I started this project before I discovered Hackaday so I'm going to quickly summarise what I have done so far. If I miss anything or if it is unclear what I'm doing please let me know and I'll try update it. I will try to post enough pics to clarify as I go.

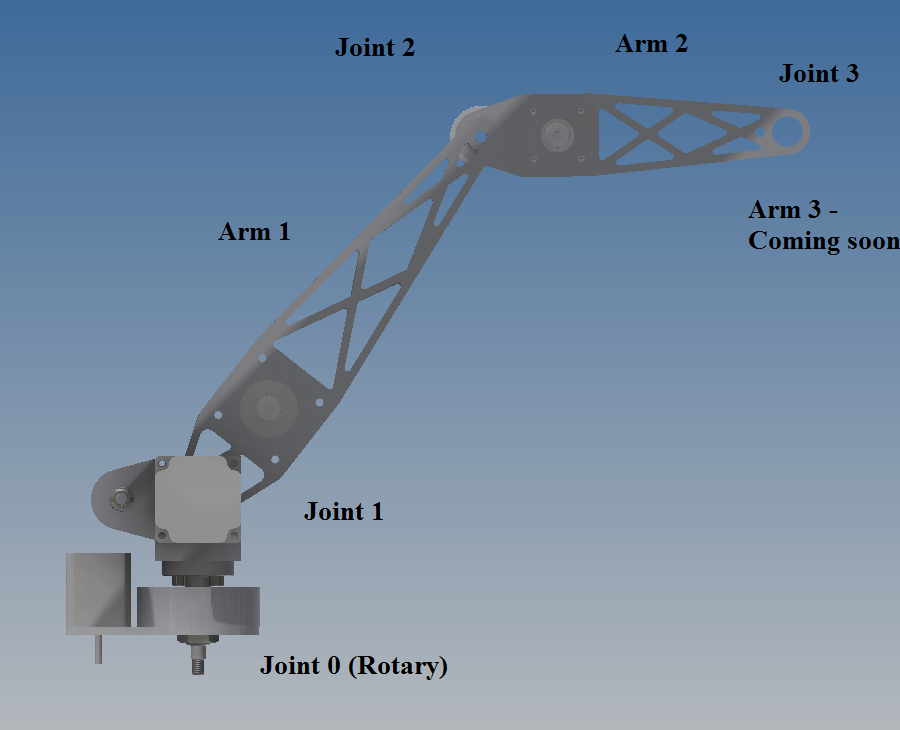

Layout and nomenclature as follows:

I started by roughly estimating the lengths and therefore the torques required for each joint. I decided on the following:

Arm 1: 300mm

Arm 2: 200mm

Arm 3: 100mm

This will suffice for a 4 axis prototype with 500mm of reach and 600mm with the 4th axis co-linear rather than perpendicular.

This means that if I want to not just hold but lift 1kg at 500mm I would need roughly 5Nm at joint 0 plus whatever torque is required for acceleration and a bit of FOS (factor of safety). Assuming an acceleration of 1g and a factor of safety of 1.5 we need around 15Nm. I know from previous experience (a 4 axis CNC mill) that linux CNC can reliably step at a rate of around 20kHz with great torque. On a stepper running a 10 microstepping driver board and 200 ppr (pulses per revolution) that is 10 revolutions per second or 600 RPM. I want a speed of around Pi rad/s or 0.5rev/s. That is 20 RPM so we can run a reduction box with a ratio of 20:1 however a 1Nm motor is a workable size so I decided to run a 16 to 1 ratio. It might turn out too fast and not powerful enough, especially considering that I'm not yet taking the arm weight into account which will be significant. As a resault am also going to make provision to use 2 motors on Joint 1 in case the gearing is too 'low' for the payload I want.There will also be time taken to accelerate the arm and decelerate it so the effective speed will be much less than this.

Joint 2 will be pretty much spot on half of joint 1 however I felt that for simplicity I would use the same motor and for the most part the same gearing. I am using custom belt drive gearboxes since low backlash planetary boxes are pricey so for the two joints I'll change the pulley sizes to customise the speed and torque. The quickly available ratios for me are 16T, 20T, 40T and 60T (local robotics shop) so there is a decent spread. I will CNC custom ratios if I need but I doubt it.

At this stage I'm not too concerned about joint 3 because the arm length is so short that I barely need 2Nm and I have some decent Nema 17 0.5Nm 200 ppr steppers I can use. With a 4:1 pulley drive this will be perfect.

So to summarise so far:

Joint 1: 1Nm Stepper 16:1 ratio

Joint 2: 1Nm Stepper 12:1 ratio

Joint 3 : 0.5Nm Stepper 4:1 ratio

I have to complete some drawings now so that I can have parts made before the weekend so next update will be tomorrow night. As a teaser I already have the steppers, drivers, pc interface board, power supply, pulleys and belts and some manufacturing drawings.

Andrew Becker

Andrew Becker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.