This week has been spent on making the front panel for the Lisssajous machine. Since it's going to be the part of the machine the user interacts with, I wanted it to be nice, and since it needs to house the screen, as well as 15 knobs and switches, I decided to take the time to do it right.

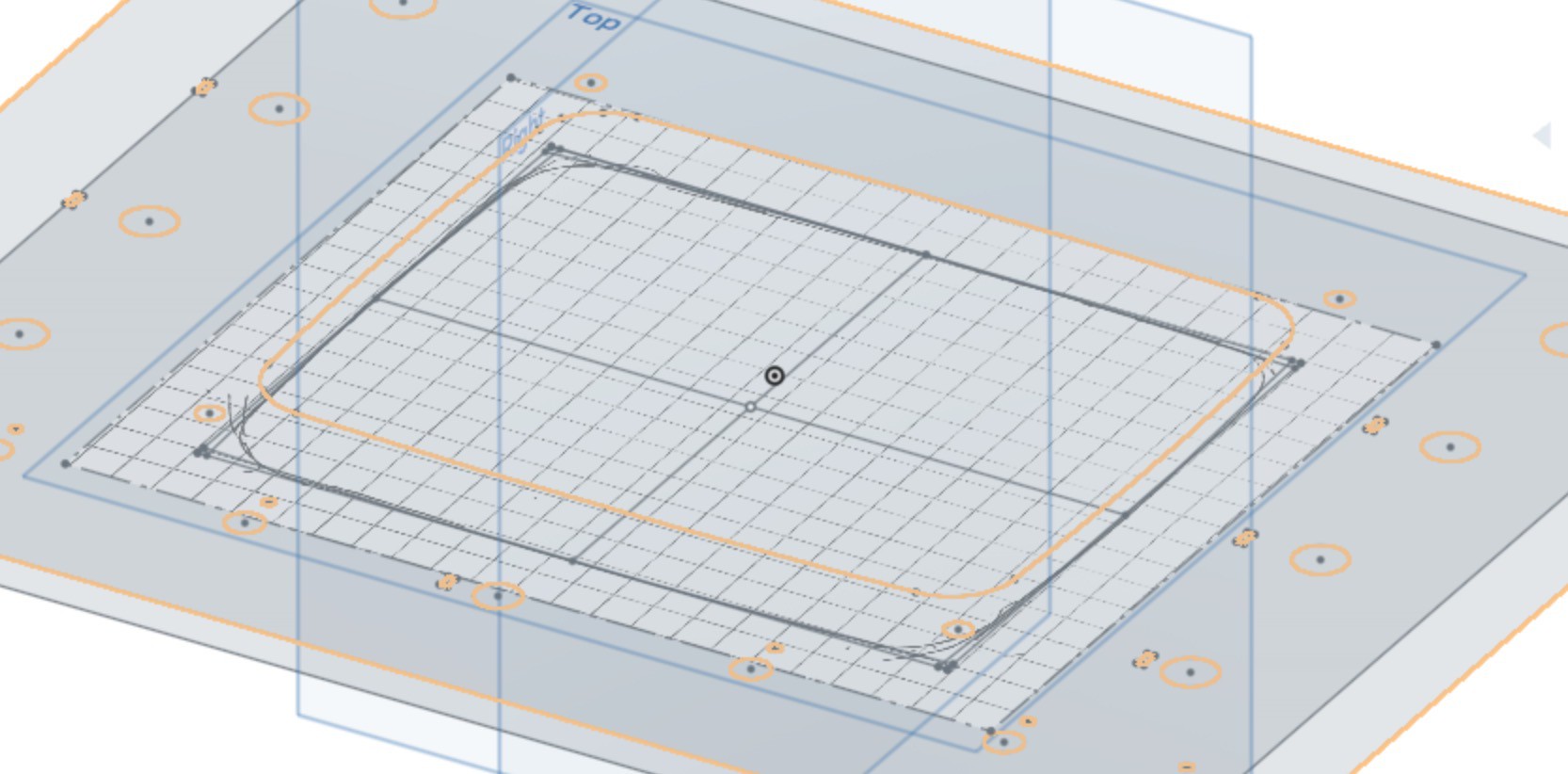

To get started, I traced an outline of the CRT screen onto some graph paper, and then scanned the tracing and uploaded it to Onshape, the free online CAD software I used for most of my CAD work.

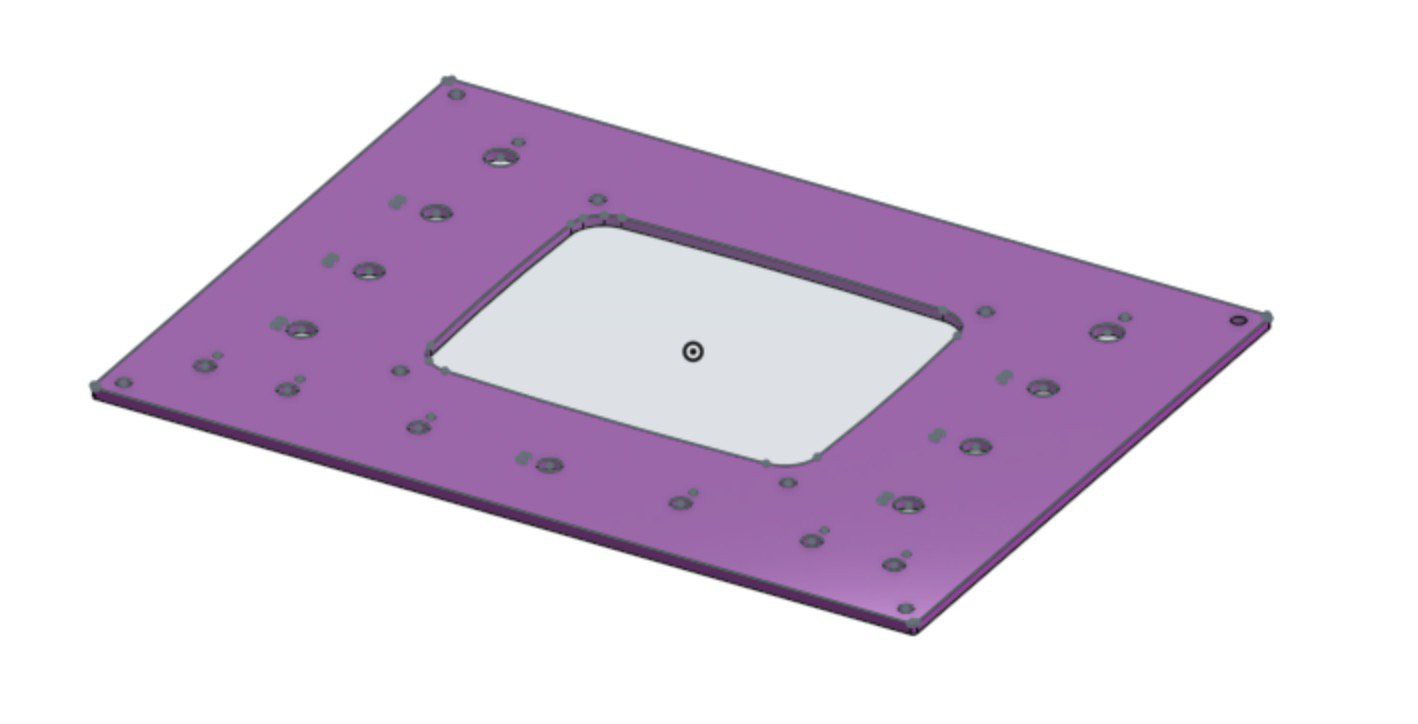

With the tracing in Onshape, it was easy to create a panel with an opening that would fit the CRT. Doing this in CAD software also gave me the option to try several arrangements of knobs before settling on what I wanted.

I had originally planned to make this panel out of transparent red acrylic, and friend of mine had a bunch of quarter-inch acrylic sheets in several colors that he was happy to share with me. But when I asked about using some for this project, he let me know that he had gotten rid of all of the acrylic :/

I started looking around for quarter-inch transparent red acrylic, but the prices were all higher than seemed reasonable to me. Another friend of mine said he had had some lucky dyeing plexiglass by boiling it in a solution of Rit clothing dye. I had some scraps of plexi lying around at home, and Rit is only $2.50 a box so gave it a try.

Did it work? No. It worked just a little bit on Lexan, but there was no discernible color change in the plexi. Someone on Twitter suggested I could try adding a some isopropyl alcohol to the dye bath, so I did, but that didn't really help.

The lexan pieces are on the left. From top to bottom: 35 mins, 45 mins, 55 mins with ten mins after alcohol addition. Plexi is on the right, top to bottom: 35 mins, 45 mins, 55 mins with ten mins after alcohol addition, 65 mins with 20 mins after alcohol addition.

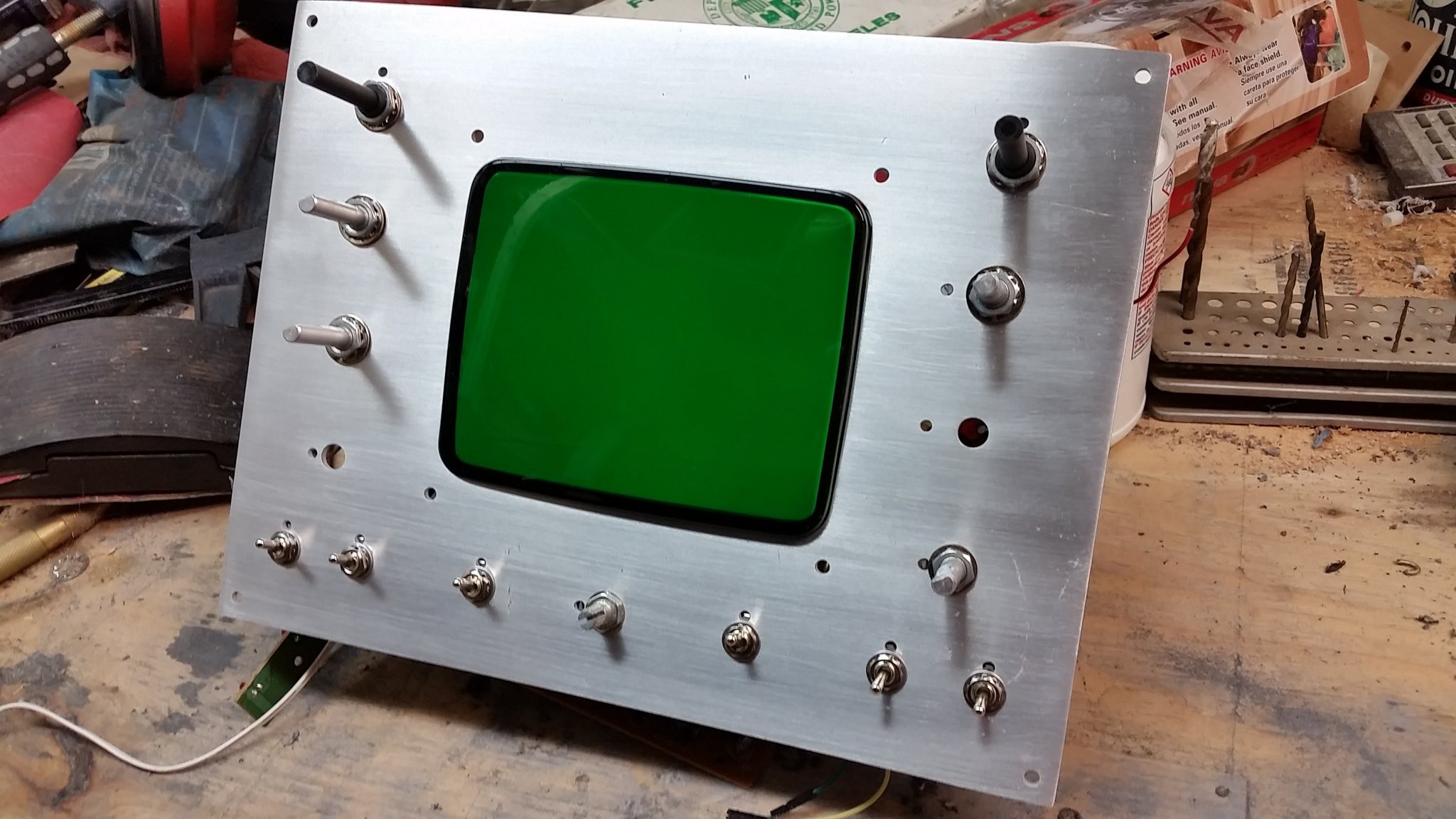

Ok, plan B for the front panel is aluminum. I'm lucky to live near a good scrap yard with lots of interesting stuff to pick through and decent prices. I got down there on a rainy morning before Sparklecon and picked up some stuff, including a sheet of aluminum that would work for this project.

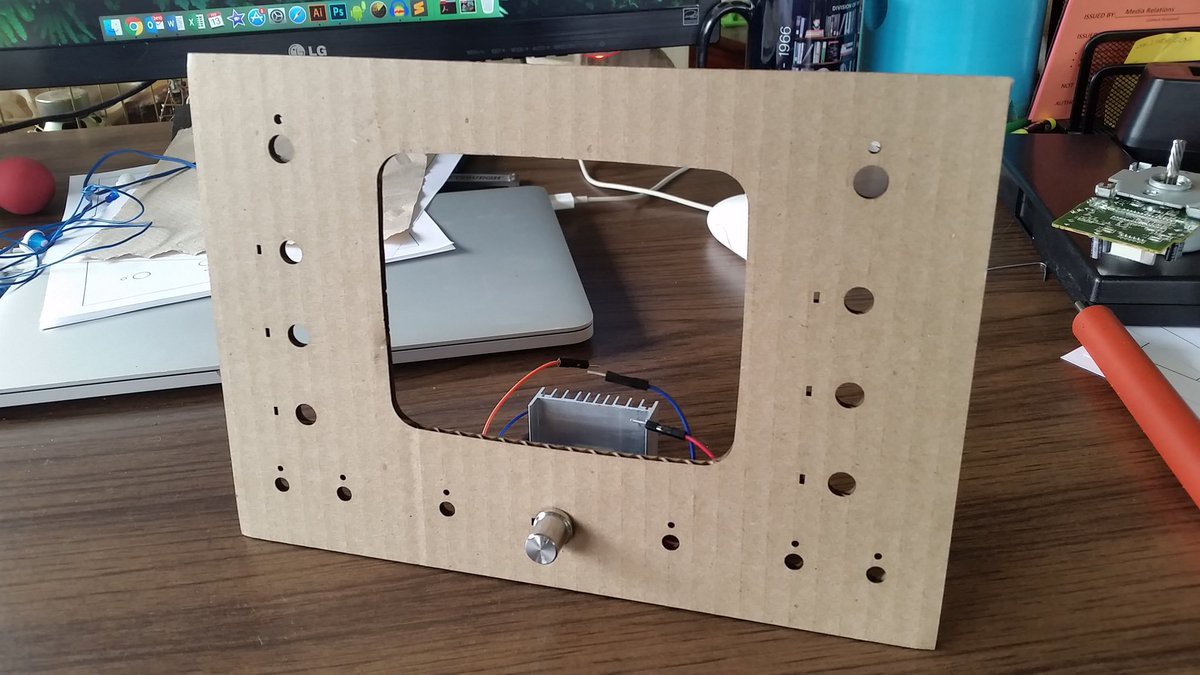

I'm also lucky to work at a place that has a machine shop that I'm allowed to use. I got down there this week first laser cut a cardboard mockup of the panel just to make sure things would fit right.

Things fit pretty nicely, so I made a few minor tweaks, and then got back down to the shop on Friday to use the water jet cutter.

The panel, being made of a piece of scrap from the junk yard was scratched, pitted and oxidized, so I spent Friday night cleaning it up. A rough sand with the random-orbit sander cleaned up most of it, but left some squiggly scratches. I put the whole thing in a bath of concentrated lye for a while to etch everything down a bit. It gave the panel a nice satin finish.

I spent the rest of the night sanding, brushing, and polishing the panel, and it looks great!

Next up, the wood parts of the case.

Emily Velasco

Emily Velasco

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

What for are those little circles cut out next to where the pots and switches pass through? This project, like all others, takes me a long time to complete (free shipping from China woot!) But I'm getting there. Can't wait to share the results.

Are you sure? yes | no

So, most panel-mount potentiometers, and many panel-mount switches have little tabs or posts that are meant to mate with a hole in the panel to keep them aligned. Those holes are meant to accommodate those posts

Are you sure? yes | no

I got you. Thanks

Are you sure? yes | no

Sorry that the embedded tweets aren't rendering correctly. I'll see if I can fix that tomorrow.

Are you sure? yes | no