The actuator for sail control has to be small, lightweight and waterproof for full submersion. There are no great requirements for strength and life span as the force needed to adjust the flap is relatively small and it will move only when the wind direction reverses which may happen max. once per hour. In the following video, a hacked actuator was completely submerged in a concentrated salt water and tested for 3000 cycles.

How to waterproof the actuator

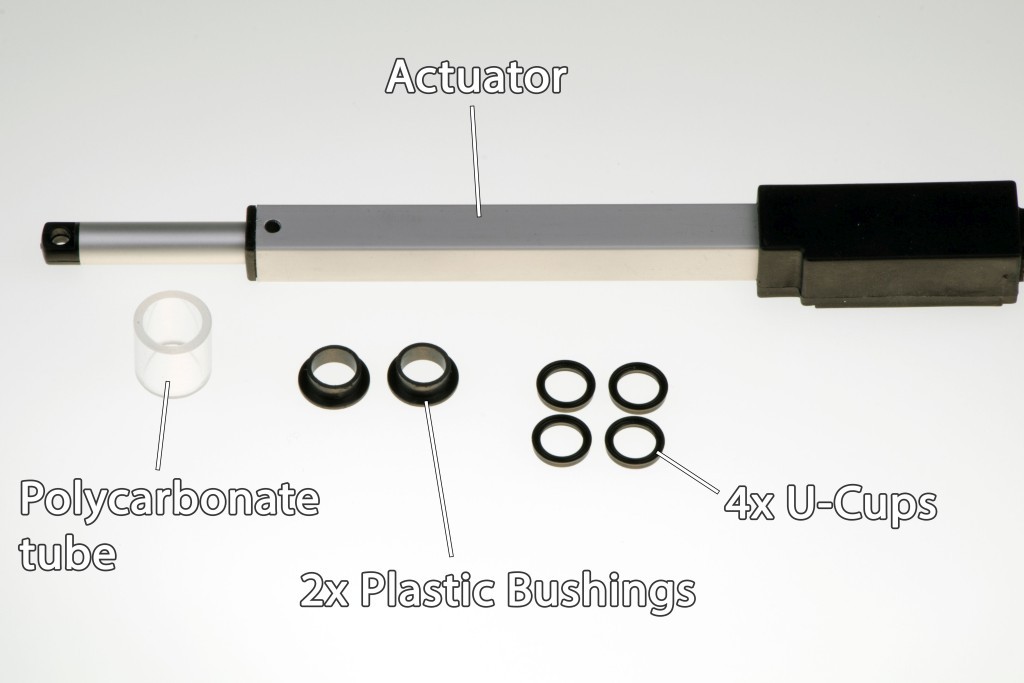

You need u-cup seals, plastic bushings and a piece of tube with a smooth inner surface, preferably a polycarbonate tube. The inner diameter of the u-cups must match the diameter of the actuator rod and the inner diameter of the tube must match the outer diameter of the u-cups.

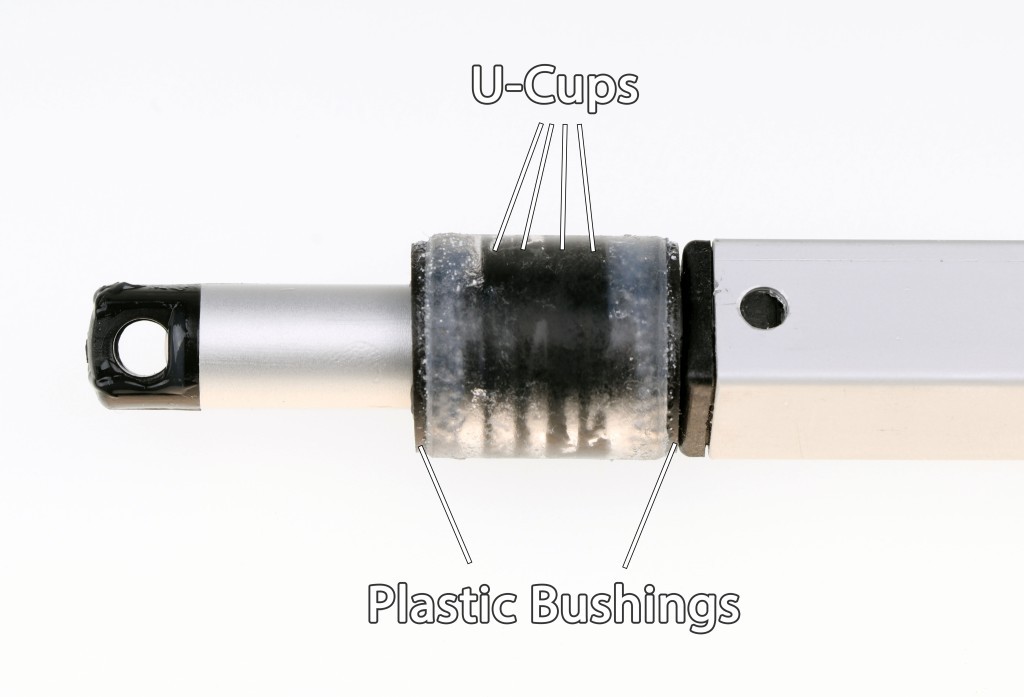

The u-cups are inserted into the tube. Plastic bushings keep the rod and tube concentric.

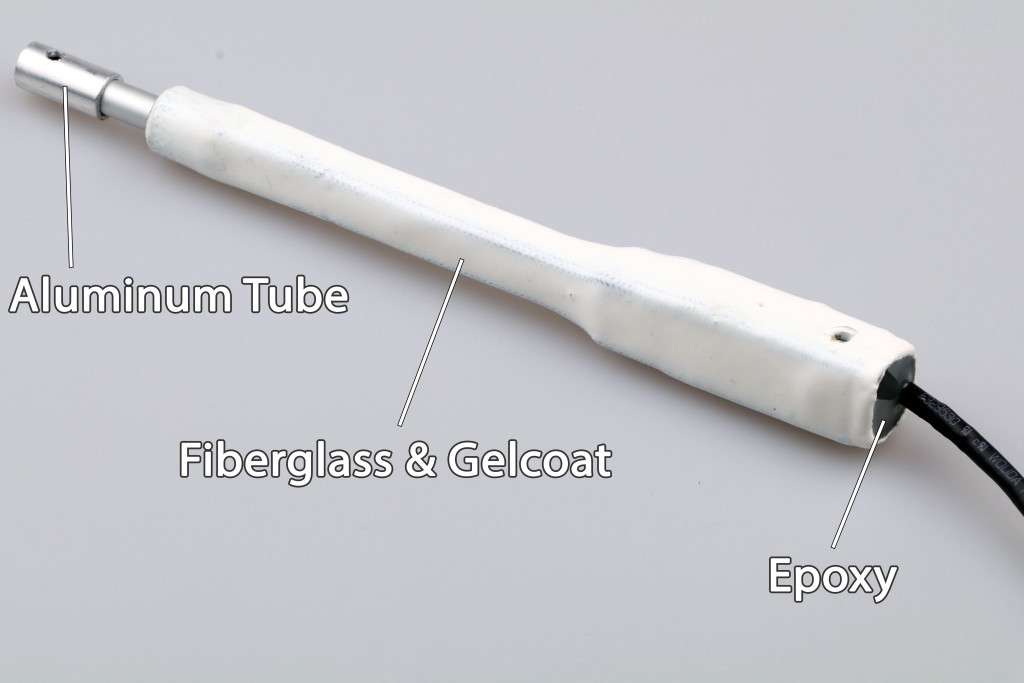

The actuator is further reinforced by a fiberglass sleeve which also makes the body completely waterproof. The plastic end of the rod on the original actuator looks like a weak point, so I glued a piece of aluminum tube over it.

Andy Osusky

Andy Osusky

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.