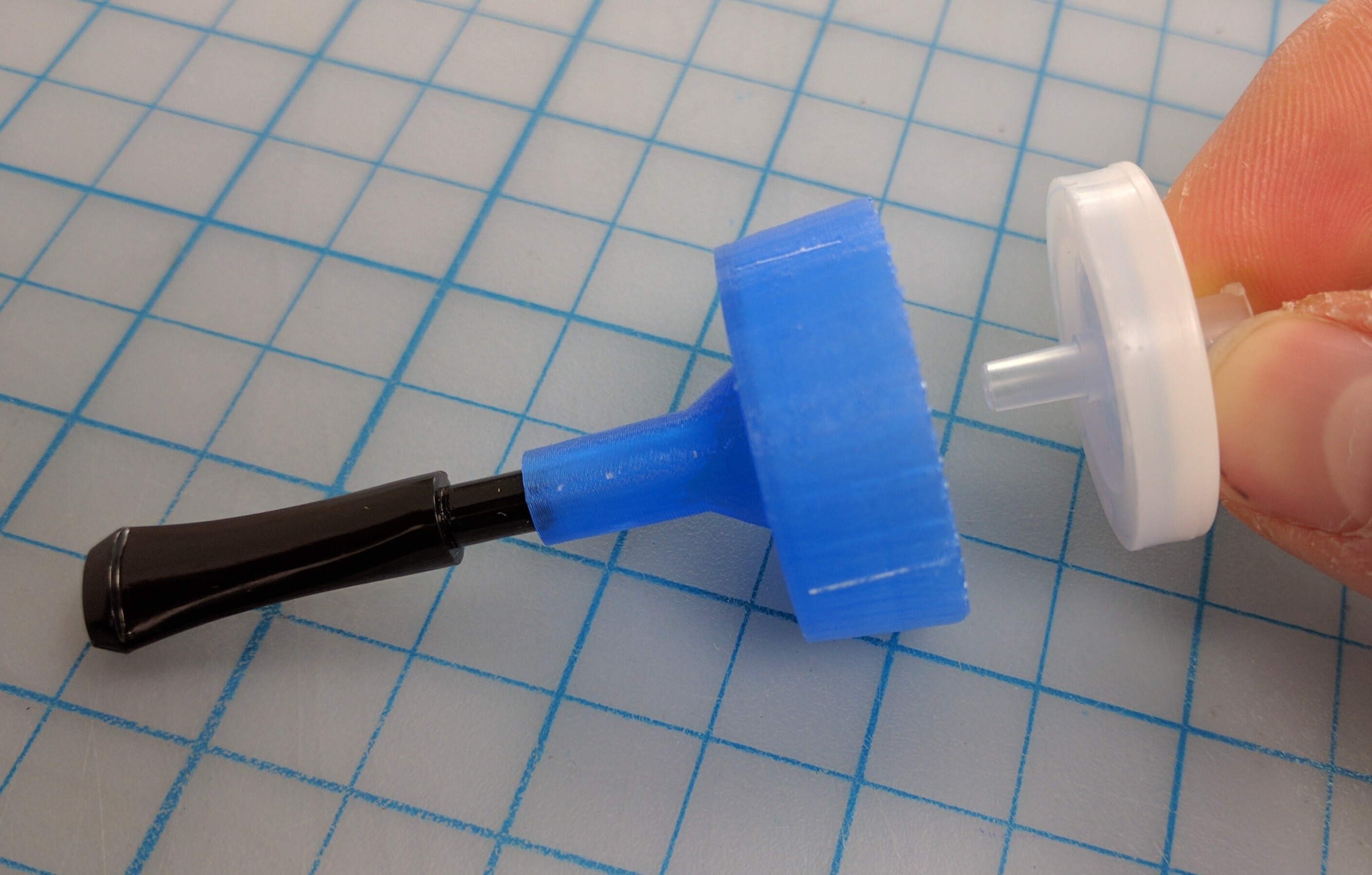

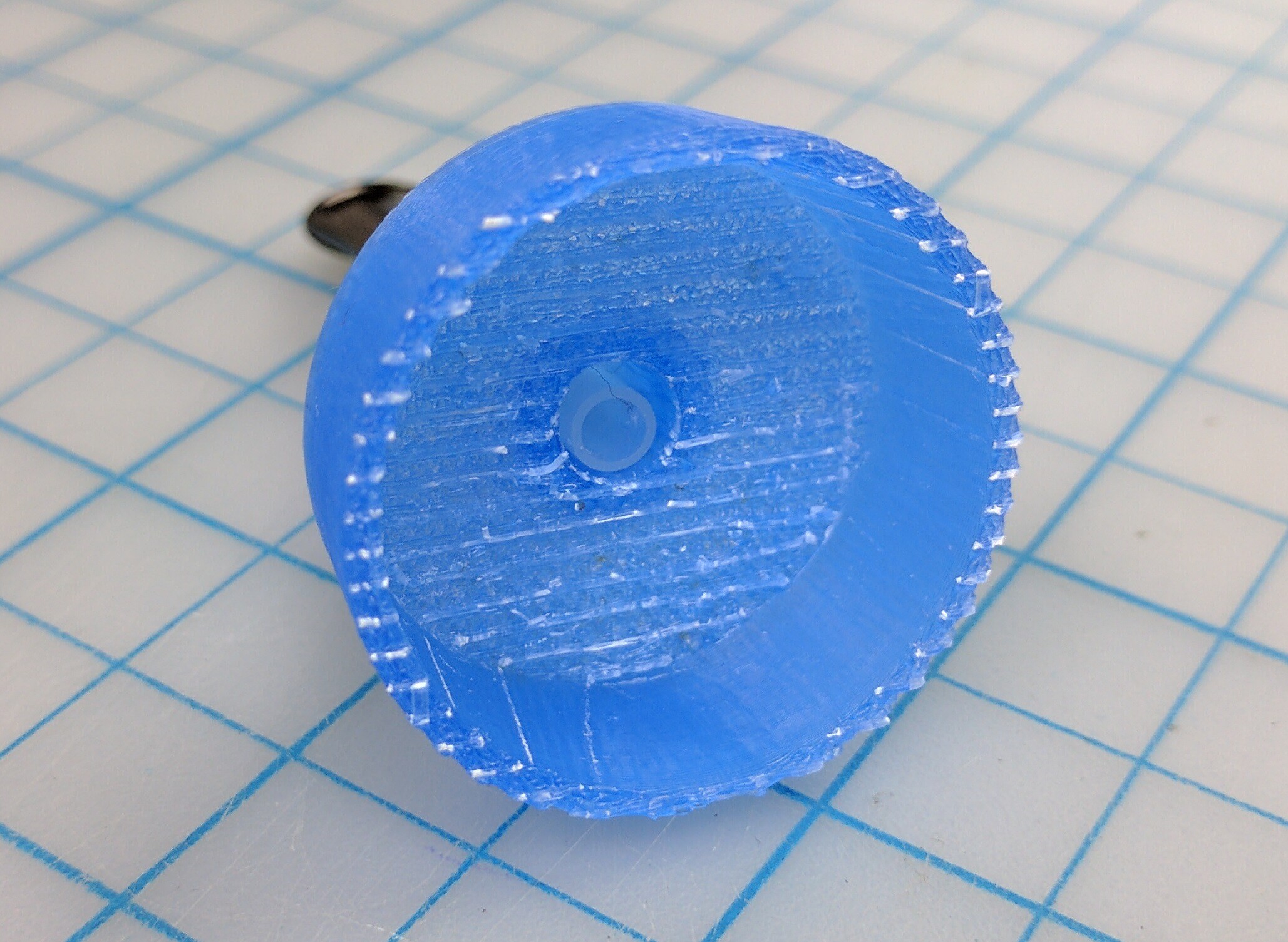

One of the disadvantages to fused deposition 3D printing is the porosity within the print. During printing, tiny air pockets are interspersed throughout the object. Once bacteria gets into these crevices, it's almost impossible to sterilize. Even food safe filament begins to harbor bacteria after the first contact with food, beverage, saliva, etc. This is a problem we had to address with our previous mouthpiece adapter design, which used 3D printed food safe ABS for the wall of the air stream. In the previous design, the black mouthpiece is inserted directly into the blue mouthpiece adapter and the white, medical grade filter is pressed in from the back:

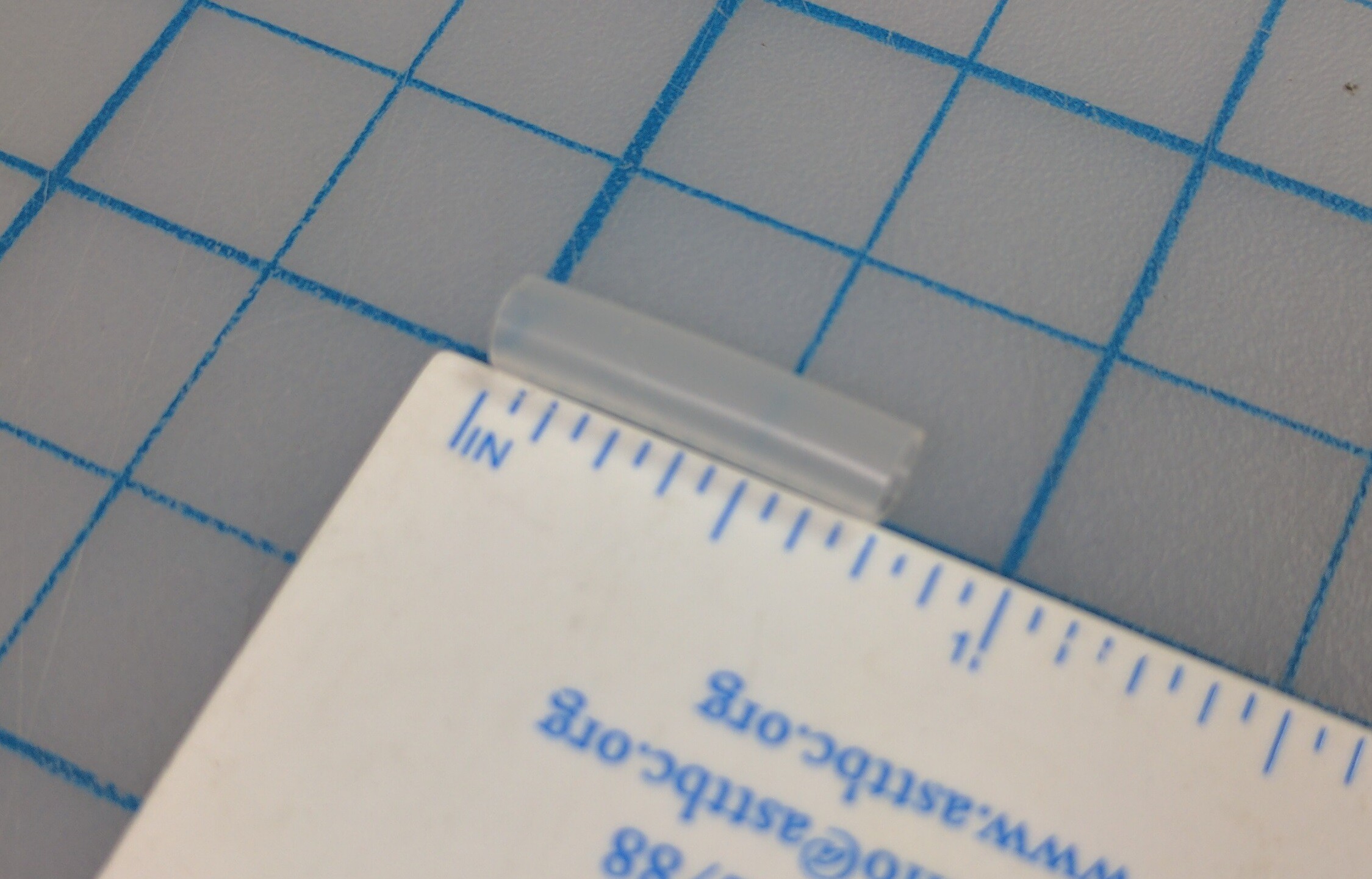

This design was fine for initial testing, as the adapters were discarded after short-term use; however, a permanent, long-term solution was required. One option was to coat the adapter in liquid polyurethane sealant, which becomes food safe and can be sterilized after hardening. This process can be messy and coating the adapter properly can be difficult. Instead, we opted to use a 3/4" length of medical grade silicone tubing:

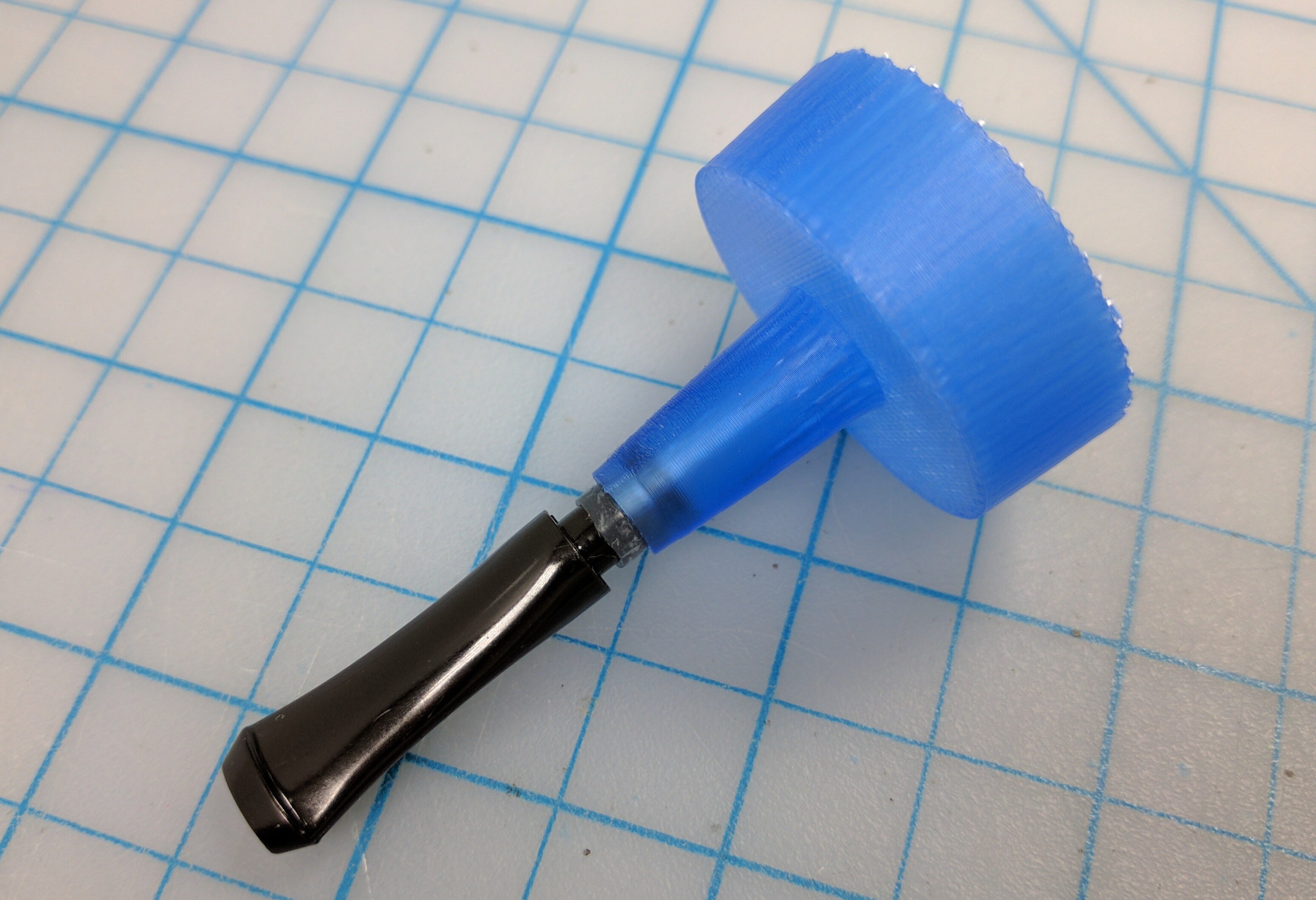

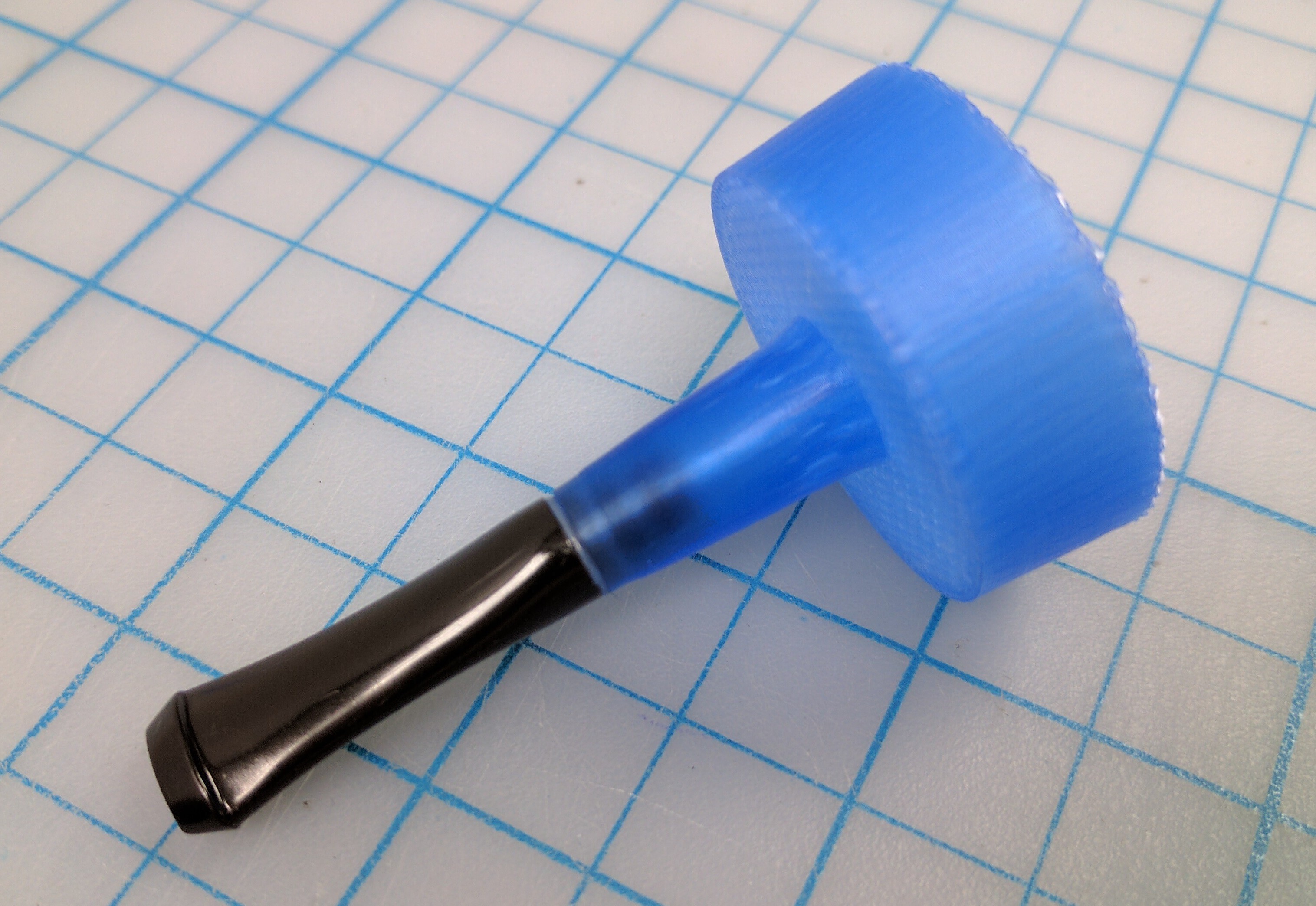

The tubing is snugged over the mouthpiece:

Charles G

Charles G

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.