In this exciting installment I continue to find new ways to possibly mutilate my eyeball, and I am unfortunately foiled!

From experimenting with the first prototype it was pretty clear that one of the first hurdles that must be overcome is the overall flexibility of substrate that the LEDs are placed on. The PCB is far less flexible than that contact lenses, and as such, the contacts are not able to force the PCB into the proper curved eyeball shape

First, let's rewind a bit. As I mentioned before, one solution to this issue would be to get rid of the PCB entirely (but then I don't think I could enter into the flexible PCB contest ;D). For those of you playing along at home, you will remember that my first attempt to dead-bug solder some leds into a ring did not go so well.

This was using 0603(1608) SMD leds. They were crusty and didn't actually work. For some reason, the solder just wouldn't wick onto the wires, making it near impossible to actually attached the lights. I even made sure to burn off the enamel coating and everything! Once again, for those keeping track, it was a this point where I decided to have the PCB made, which is what you can see in my friend's eyeball featured at the top of this project. The thought of a substrate free design still seemed like the most feasible option though. So I ordered some more leds and decided to give it another shot.

This was using 0603(1608) SMD leds. They were crusty and didn't actually work. For some reason, the solder just wouldn't wick onto the wires, making it near impossible to actually attached the lights. I even made sure to burn off the enamel coating and everything! Once again, for those keeping track, it was a this point where I decided to have the PCB made, which is what you can see in my friend's eyeball featured at the top of this project. The thought of a substrate free design still seemed like the most feasible option though. So I ordered some more leds and decided to give it another shot. This time I stepped it up notch though, and attempted something only fools would think about....I used 0201 (0603) LEDs. That's right. I attempted to open air solder some of the smallest LEDs that money could buy. I guess I technically succeed? Before I show you the final result, let me first show you my method, because I think it was pretty clever.

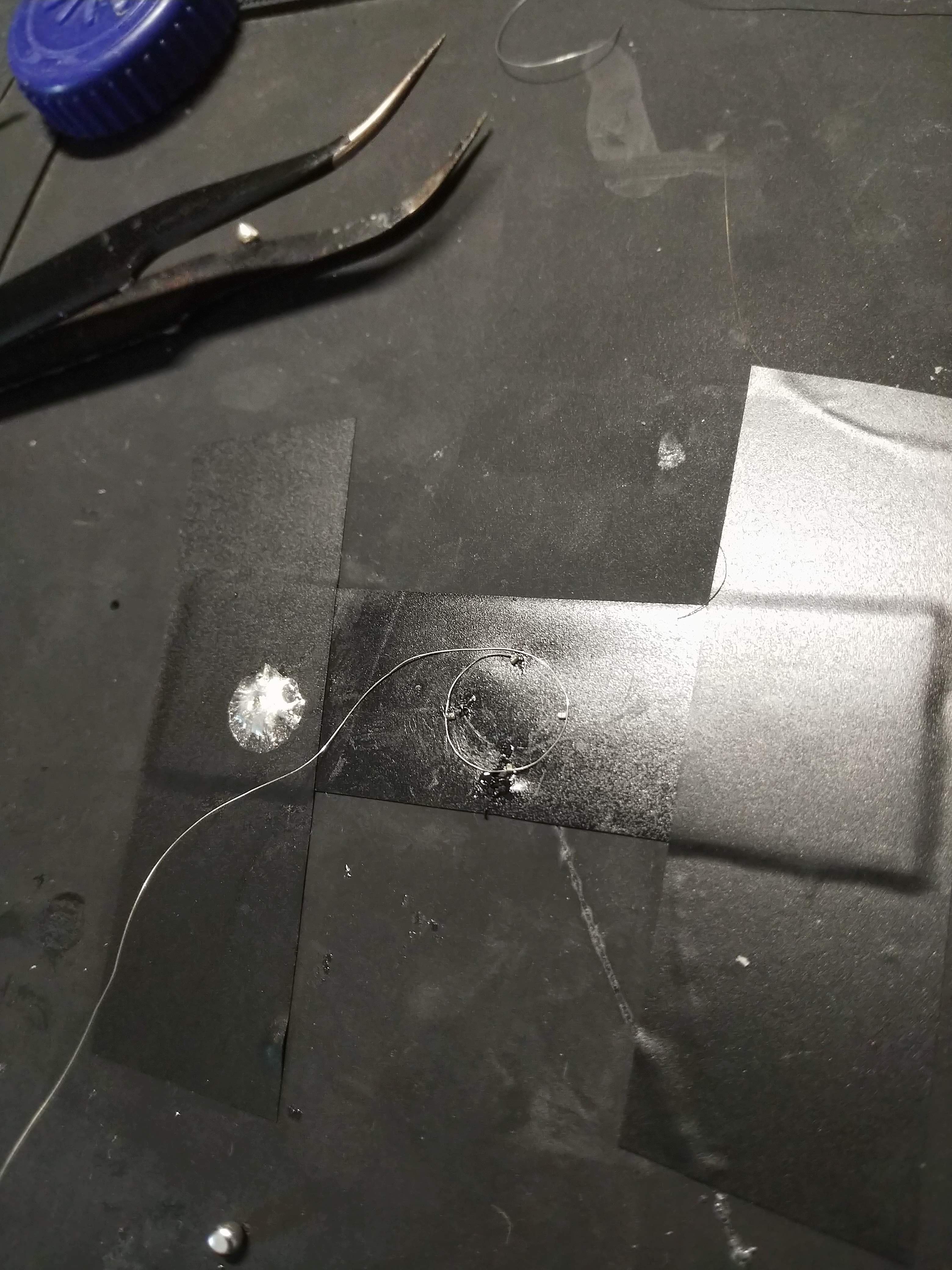

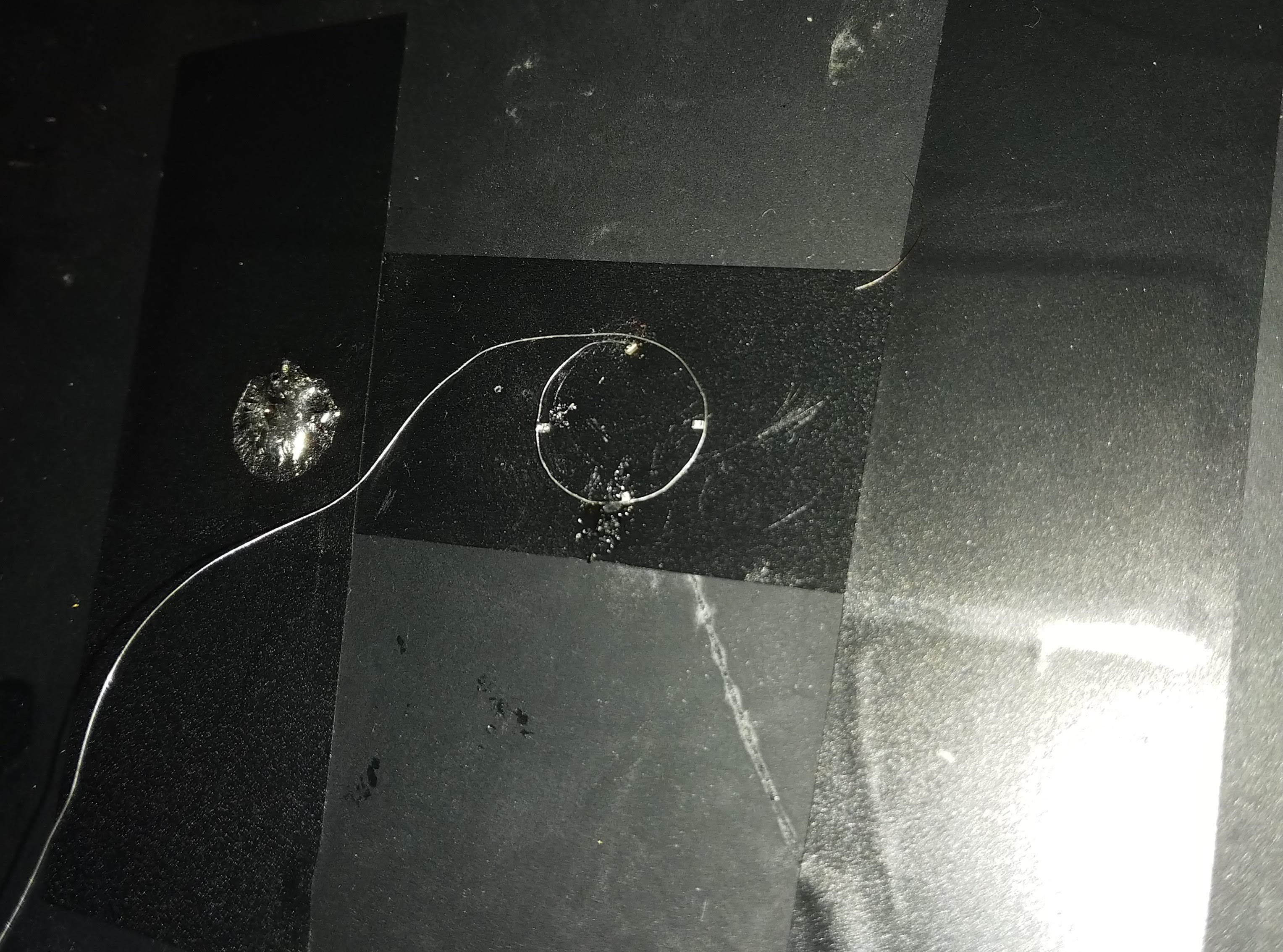

I quickly realized that the biggest issue that I was going to have was holding everything in place all at once. Thankfully, my good ol' friend Mr. Electrical tape came to the rescue. I placed once piece of tape sticky side up, and then tape it down on either side. This then gave me a nice sticky substrate that I could arrange my sand-sized LEDs on. Once they are in place, I can then go around to each and gently place a tiny amount of solder on them, working around in a circle one by one. It was soooo much harder than it sounded

It is also worth noting that I switched my choice of wire as well. Rather than using hair thin enameled copper wire, I instead used some slightly thicker strands of wire that I extracted from an old IDE cable. This seemed to take solder much more readily, but it did increase the overall stiffness of the assembly.

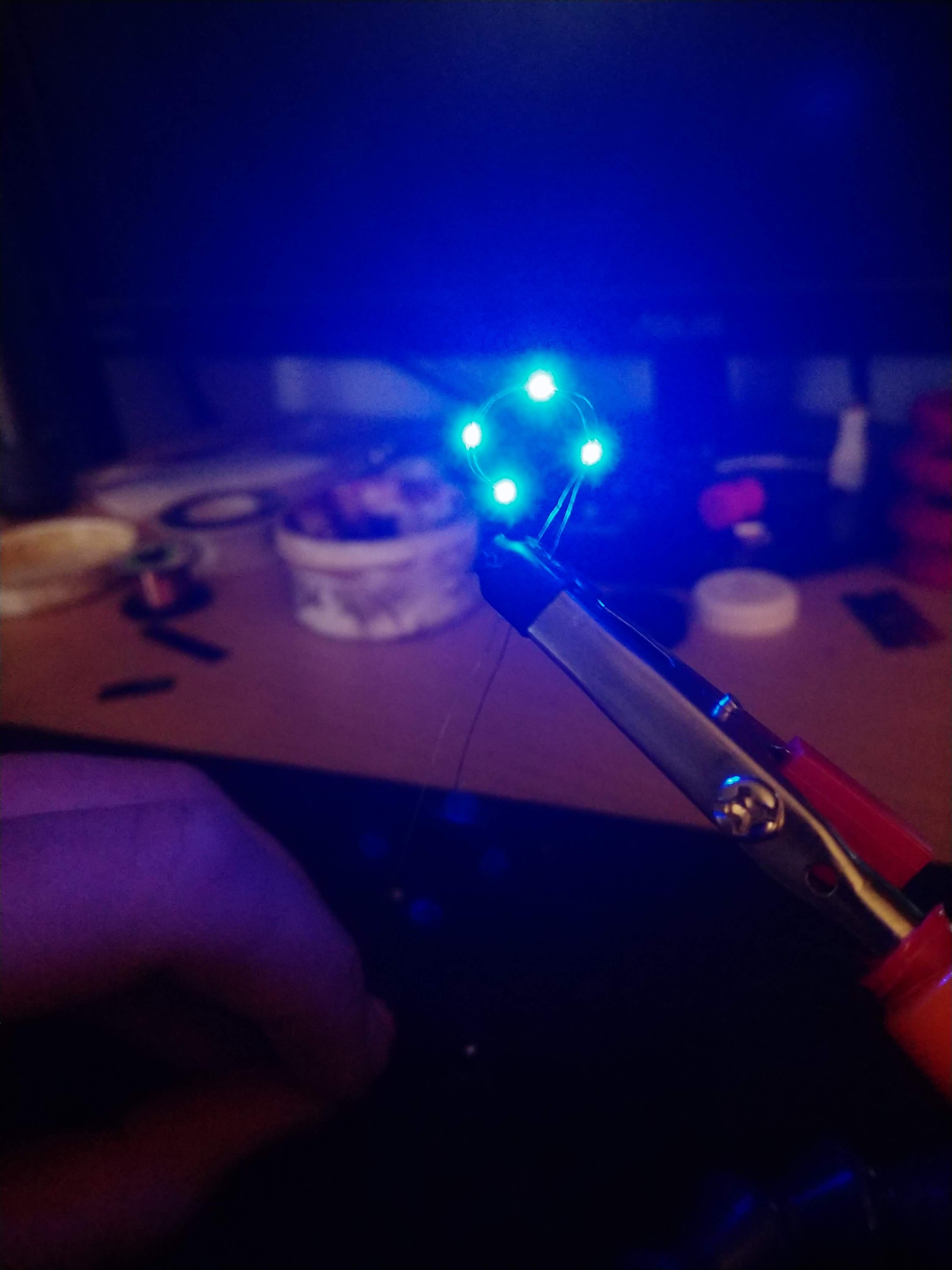

At the end of the day this was the final result.

I am a bit disappointed that after all that work I couldn't get a better result. I have a feeling that if I had just one more shot at it I could have gotten something more presentable. However, everytime I went to set it up, I either accidently smashed it out of shape, or broke one of the solder connections. Regardless, I think what I was able to make has a very cool vibe to it. The LEDs are plenty bright enough despite being so so tiny.

This endeavour has also been pretty enlightening for the next steps I need to take. I still think that the dead-bug style cyborg eye has some potential when it comes to embedding into a contact lense, but it suffers from two major flaws:

- Repeatability

It took about 8 hours of work just to get the crappy pictures that you see above. I would really like other people to be able to replicate this, but not everyone has the young eyes and hands of an undergrad. So I think that it would be best to revisit the PCB option.

2. Light Leakage

Something that I initially overlooked when comparing the dead-bug vs. PCB approaches was light leakage. Theoretically, all of the light that comes out of the LED should shine away from your eye, so you shouldn't even really be able to tell if it is turned on. Of course this is the real world so some of the light will be diffused and reflected by the contact lense covering the LED. However, I noticed that substrate actually served somewhat as a shield, blocking a miniscule area of that reflected light, something that the dead-bug ring doesn't have.

That being said, I think that I am going to take another wack at getting a flexible PCB made, and I highly doubt that it will pass OSH Park's DRC. Oh Well! We will cross that bridge when we get to it! Anyway, I think that just about wraps it up for this misadventure. I still need to find a source of contacts that I can experiment with as I don't actually have a prescription and my friend ran out of old ones. If anyone has any ideas or want to send me some older, low power ones, please send me message!

As always any feedback or ideas are much appreciated. At this point I feel like I have heard just about every warning and concern out there, but if you come up with a new one do tell!

Until next time.

Chris

Chris

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.