I want to start by building a heated tube with piston and orifice. That way I can get a feel for what it takes to melt a bag and squeeze the plastic through a hole before I put too much effort into the rest of the design. For that purpose I acquired a couple of internally smooth steel pipes, and set to work making a heater.

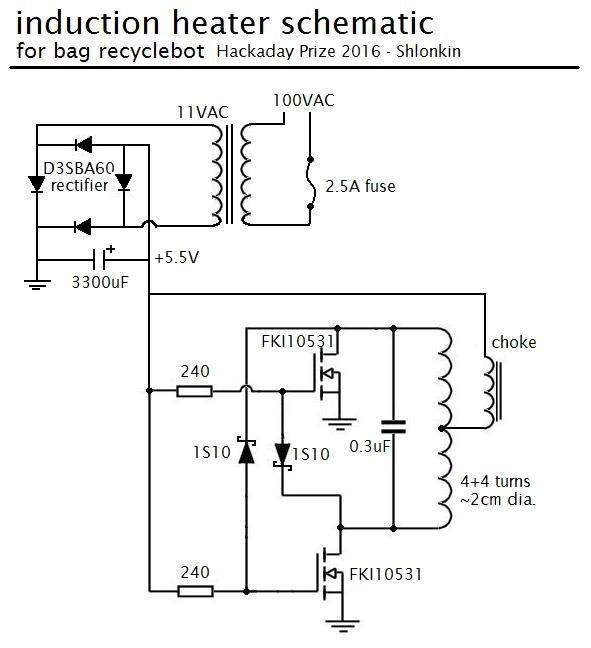

First, research induction heaters. There are many tutorials and videos about DIY heaters. One I found particularly useful was: http://www.rmcybernetics.com/projects/DIY_Devices/diy-induction-heater.htm . I based my design off theirs and even copied parts of their schematic, so I must give them some credit. Here is my schematic.

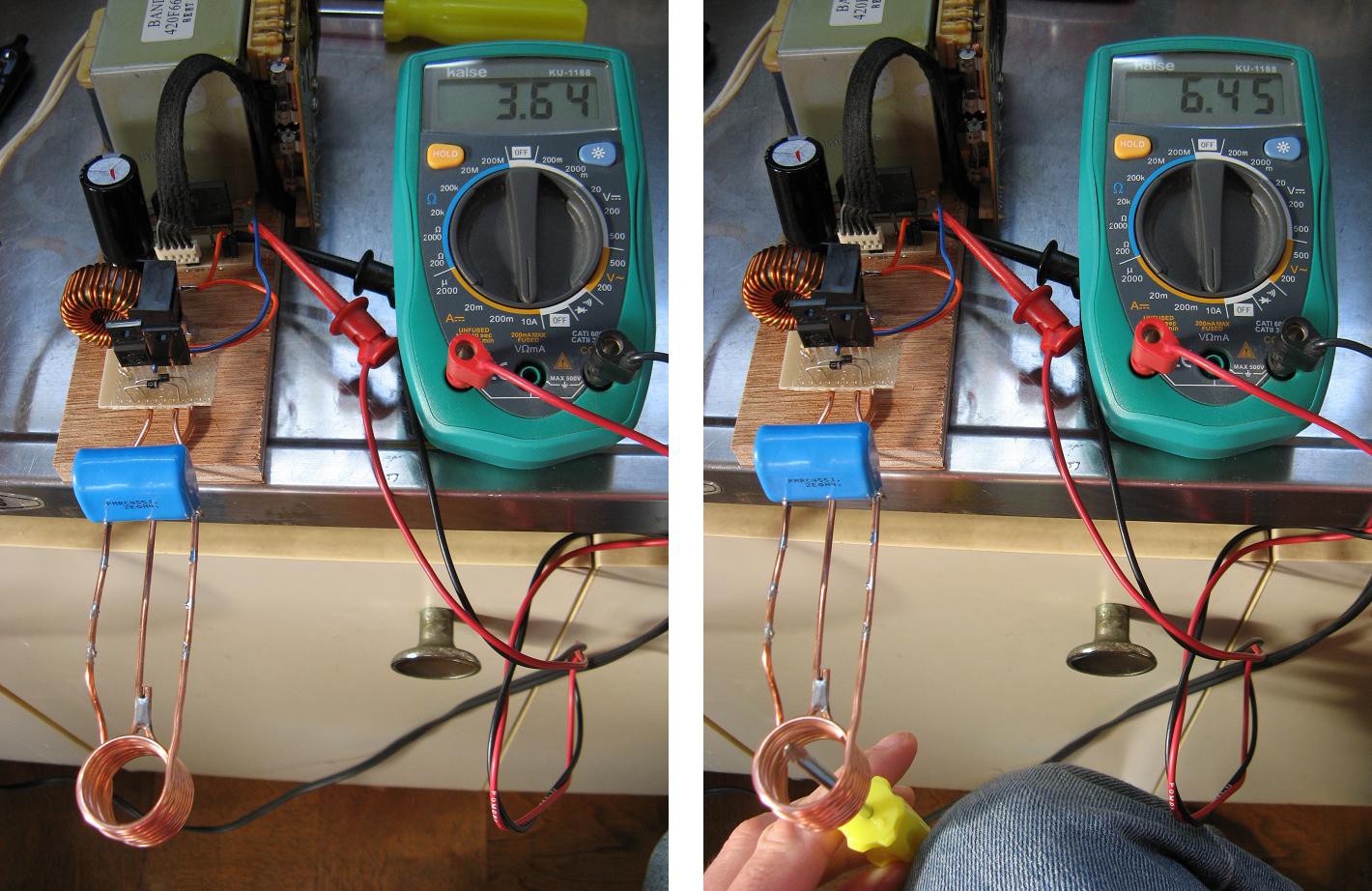

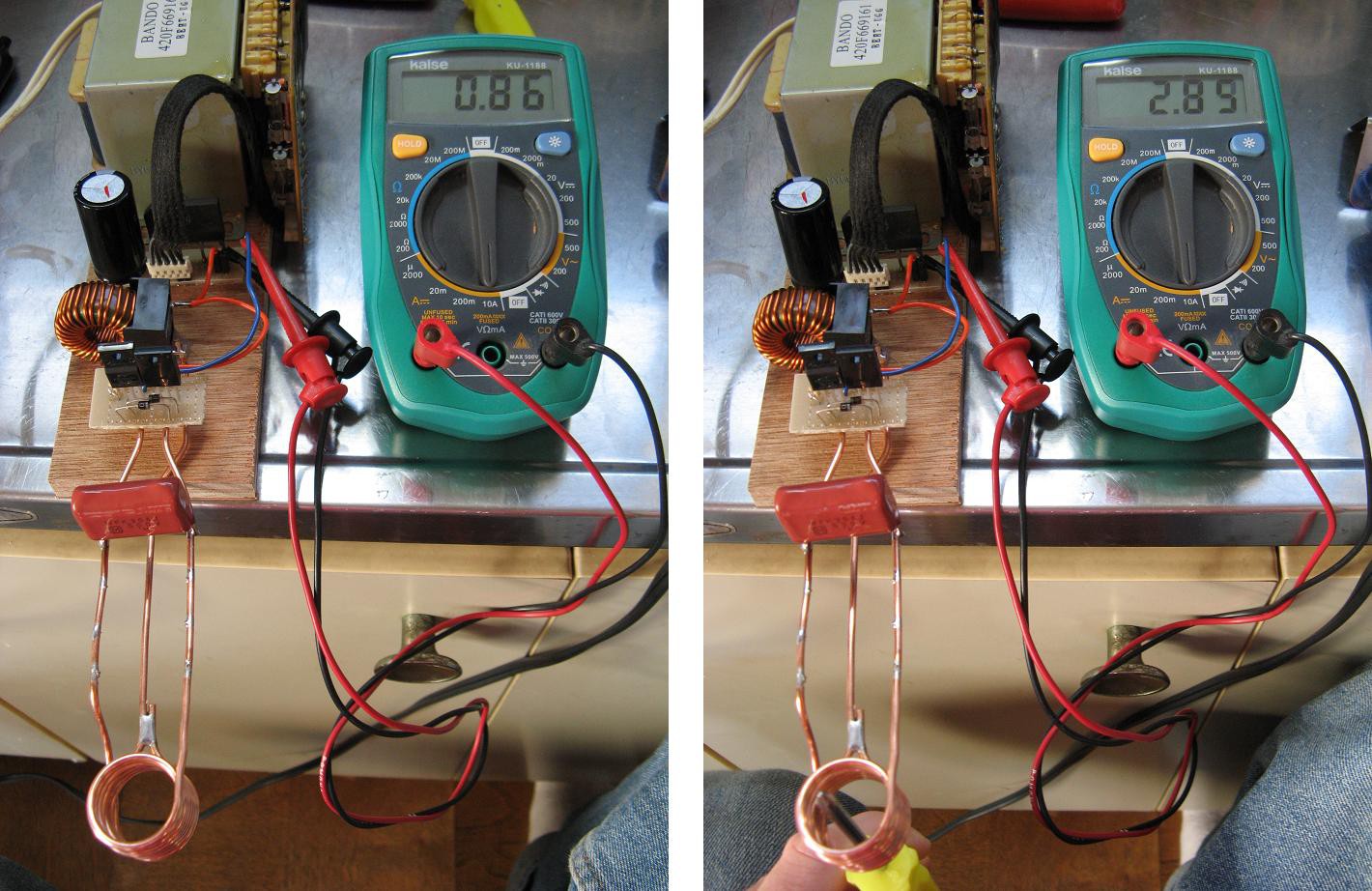

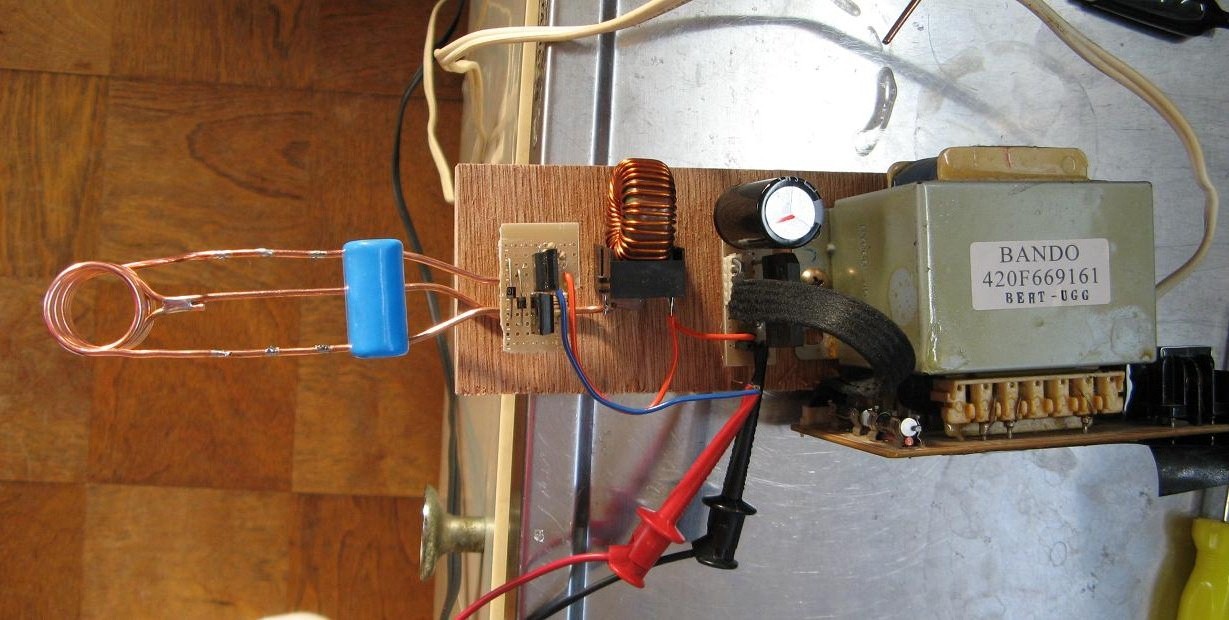

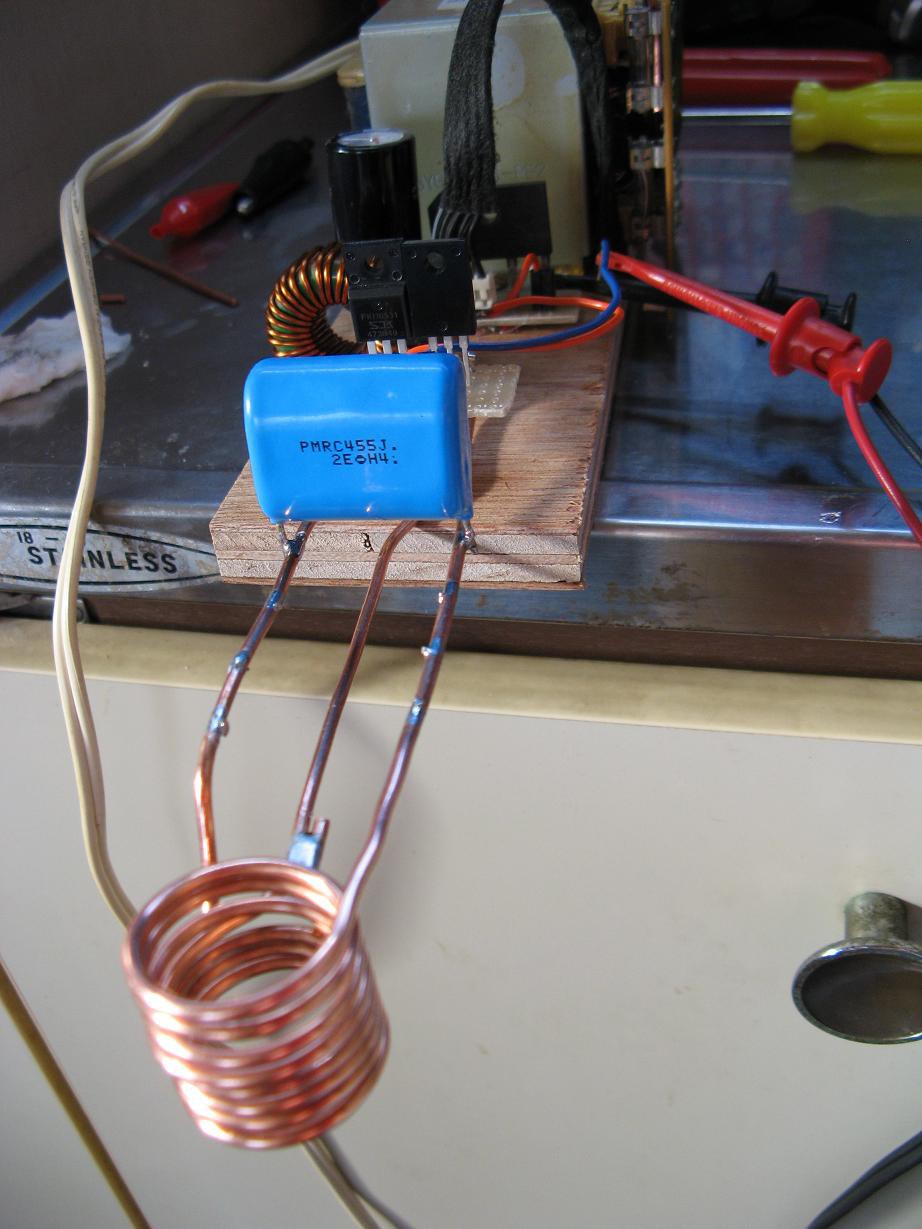

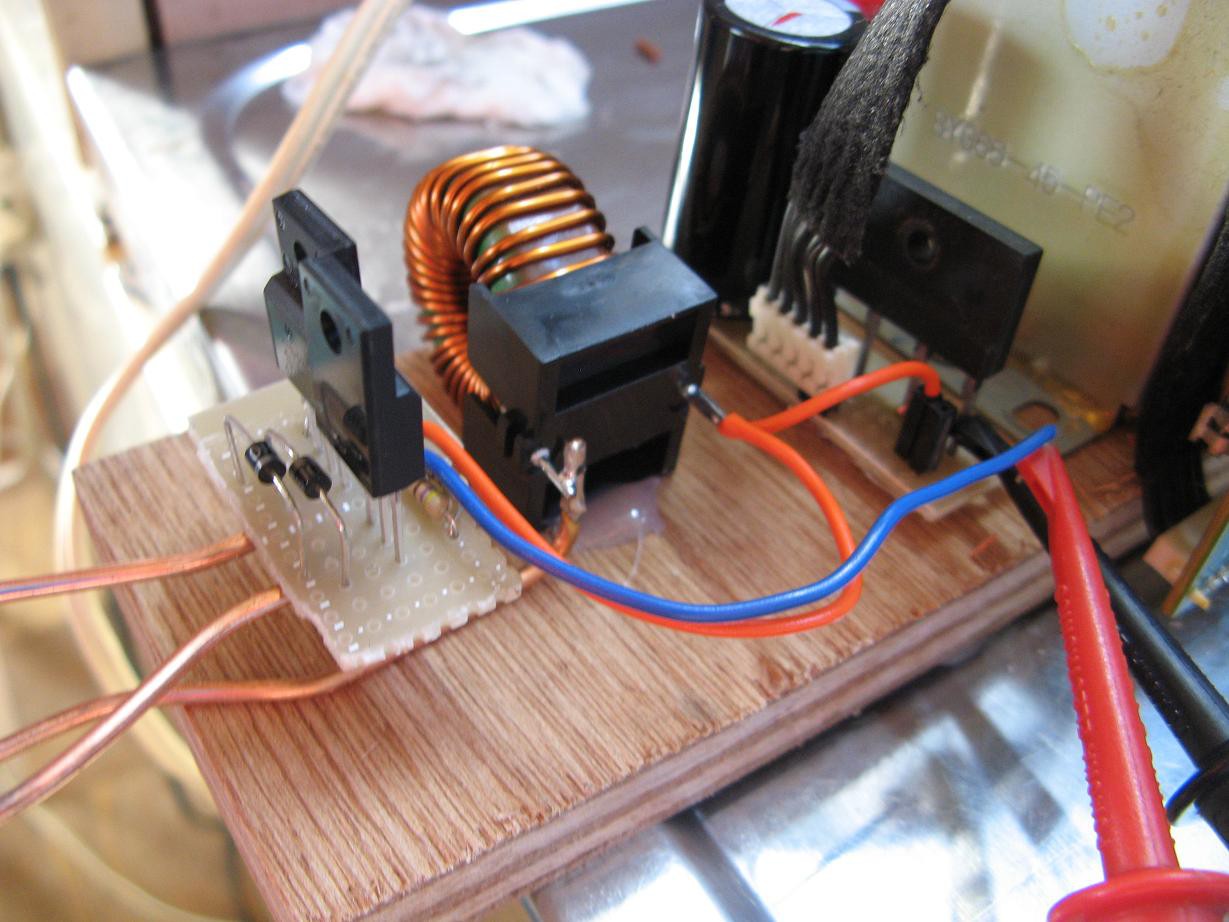

Second, salvage the necessary components and just give it a try. The power supply consists of a heavy transformer salvaged from something I don't remember, a rectifier from a microwave oven, and a large capacitor. The Schottky diodes are rated for 100V and 1A, and the MOSFETs are 100V and 18A. At first I just grabbed a few high frequency/voltage capacitors for the oscillator part of the circuit and put things together without thinking too much about frequency or power. I figured I'd tune those details once I got something working. Here are some pictures after removing most of the oscillator capacitors as I'll explain below.

Third, make it work well. When I first plugged it in I had 18uF worth of capacitors and somewhere around 1uH of inductance. There was no smoke, explosions or obvious issues, so I tried sticking a screwdriver in the coil. I immediately knew something needed to be changed because I could feel the vibration in the handle and a couple seconds later the fuse blew. I sat down to calculate my frequency, which I know I should have done in the beginning, and found it to be about 37kHz unloaded and lower when loaded. Not so unreasonable for a high power heater, but no good for this project.

So I removed most of the caps leaving 4.5uF which should double the frequency. It worked much better. It was silent, vibrationless and didn't blow a fuse. But everything was getting too warm (rectifier, mosfets, coil). I measured the current and found this. 3.6A no heating, 6.5A heating

I will regulate temperature by sticking another mosfet on the supply output and switching it with a microcontroller. It doesn't need to be anything fancy. It could switch off above 180C and on again below 175C or so. Of course I'll have to take care not to switch too quickly. Maybe the minimum interval between switching could be a second or so.

Next I need to attach it to the pipe and figure out how to measure temperature in this noisy environment.

shlonkin

shlonkin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.