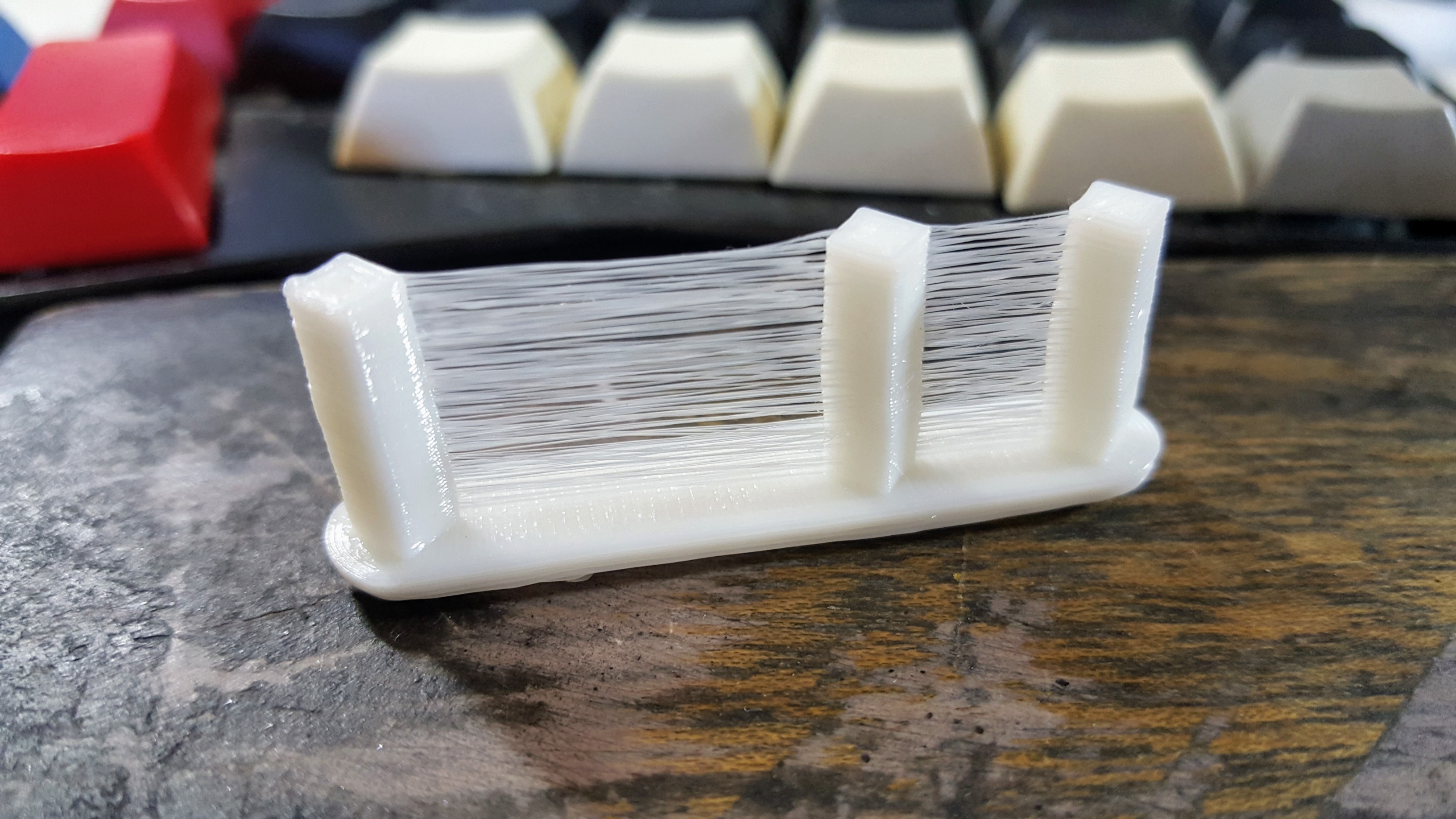

One problem that became glaringly obvious as soon as I printed a torture test object on my printer is the abundance of strings similar to the one found on my previously printed frog:

I printed a pillar test and found out just how bad it was.

Initially I thought strings are not a big deal as they can easily be cut off. But turns out they can be a huge headache if left unchecked.

Stringing is caused by filament oozing out while the printer is doing a non-print move. Fixing this should have been as easy as increasing the retraction distance but I'm using a chinese knockoff of a bowden style hotend where too much retraction could lead to a jam.

Jams did happen a lot which forced me to keep the retraction distance at a low number (Not exceeding 5mm) and finding a fix elsewhere.

The retraction speed was the next logical place to check. I slowly increased the speed by small increments starting at 20 mm/s to 100 mm/s. The theory was that the fast retraction would quickly release the pressure in the nozzle causing it to not leak. This did not have a noticeable improvement, but I had the suspicion that it'll work well with other settings so I kept it as is.

I tried lowering the temperature to prevent oozing while idle. This helped reduce the ooze a bit and it also made me realize that I've been printing at a very high temperature before. I've since then reduced my operating temperature from 220 to 190/195. It still not enough though.

I've read somewhere that increasing the non-print speed to an insanely fast number would make it so that the ooze won't have time to spill out. This makes sense but my printer could not handle very high speeds without sacrificing quality.

I tried lowering the extrusion multiplier as I thought it would mean a lower filament flow but this just affected the overall quality of my prints. I left this to my previous setting of 1.

I also tried lifting the nozzle while retracting which was good for fixing blobs that forms on the sides but still did not prevent the oozing.

Fixing this problem took a lot of time and filament. I was ready to throw in the towel but thought of increasing the retraction distance just a tad bit just as a last resort. At this point I was willing to risk another jam, I was all out of options anyway.

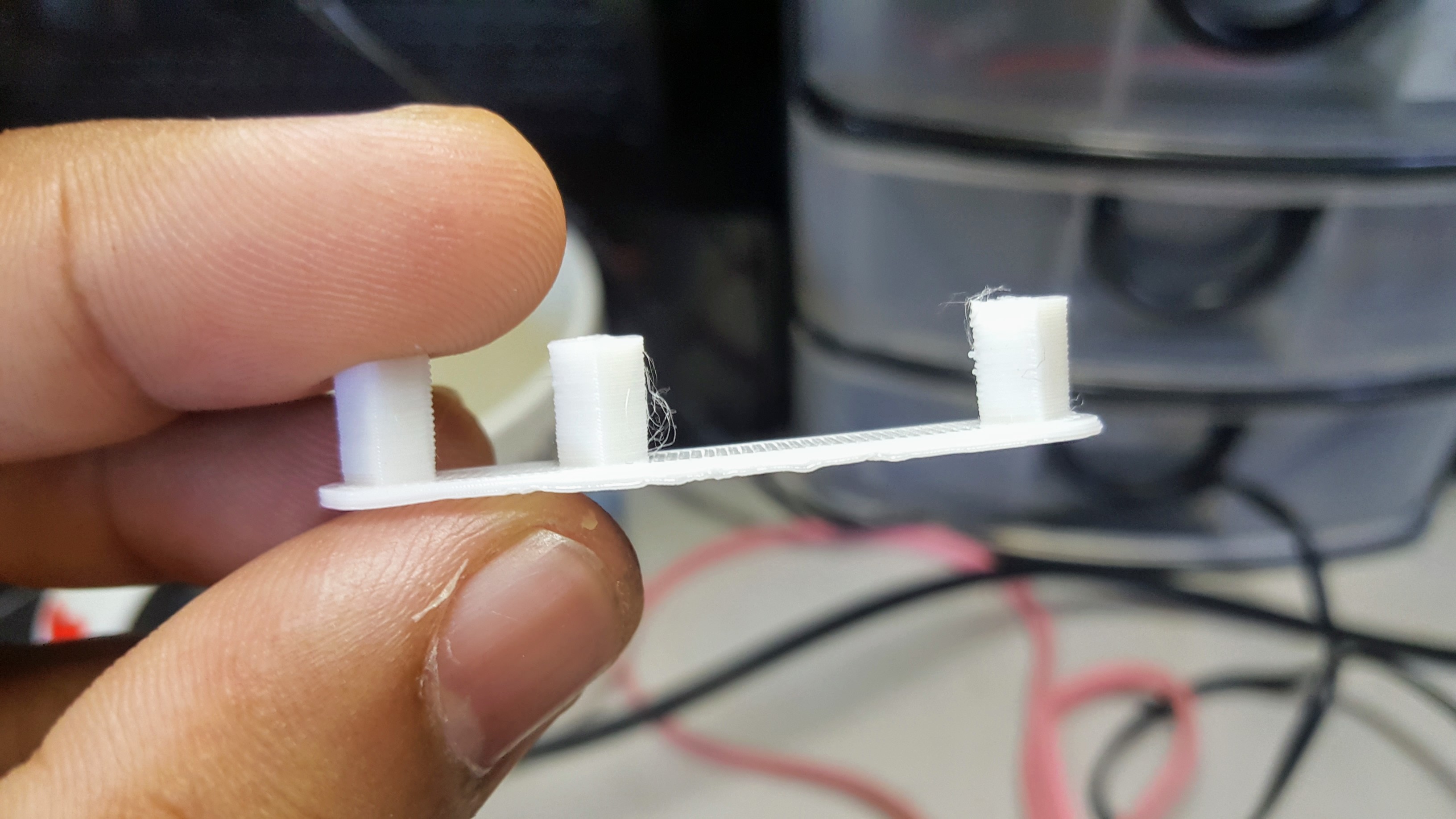

And of course, it worked!

There are some strings but they are very thin and barely visible that they can be easily be fixed with a heatgun. I'd consider this a big success!

Up next: Fixing the jamming once and for all.

AccidentalRebel

AccidentalRebel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Well, I never experience or read anywhere when a writer tells about his/her experience doing things like this. You have provided us the different ways through which we can use it. Thanks for this useful content. I really like to read content like this and also this content in which I read useful tips to win a casino game to earn money through it.

Are you sure? yes | no