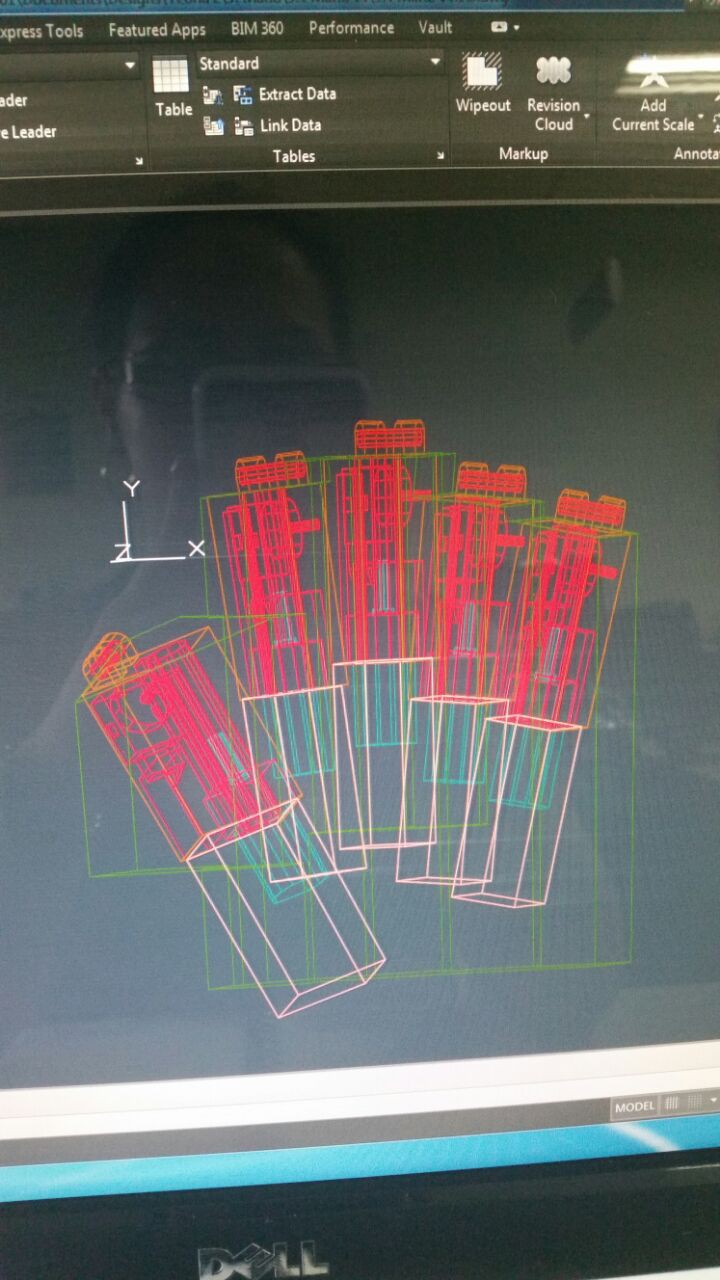

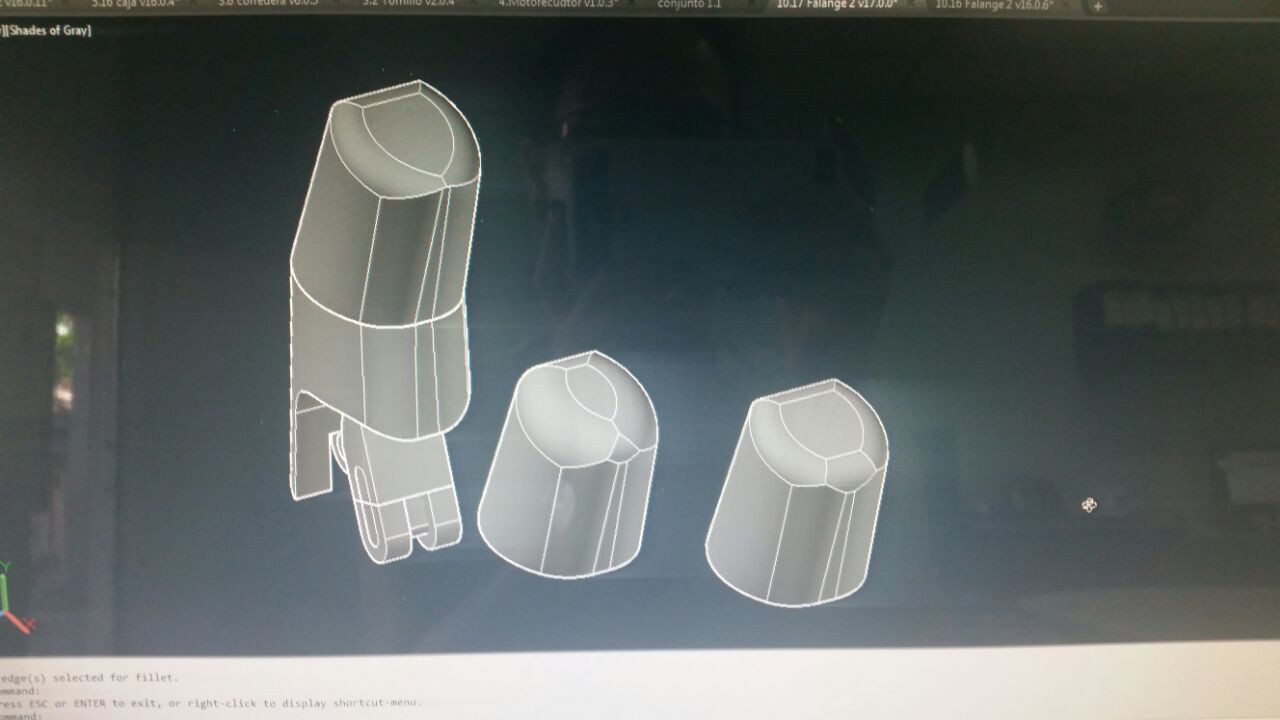

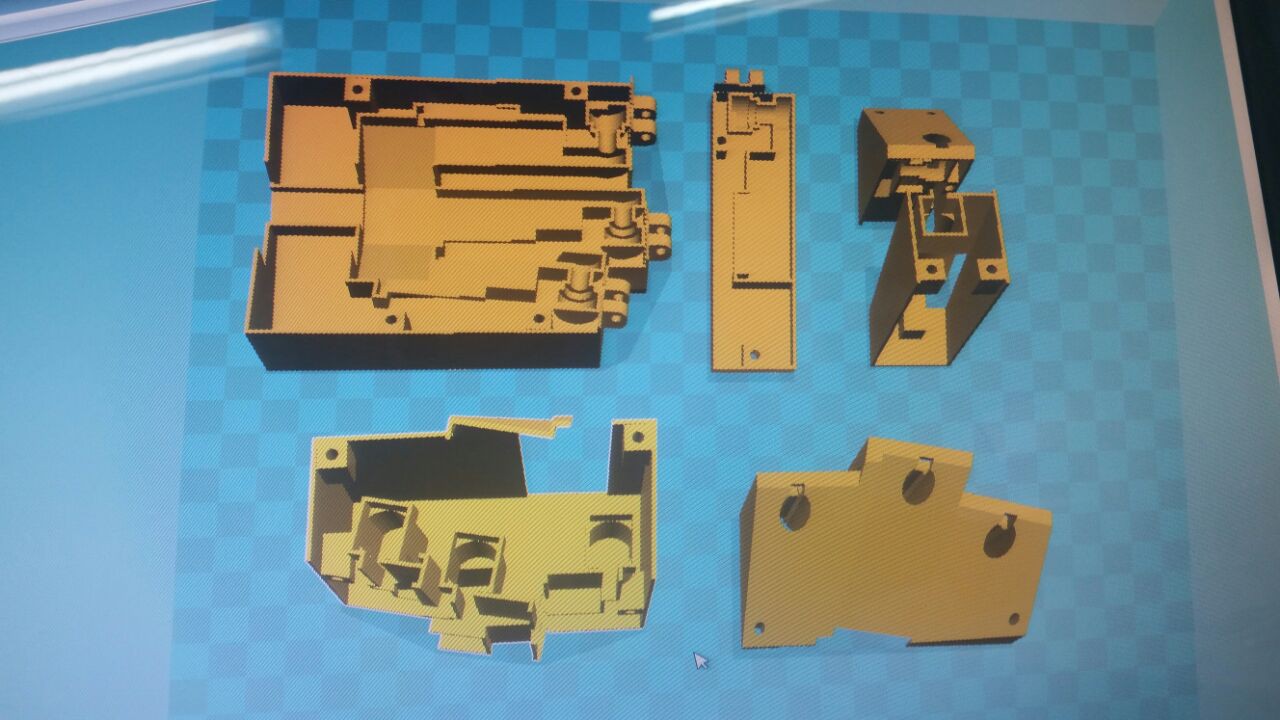

Now that we had a reliable linear actuator ( we thought that!!! but you will see) we started to think about the whole hand and to do this we had to place all the mechanics of each finger, sculpt a shape that includes all the components and pleases the eye and finally cut it into tree pieces with the corresponding holes for the screws (we utilized the screws from the servos, we had a bunch and they are great).

So about the first thing that everyone always asks. Why fourfingers?

Well we always try to consider every input and we really tried in our earlyest version to find a good reason for keeping all the five fingers. Indeed there is the proof about that.

We cramp it up all inside but the real question was. Is there anything that you NEED five fingers for?

The extra finger adds cost, weight, complexity to the design and build of the hand. Think about it, those are the big cons of a myoelectric prosthetic hand that we want to change. We want to offer a cheap light weight prosthetic, also we don't want to build something that seems that you have a natural hand that not the goal, we hope that the people that wear this prosthetic wear it proudly because you have a freaking robotic hand.

So we needed inspiration and started looking for it. The design for everything was up for votes on the different areas of the company.

Mock ups like this were rotating constantly asking, which do you like the most?

We found a design for an alien for a game that really caught our attention an gave us some idea for the proportions of the fingers if we wanted to make it appealing. We also consulted physiciansand a bunch of anatomy books so don't worry.... that much.

But first... we wanted proof of concept. So meanwhile the design was taking place, a basic functional palm was getting printed.

These designs also includes a shot to try to make a functional electrical rotating tumb and gave us a lot of feed back.And it came up something like this.

Giovanni Leal

Giovanni Leal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.