Having the components in mind I have to think of ways to connect them together, the requirements of each one and the restrictions that they impose.

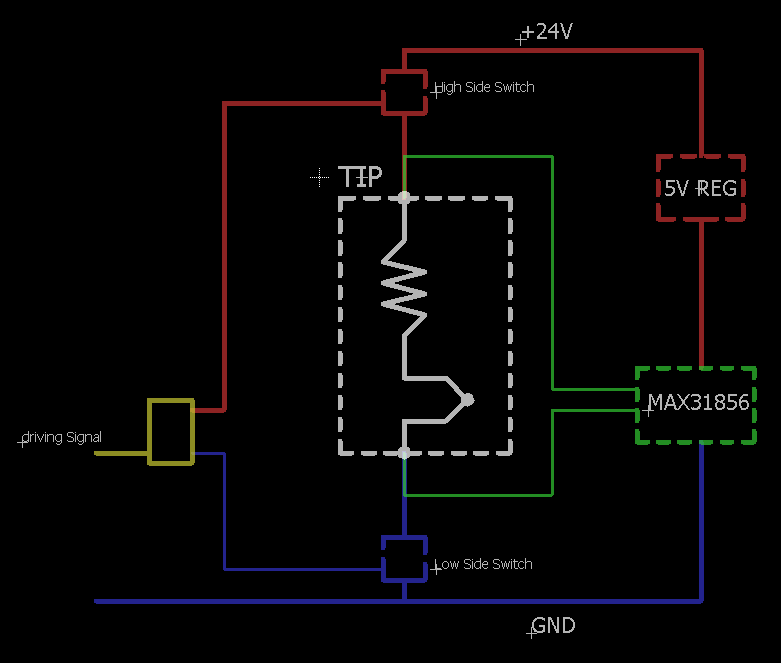

The soldering tip has only two terminals, that means that the heating element is connected to the thermocouple (in series).

The implication of this is that we can't heat the element and measure the temperature at the same time, we have to do it alternatively, first we supply the element with 12-24V, stop, then measure the voltage across the terminals which gives us the temperature of the thermocouple, stop and start again with heating if it's the case. But this gives us some problems as the voltage difference is so high, the heating element is resistive and should not make problems by inducing currents after it has been disconnected.

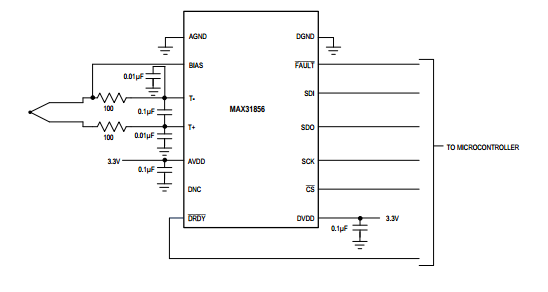

Let's get to the thermocouple converter MAX31856. The first obvious thing is that we cannot supply 24V into this one while making a reading although it has ±45V input protection. The next requirement is that it requires floating connection of the thermocouple to make a precise reading, that means that none of the two ends should be connected to anything else (like GND or V+) while measuring temperature. Also as you can see in the typical schematic the BIAS pin introduces a voltage to make the reading.

The conclusion is that we should have both a low side and a high side switch for driving the tip element that open/close at the same time.

insidecircuits

insidecircuits

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.