Does the world need another 3D-printed prosthetic hand?

While the introduction of 3D-printing has led to many new concepts for prosthetic hands, there is still a shortage of products--devices that are actually adopted by end users for regular, long-term use. The goal of the Hintha Hand project is to begin with end users in mind, and creating a device that is dependable and attainable for users in low-income and under-served settings.

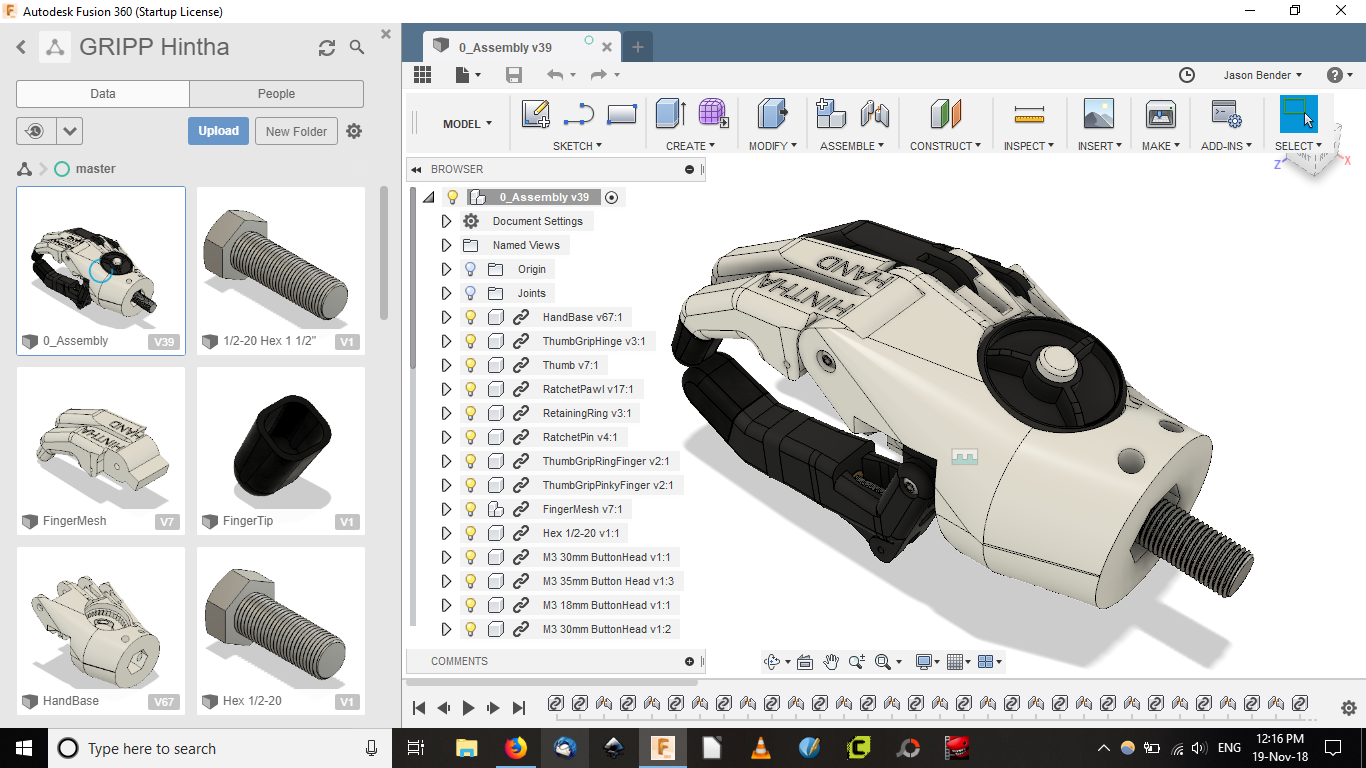

The Hintha Hand project was started in 2018 by Jason Bender, CP, a prosthetist living and working in Myanmar, in response to the lack of effective options for the limb-loss community in the region.

Design Features

Voluntary Opening Terminal Device

Most 3D-printed designs are based on a 'voluntary closing' design--one in which the force applied by the user is directly used to close the hand and grasp an object. While this design has a few advantages such as control over the grip force, simpler design, and better cosmesis, it also has significant flaws. The biggest flaw is that a voluntary closing design requires active force input from the user to maintain a grasp. This means that in order to simply hold an object and carry it across the room, the user must continue to actively contract his or her muscles to maintain the grip--which can become exhausting over time. In the case of a motorized or myoelectric hand, voluntary closing means that some type of back-drive prevention must be included--usually in the form of a leadscrew or worm gear--to maintain grip strength, thus increasing the complexity of the drive mechanism and cost of the device.

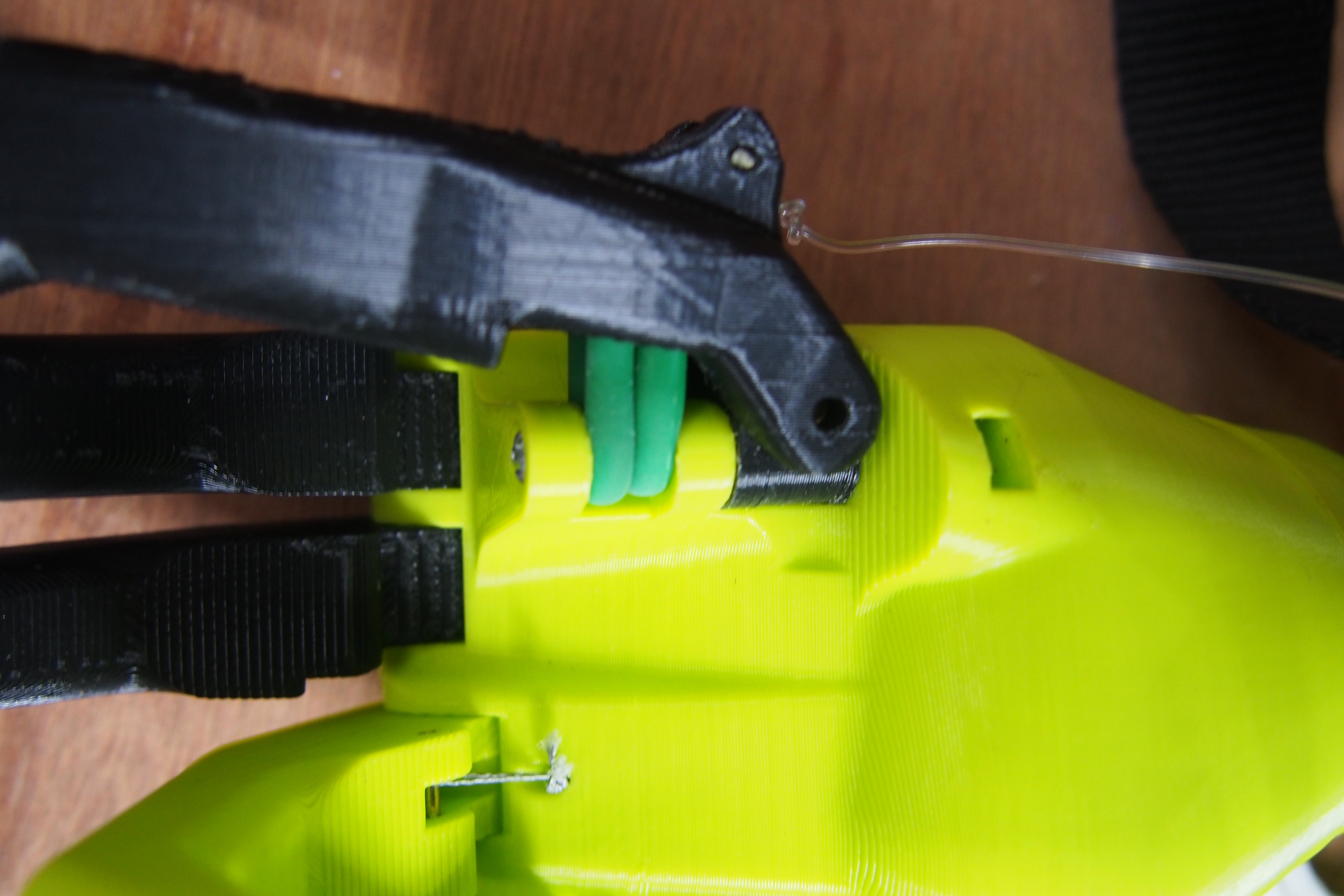

The Hintha Hand uses a 'voluntary opening' design, which means that grip force is applied by a spring (rubber bands), and the user must only apply force to open the hand. In a body-powered setup, this means the user is able to relax while holding an object, and in a myoelectric device, removes the need for a anti-backdrive mechanism, thus opening the door for more cost-effective drive mechanisms, such as gearmotors or standard servos.

Opposable Thumb

The other novel addition to the Hintha Hand is the incorporation of a passively-opposable thumb. This allows the user access to multiple grip patterns, which is extremely unique for a voluntary-closing device. The user is able to move the thumb between 0 and 90 degrees of opposition, allowing cylindrical, lateral (key), and hook grasps in addition to the "standard" 3-jaw chuck.

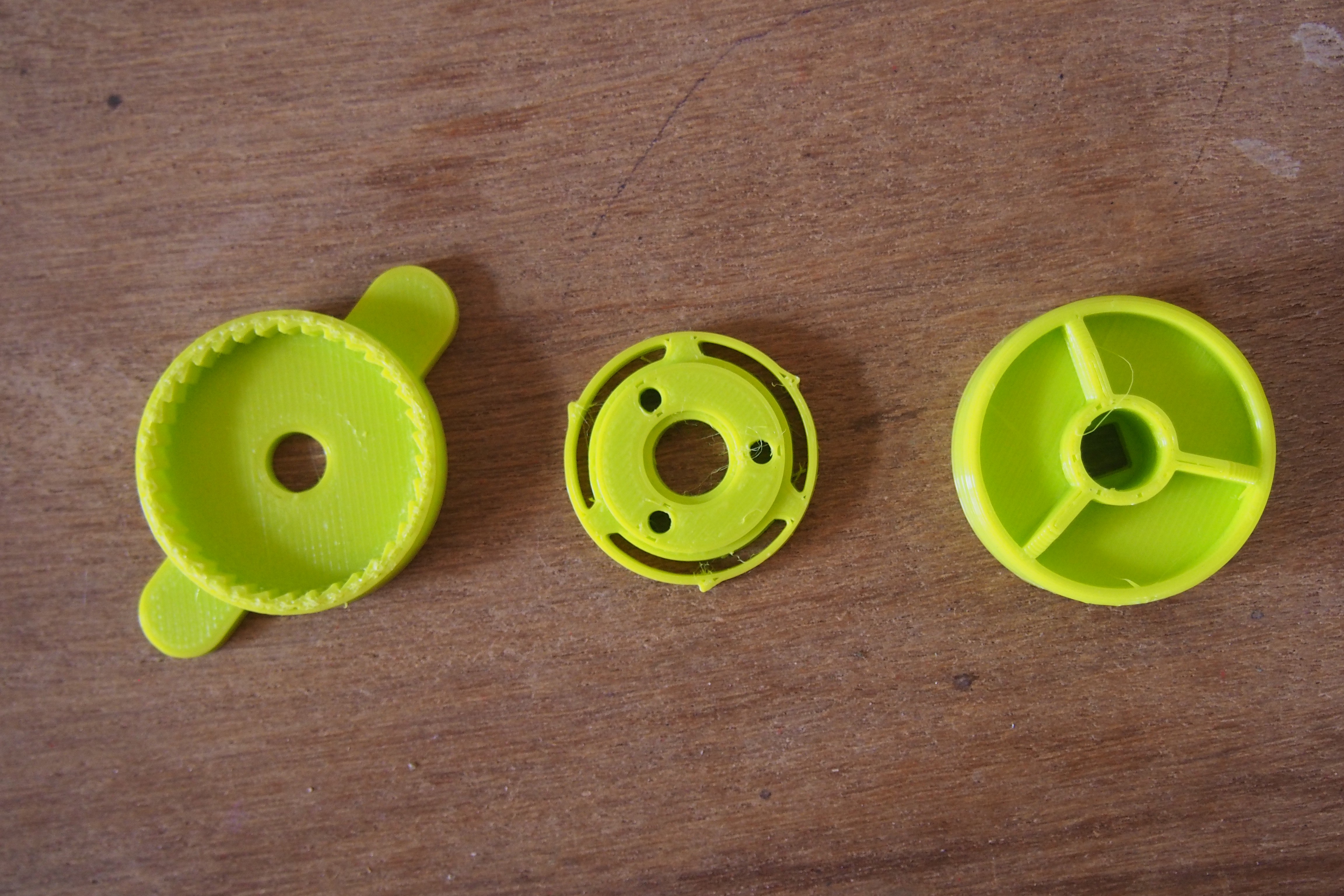

Ratcheting 4th and 5th Digits

In order to further increase the grip strength and grip variations available to users, a cable-ratchet system will be used to control the 4th and 5th (ring finger and pinky) digits. This allows the user to either pre-position these digits for particular grasp patterns, or "lock down" the fingers after grasping to increase the hold for heavy or unwieldy objects.

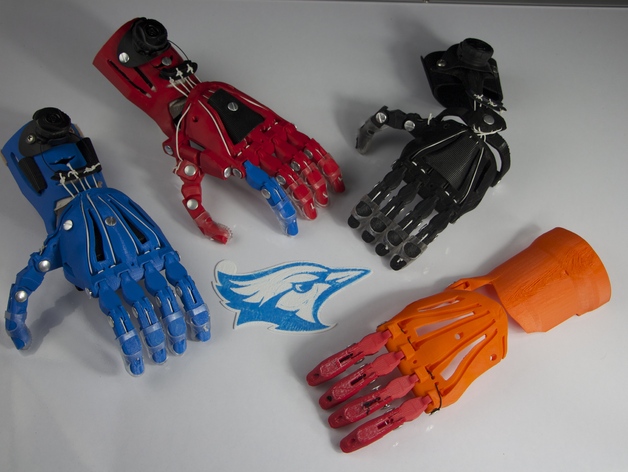

Standard, HD, Body-Powered, and Myoelectric Modular System

The goal of the Hintha Hand is to incorporate a standard (plastic) and heavy duty (sheet metal skeleton) design branches in order to allow flexibility in both pricing and durability of their devices depending on needs. It is also planned to provide a seamless modular system that allows users to switch or upgrade from body-powered to myo-electric without having to reproduce the entire device.

The goal of this modular approach is to allow users a diversity of options, but also a seamless "upgrade pathway" that will allow users to change their devices in a piecemeal fashion as changes become necessary and/or economically viable.

Like any other consumer group, prosthetic users are a diverse group with diverse needs. While the intention of the Hintha Hand is not to become a silver bullet for all upper-limb prosthetic users, but to provide a variety of options within a single platform/system that gives users flexibility while reducing risk for those with little expendable...

Read more » Jason Bender

Jason Bender

Great work....When will you be ready to share the files for others to make if possible or buy ?