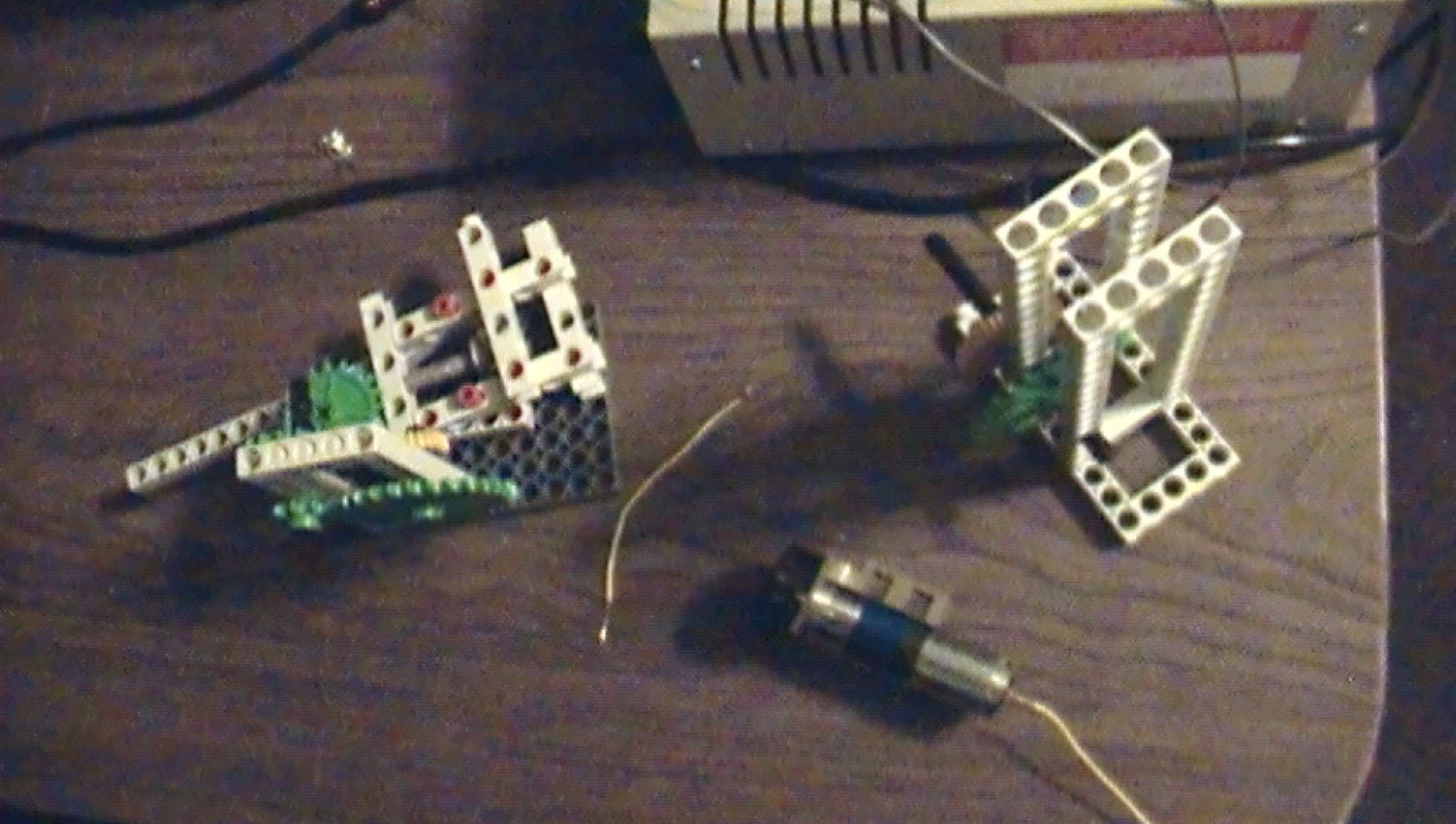

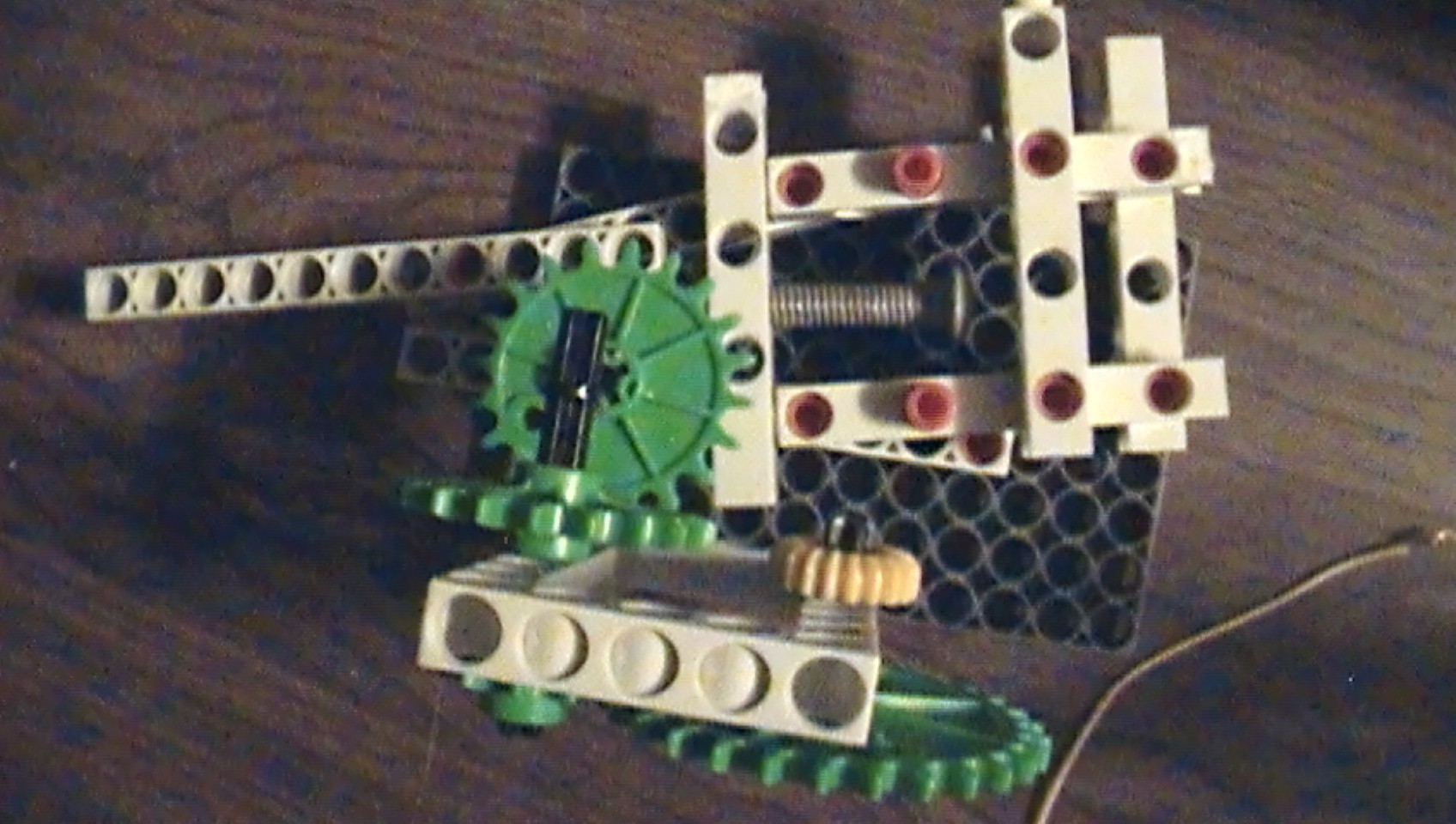

Today we worked on prototyping ideas for a shooter mechanism. After a discussion, we determined that our best bet with making a fully functional shooter would be one that uses either solenoids or some other configurations of electromagnets to move a ferrous rod in a linear motion. The problem with this idea is power consumption - hence why you will not see any work on an electromagnetic shooter mechanism, we are considering other power efficient options first. Below are photos of our first prototype which is supposed to be able to shoot a ball very slowly and only move it a few inches. The purpose is just to get an idea of what components we will need for our actual shooter mechanism and to work out a more finalized design.

As mentioned here are the photos:

Please note: The above shooter successfully shot a dense foam ball down the length of the table. The final assembly will have a stronger, more precise motor, the gear assembly will be upgraded to either aluminum or a more durable plastic, and we will use a modified cue stick which has a spur rack fixed to it.

VPugliese323

VPugliese323

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no

Are you sure? yes | no

Are you sure? yes | no