Video below shows process of PCB assembly. Since there is small number of components and most of them are TH, I decided to save on stencil and apply solder paste by hand. This approach is not optimal for small pitch packages because it require additional rework to remove formed short circuit bridges. In the end, because there is only one small pitch component it will be more time efficient than soldering components one by one.

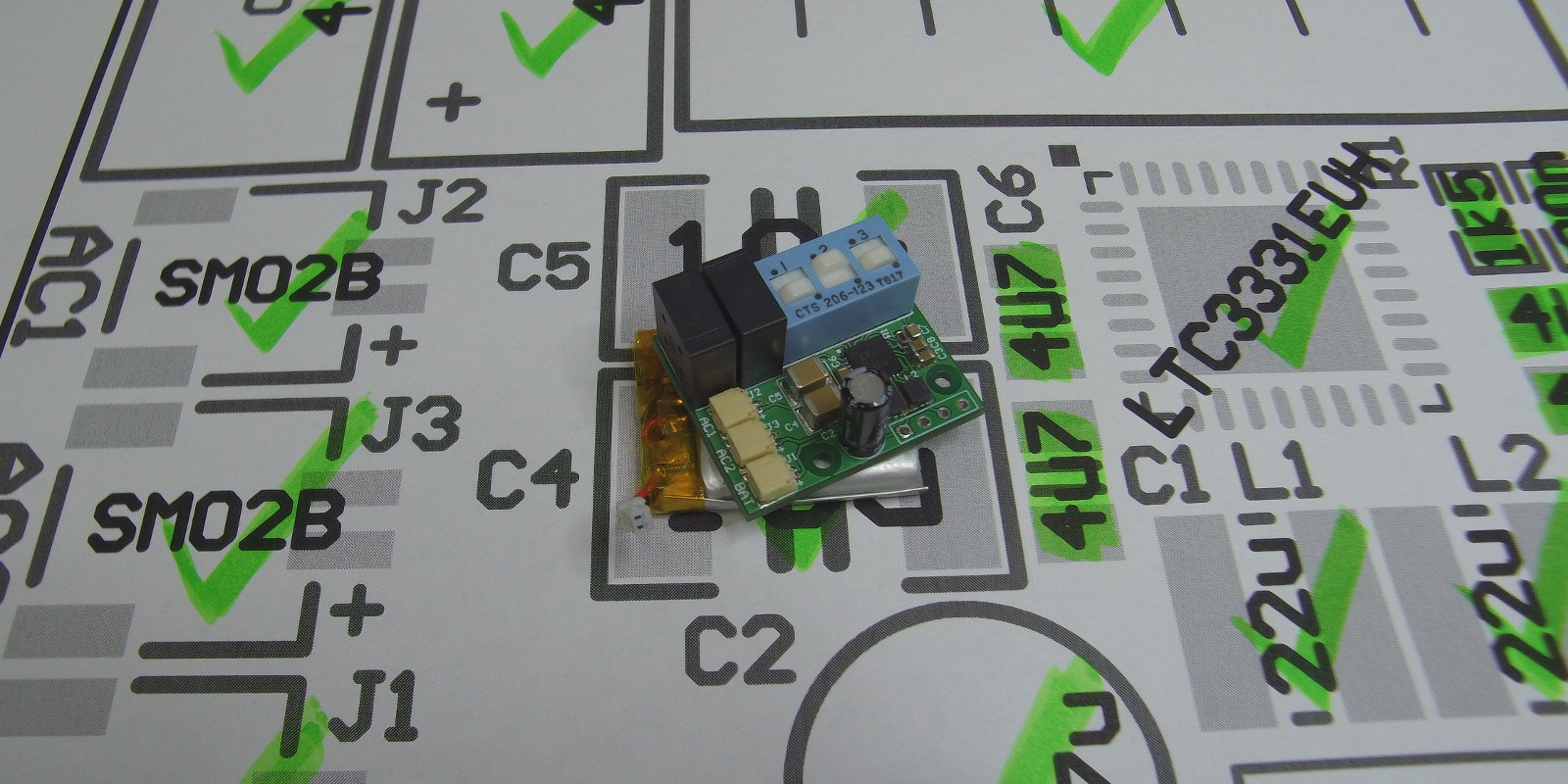

Assembly drawing makes placing components easy, fast and decreases chance of placing component in wrong position and ruing your day.

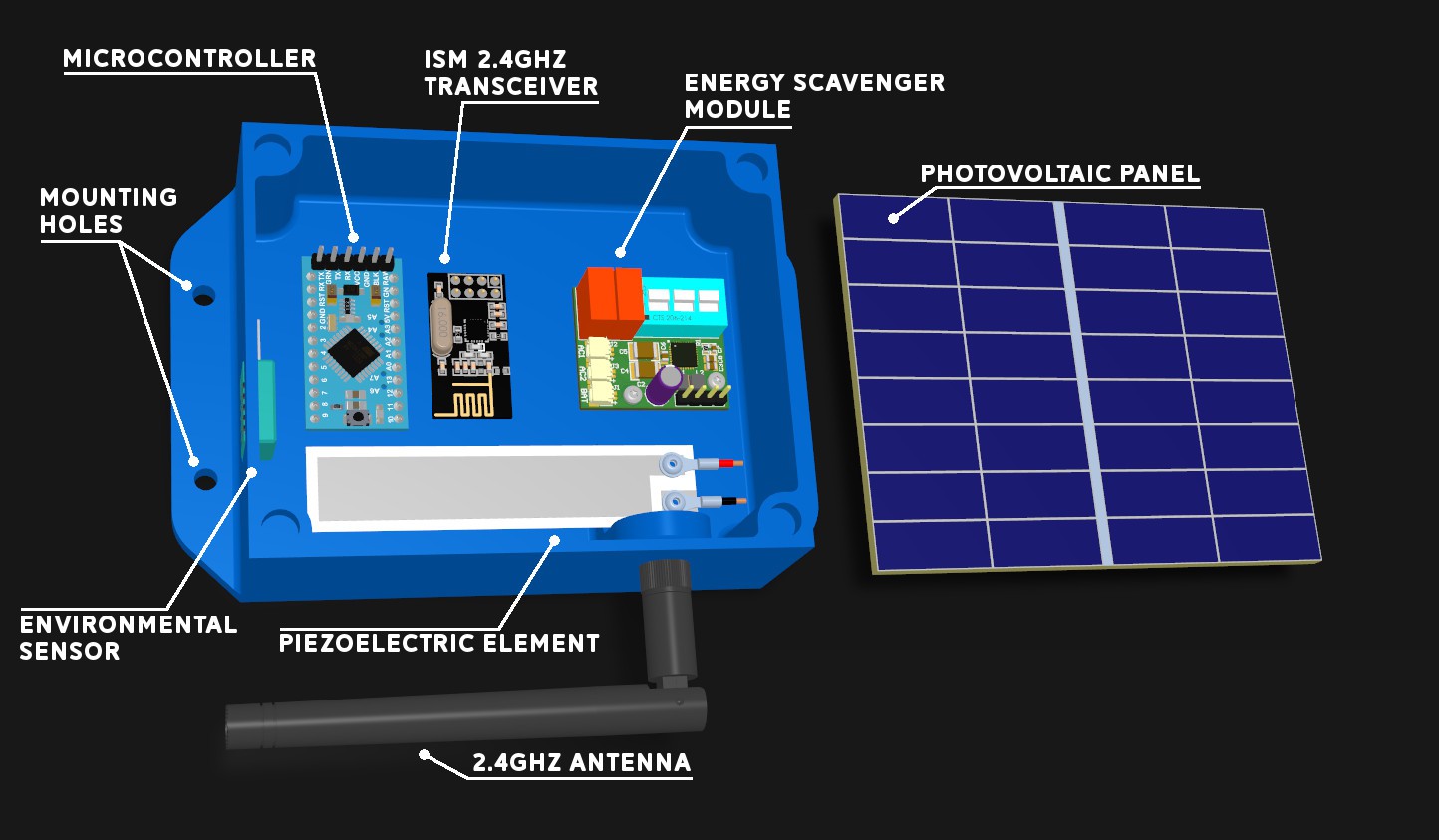

Enclosure is 80x100mm so that it accommodates photovoltaic panel of the same size. It can be mounted using magnets(fast and less labor intensive) or screws(more secure option). Cover lid with photovoltaic panel is held with magnets. Inside, there is place for custom electronics, sensors and additional external antenna to increase signal range. Since enclosure is 3D printed and used just as proof of concept it does not have proper IP protection against environmental effects, therefore alternative protection of electronics is needed.

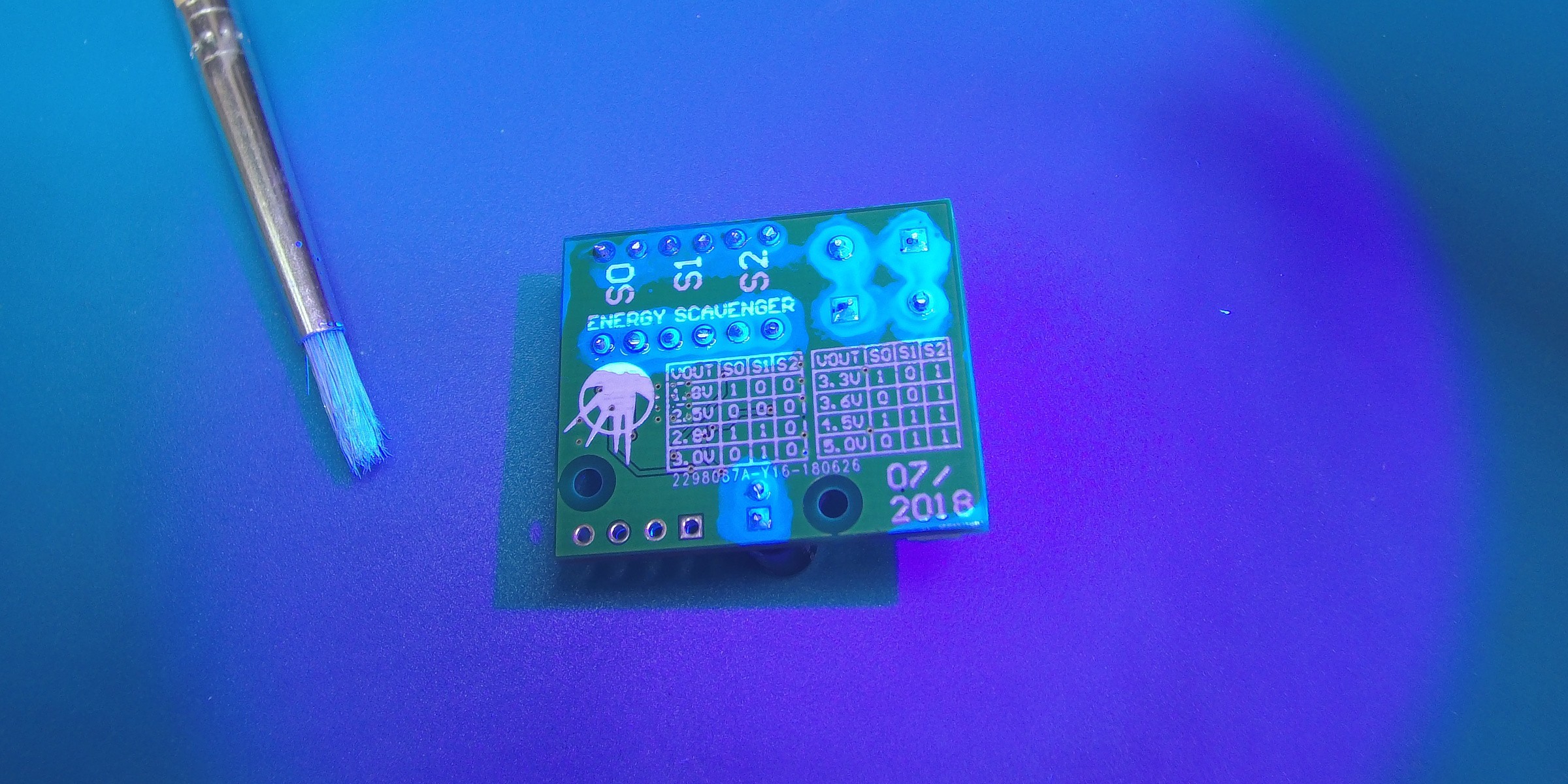

After assembly module is conformally coated to protect solder joints from corrosion. Corrosion may occur when module exposed to moisture and humidity. This is necessary since module will be enclosed in 3D printed prototype enclosure which can't properly protect against environmental effects.

Mile

Mile

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.