Problem Statement

The Metabolizer is sort of like an ecological Rube Goldberg machine- it's a chain reaction-type system intentionally designed to perform a simple task in an overly complicated way.

In this case, the simple task is "not throwing our plastic trash in the ocean", and the overly complicated way of doing it is "by designing an artificial metabolic system that can literally eat trash."

Like a Rube Goldberg machine, a big part of the challenge of this project is to see how long you can keep the chain-reaction going for. Unlike a Rube Goldberg machine, the chain reaction is fundamentally reciprocal and solar powered and can generate energy while breaking down and wastes and recycling plastics, for as long as there is trash and sunlight around for it to eat.

How long could a system like that realistically sustain itself? Hours? Days? Months? Years? Centuries? Forever? At what point would you start to consider it to be a single living organism, not just a collection of independent parts?

I don't know the answer to those questions, but those are the questions that motivated me to build this project. The central challenge of the Hackaday Prize is "build the best hardware module or device possible for the boldest solution you can envision." This is the boldest solution I can envision.

Going Live

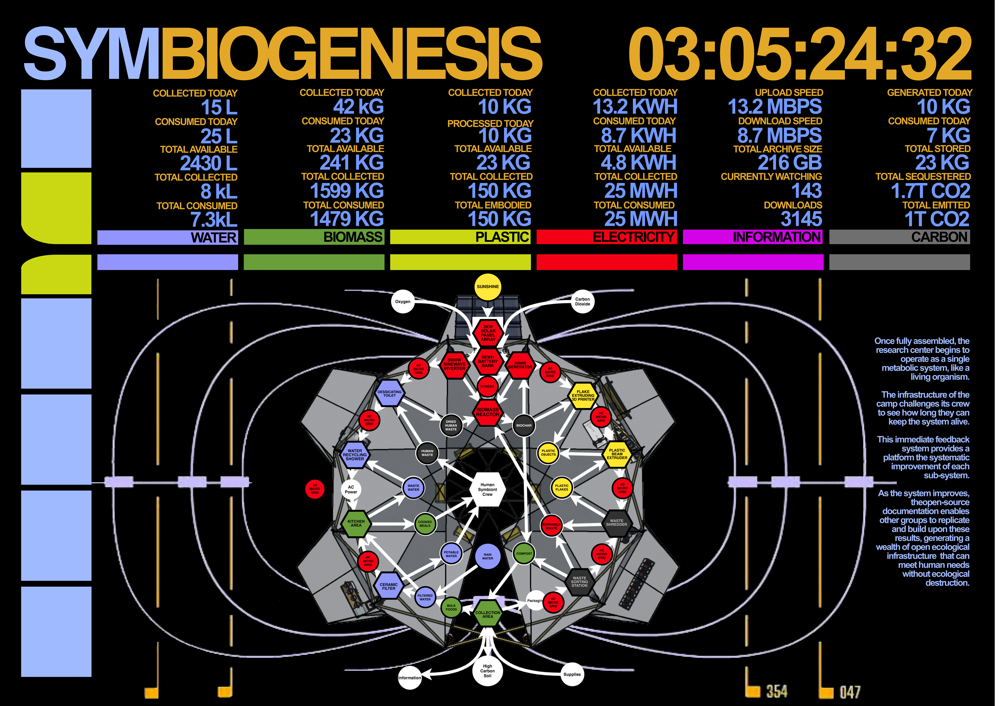

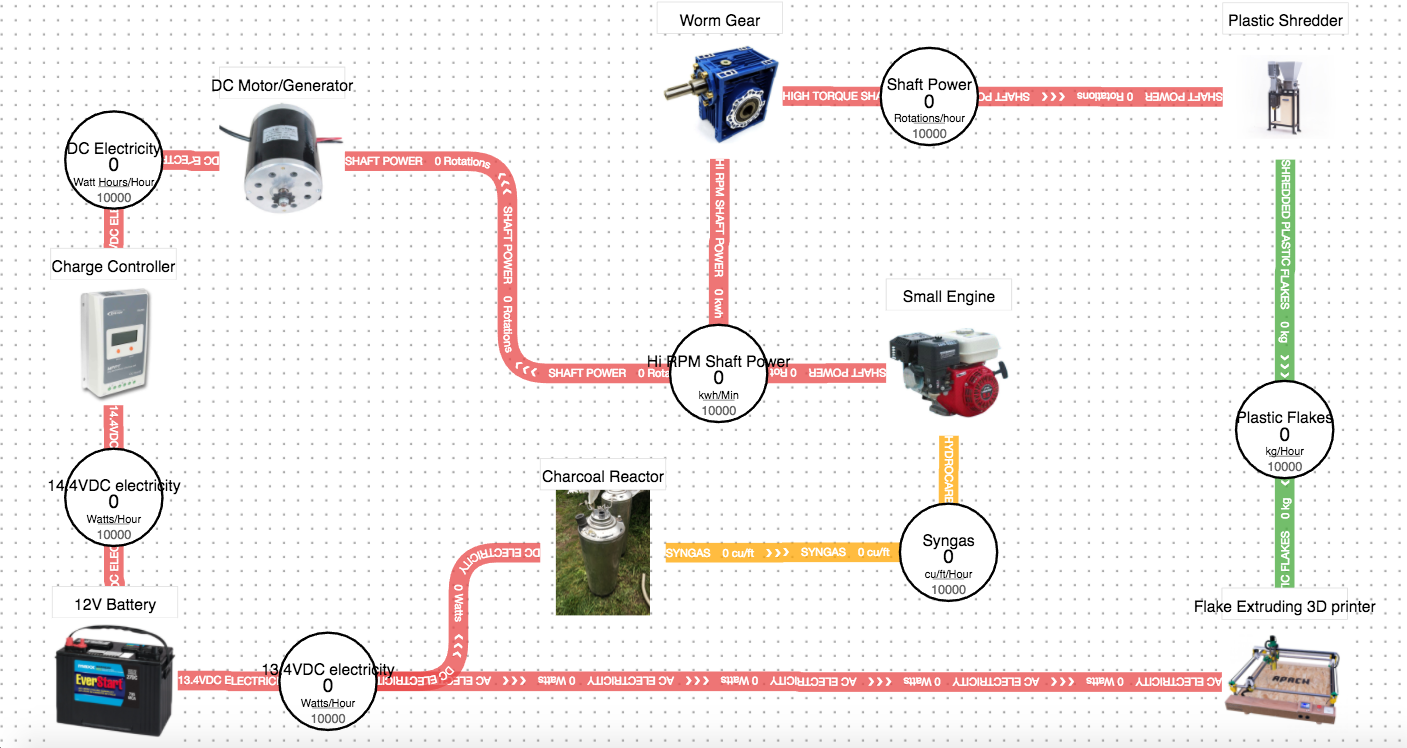

Here's how it currently works: When sunlight hits the solar panels, it charges up the battery bank inside of the Powerplant, providing the base power that starts the reaction. When the battery fills up, solar power is dumped into a heating element inside of the Biochar Reactor, causing the biomass inside to heat up and reducing it to biochar, generating a thick smoke that is cooled, collected, and refined, before it is pumped into the air intake of a small gasoline generator, which generates 200-900W of DC power, which feeds back to the Power Plant, and is converted into 120V AC which powers the 3/4hp motor attached to the Waste Shredder, which grinds up waste plastic trash into flakes, which are fed into the hopper of the Trash Printer, which extrudes the plastic into light, strong 3D printed objects.

Sorry for the run-on sentence there, complex systems are really hard to describe.

The system operates entirely off the grid, which means that if the battery dies, the whole system dies. The chain reaction stops. The lights go out, your phone stops charging, the counter resets. You have to wait until the sun comes out and try again. It's kinda like a giant trash-eating Tomagachi.

The challenge that fascinates me, and that I hope will be interesting to y'all as well, is to see how long I can keep this system alive, and keep score of how many useful resources I can generate in the process - how many kilowatt hours of sunshine energy I can sink through the system, how many kilograms of carbon I can sink into the soil, how many kilograms of plastic I can forge into something useful.

With the current prototype, what I'm calling my Latest Stable Release, my high score is about 4.5 hours. But in that time, was able to turn a handful of old take-out containers into a 3D printed cup, and I generated about 450 watt-hours of energy from trash, and a not-zero amount of biochar, using ONLY a days worth of sun-shine, amazon packaging, and woodchips as the fuel (3.8kWh). I even mixed some the powdered char dust into the trash printer which turned the prints a very nice shade of black.

Not too bad, for a first run ever, all things considered.

You can watch a highly-abridged timelapse of that first run here:

I've come A LONG way over that past 3 years, and in that time the system has gotten significantly cheaper, efficient, and easier to build. But there's still a long way to go before the system is really useful, let alone disruptively useful.

This is my call to all the makers, tinkerers, and mad engineers out there who may be reading this- A very wise friend of mine once said to me, "Sometimes the best way to get people to help you do something hard is to just start doing it badly in front of them."

So this is me, doing it badly in front of you. I would love your help figuring out how to do these things less badly.

For systems like these to become as widespread as they would need to be to make any real difference in the world, they will need to be vastly improved, and they will need to easily replicable by small independent groups around the world, exactly like what is currently happening with the open-source precious plastic machines. Just search for #preciousplastic on Instagram, and you'll see what I mean.

The ultimate test of any open hardware project is - can people actually build it?

I've tried to make this documentation as complete as possible, but it turns out that generating good documentation is a lot of work, and it is still not as complete as I would like it to be. If you get stuck, or are unclear about how things work, feel free to leave a note or questions in the comments, and I will try and add the answers and fill in the gaps to the existing documentation.

Also feel free to mercilessly steal this information, without contacting me or asking for permission. My goal is to generate documentation so complete that it can stand on it's own, a single drive that contains all the information that you need to build and operate each part of this system, so that the information can spread horizontally like a spore or a seed, taking root wherever it finds fertile ground.

So if you do end up replicating any or all of these machines, PLEASE do send me pics and let me know your results.! Independent replication is the highest form of flattery! Ultimately, it's the only way for me to know that all this work was worth it. Bet you can't beat my high score!

Sam

10/26/2021

----

Original Details from 2019 Below

(Info is still relevant but out-of-date)

Problem Statement:

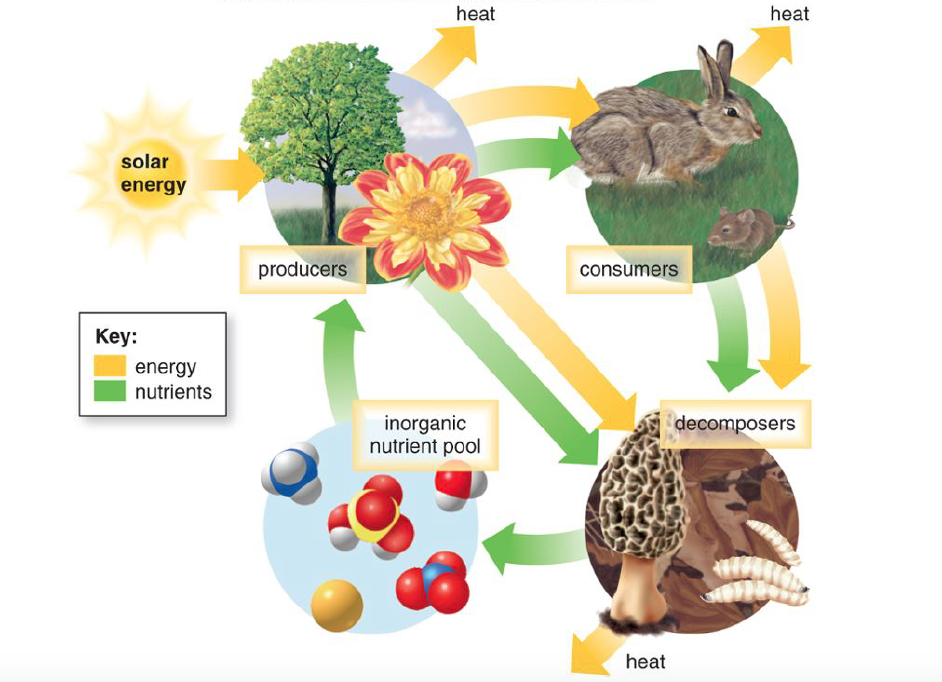

Unlike all healthy living ecosystems, which can regenerate "wastes" back into living things in an infinite loop powered by sunshine, modern human systems increasingly tend to pile up wastes faster than the biosphere can break them down again. Waste plastics are a particularly problematic example of this paradigm of consumption, because very few living organisms exist that can break plastics down, and none exist that can do it as fast as we're producing them.

Yet, however dire our current situation may be, it is not unprecedented in Earth's history. 360 million years ago, plants suddenly evolved the ability to synthesize Lignin- which was up until that point the most complex organic compound that had ever been synthesized on Earth. For 60 million years (!!!) trees grew, died, fell over, and we're buried, but the solar energy trapped in their chemical bonds was never broken down and released- because no fungi or bacteria existed at that time that could break down woody biomass. That's where most of the worlds coal came from. It wasn't until white-rot fungi evolved specialized enzymes that wood became the 100% compostable component of living systems that we know it as today.

Plastics are mostly made of the same stuff that wood is, and they are extraordinarily energy-dense. A gallon of plastic has roughly the same energy content as a gallon of diesel fuel. So whether or not humans survive the Anthropocene, we'd be flattering ourselves to believe that we could end ALL life on Earth, and that means that eventually SOME living organism will almost certainly evolve a metabolic pathway that can convert the nutrients and solar energy locked up in the plastics in our oceans and landfills, and use those resources and energy to synthesize the physical structures that allow them to continue to live, grow, and self-replicate. It's only natural! It's what life does.

But why should we wait for humans to go extinct? We built the systems that made the plastic, we can build systems that break them down. We can designs systems that can break down our wastes and use the energy and material in them to meet human needs, for things like food, water, shelter, energy, and information. We can create human-made systems that integrate with the local ecology, that behave as living organisms do, that resolve the conflict between modern human society and the rest of the biosphere. Don't believe me? Great! That's what makes this project interesting!

Check it out:

It's possible to use plastic and biomass to make a flammable gas that can power internal combustion engines.

It's possible to use internal combustion engines to do things like shred waste and make electricity.

It's possible to thermally decompose many common plastics into liquid fuels that can run unmodified gas and diesel engines.

It's possible to use electricity and and shredded plastics to 3D print or mill plastic objects in very nearly any shape (that's why it's called plastic)

So....

The Design Challenge:

This project is my best attempt to design a machine that mimics the metabolism of a living organism, that meets or strives to meet the following criteria:

1) Is capable of metabolizing as many common household waste materials (cardboard, paper, plastic, glass, aluminum, etc, etc, etc) as possible into the resources and energy required to power itself as long as there is trash or biomass available to eat.

2) That is capable of synthesizing and replicating ALL of it's own parts, enabling it to grow, adapt, evolve, and self-replicate. Similar to the Rep-Rap project, the goal would be to build a machine that fabricate all parts of itself.

3) That is open-source, well-documented, and designed for easy replication, using parts that can EITHER be fabricated using common CNC tools like CNC routers, laser cutters, plasma cutters, or 3D printers, OR parts that are so ubiquitous and easy to access that they are functionally open source, and commonly available in the waste stream or second-hand on craigslist, such as car parts, building materials, and standardized plumbing fittings.

4) That is capable of monitoring its own performance using a series of sensors, such as temperature, pressure, and flow rate, and controlling a series of actuators, such as switches, valves, and pumps, and give the user an interface for montoring and tweaking these parameters, and creating rules that allow the system to be as precise, efficient, and self-regulating as possible.

5) That is capable of monitoring, recording, and publishing it's real-time performance data and streaming that data to the internet, so that people around the world can compare their results, copy successful strategies, and learn from each other's mistakes, so that we can systematically work towards an easy to build, easy to replicate, constantly improving and adapting, open-source and biologically-integrated energy device that meets human needs for energy, water, food, shelter, and infromation, while meeting ecological needs for decomposition, bioaccumulation of environmental toxins, and nutrient cycling.

The Prototype

Of course, what I am actually building is not going to be that- not for a long time, and maybe not ever. I'm just one person. Rather, my goal here is define what I believe to be a possible, plausible, and preferable future outcome, and systematically work towards it in such a way that allows other people learn from my mistakes, build on my successes, and engage with this design challenge that I find so fascinating.

What I am actually building is a system that uses heat to thermally decompose shredded wastes into a combustible gaseous mixture of Carbon Monoxide, Hydrogen, and a few trace hydrocarbons, such as Methane. This mixture is often called "Syngas" or "Synthesis Gas". I will then capture, clean, and store this gas at low pressure using a gasometer (like this one by Hackaday user [NightHawkInLight's] and then use that gas to power a small lawnmower-type Briggs and Stratton engine to produce shaft power, heat, and electricity. Once I have those things, I'll use the shaft power/torque created by the engine to power a Precious Plastic plastic/waste shredder, which can shred most plastics as well as other waste items like cardboard, paper, packaging, food scraps, etc. I'll use the shredded burnable wastes and safe-to-pyrolize-but-unrecyclable plastics (such as PE, PP, PS) to make more fuel to run the system. I'll use the electricity from the generator to control the system, and power a Mostly 3D-printed CNC gantry, which is an open source 3D printable CNC router that can move lots of different tools very precisely. Adding a dremel or router tool to the MPCNC will allow me to 3D mill (subractive manufacturing) plastic parts out of recycled plastic blocks, and I'm also working on a prototype for an open-source vertical axis flake-extruding 3D printer head, that is designed to extrude a fairly large bead of recycled plastic (unlike the very small bead of most common 3D printer heads) which I'm hoping will allow me to 3D print (additive manufacturing) large-format, relatively low-resolution parts directly from recycled plastic flakes, without the need for making filament.

If I can accomplish that (and I think there is ample precedent of other people successfully doing all of the individual the parts, that we can safely assume that it is possible, if difficult, to do) then we will have created a synthetic 4machine metabolism that does for plastics what White Rot Fungi did for wood 300 Million years ago. BREAK IT DOWN! (*DJ scratch*)

Acknowledgements:

This project build upon many already-existing parts, tools, and projects, many of which are open-source themselves, and/or inspired by the work of other makers around the world. Throughout this project, I will attempt to give proper links and specific credit where they are due, but just right here, let me say that this project would not be possible with out the hard work of people I have never met.

I want to make it really clear that I didn't invent nearly any of this stuff myself, this is not new technology, and I think it's way cooler that we live in a time where I can just learn how to do stuff like this from other people through the internet. Many parts of this project are far beyond the scope of my personal skillset, and I am only able to build them because other people have taken the time to share their work, which lowered the barrier to entry enough for me to replicate and build upon it - and that is the power of open hardware. That is what I hope this documentation will do for others.

So first, some acknowledgements:

Dave Hakkens- Precious Plastic

Dave Hakkens started the precious plastic project- he designed and published plans for four small-scale plastic recycling machines. But he did it an extremely clear, well-documented, and accessible way, and in the past 4 years his designs have spread literally around the world, with thousands of independent builds worldwide.

Allted- MPCNC (Mostly Printed CNC)

I designed a pellet/flake-extruding 3D print head based vaguely on the Rich Rap and the Precious Plastic Extruder, and I started looking for CNC gantry to move it around. I found the MPCNC (Mostly Printed CNC) that can be made, as the name implies, out of mostly printed parts and 1" conduit. Check out the MPCNC documentation at V1 Engineering.

Jim Mason- The Mechabolic Project

Jim Mason is a pioneer in waste-to-energy technology. He is an integral part of All Power Labs in Berkeley, which famously designed the open-source GEK (gasifier experimenters kit) and used it power a honda accord with trash (yes, like Mr. Fusion). His Mechabolic Project at Burning Man in 2007 was a mobile waste collection unit powered by trash, which was a huge inspiration for this project.

Gary Gilmore- Charcoal Gasifier

Gary Gilmore is a farmer who developed a simple technique for powering internal combustion engines with charcoal instead of liquid hydrocarbons. The technique is extremely simple, and many modifications and experiments have been built upon his original design.

Rich Rap- Pellet Extruding 3D printer head

The open-source pellet extruding head available on the thingiverse was an inspiration to me, and helped me gain the confidence to build my own design based on the same working principle. Either design could be used, and I suspect that Rich Raps design will be better for high detail printing, while mine is optimized for low-detail but large scale printing.

Marcin Jukobowski's vision of a set of open-source tools that make modern society possible has been a huge inspiration to me, and his work on running an Open-Source Tractor on charcoal led me to research biomass gasification as fuel source.

If the idea of a self-replicating 3D printer machine sounds familiar, it's because it's the central goal of the Rep-Rap project. Although this project doesn't currently incorporate the Rep-Rap design, their bold vision guided my thinking when conceiving of this project.

Now, head on over to the Instructions Section to check out details on each of the systems that make up the Metabolizer, or check out the BOM in the Components Section.

Sam Smith

Sam Smith