The plasma cutter that is being used for this table is Thermal Dynamics Pak Master 38XL. From what is found online it is a high frequency start (read electrically noisy) cutter.

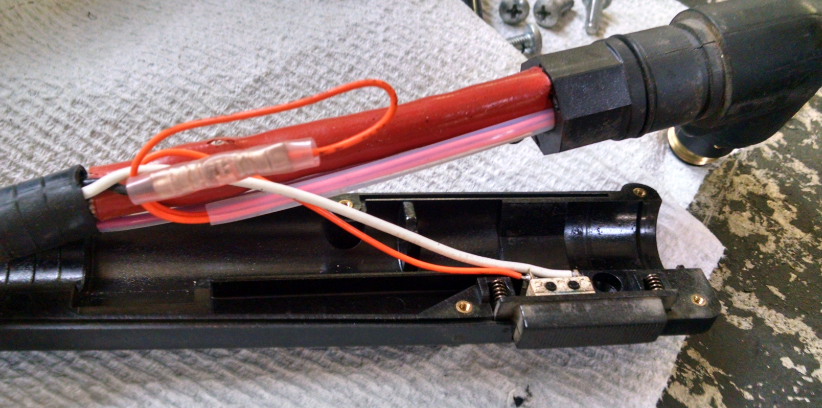

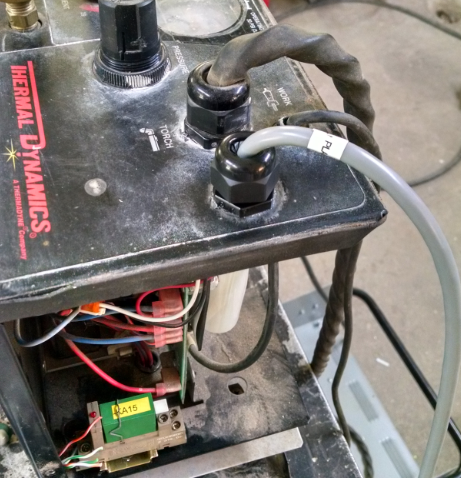

The handheld torch has a NO trigger that simply closes a circuit back at the main unit. In the picture below the black and white wire coming out from under the sheath is the fire command. The black wire connects to an orange wire that feeds out to the torch head's PIP (part in place) connection. A second orange wire feeds back to the NO trigger.

Below is the PIP contacts that detects that the tip cover is attached.

The CNC will bypass the PIP circuit and act only as a basic fire. A relay was placed back in the main unit that connects the black and white wire together.

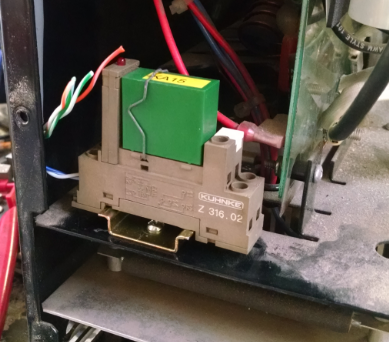

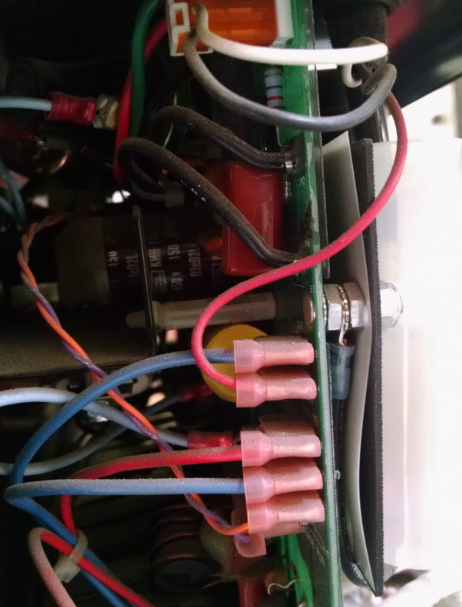

In the picture below, the upper white and black wires are the torch fire circuit and the red wire is the main cutting circuit to the plasma torch.

The firing circuit was spliced and the wires fed to the NO contacts of the relay.

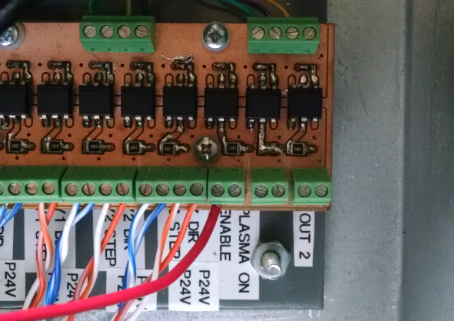

A 24V relay was chosen since the opto coupler output card in the controller box uses 24V. The card was modified as a direct short to 24V with the relays coil as the load. The second from the right opto has the output resistor removed and the pads were solder bridged together.

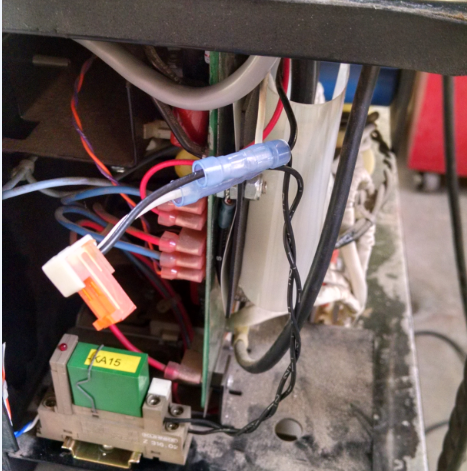

A strain relief was added to the top of the plasma unit for cable routing.

willbaden

willbaden

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.