One of the goals of the project is to use as much off-the-shelf hardware as possible. The prior rotor pulleys were standard pulleys and readily available. A few of the issues with the prior pulleys were that they were made of steel and required a separate steel bushing. While aluminum pulleys can be purchased, they have to be custom ordered.

How Timing Pulleys are Constructed

There are several examples across the Interwebs about how to build timing pulleys and in particular HTD pulleys. Building a single pulley or a small batch of pulleys can be done with machine tools. Below is a good example by DIYisFun building a small pulley from a block of material on a mill.

Another way is to use a fly cutter to create pulley stock from a block of material. Here is another video from DIYisFun showing how a fly cutter is used to create a timing pulley.

This method is a bit time consuming. A good compromise is to purchase the raw pulley stock and cut the pulleys from the stock. This will only require basic machine tool operations. Aluminum stock of different sizes and pitch can be readily purchased.

One last consideration is adding flanges to the pulleys. The flanges are required because the belts operate in a horizontal position. The flanges can also be readily purchased with the pulley stock, but there are several methods of attaching them. The prior pulleys appear to have flanges attached using a method called roll staking. Here is a video showing how roll staking is done.

The roll staking requires special equipment, so the options are either to use bolts to attach the flanges or use a punch to do conventional staking.

New Rotor Pulley Design

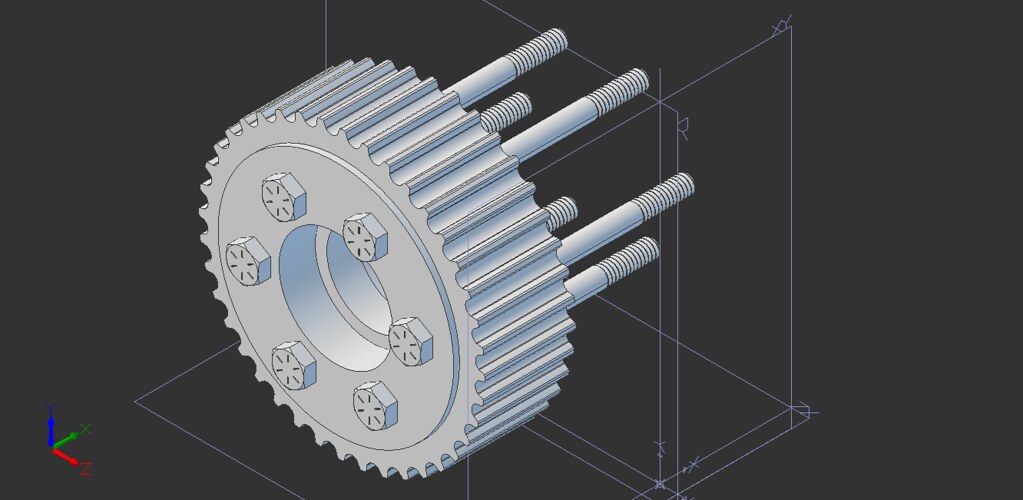

Making the rotor pulleys isn't as simple as lopping off a piece of pulley stock. The rotor pulley has to accommodate the flanges, the bearings and the rotor bolts. Below is the CAD design of the pulley with 6 fitted 1/4" diameter bolts, 4" long.

Machining steps:

Machining steps:

- Mount pulley stock

- Cut 1st shoulder to 1.77" radius 0.22" wide

- Cut off the length of pulley from the pulley stock (1.60" wide)

- Remount using 1st shoulder

- Cut second shoulder 1.77" radius 0.15" wide

- Bore center hole

- Bore 1st bearing pocket

- Face Surface

- Remount using second shoulder

- Bore 2nd bearing pocket

- Face Surface

- Drill bolt holes

Any feedback on the pulley design or tips on doing the actual machining would be appreciated.

Benefits

The new pulleys should weigh about 1.3 lbs and the previous pulleys weighed 2.6 lbs so the total weight reduction for the four rotor pulleys will be at least 5 lbs. There will likely be further weight reductions since the bushings are being eliminated as well. Finally, having the six fitted bolts vs. the three fully threaded bolts will solve the rotor bolt issues.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Very interesting, keep up the good work!!

Are you sure? yes | no