The plan is to take apart an existing soldering iron, install an ultrasonic transducer, and then somehow put it all back together. Here's the parts I have so far:

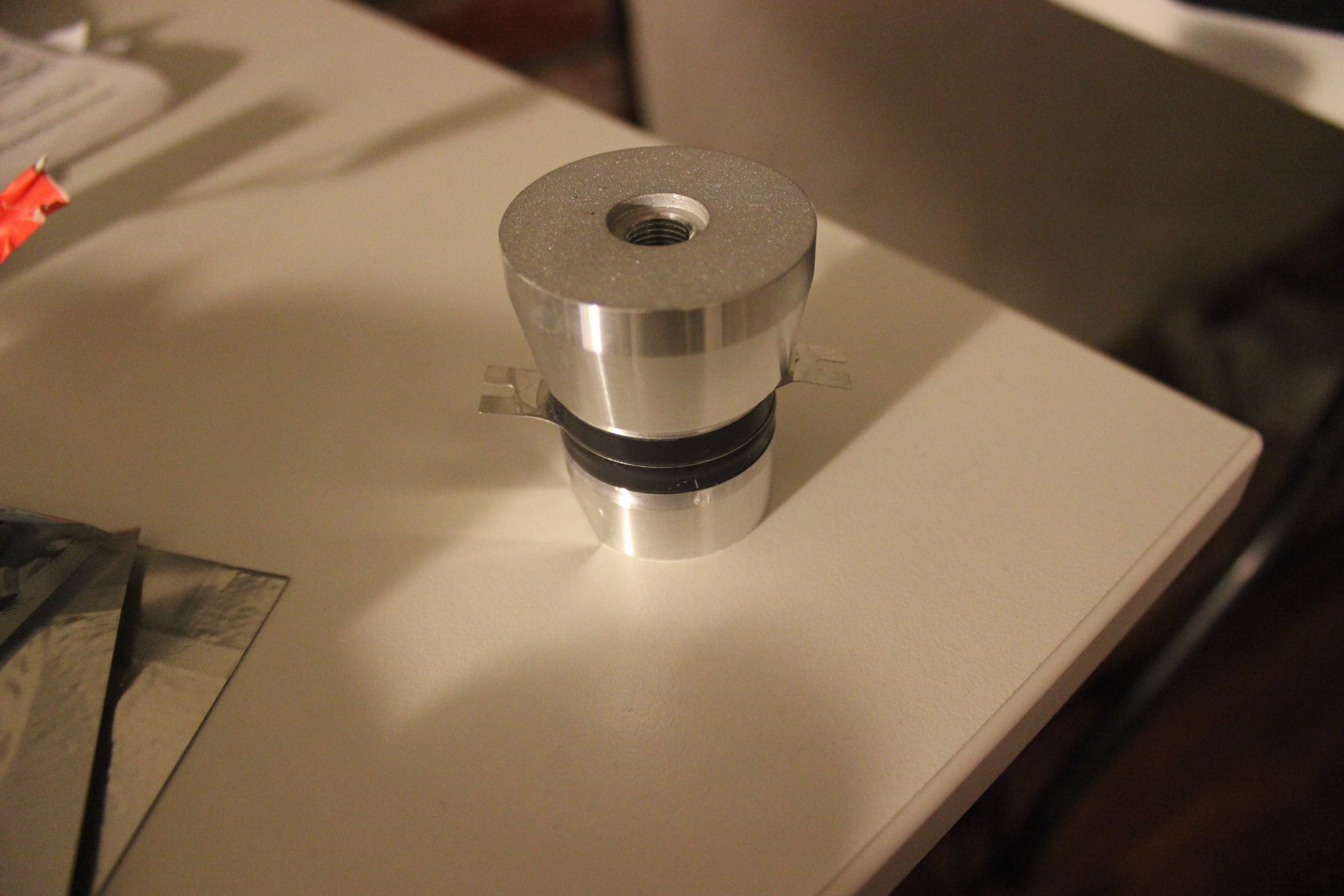

A 40W ultrasonic transducer. This was originally meant to be used on an ultrasonic cleaner. I got it from eBay and it came with a driver circuit that is powered by 120VAC. It's got an M10-1.0 threaded hole in the middle. The "manual" that came with it says not to drive it without a correctly matched load. Basically they don't want you to try to run it without there being any water in the ultrasonic bath. If you do, it can get hot, overheat the power supply/driver and destroy the transducer. Of course, I'm going to be doing exactly that and never driving it with a load. So to keep it from overheating, I'm going to install a momentary normally off button on the handle of this thing somewhere so you can heat the solder without ultrasound and then engage it when you need it.

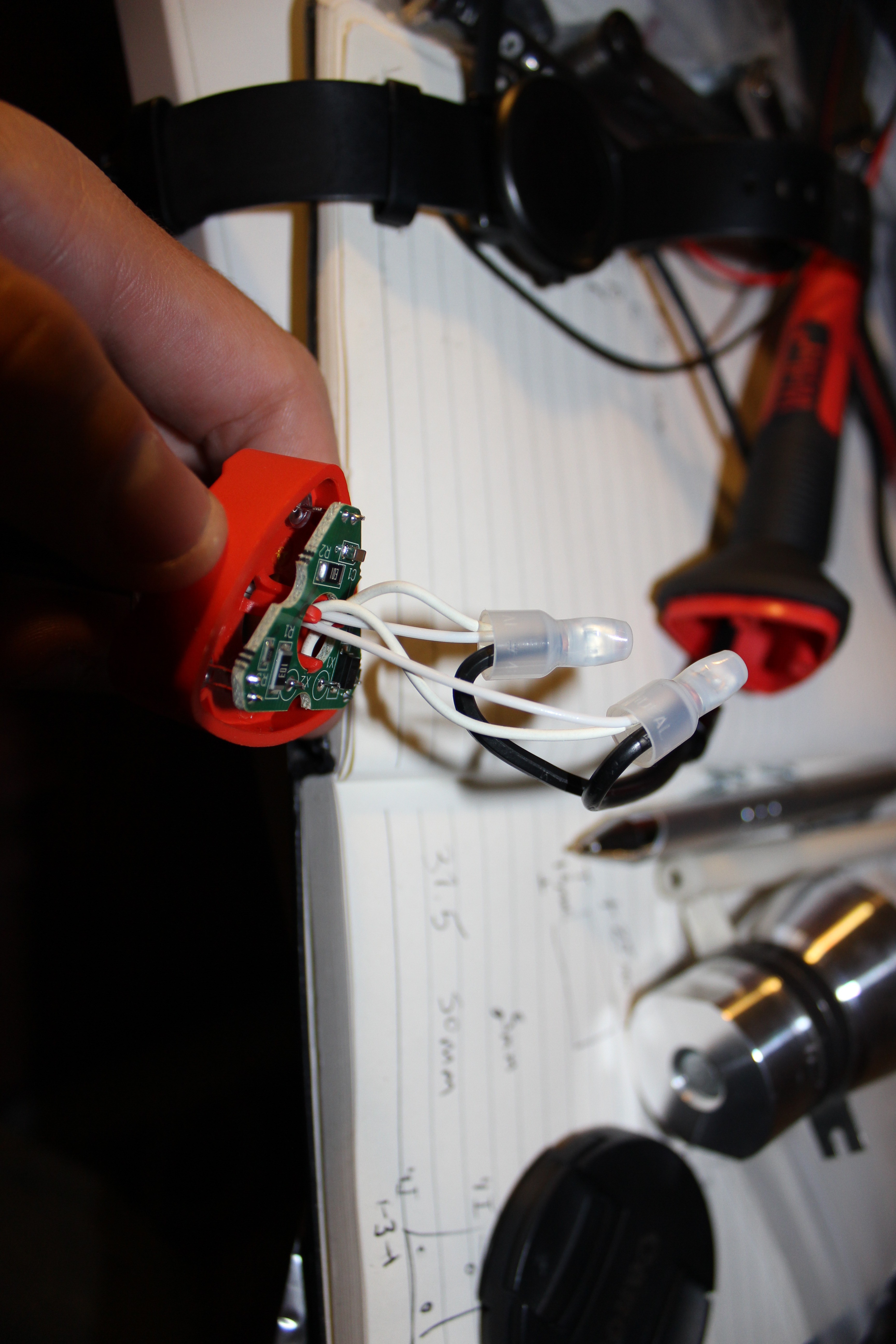

The soldering iron I got is a Weller. It doesn't have temperature control or anything. I just got it from Home Depot and it plugs straight into the wall. This is actually perfect, because I can splice into that connection to power the ultrasonic transducer. This iron also comes apart easily and the heating element is connected with 3 screws, which makes it easy to move elsewhere.

Hunter Scott

Hunter Scott

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.