Rogue: When they come out... does it hurt?

Wolverine:

Every time.

Yeah there's some sharp edges there alright. XD

Yeah there's some sharp edges there alright. XD

I've been experimenting with materials again trying to create a tough skeleton system for Pandelphi Cub, having picked up some Polypipe which is light and strong.

I've used this before on numerous occasions, and made some great hardware with it.

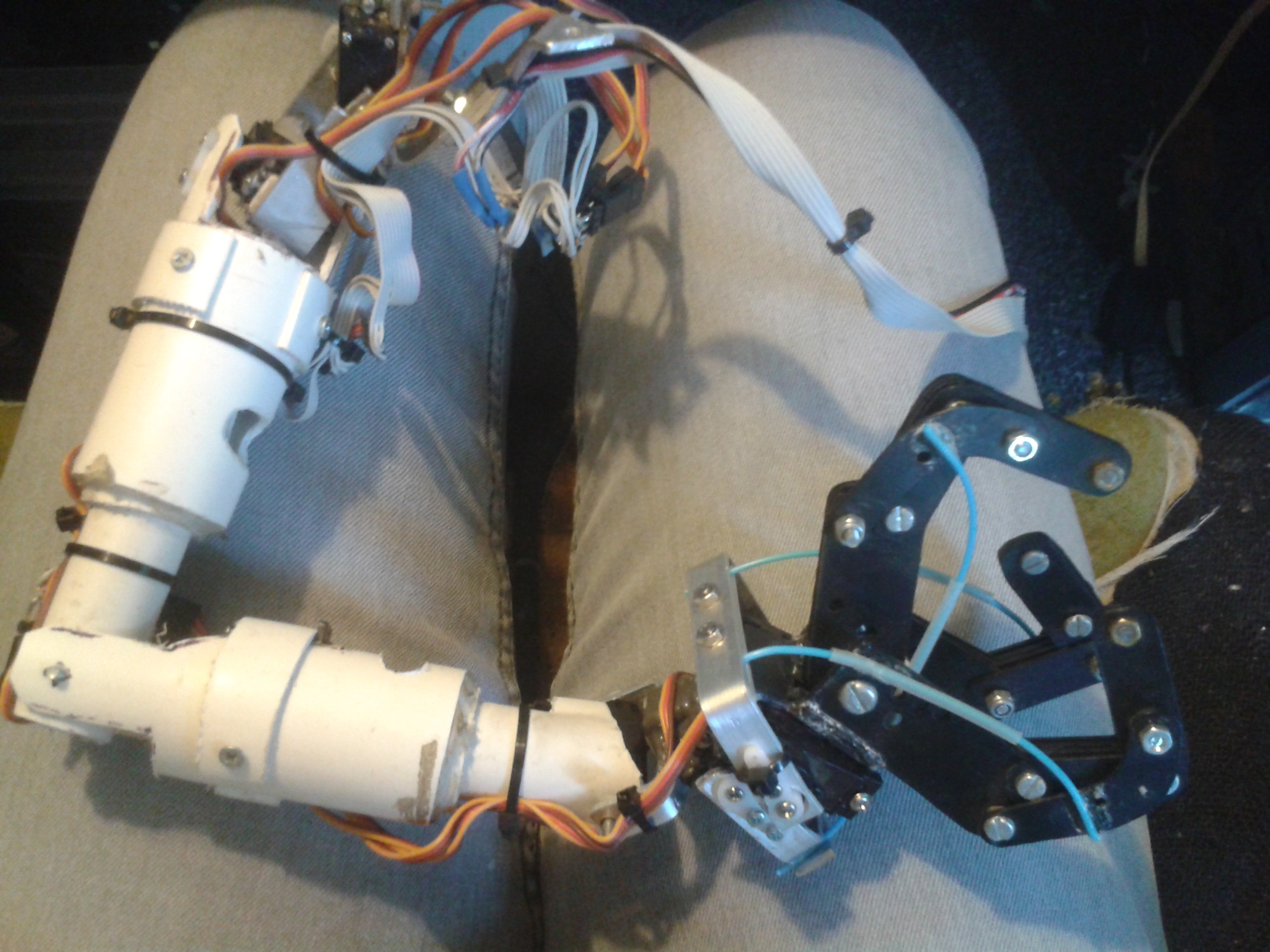

AIME's arm with Gripping Hands.

AIME's arm with Gripping Hands.AIME was mostly constructed of Aluminium, but her arms were polypipe. Besides being strong and light, PVC pipe is also extremely slippery and doesnt take glues very well. I used Hot Glue on this, as it holds the best of all. When I was building it, I noticed that the hot glue made the pipe slightly soft and flexible for a moment, but didnt think much on it.

Cubs frame however isnt linear and has some joints in it that are hard to accomplish on round tube, so I had a bit of a play with some scrap to see how it reacted to heat. I was pleasantly surprised, PVC is a mesh of long molecules all tangled together like Felt, and when it is heated it has an extra phase between liquid and solid, where it behaves almost like a fabric. Above 120 degrees or so the molecules loosen up but remain joined together so the material goes floppy, and above 160 degrees it melts to a liquid, so its quite easy to keep it in a handleable range and work it.

This was filmed using the scrap I experimented on :-D I can now film myself filming myself. Better not go there lol, we'll be here all day.

What I learned from heating and cutting the pipe, I put into practise. The material retains all its former strength no matter how many times you heat and form it, but it is possible to tear the stuff as it doesnt stretch or expand during heating.

What I learned from heating and cutting the pipe, I put into practise. The material retains all its former strength no matter how many times you heat and form it, but it is possible to tear the stuff as it doesnt stretch or expand during heating.

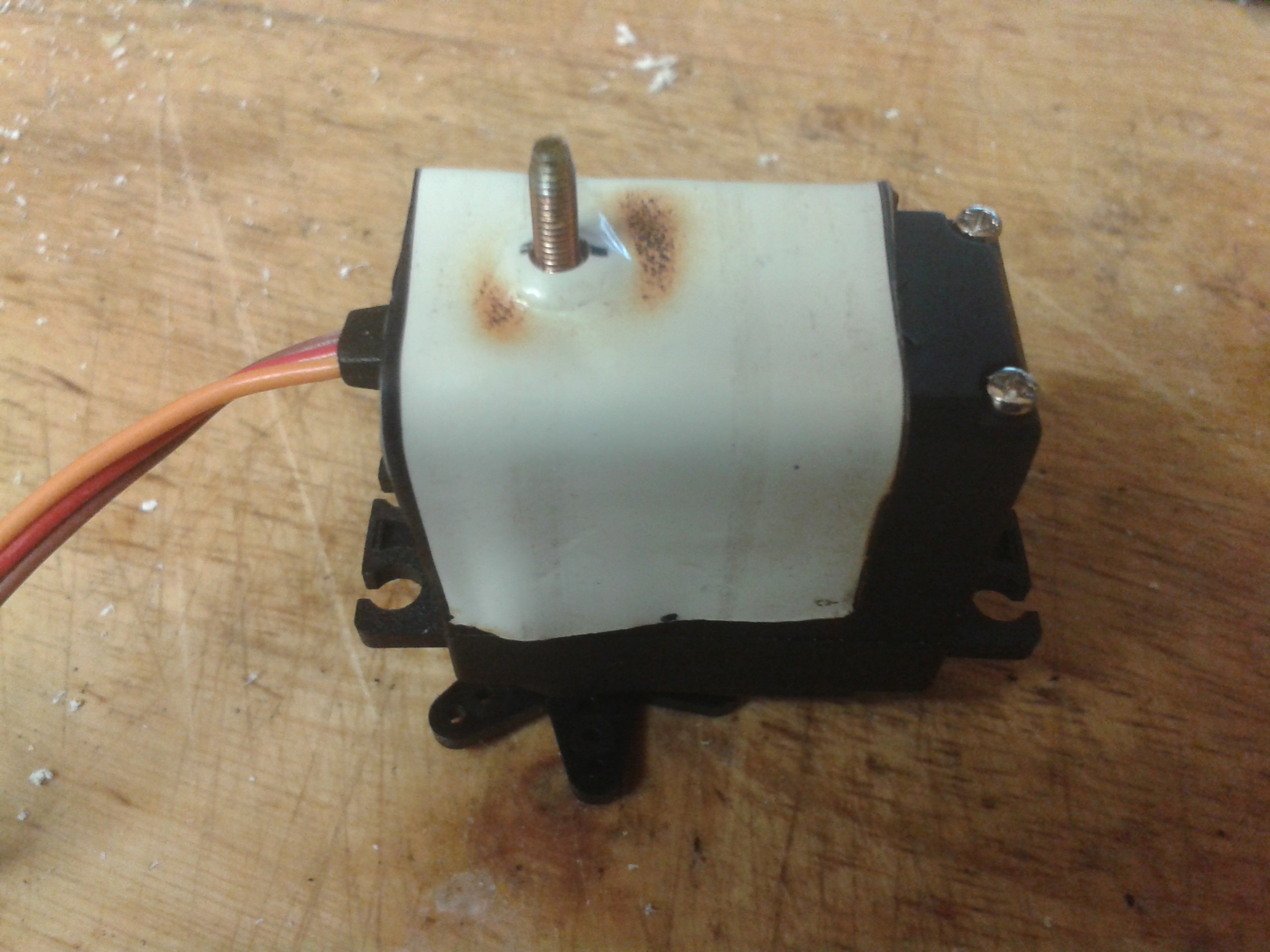

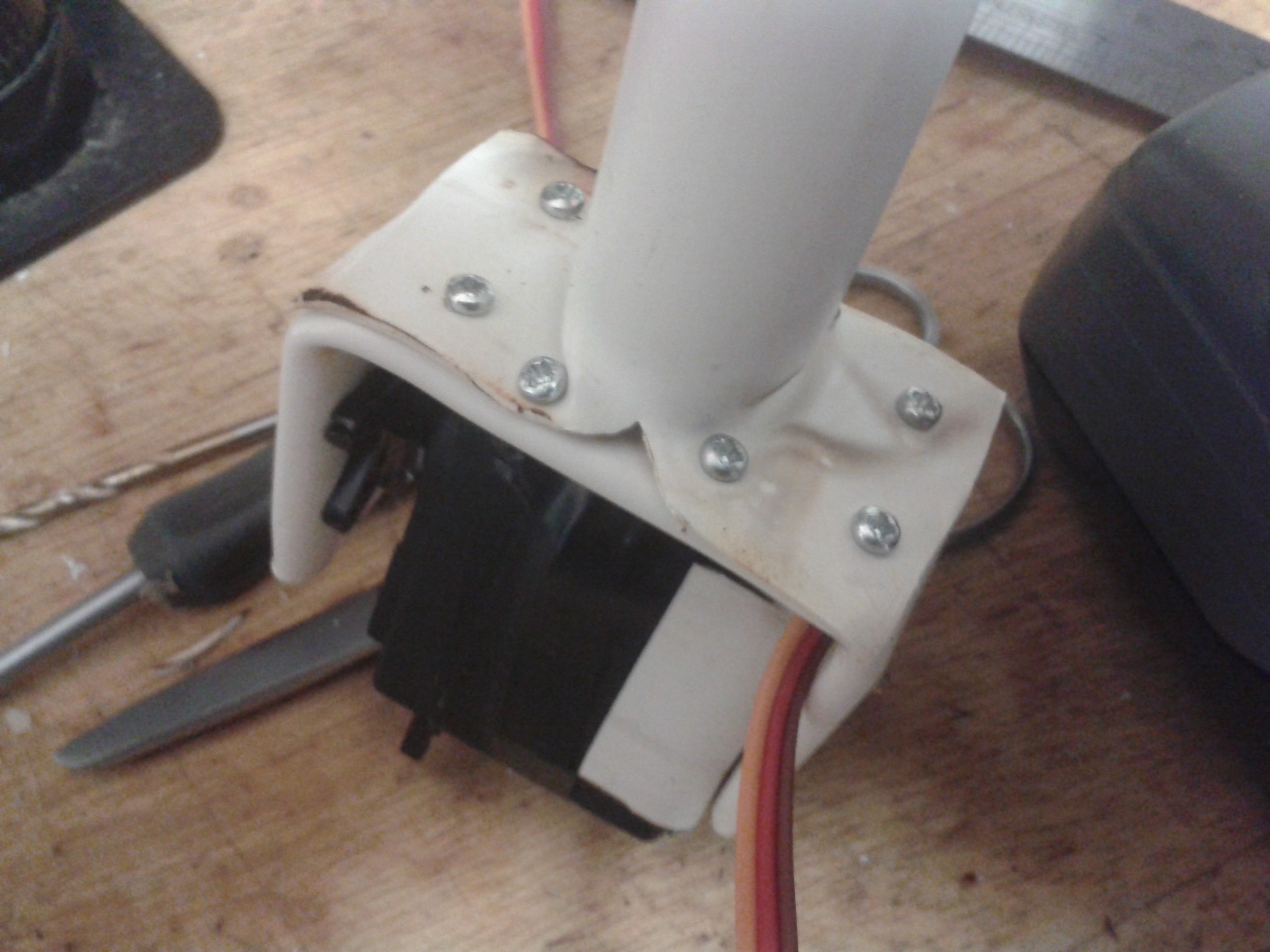

An experimental servo mount. I had to do a lot of cutting and measuring to get that to fit, there must be an easier way.

There is as well. This worked out so much better than I hoped.

The screws that mount the servo also join the plates together so they dont move. Its rock solid and will easily deal with the 13kg torque from these evil servos. Metal-Gear Futaba clones with uprated motors and electronics. They are badged as 'Robot' servos, but I see no difference to the mounting and interface from the ones around half a decade ago. My stepdad used to fly RC, and nothing has changed since... Bad show guys, Especially Turnigy and Futaba, the two biggest names out there.

Make us a hinge, dont just change the description you bums. >;-P

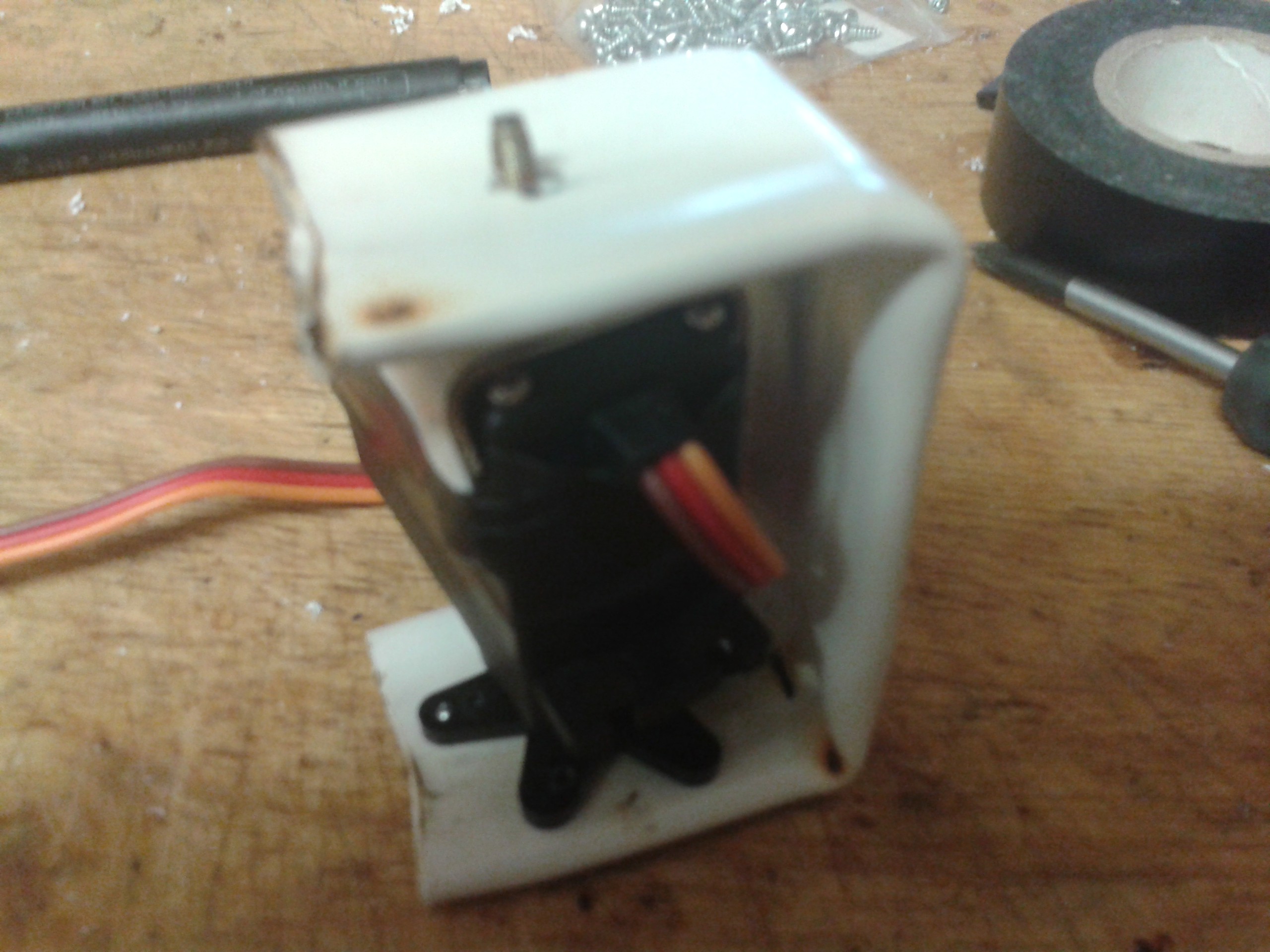

All the tape does is hold down the flap so it doesnt rattle, the two side cheeks cross and the screws go through both, and into the pipe at the other end. It's ludicrously strong and all in one piece, better than a PLA print and probably stronger than an ABS one as well.

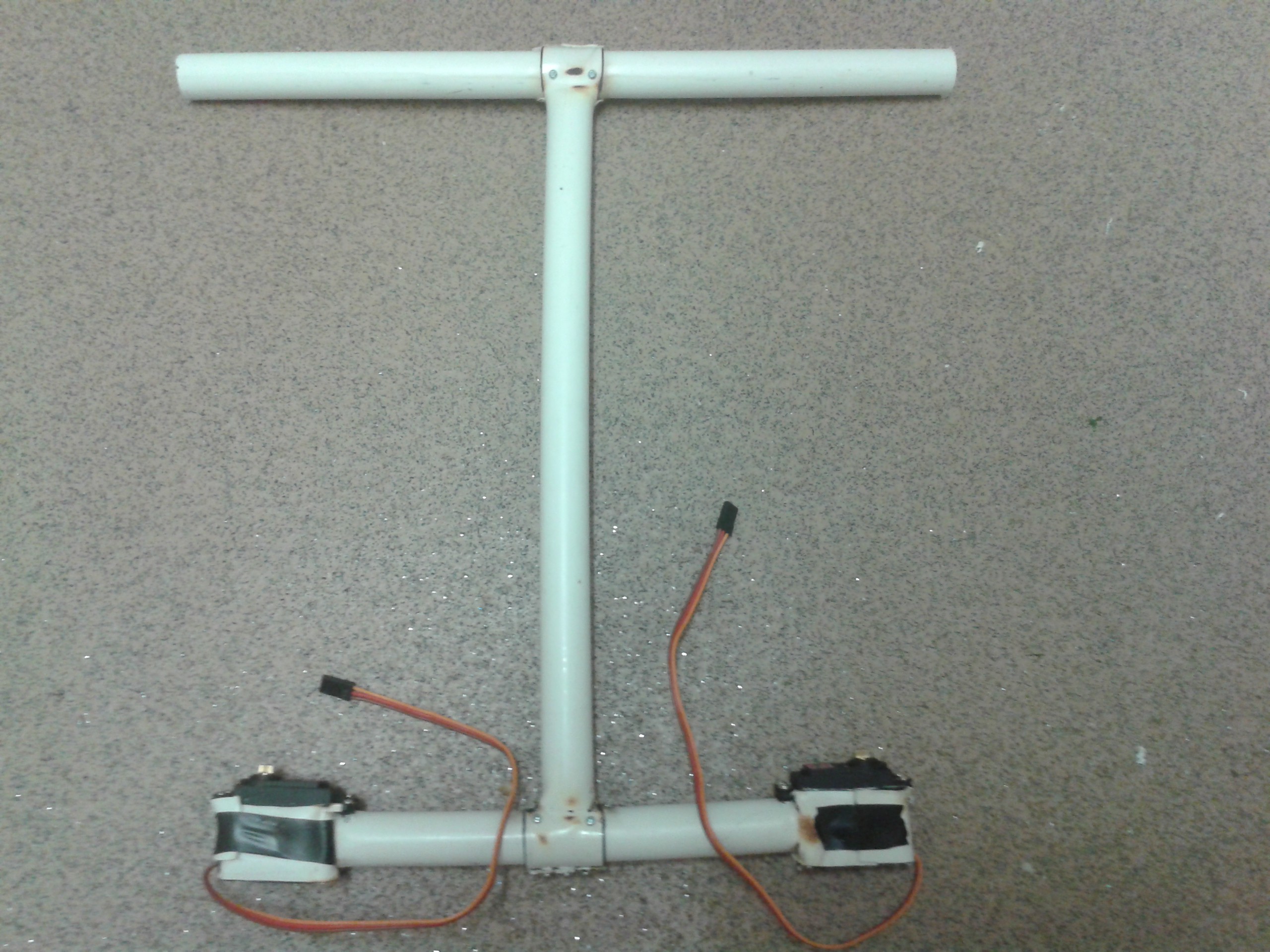

Joints in pipe are a total pain in the butt. Polypipe is slippery and smooth, but get it formed properly and its extremely rigid. I copied a bicycle handlebar for this, figuring metal and plastic would behave similarly and it worked really well.

A little heat on the tube and that will straighten right out. ;-)

I did have a little trouble interfacing to the servos, until I retried the trick I used with Cardware...

The Dead Yoke...

A cross of material with the arms folded out has the same geometry as the Hip Unit but it doesnt have to be round and braced to take the strain like cardboard.

This bolts onto the end of a tube that has been split into flanges, or bolts to another one back-to-back to make all the moving joints.

I love how the material pulls around and smooths under my fingers, its a very organic way of working with it and very satisfying.

Once this is finished, all that remains is to make a panda skin from fabric with a double pocket in the stomach. One to take all the hardware which doesnt even need mounting, and another with a zip to take the Echo Dot.

Morning.Star

Morning.Star

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.