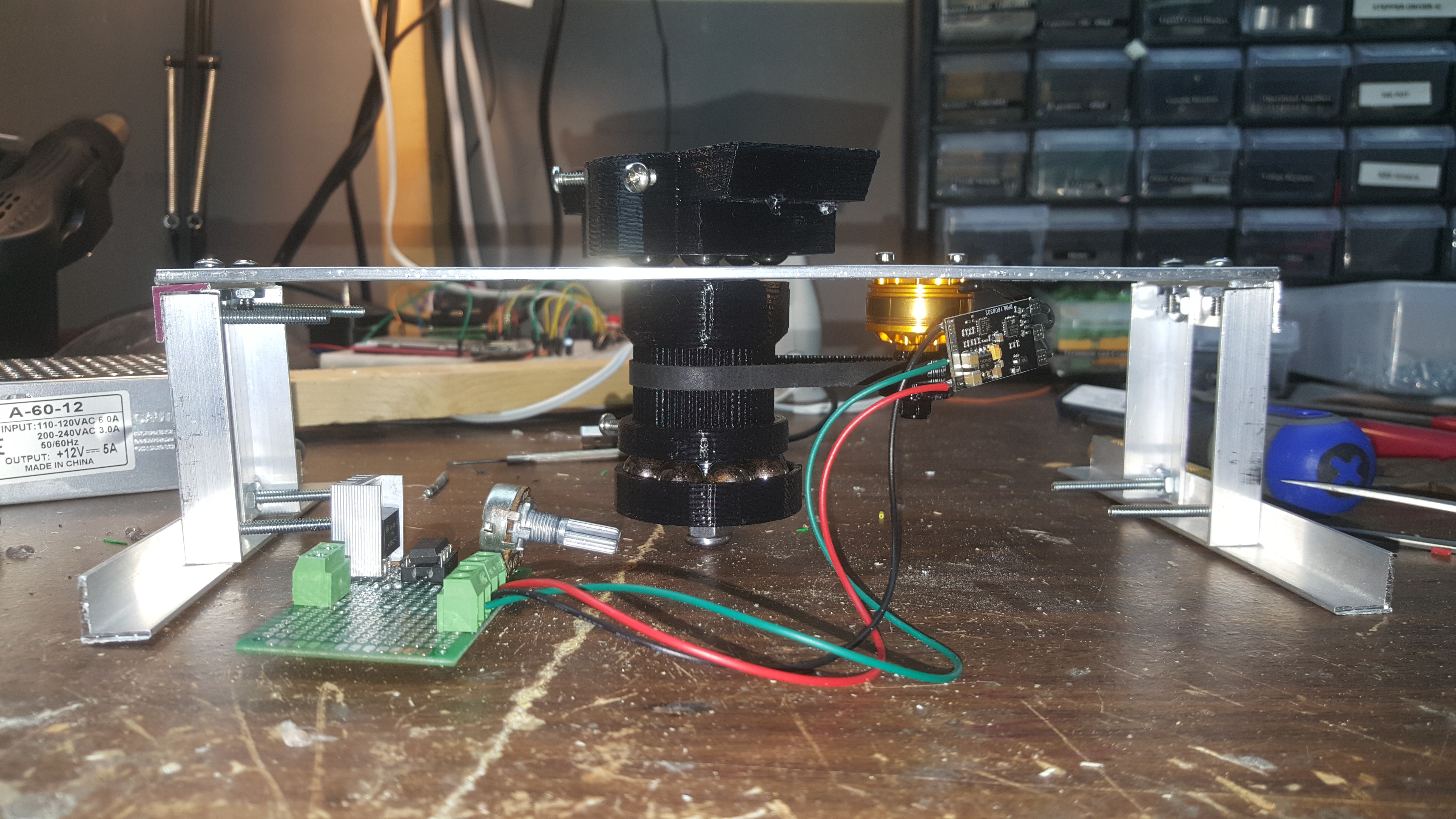

it's been a while since the last update, mostly due to school. the base for this project has been completed and is much different from what i had originally planned when i envisioned this project. for this part i decided to utilize a brushless FPV motor on a belt system to drive this project (only decently fast motor i had on hand, also i have a ton of ESCs sitting around). every part pictured was printed with 40% infill at 35mm/s and 15mm/s on the outside layer... which took a whole day after two prints failed. to drive the motor i whipped up an attiny circuit that's controlled by a potentiometer, and powered by 12 volts. I'm not really a mechanically inclined person so this part of the project was significantly more difficult for me than laying out the board or planning the circuity. The mechanical part of this was difficult and took quite a bit of time to complete:

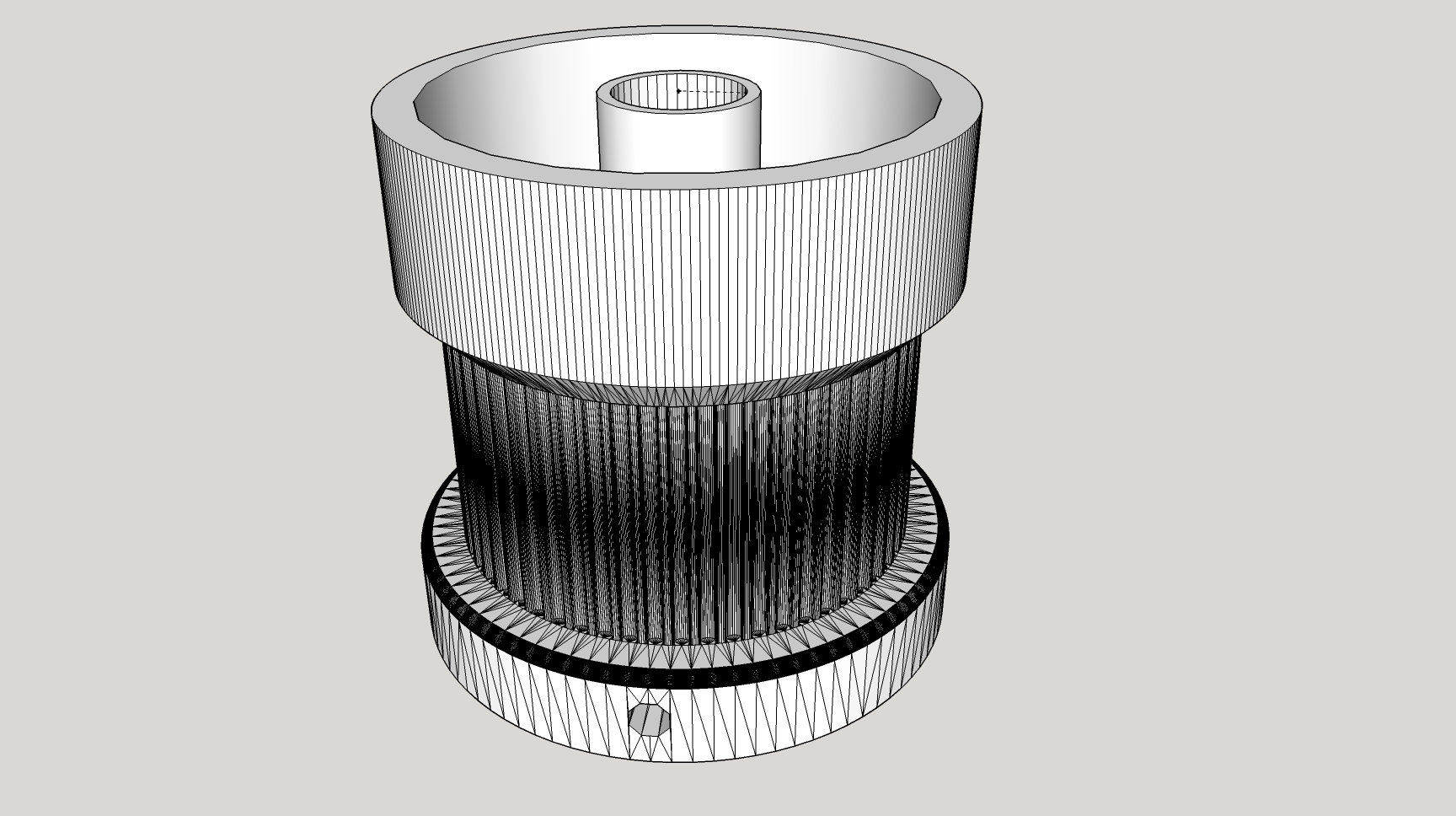

I created the main gear using the customizer on thingiverse then customized it in google sketchup. You can find the parametric design i used here (https://www.thingiverse.com/thing:16627), credit really goes to droftarts here. The only real modification i made here was to add the space in the top to accept 1/4" ball bearings. This design utilizes a 5/16-18x3.5 bolt as the main shaft, while the bolt and nut hold the parts together vertically the ball bearings allow a low friction surface while keeping the gear and top mount from moving left or right. this design works pretty well actually, the only issue is that the combination of some ball bearings, an aluminum plate, and some rough 3d printed surfaces results in a lot of noise. however vibration is at an acceptable level and the noise isn't too loud. Might switch to proper thrust bearings if i get sick of hearing it.

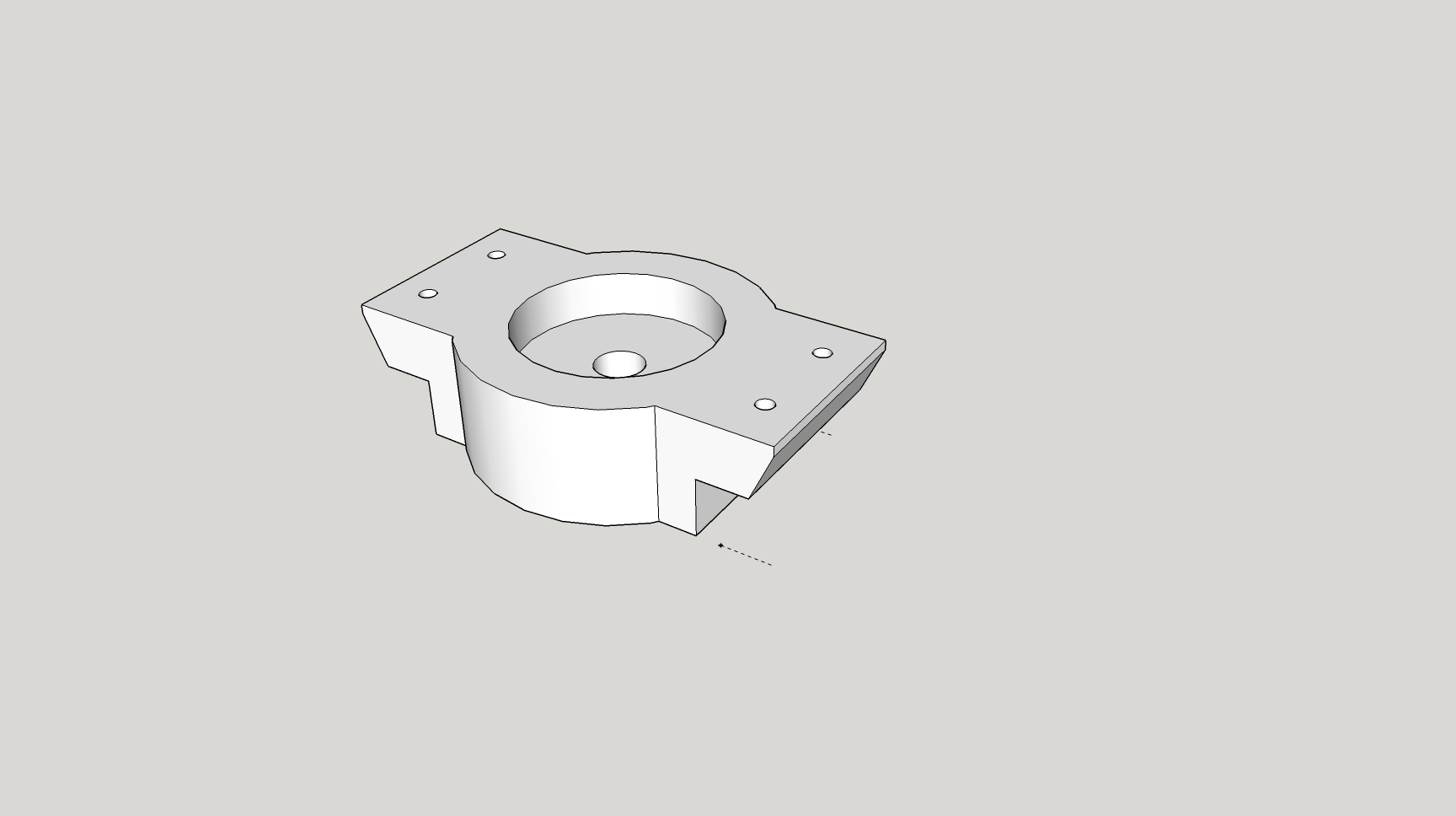

the top mount is simple, just some screw mounts and a hole for the bolt to go through. Additionally this one shares the same ball bearing design as the main gear.

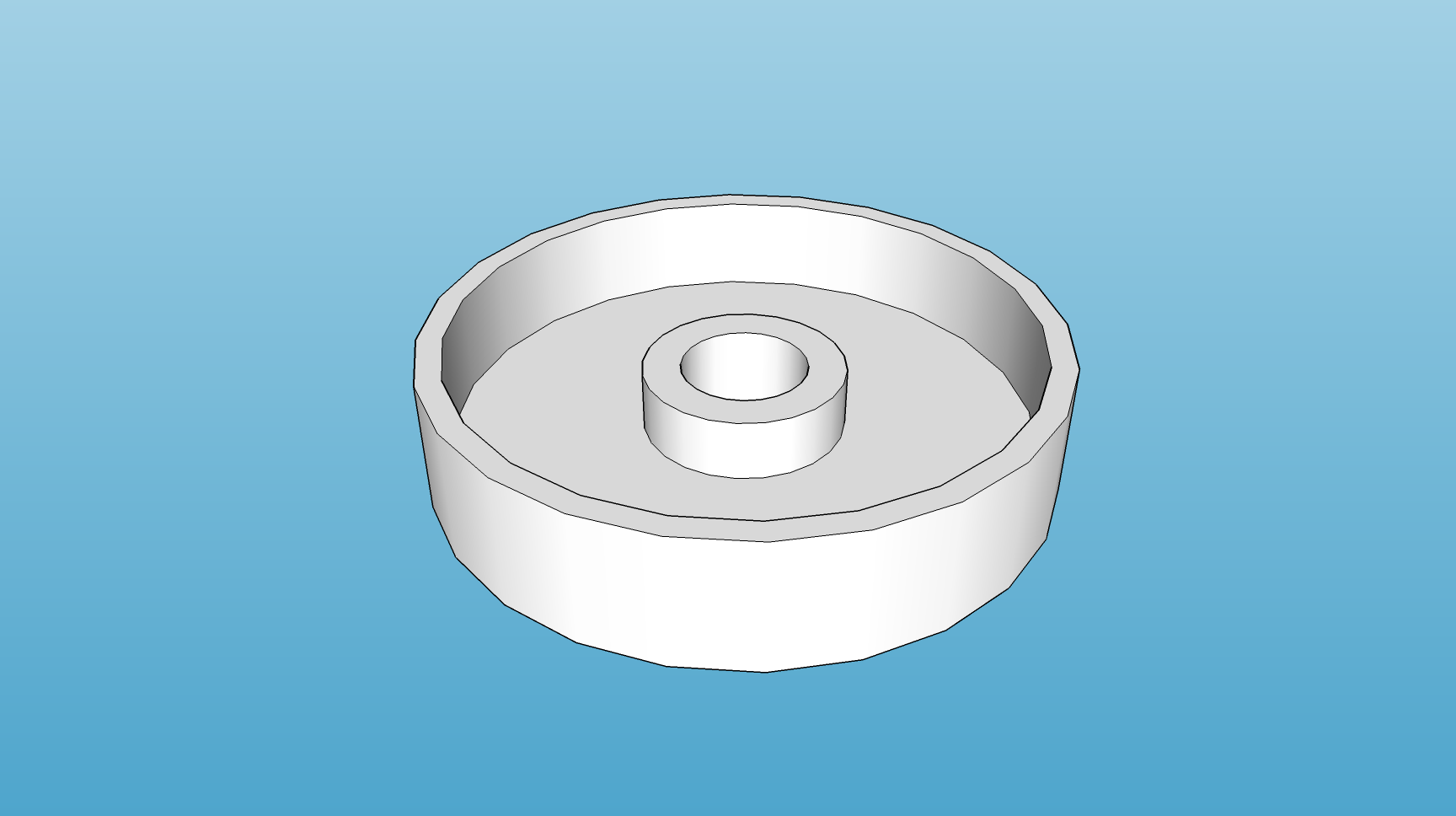

the only purpose this bearing serves is to prevent the main gear from having direct contact with the nut on the end of the bolt, this way the entire system can be locked down fairly tightly without resulting in too much friction on the motor.

the whole thing came together fairly well on the aluminum stand i made for this project in the early days while waiting for the circuit board to arrive. It's also almost scary how fast this system can spin, i don't intend to ever take it near it's top speed but it's cool nonetheless.

look forward to the next update when this project really comes together!

Matthew James Bellafaire

Matthew James Bellafaire

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.