Short Project Description

My objective in my project was to create a flashlight that runs solely on the heat of the human hand. Using two Peltier tiles and the temperature difference between the palm of the hand and ambient air, I designed a flashlight that provides bright light without batteries or moving parts. My design is ergonomic, thermodynamically efficient, and only needs a five degree temperature difference to work and produce up to 5.4 mW at 5 foot candles of brightness.

Summary

I chose to investigate the aspect of human energy when I found out that we are like walking 100 Watt light bulbs. The goal of my project became a flashlight powered solely from the heat of the human hand. I decided to use Peltier tiles. If one side of these tiles is heated, and the other is cooled, electricity is produced. For my flashlight, I would be heating one side with the palm, and cooling the other side of the tile with a heat sink.

I calculated that our bodies radiate 5.7 mW/cm2, but only 0.5 mW is needed to generate a bright light at the LED. I characterized both Peltier devices. Both produced power, but only a few millivolts. I need 2.5 V ! I had to convert my DC input to AC, and then run it through a oscillator circuit with a step up transformer. My final circuit had only 3 parts and produced a step up ratio of 100:1. So for 50 mV DC from the Peltiers I obtained 5 Volts AC which was sufficient to light the LED. The final design included mounting the Peltiers on a hollow aluminum Rectangle tube and acrylic sheet was wrapped on hollow aluminum rectangle sheet leaving aria ofpeltier that allowed ambient air to cool the tube. The palm wrapped around the peltier to warmed the peltier tiles. The result was a bright light at 5 degree Celcius of Peltier differential. The flashlight worked!

About Me

Hello, my name is Muhammad Wasim. I live in Pakistan. I have a great love for science, and have been competed many project about power generation and energy saving. A full size of ceiling fan 56” powered by cell phone battery. Cell phone battery charging system through walking for shoes with piezoelectric. Hydrogen fuel cell and hydrogen production from water with cheap way and running a bike through hydrogen. Cell phone charging system through radio signals coming from cell towers. I also submitted propeller design which is able reduce 70% noise and about 30 save energy to DJI drone company about a year ago with no replay. Now DJI is using these propellers in mavicpro platinum. This time I am going with the project; The Infinity Flashlight.

My next projects are power generating football 2 a bike helmet having personal air conditioning and heating system on demand. Creating water from air. Creating a energy harvester on mass base like Nikola Tesla.

My family has encouraged my interest in the sciences, and my first toy was a box of transistors. Nikola Tesla and Edison have both inspired me greatly as role models.

To be honest, I am not sure exactly what I want to study in the future just yet; I'm thinking it will probably be the Sciences. My passion is “Serve the humanity through advance science”.

Question / Proposal

Hypothesis: If I can capture enough heat from a human hand and convert it efficiently to electricity, then I can power a flashlight without any batteries or kinetic energy.

Objective: To make a flashlight that runs on the heat of the human hand.

Research

The website was dedicated to low voltage transistor oscillator circuits. I also found one other source that really made me believe that my battery-free flashlight was indeed possible when surfing the internet and found a paper entitled "Ultralow Voltage Energy Harvester Uses Thermoelectric Generator for Battery - Free Wireless Sensors".

Step 1 in my procedure, involved much research, as I decided to calculate how much heat per cm2 we radiate in our inner palm, where we normally hold a flashlight. I found that an average human dissipates around 350,000 Joules per hour, or 97 watts1. The average surface area of the human skin3 is 1.7 m2 or 17,000 cm2, so the heat dissipation equals to (97/17000) * 1000 = 5.7 mW / cm2.

A useful area of the palm is about 10 cm2. This implies that 57 mW could be available.

The thermal efficiency of a Peltier tile is cited at about 10%4. This means that I should be able to generate 5.7mW in the palm of the hand. From testing a new batch of LED’s, I knew that I needed at least 0.5 mW to obtain usable LED brightness5. Now I could go on to step 2 and the physical measurement and design of the flashlight

Method / Testing and Redesign

(Step 1 was research oriented, so it is not included here).

Step 2: Characterizing the Peltier Tiles:

Two sets of cheap, same sized peltier tiles were obtained6. Both Tiles had an area of 40mm. I tested the power generated by each Peltier stack on a per cm2 basis.

To do this, I taped each tile onto a rectangle aluminum tube. One side of the Peltiers was cooled by an ice pack, and the other was heated with a 12-volt light bulb connected to a variable power supply. The temperature difference between the sides of the Peltier tile was measured. Both Peltier tiles produced enough power to light an LED, but only at 50 and 73 mV.

I needed 2500 mV to light the flashlight LED.

Step 3: Boosting the Voltage.

Direct Current cannot be multiplied, but if the DC is changed to AC, the voltage can be stepped up with a transformer. The answer lay in constructing a simple oscillator circuit with a step-up transformer.

To do this I constructed a feedback oscillator with a field effect transistor and wound my own transformers with step-up ratios of 5:125.

The oscillator worked, but the LED did not light up until the Peltier voltage was 120 mV. I needed it to light up at about 50 mV (voltage produced at a 5°C temperature difference).

Searching the Internet, I came across an article about energy harvesting7 and the use of a power converter integrated circuit, LTC3108. The circuit contained FET’s that would oscillate at voltages as low as 20mV. When used with a recommended transformer, the IC would provide well over 2.5 volts AC.

The IC also worked fine as a very low voltage transistor oscillator. My circuit now had only 4 components: The IC, the step-up transformer, a 47µF capacitor, and the LED. With the LED across the transformer, I was able to obtain good LED brightness with only 50 mV DC input across the oscillator. Next same results I found using Unipolar Boost circuit convertor from txl group.

Step 4: Physical Flashlight Design.

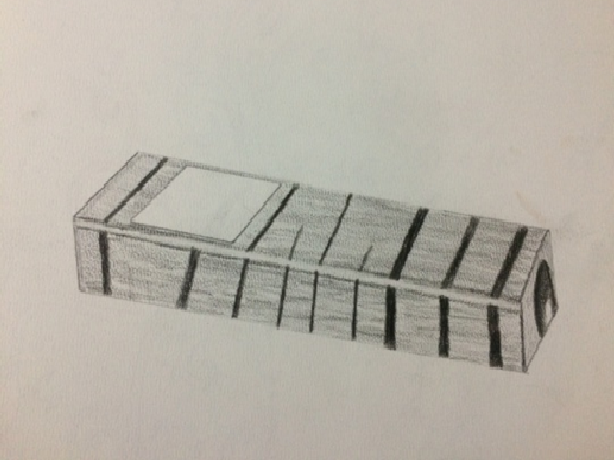

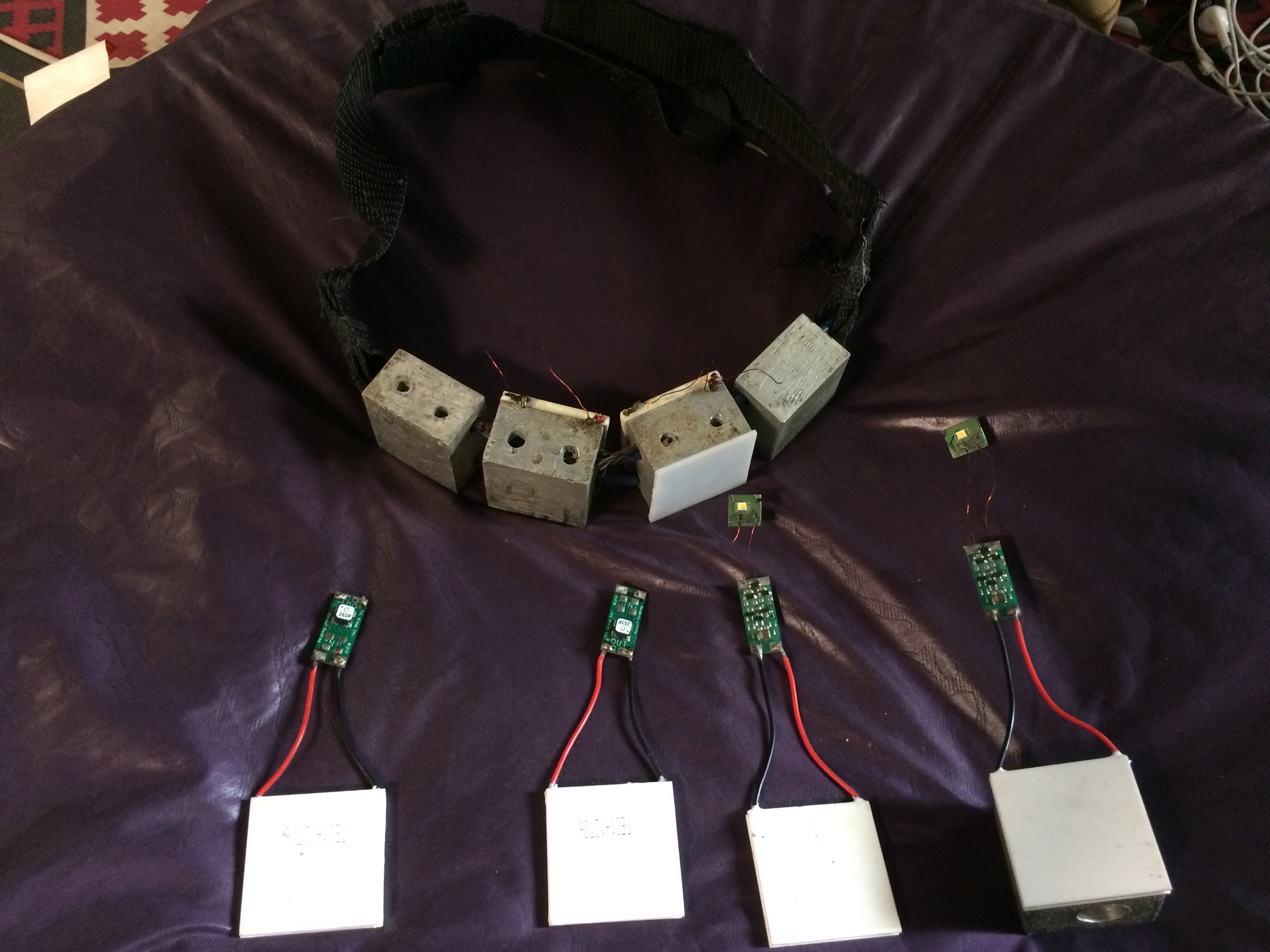

I decided to make the flashlight with dimensions of height 2.75cm, width 4.50cm and 17.1cm long. Tiles were mounted on a milled area of 40mm on both sides on aluminum rectangle tubing. Insulated from it by air. The hand griped the tiles through an opening in the acrylic sheet cover. Air flowing through and around the aluminum tube cooled the flashlight. The circuit was mounted in the front, and the LED was centered in the middle of the tube. I made two flashlights, the F1 with 2 peltiers 40mm tiles, and F2, with 4 peltiers 40mm tiles in headlamp form.

Results:

The results prove my hypothesis that even with all the thermal and voltage conversion losses, there was still enough power in the palm to provide usable light. The actual power at the LED was difficult to measure accurately because it was an irregular square wave at 40 kHz. So I made a comparative measurement with a light meter and an external white LED (connected to a DC power supply). I measured the DC power into the external white LED that gave the same amount of light as the white LED in my circuit. Both LED’s were identical types, 5mm, 15 degree types from Digikey.

For my F1 flashlight, I calculated the theoretical power at the LED to be around 1.5 mW. When I did the comparative measurement, my prediction turned out to be very close, with a 1.4 mW. The F2's theoretical power was supposed to be around 4.5 mW, but instead I got 5.4 mW.

The theoretical power calculated, and the actual power obtained was within 20% of each other! Bravo!

Measurements with a Spectra light meter showed that both flashlights produced good light.

Flashlight F1 produced 5 footcandles of light at a 5ºC, and 10 footcandles at 10ºC Peltier temperature difference.

Conclusion / Report

In conclusion, I succeeded in powering a flashlight using only the heat of the hand.

I made two flashlights that do not use any batteries, toxic chemicals, or kinetic energy. They do not create any noise or vibrations and will always work. The flashlight’s only limitation is its need for at least a 5°C temperature difference to provide usable light.

In the beginning of my project, I had hoped and believed that my flashlight would perhaps work, but I did not expect my final brightness that I received to be as high as 5 footcandles. I am pleased with my results, but do have some future improvements in mind.

In the future, I hope to work on improving efficiencies of the converter, increase the flashlight brightness, and perhaps use this technology for powering wireless medical sensors. My circuit and design has infinite possibilities and uses for the future! For example, imagine holding your phone, and at the same time charging it just from the heat of your hand! Or perhaps all school chairs in classrooms having Peltier tiles, and we could harvest the heat and amplify it into electricity using my method. I am very excited for the possibilities my project has! It is but a means of showing what this concept, and what human heat energy, can do.

In my experiment, I had several general errors in my sources and calculations. For instance, palm temperature, and total skin surface area varies widely between individuals. The skin area was averaged from several sources and varied from 1.6 m2 to 2 m2. Another questionable figure is the thermal to voltage conversion efficiency of the Peltier tiles. This is a complex problem in thermodynamics depending on the heat conduction properties of the tiles, contact areas and heat sinks, and is not usually given in the manufacturers specs. The same efficiency figure of 10% was obtained from a text at Stanford and an online encyclopedia. The voltage, current, and temperature measurements I made, were done on Fluke meters, and had more precise accuracies which varied from .01% to .1%.

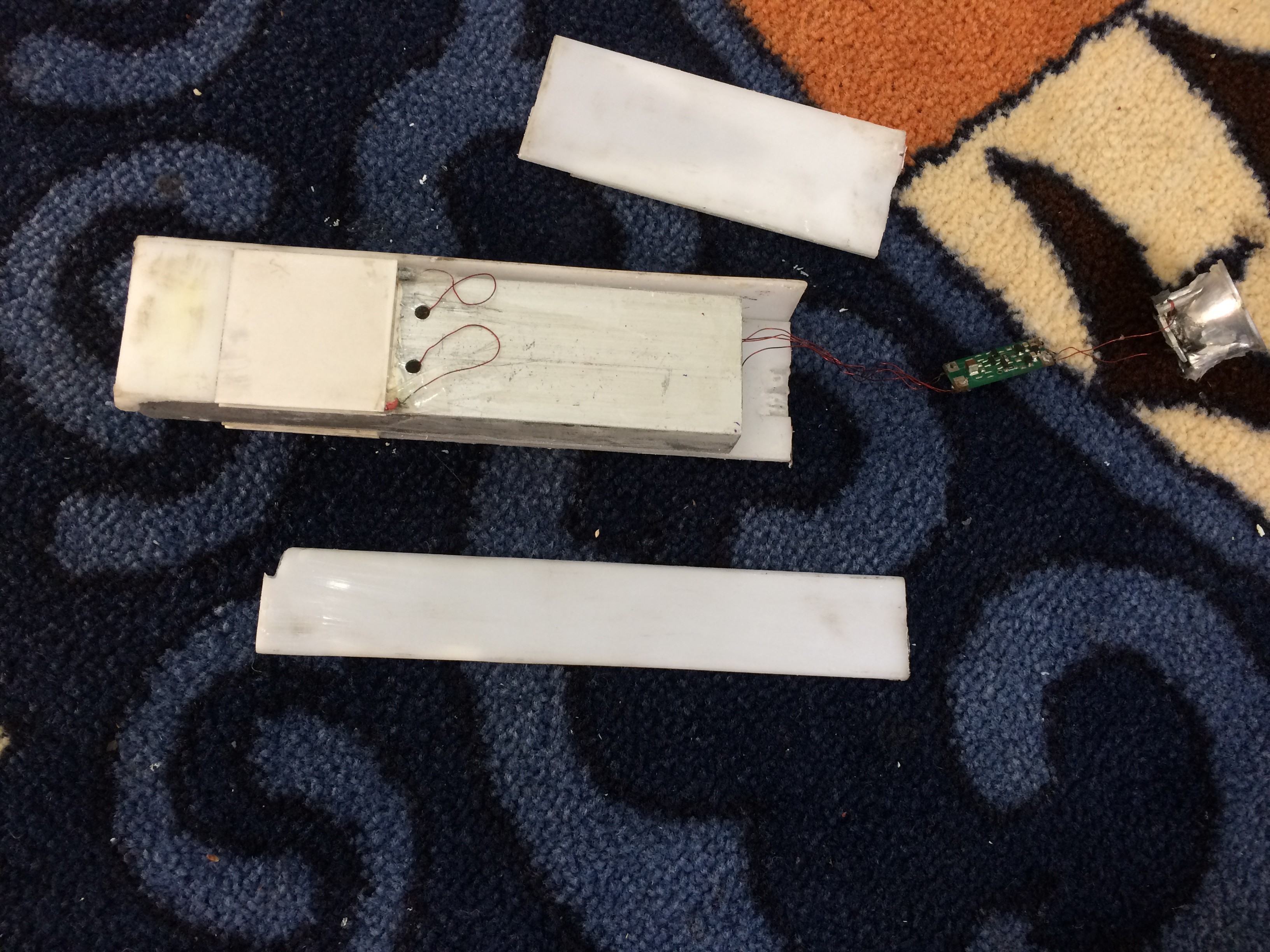

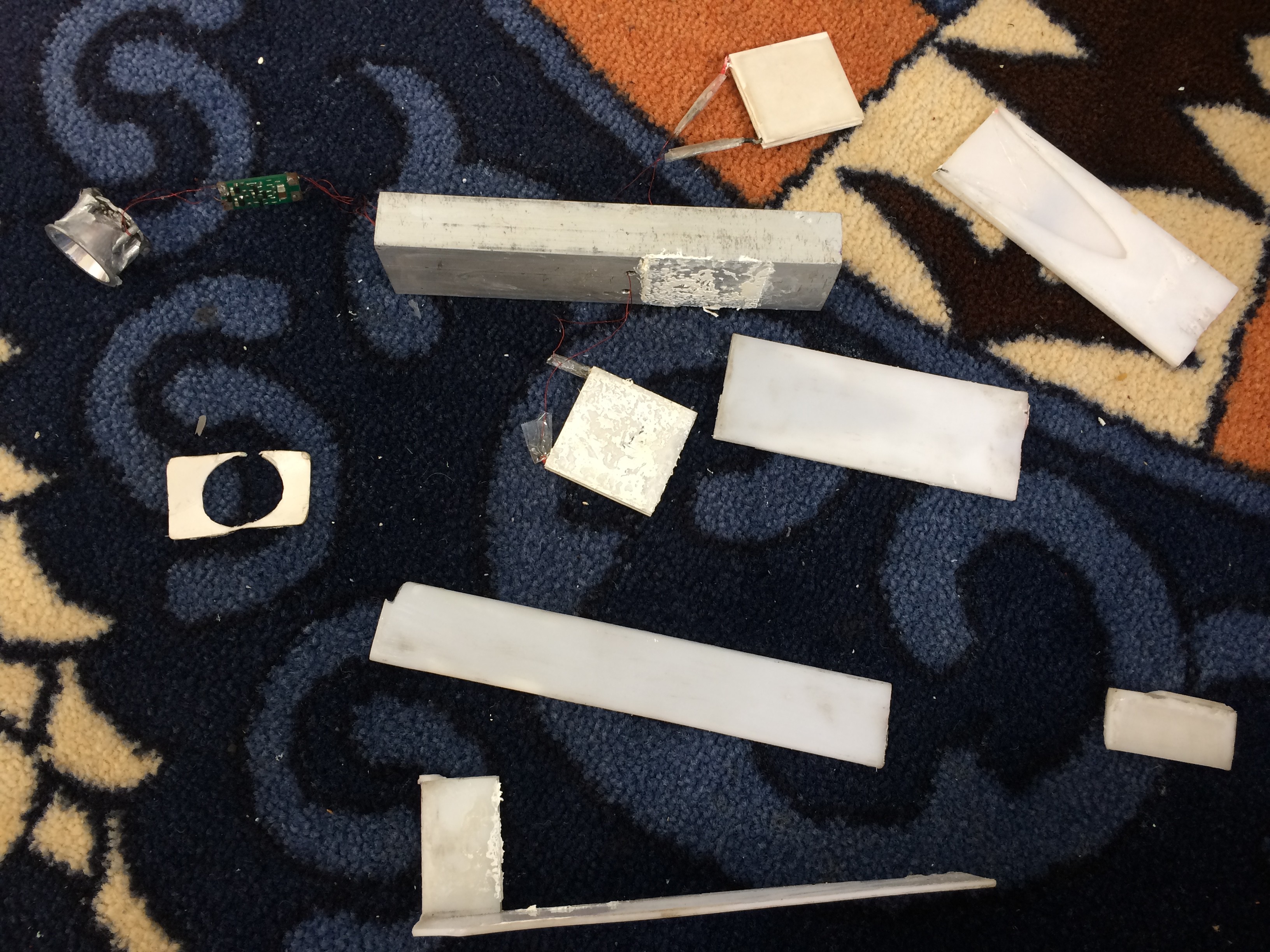

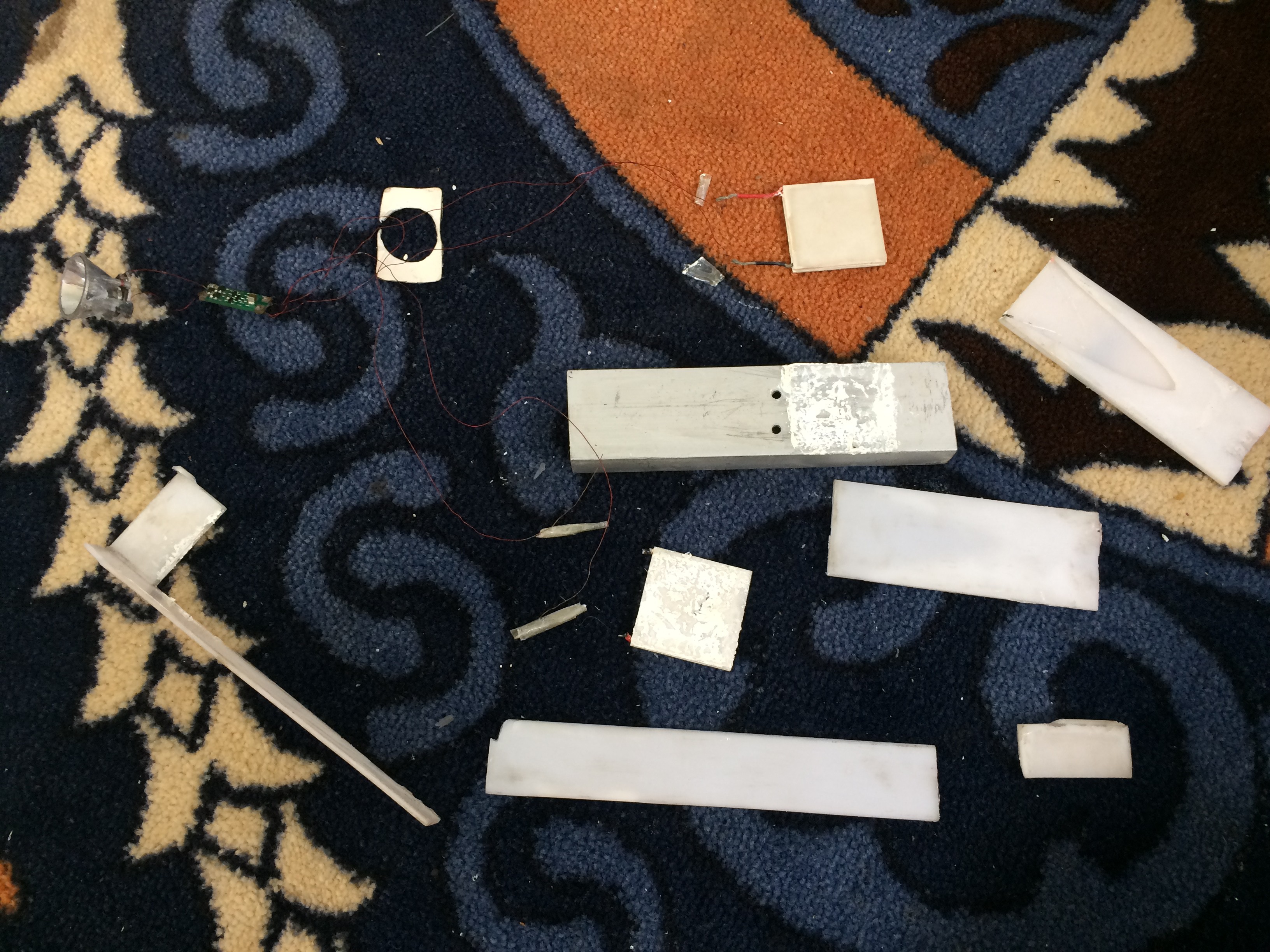

High Resolution Photos inside and outside of Flashlight

Removing attractive paper from flashlight

Removing LED lamp and circuit

Removing back cover of flashlight

Removing acrylic sheet step by step from aluminum rectangle pipe

Reproducible build instructions

These are the instructions if you want to reproduce the Flashlight or headlamp.

Thermoelectric Peltiers

As you increase thermoelectric peltiers in your project you should increase the series

Heat Sink

Always use heat sink that has more legs. A good heat sink gives you the right results.

Volt Boosting Circuit

Volt boosting circuit is the key of our unit. Only two types of circuit are use full (1) taken from txl group has only two sides input and output side. Peltiers should be connected with input side of circuit and LED should be connected with output side of circuit. While the other has IC LTC3108. It making process is available at instruction area and in files feeding area.

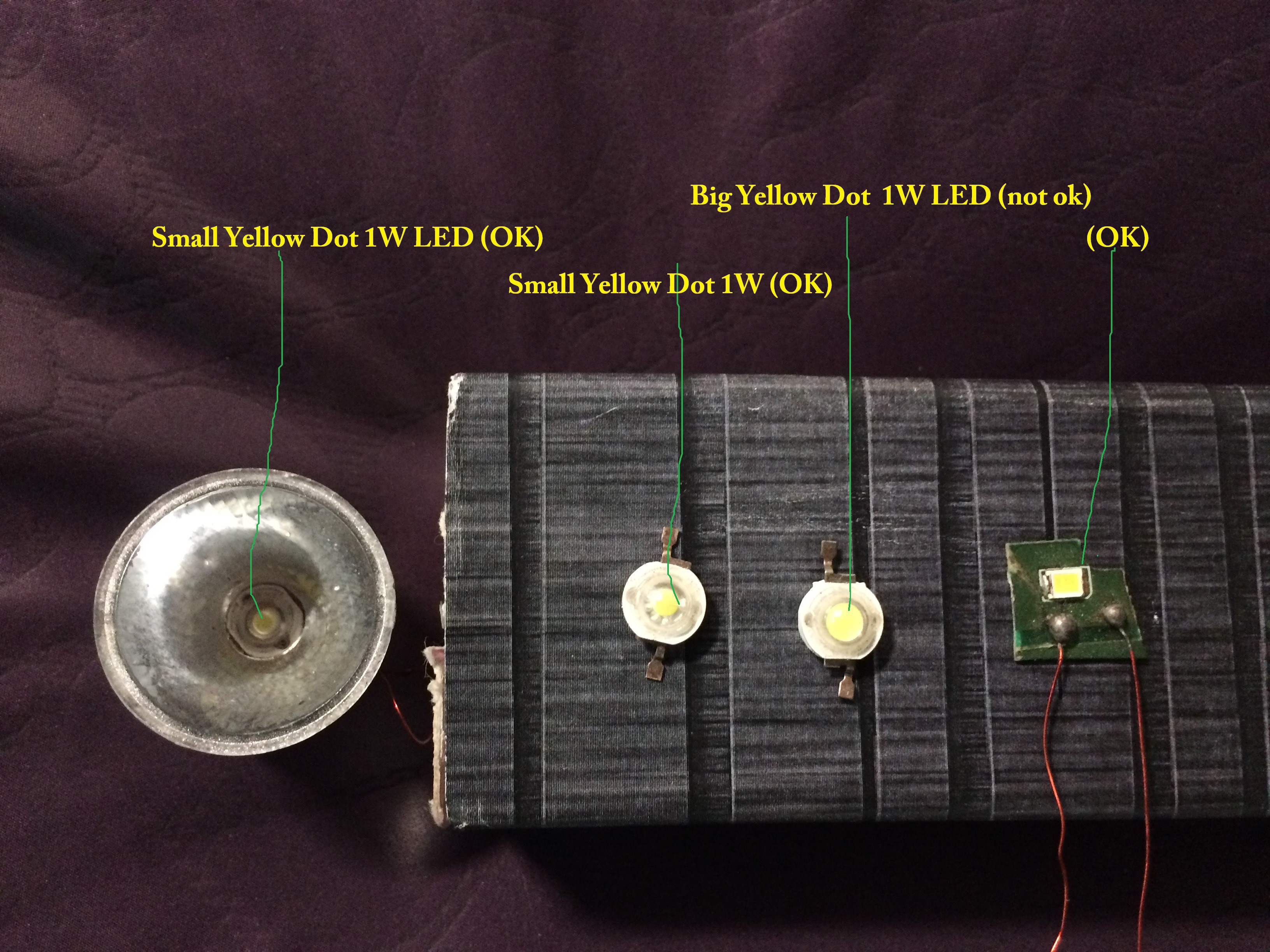

LEDs There are lot of LEDs those are useful. Straw hat 0.28 watt is best in results. In 1watt LED I prefer to use the LED that very small yellow dot in it

Certificate

We applied for certification at arrow electronic that our product is feasible consumers. Where the first time applying is free.So They awarded a certification's badge. Here is a screen shot and picture of their badge.

Body Heat power Headlamp F2

Previous headlamp and some volt boosting circuit with peltiers

What thermoelectric can do for us now

Here I will discus to you what we can do with thermoelectric right now also can think how would be our future about thermoelectric.

Cell Phone charging with heats of your tea any hot or from cool

You self can create a smart cup that can charge your mobile phone easily with the help of LTC3108. Its explanation is available in my instructions area. In this project your need a hot tea of any hot thing instead of body heat. If you have hot from the one side of peltier you can charge you’re mobile. If you have a cool you can charge your mobile from the other side of peltier.

Body heat powered smart watch

A USA matrix power watch company created a smart watch that has no need of charging only powered by our own body heat. They are also using LTC 3108 in their watch also using low power electronic like eink display. www.powerwatch.com

NASA and Nextreme

NASA is the first company who uses thermoelectric device on big level in his mars rover curiosity mission. For this they contact to nextreme those thermoelectric module were high efficient. Now nextreme changed its name with the name of www.lairdtech.com . They I also produce a high quality thermoelectric devices. They are thin film based. I like only one that uses a thin film that does not any charging system not powered by body heat. This is powered by ambient that is available for life for day and night for month and year. That you can see here.

Alphabet Energy

Website www.alphabetenergy.com

Alphabet Energy is a start-up company founded in 2009 at the University of California, Berkeley by thermoelectric expert Matthew L. Scullin and Peidong Yang.The company uses nanotechnology and materials science applications to create thermoelectric generators that are more cost effective than previous bismuth telluride-based devices. The company is based in Hayward, California. It started with a license to use silicon nanowire developed at Lawrence Berkeley National Laboratory.They moved from UC Berkeley to offices in San Francisco in 2011, and later to Hayward

Nitinol

Nitinol alloys exhibit two closely related and unique properties: shape memory effect (SME) and super elasticity (SE; also called pseudoelasticity, PE). Shape memory is the ability of nitinol to undergo deformation at one temperature, and then recover its original, undeformed shape upon heating above its "transformation temperature". Super elasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the undeformed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal.

Stirling Engine

A Stirling engine is a heat engine that operates by cyclic compression and expansion of air or other gas at different temperatures, such that there is a net conversion of heat energy to mechanical work.

Thanks

Best Regards Muhammad Wasim

Wasim Sahu

Wasim Sahu