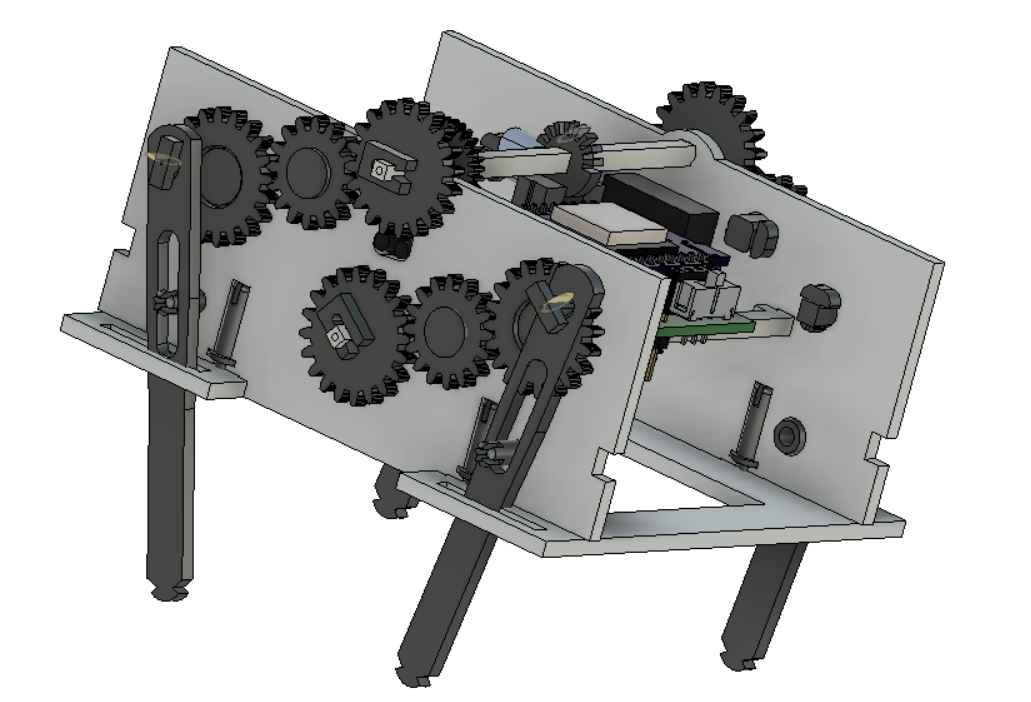

I had planned to use Chicago screws or book binding rivets. However, not only are they an additional cost and a impediment for someone to reproduce my work, the were binding when it was walking. The Chicago screws would come unscrewed and crash into the leg. Although I liked the feature that the robot could be disassembled, the has got to be a better way.

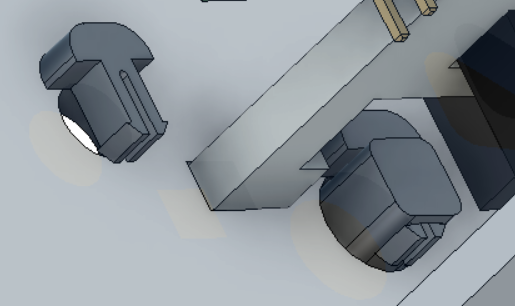

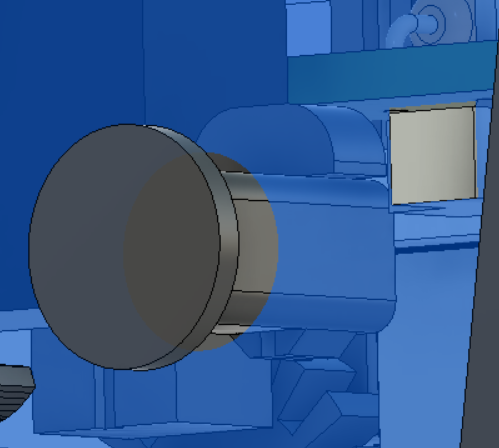

So after a few days of head scratching, I came up with a 3D printed and laser cut hybrid. First of all, this is more square pegs in round holes to try to reduce the points of friction. This robot does not go fast enough to worry about friction welding but the motors do not have enough juice to overcome a lot of friction.

The second feature is the super low profile and simple to print shape. There is a bit of bridging but I think the Prusa will print it like a charm. I went line to line on the vertical walls and gave it and extra 0.3mm on the overhang length. Lets see if my estimation is good.

The other great thing is that this removes 4 of the 8 counterbores from the laser. It will speed up the cut by a few minutes because it takes a long time to scan. I hand added the counterbores to adjust to a specific rivet width.

Here are some pictures.

shane.snipe

shane.snipe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.