Since I received ball bearing 16014 this week, I could finally assemble the base so we can test the full base mechanism driven by a stepper motor.

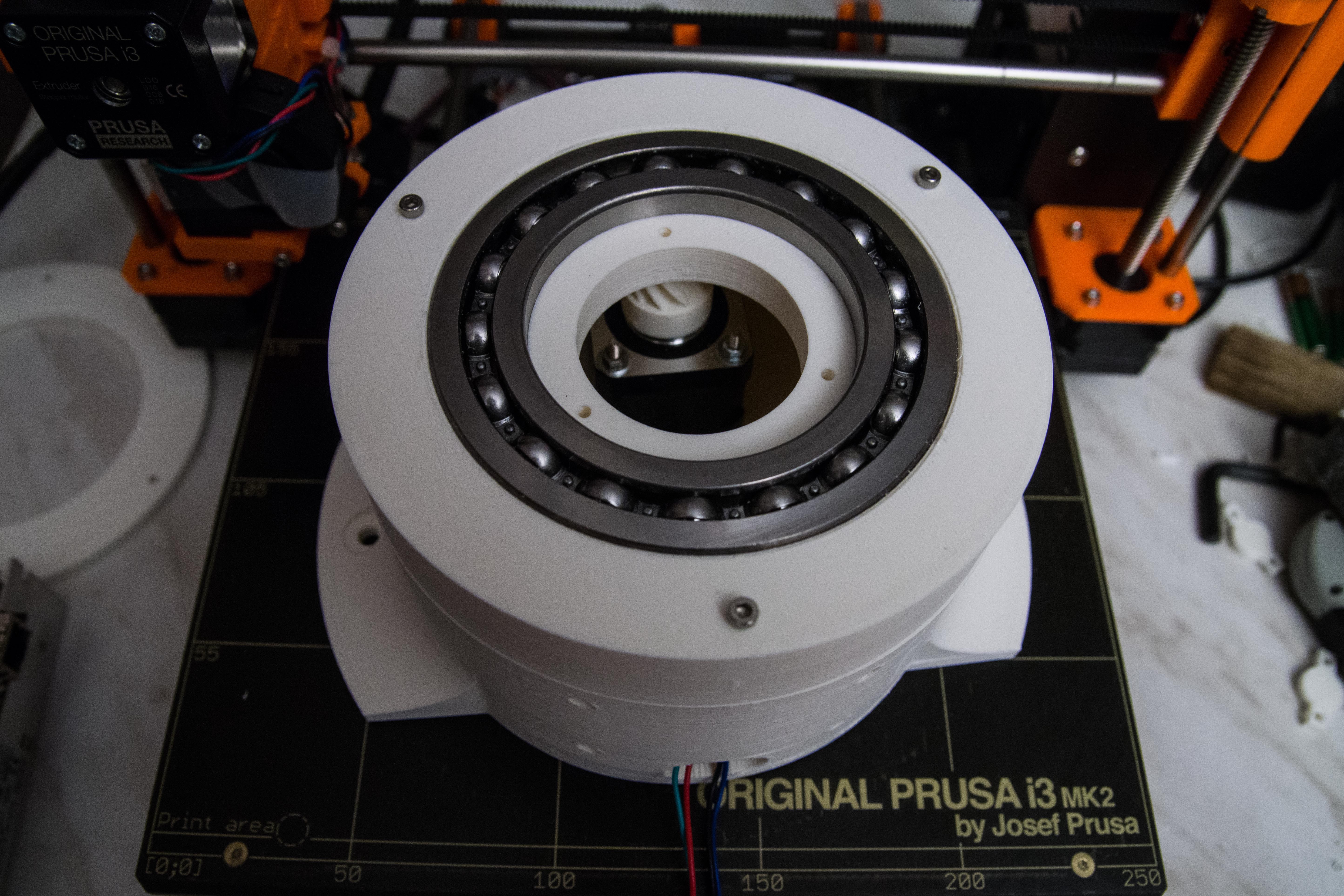

Top view of the base, put on my 3D printer to give a sense of dimensions.

You can clearly see the stepper motor that will drive the inner cog that is hooked to the base top (not shown in this image)

To mount the electric motor you have to remove the screws from the bottom of the stepper motor. Then insert screws that are longer.

There is still a ring (seen at the left side of the photo) that should go onto top if this, so the screws are sunk into the plastic.

Danny And AngelLM and Danny warned me to paint the inner cog black because the translucence of the plastic could give the photo detector a wrong signal the home position.

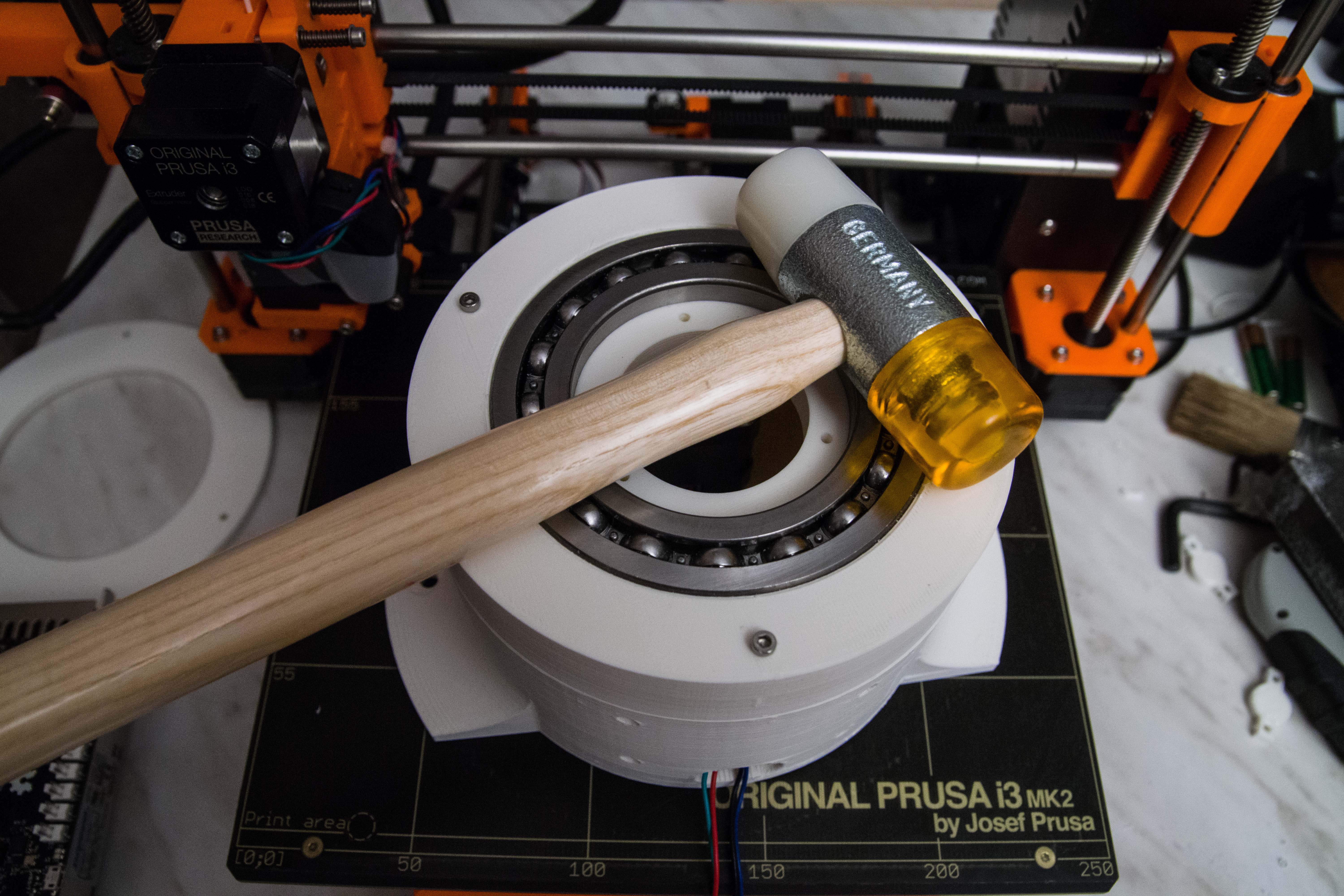

The ball bearing did not fit the 3D plastic. I think the inner wall was about 2 mm too thick.

I had to scrape the inner wall to make it fit the ball bearing and then slightly hammer it with a soft hammer in place.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

First test of the stepper-motor in combination with the controller works, but the ball bearing does no move fluent. I think I accelerate the stepper-motor too fast and the cog don't get a grip. When I hand move the wheel then I see the stepper-motor rotate normally.

Are you sure? yes | no

SUCCESS! It turned out that the base stepper motor needed 2 Amperes but the current ( DVR8825) was configured for the other stepper motors = 0.4 A.

The motor itself did not get enough current to rotate when it encountered a bit of friction.

Are you sure? yes | no