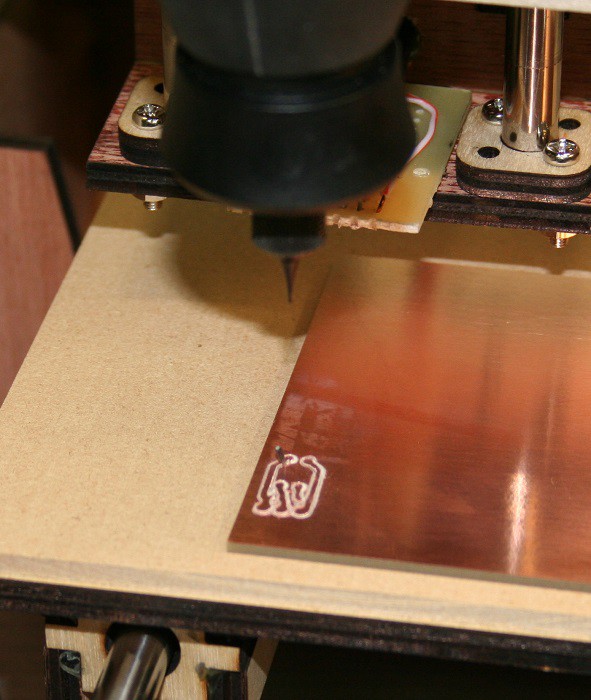

I made the first attempts at milling a PCB, I generated the G code with the pcbgcode ULP for Eagle. I also experimented with pcb2gcode program as well but it produced gcode that pronterface didn't seem to agree with. I will look into it more once I switch over to GRBL and see if it understands the compact gcode pcb2gcode appears to produce.

The first cut, pictured above, nearly worked, it got through 2 passes of the isolation milling, out of 4 then the bit broke. I was using a cheap cutter I had in a kit that was an elongated ball cutter with a pointed tip, it broke just behind the ball at the narrowest point in the shaft.

I tried twice more with diamond abrasive bits, which were the only other bits I had with small tips, they failed to remove copper and mostly just pushed it around.

Overall the mill seems to behave, the movements were good, it didn't drift during multiple passes. I just need to work out the appropriate cutting depth and cutters. I have a few 0.010in end mills on order that should arrive in a couple days, and a set of triangular engraving bits that will likely arrive in a week or so.

Until the new cutters arrive I will continue working on refining the cad models, and investigating the various tool chains. I am also going to start doing schematics and board design for the final electronics and probably start laser cutting updated parts for the second prototype as I finish the cad updates. I am planning to produce build instructions while I assemble the second prototype, which I should get through over the next couple weeks.

Wudagem

Wudagem

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.